All Categories

History

This section provides an overview for induction motors as well as their applications and principles. Also, please take a look at the list of 7 induction motor manufacturers and their company rankings. Here are the top-ranked induction motor companies as of March, 2026: 1.ARC Systems Inc., 2.Hordu Electric Motor Manufacturer, 3.NIDEC SANKYO.

Table of Contents

Categories Related to Induction Motors

Induction Motors are motors that operate on alternating current and are powered by the force generated by electromagnetic induction.

Therefore, they are also called AC motors with "AC" meaning alternating current. The induction motor is one of the oldest motors, with a simple structure that does not require any special power conversion, and operates simply by connecting to an AC power source.

As a result, they combine high reliability and long life and are still widely used today. Another advantage is that they do not use magnets that contain rare metals, so they provide highly efficient rotation at low cost.

Induction motors are used in a wide range of applications, from home appliances such as washing machines and fans to large-scale production equipment for factory facilities, because of their characteristic of higher efficiency with larger capacity.

By changing the characteristics of motors, they are also used as a power source for items that require high starting torque, such as automatic doors, and for items that require high stopping torque, such as shredders.

Figure 1. Principle of induction motors

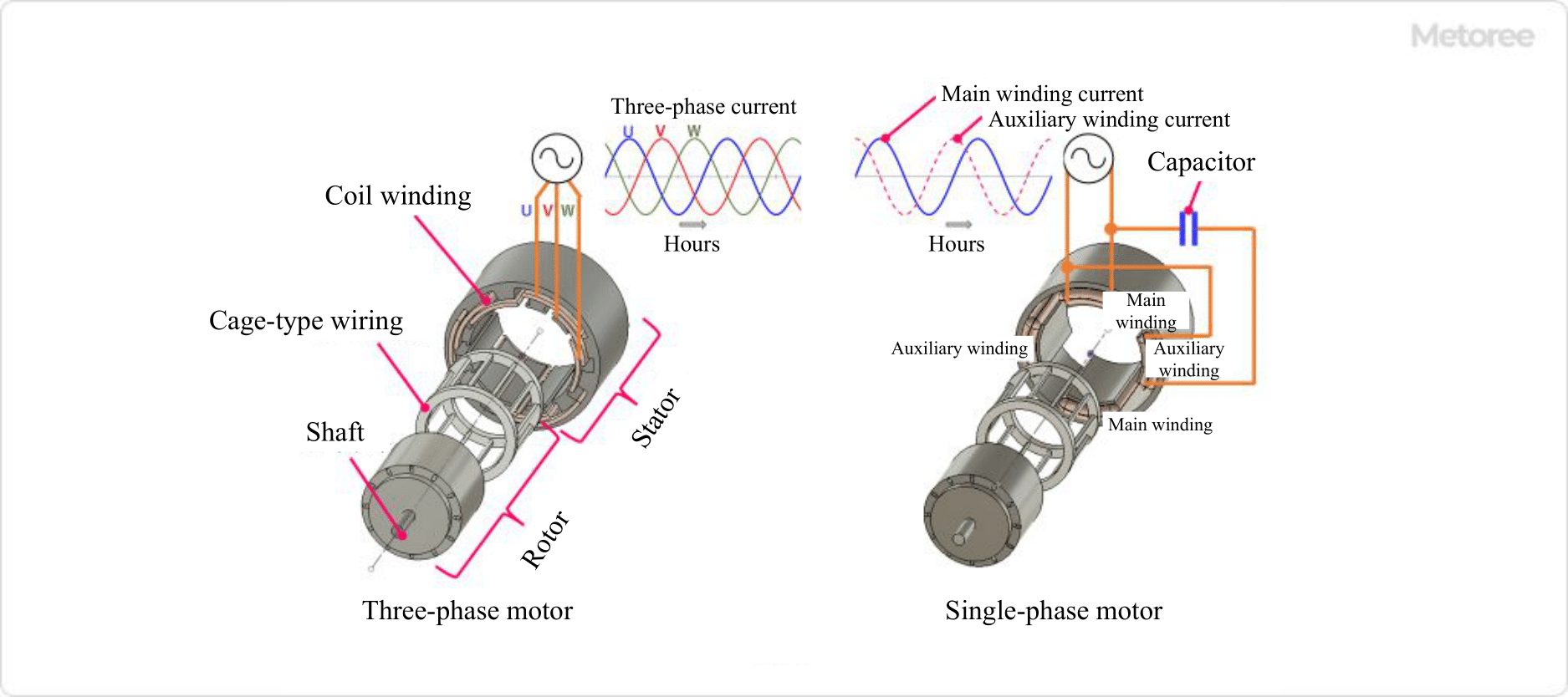

Induction motors are broadly classified into two types, three-phase motors, and single-phase motors, according to the difference in AC.

Induction motors are composed of a "stator" and a "rotor". The stator has coil windings that conduct three-phase alternating current, and the rotor has cage-shaped wiring that conducts current due to electromagnetic induction from the rotating magnetic field.

When this magnetic field passes through the cage-shaped wiring incorporated in the rotor, which is a conductor, a voltage is generated by electromagnetic induction. This induces a current to flow through the cage wiring, which in turn interacts with the rotating magnetic field from the stator to produce torque. The rotation of the rotor asymptotically approaches, but never equals, the speed of the rotating magnetic field generated by the stator.

The ratio of the rotating magnetic field speeds of the rotor and stator at this time is called the "slip" and is one of the major factors that determine the torque characteristics of induction motors.

To rotate a motor with single-phase AC, it is necessary to generate a rotating magnetic field. Therefore, a capacitor is incorporated in the auxiliary winding of the motor to generate a rotating magnetic field by connecting the main winding directly to the power supply and the auxiliary winding to the power supply via a capacitor.

When a single-phase alternating current is connected to the main winding and the auxiliary winding via the capacitor, the current in the auxiliary winding flows 90° ahead of the current in the main winding. These two 90° offset currents generate a rotating magnetic field and the motor gains rotational power.

The rated rotational speed of induction motors is derived by the following equation.

N(rpm) = 120/p(number of poles) × f(Hz)

P is the number of poles of the motor and f is the power supply frequency. The lower the number of poles, the faster the motor rotates, and the higher the power supply frequency, the faster the rotation speed. Since the commercial power supply in Japan is set at 60 Hz in Western Japan and 50 Hz in Eastern Japan, the rated rotational speed of the motor depends on the number of poles when the motor is operated by the commercial power supply.

In addition, induction motors have slippage, which means that the rotation speed decreases little by little by the load torque, and the actual rotation speed is given by

N(1-s) (rpm).

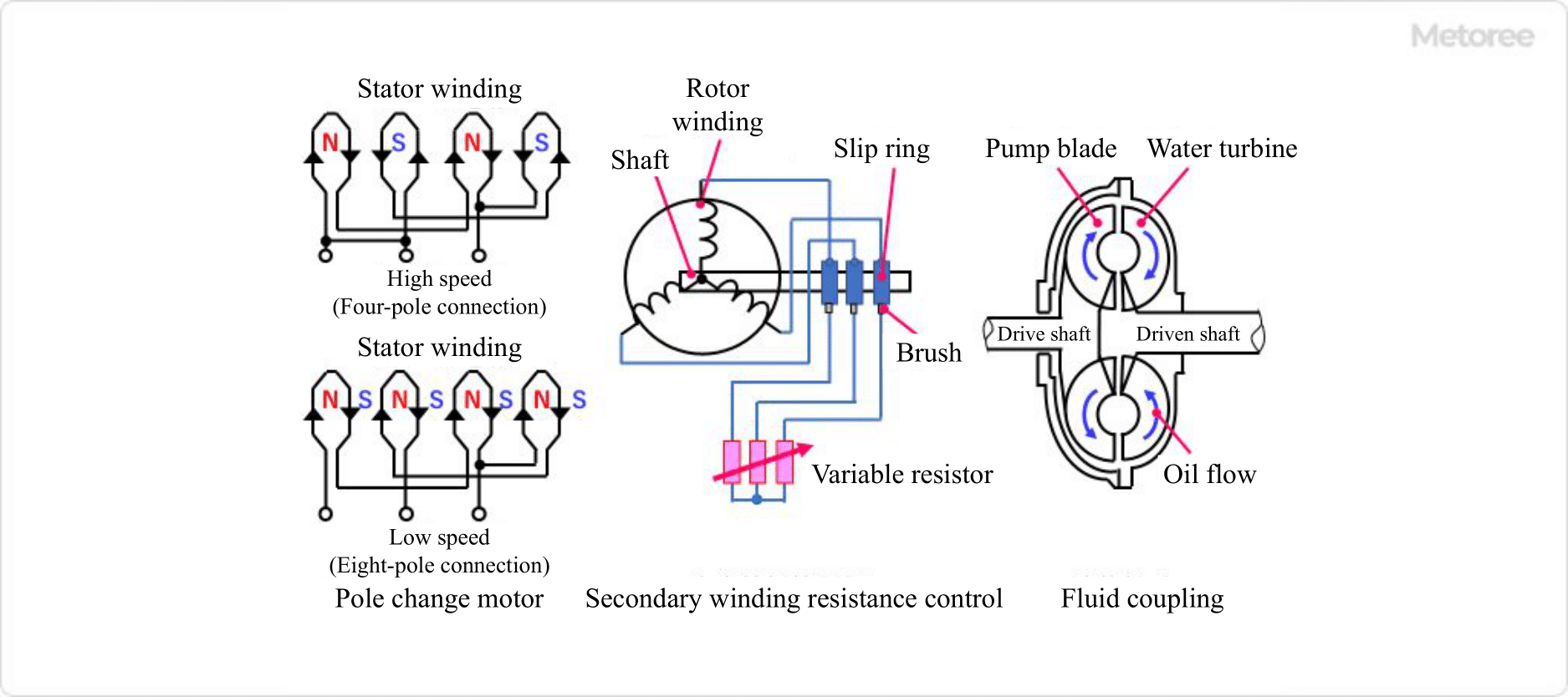

Figure 2. Speed control of induction motors

As mentioned earlier, the rated speed of induction motors is determined by the power supply frequency and number of poles. However, depending on the type of motor and power supply, the rotational speed can be changed. Speed control of induction motors is implemented in the following manner

Use of Pole-Change Motors Pole change is a motor in which the number of poles can be determined by the method of wiring. The disadvantage is that the motor itself becomes larger and less versatile. Also, the rotation speed can only be changed in steps according to the number of poles.

Resistance Control of Wire-Wound Motors Speed control is possible with wire-wound induction motors. The principle is a motor with coil windings instead of cage wiring for the rotor, and by passing a current through a resistor through the windings (secondary windings), slip is increased and the speed can be slowed down further from the rated value. However, there is a disadvantage in that a resistor is required.

In addition, a separate slip ring is required to pass current through the rotating rotor winding, which increases the number of parts and maintenance costs. Energy loss is also significant because of the heat generated from the resistance.

Rotation Speed Control by Fluid Coupling Smooth acceleration at startup can be achieved by using a fluid coupling, which connects the drive and driven shafts via hydraulic pressure.

Since the drive and driven shafts are connected via fluid, the fluid coupling absorbs large load fluctuations. However, since the drive and driven shafts are not rigidly connected, the oil is agitated, causing the oil to heat up and losses to occur, which is a demerit.

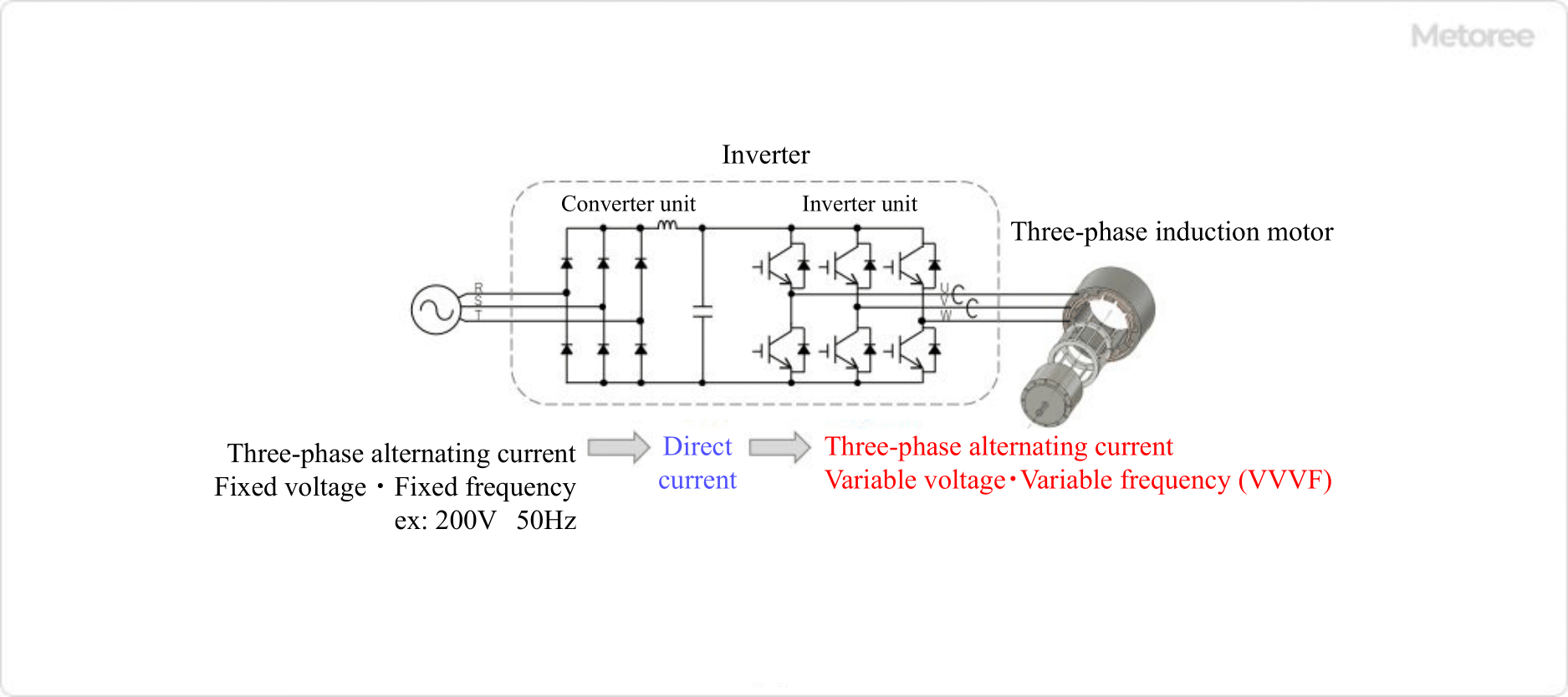

Inverter Speed Control of Induction Motors

Figure 3. Rotation speed control by inverter

Currently, induction motors generally use inverters for speed control. Three-phase AC power with fixed voltage and frequency is controlled by switching a three-phase bridge using power devices such as IGBTs to vary the rotation speed of the motor. By varying the voltage along with the frequency, the motor can be driven with a constant torque.

Energy loss is also extremely low, at only a few percent of the drive energy, thanks to improvements in semiconductor and control technologies, and is most widely used to control the rotational speed of induction motors at a time when the SDGs are being actively called for.

*Including some distributors, etc.

Sort by Features

Sort by Area

ARC Systems, Inc., located in Hauppauge, New York, is an electric motor and AC components manufacturer founded in 1967. It offers integrators, RVDT parts, magnetic coils, and various types of motors. It can provide products based on existing blueprints or create custom-designed products tailored to clients' specific requirements. Its motors and components apply to diverse end users, including Power Plant Instrumentation, Telecommunications, and aerospace industries. The company has been a certified ISO 9001:2015 and AS9100D manufacturer since 2003.

Nidec Corporation was founded in Kyoto, Japan in 1973 and is a conglomerate with over 200 subsidiaries. Primary products are hard-disk drive motors and automotive parts, and specializes motors ranging from miniature to gigantic. Nidec’s products are used in robotics, automotive, home appliances, agriculturel equipments well as molding, cutting, and machining equipment and sensors.

Taizhou Dongchun Motor Co., Ltd., founded in 2010 and located in Zhejiang, China, is a manufacturer of electric motors. The company’s broad range of products includes brake motors, VFD motors, single-phase motors, and three-phase motors. These electric motors find general use across industries and applications, powering an array of machinery, equipment, and systems. The company’s product-specific applications include industrial machinery, agricultural equipment, HVAC systems, automation and robotics, and transportation. The company’s products serve as crucial components for generating motion and power in numerous mechanical and electrical operations in both industrial and consumer contexts.

Hordu, located in Zhejiang, China, was founded in 2016 and is an electric motor manufacturer for industrial, mechanical, and electrical applications. The company is a subsidiary of Taizhou Dagong Explosion-proof Electromechanical that was set up to handle export operations and expand the business internationally specifically. It offers a diverse range of motor products, including three-phase, single-phase, explosion-proof, ICE, and electric motors. The products have been exported to over 20 countries, including Russia, Kazakhstan, Lebanon, Brazil, Bangladesh, etc. Its products comply with CE standards, and its quality management system has achieved ISO 9001 certification.

Nidec Industrial Solution, founded in 2012, was formed due to the acquisition of Ansaldo Sistemi Industriali S.p.A. (ASI) by Nidec Corporation and is a manufacturer of power, motion, and control systems in Cinisello Balsamo, Milano. It specializes in producing engineered-to-order electric motor and drive systems, industrial automation, and power quality solutions for Oil, Gas, Metals, Marine, and General industries. The company is also involved in renewable energy, with a focus on the battery energy storage sector. Its quality, environmental, and safety management system is certified with ISO 9001, 14001, and 45001.

Luyang Technology Co., Ltd., founded in Taichung, Taiwan, in 1981 is a supplier of gear motors and reducers. The company's product portfolio includes induction motors, alloy worm motors, separate speed control motors, vacuum pumps and ring blowers. The company serves industries such as Oil and Gas, Aerospace and Defense, Automotive and Transportation, Construction, and Power Generation. The company provides services such as Product Selection Guidance, Engineering Support, New Product Design and Development and Custom Manufacturing.

Ranking as of March 2026

Derivation Method| Rank | Company | Click Share |

|---|---|---|

| 1 | ARC Systems Inc. |

32.6%

|

| 2 | Hordu Electric Motor Manufacturer |

16.0%

|

| 3 | Nidec Industrial Solutions |

13.8%

|

| 4 | NIDEC SANKYO |

13.8%

|

| 5 | Luyang Technology Co., Ltd. |

12.7%

|

| 6 | Taizhou Dongchun motor Co., ltd |

9.0%

|

| 7 | Oriental Motor Co., Ltd. |

2.2%

|

Derivation Method

The ranking is calculated based on the click share within the induction motor page as of March 2026. Click share is defined as the total number of clicks for all companies during the period divided by the number of clicks for each company.Number of Employees

Newly Established Company

Company with a History

*Including some distributors, etc.

*Including some distributors, etc.

| Country | Number of Companies | Share (%) |

|---|---|---|

Japan

Japan

|

2 | 28.6% |

China

China

|

2 | 28.6% |

United States of America

United States of America

|

1 | 14.3% |

Italy

Italy

|

1 | 14.3% |

Taiwan

Taiwan

|

1 | 14.3% |

101 products found

101 products

Tatsuta Co., Ltd.

640+ people viewing

Last viewed: 7 hours ago

■Features ・There are capacitor run type single-phase motors and three-phase induction motors. Although the starting torque of a capacitor run type...

Tokai Trading Co., Ltd.

580+ people viewing

Last viewed: 7 hours ago

Murai Equipment Co., Ltd.

540+ people viewing

Last viewed: 7 hours ago

■About single phase motor ・Special products...A wide range of types including various starting methods, thermal protectors, anti-vibration types, ...

Tatsuta Co., Ltd.

670+ people viewing

Last viewed: 7 hours ago

■Features ・There are capacitor run type single-phase motors and three-phase induction motors. Although the starting torque of a capacitor run type...

Sowa Electric Manufacturing Co., Ltd.

680+ people viewing

Last viewed: 7 hours ago

■Features ・Rotation direction can be unidirectional or bidirectional. ・A rotation speed detection circuit can be installed. - Types of stator sta...

7 models listed

MIKI PULLEY CO., LTD.

390+ people viewing

Last viewed: 7 hours ago

■Features Induction motors, which are generally used as power sources for industrial machinery, rotate at relatively high speeds, so a reduction me...

10 models listed

CHAMPION CORPORATION Co., Ltd.

840+ people viewing

Last viewed: 7 hours ago

One-cycle motors are primarily developed for the rotational positioning of screws and screw caps in plastic molds that use screw cores. This is a m...

Murai Equipment Co., Ltd.

570+ people viewing

Last viewed: 4 hours ago

■About three-phase motor ・Special products...Suitable for a wide variety of requests (explosion-proof motors can be manufactured) ・MET product......

Ichinomiya Electric Co., Ltd.

890+ people viewing

Last viewed: 7 hours ago

Standard motor based on JEM and JIS standards. The use of a steel plate frame allows for compact yet powerful operation. Main features ■Small and ...

Murai Equipment Co., Ltd.

550+ people viewing

Last viewed: 7 hours ago

■About single phase motor ・Special products...A wide range of types including various starting methods, thermal protectors, anti-vibration types, ...

Tatsuta Co., Ltd.

820+ people viewing

Last viewed: 7 hours ago

■Features ・There are capacitor run type single-phase motors and three-phase induction motors. Although the starting torque of a capacitor run type...

Nerve Motor Co., Ltd.

590+ people viewing

Last viewed: 7 hours ago

■Summary - Reduction gears and intermediate reduction gears can be purchased separately. ・When displayed in red, the reducer rotates in the same d...

Sowa Electric Manufacturing Co., Ltd.

540+ people viewing

Last viewed: 7 hours ago

■Features ・The rotation direction is specified in one direction. ・A rotation speed detection circuit can be installed. - Types of stator stack th...

3 models listed

Murai Equipment Co., Ltd.

510+ people viewing

Last viewed: 4 hours ago

■About three-phase motor ・Special products...Suitable for a wide variety of requests (explosion-proof motors can be manufactured) ・MET product......

Tatsuta Co., Ltd.

750+ people viewing

Last viewed: 7 hours ago

■Features ・There are capacitor run type single-phase motors and three-phase induction motors. Although the starting torque of a capacitor run type...

Murai Equipment Co., Ltd.

610+ people viewing

Last viewed: 7 hours ago

■About single phase motor ・Special products...A wide range of types including various starting methods, thermal protectors, anti-vibration types, ...

Tatsuta Co., Ltd.

690+ people viewing

Last viewed: 7 hours ago

■Features ・There are capacitor run type single-phase motors and three-phase induction motors. Although the starting torque of a capacitor run type...

Murai Equipment Co., Ltd.

580+ people viewing

Last viewed: 7 hours ago

■About single phase motor ・Special products...A wide range of types including various starting methods, thermal protectors, anti-vibration types, ...

Oriental Motor Co., Ltd.

710+ people viewing

Last viewed: 7 hours ago

■Summary ・Ideal for applications that operate continuously in one direction ・Three-phase high-efficiency motor for inverter control is also avail...

Japan INSDAC Co., Ltd.

540+ people viewing

Last viewed: 7 hours ago

Tatsuta Co., Ltd.

850+ people viewing

Last viewed: 7 hours ago

■Features ・There are capacitor run type single-phase motors and three-phase induction motors. Although the starting torque of a capacitor run type...

Keisei Co., Ltd.

390+ people viewing

Last viewed: 7 hours ago

■Applications We handle all Nidek Advanced Motor (formerly Nidec Servo) products, so if you cannot find a product in your search, please contact us...

Oriental Motor Co., Ltd.

920+ people viewing

Last viewed: 7 hours ago

■Summary ・Built-in clutch and brake in induction motor ・Ideal for high-frequency operation, positioning, indexing, intermittent inching, etc. ・O...