All Categories

History

This section provides an overview for brushless motors as well as their applications and principles. Also, please take a look at the list of 56 brushless motor manufacturers and their company rankings. Here are the top-ranked brushless motor companies as of July, 2025: 1.ISL Products International., 2.Lin Eng. Inc., 3.NMB Technologies Corporation.

Table of Contents

Categories Related to Brushless Motors

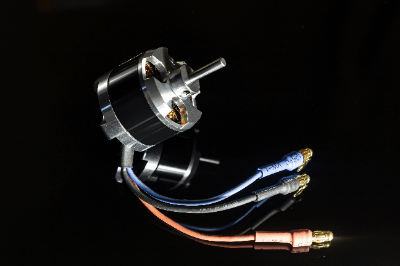

A brushless motor is a motor in which the commutator, brushes, and other mechanical contact parts have been removed. The commutator and brushes are eliminated by having an electronic circuit take the place of the commutator. In a DC motor, the magnetic force of the stator winding circuit drives the permanent magnet rotor. The current is switched by a sensor and a semiconductor switch to rotate the motor.

DC motors have the characteristics of DC motors in that the current is proportional to the torque and the voltage is proportional to the rotation speed, while the structure of AC motors incorporates the best features of both. A brushless motor is a compact, high-power, high-efficiency, and long-life motor that does not generate sparks or noise and is used in a wide range of applications, from computers to home appliances.

Brushless motors have DC motor characteristics and are characterized by high efficiency, long life, and low noise. They are widely used in home appliances, electronic devices, and automobiles. In-home appliances and brushless motors are used in fan motors and drive motors for air conditioners, dishwashers, washing machines, refrigerators, fans, vacuum cleaners, etc. They are ideal for compressors in inverter-controlled air conditioners and refrigerators.

Professional electronic equipment, they are widely used in paper feed for laser printers, propeller drive and gimbal control for drones, hard disks, and optical disks, and drive for drills, screwdrivers, and saws for tools. They are also used in vending machines, financial terminals, ticket-vending machines, copiers, water heaters, and refrigerated showcases.

In addition, adoption in the automotive field is rapidly increasing. Applications are expanding to include drive motors for electric power steering, door locks, headlight optical axis adjustment, door opening and closing, air conditioner compressors for electric vehicles, and traction motors for electric vehicles.

Brushless motors consist of a rotor and stator, a sensor to detect the rotor's rotational position and a driver circuit to drive the motor.

The rotor creates a magnetic field with a permanent magnet, and the stator generates a magnetic flux by winding the rotor. The direction of the magnetic flux is changed by changing the direction of the current flowing through the stator coils according to the rotation angle of the rotor. Brushless motors use sensors and semiconductor switches instead of commutators and brushes as a means of changing the direction of the magnetic flux.

Hall ICs or optical encoders are used as sensors to detect the rotational position of the rotor. Another method is to detect the back EMF. The rotor is rotated by detecting the position of the rotor and switching the current so that the direction of the magnetic flux in the stator advances sequentially. If the motor winding is 3-phase, three sensors are placed inside the stator and digital signals are output according to the rotation of the rotor.

Brushless motors require an inverter circuit driver to control the motor as a power source. A switching transistor is connected to the motor winding, and six transistors make up the inverter. A diode bridge rectifies the commercial power supply to convert it to DC voltage, which is then supplied to the inverter circuit.

A digital signal from the rotor position detection sensor is input to the transistors in the inverter circuit, turning the inverter power supply ON and OFF. This power is supplied to the motor windings to drive the motor. The magnetic pole angle of the rotor is detected from a combination of signals from the sensors, and the transistors in the windings where torque is required are controlled to create a rotating magnetic field.

The rotational speed of the motor is fed back from the sensor signals to the control circuit so that a predetermined speed can be maintained.

1. Long Life

Brushless motors have long-life characteristics because they have no commutator, no brushes, and no sliding parts. They last 10 times longer than brush motors and are easier to maintain.

2. Motor Characteristics

The motor has the characteristics of a DC motor, with current proportional to torque and voltage proportional to rotational speed, and high torque can be obtained even at low speeds. It has the highest efficiency compared to other motors, and its small size and low noise make it suitable for a wide range of applications. High-speed rotation is also easy, and the noise generated is low.

3. Controllability

The small size, lightweight, and relatively small moment of inertia provide excellent controllability in response to changes. Even if the load changes, it can be operated at a stable speed from low to high.

4. Disadvantages

Requires an inverter circuit to control motor rotation as the motor's power source. The cost of the entire device, including the control unit and rotation position sensor, is unfavorable.

*Including some distributors, etc.

Sort by Features

Sort by Area

ISL Products is a designer, manufacturer and supplier of engineered electromechanical component solutions, founded in 1975 and headquartered in New York. With a focus on meeting specific application requirements, they provide unique solutions at the component level. They specialize in a wide range of components such as dc motors, dc gear motors, electronic ballasts for uvc lamps and audio components. Their comprehensive component solutions are tailored to match the unique needs of diverse industries, including healthcare, medical, commercial, and industrial applications. Alongside their product offerings, they also provide integration assistance, industry leading customer service, and global logistical support.

Regal Rexnord Corporation, established in October 2021 as a combination company of Regal and Rexnord, is a manufacturer and service provider of motors and conversion systems. Its parent companies have over 125 years of industry experience, with its products powering HVAC systems, smart buildings, agricultural and food service equipment, and conveyor systems. As a producer of motors and related components, Regal Rexnord supports various industries such as healthcare, food and beverage, and pharmaceutical production. Their global presence spans over 220 sites, and their product range and services include AC/DC drives, bearings, blowers, conveyor technologies, and predictive maintenance solutions.

Sensata Technologies was originally founded in 1916 as General Plate Company and is now headquartered in Attleboro, Massachusetts. The company is a developer, manufacturer, and seller of sensors and sensor-rich solutions, electrical protection components, and other products used in automotive, industrial, energy, telecom, and construction industries. The company has 20 product categories including force sensors, tire management solutions, inverters & charges, and pressure sensors.The company’s next generation of products are designed to improve the efficiency of industrial pumps, fuel efficiency in ICE cars and energy efficiency in TVs, and facilitate usage of IoT devices.

NMB Technologies Corporation, founded in 1951 with facilities in the USA, is a MinebeaMitsumi Group company and a manufacturer of electromechanical and semiconductor components such as small motors, backlights, sensors, and wireless technology. The company's products include cooling fans, precision small motors, mechanical bearing assemblies, battery protection components, and programmable drivers. NMB Technologies Corporation also offers custom design, engineering, and manufacturing to its customers in the automotive, robotics, medical, consumer technology, and industrial markets.

Geeplus was founded in 2004 in Beckenham, UK as a management buyout of the electromechanical division inside Densitron Control Systems, Ltd. The company is a worldwide designer and manufacturer of both standard and customized electromagnetic and electromechanical actuators. The company’s primary catalog includes voice coil motors, linear and rotary solenoids, control circuits, and other related components. The company’s custom actuator solutions include design options for custom voice coil actuators, custom solenoid actuators, custom stepper motors, and custom electromagnets.

AEROTECH creates solutions for motion and positioning of devices. Customers are from industries as diverse as data storage, medical devices, and aerospace. AEROTECH develops controllers, drives, motors, and other parts for motion and positioning devices and offers custom-engineered motion systems. AEROTECH’s serves both manufacturers of individual parts as well as equipment operators offering full range of support rom design to manufacturing to deployment.

Terra Universal Inc. was established in 1976, headquartered in Fullerton, CA, and is a manufacturer of critical environment applications for designing and fabricating cleanroom- and laboratory-based industries. The company offers comprehensive lines of modular cleanrooms, desiccator cabinets, pass-through chambers, glove boxes, furnishings, and many more. The company also stocks thousands of these products for immediate shipment. Custom work is no problem; the company is also able to work to meet the requirements of its clients.

ElectroCraft Inc., established in 1960 and headquartered in Stratham, United States of America, is a supplier of application-engineered fractional-horsepower motor and motion products. The company provides DC motors, motor drives, linear actuators, and brush motors. It also delivers AC motors, gear motors, mobile drivetrains, and cables. It provides advanced precision solutions for the lowest cost of ownership for the largest brands and the newest cutting-edge companies. The products are used for medical equipment, laboratory automation, mobile robotics, industrial automation, agricultural automation, and military & defense industries. It serves North America, Europe, the Middle East, Africa, and Asia markets.

Lin Eng. Inc., established in 1987 and headquartered in Fremont, California, is a manufacturer, specializing in motion control solutions. Its product range encompasses stepper motors, including hybrid, PM, and integrated options, facilitating precise motion control. The company also offers a diverse selection of BLDC motors, from frameless to servo, ensuring smooth motion control. Additionally, provided too are motion control components such as drivers, controllers, encoders, and gearboxes, enabling the creation of customized motion control systems. The company keeps data with accordance to ISO9001:2015, AS9100D and many other standards, and its motors can be found in numerous FDA and FAA-approved applications.

Allied Motion Technologies Inc., established in 1962 is a designer, manufacturer, and retailer of precision and specialty motion control components and systems headquartered in Amherst, New York The company offers electronic, electromagnetic, and mechanical motion technology segmented into brushed DC motors, AC motors, gear motors, brushless motors, and vehicle steering & traction brushless. Its products are used in various motion control applications in the industrial, vehicle, electronics, and aerospace & defense markets. They also supply the medical sector with critical motion control solutions such as power wheelchair control systems, motion control for ventilators, and respirators & medical robots.

Moog Inc. was incorporated in 1951 and is headquartered in East Aurora, New York. The company designs manufactures and integrates precision motion and fluid controls and control systems for customers including OEMS in industries such as aerospace, defense, industrial machinery, motorsports, and construction. The company’s product offerings include both systems and components. Examples of systems include actuation systems, naval systems, turreted weapon systems, and space vehicles. Examples of components include manifolds, slip rings, actuators, and servo actuators.

Orbex Group, founded in 2007 and headquartered in Austin, Texas, USA, is a manufacturer and supplier of electric motors and slip rings. The company's product range involves an array of products, including miniature capsule slip rings, through-hole slip rings, DC-coreless motors, and brushless motors. These offerings cater to a wide range of industries, meeting client demands. It emphasizes delivering quality customer service as a certified ISO 9001:2015 company. It maintains quality standards in its operations As a dependable partner, it serves diverse industries as a good provider of electric motors and slip rings.

Neutronics Enterprises Inc., established in 1983 and located in Los Gatos, California, USA, is a manufacturer and supplier of advanced brushless motors. The company's product range includes a diverse array of brushless motors, such as outrunner motors, inrunner motors, sensorless motors, and high-voltage motors. These products cater to various industries such as radio-controlled (RC) vehicles, robotics, military, aerospace, and industrial sectors. Its services include comprehensive support solutions, including technical assistance, training, and spare parts. The company also delivers quality products and services that consistently surpass expectations making it a dependable partner in motion control solutions.

Holmes Hobbies LLC, established in 2005 and headquartered in Lee's Summit, Missouri, USA, is a manufacturer and supplier of motion control electronics. The company's products include ESCs employed for regulating the speed and direction of electric motors, motors tailored for various applications, servos designed for precision movement in RC vehicles and robots, batteries catering to diverse needs, and chargers serving different battery types. Its offerings find relevance across industries, including radio-controlled (RC) vehicles, military, aerospace, and industrial sectors. It maintains support to deliver quality products and services making it a dependable partner across an array of industries.

Sinotech is based in Portland, Oregon with offices in China. Sinotech is a distributor for custom-engineered electrical motors, motor components, and mechanical components manufactured in China. Sinotech’s motors include AC motors, DC motors, brushless DC motors, slotless high speed BLDC motors, stepper motors, cordless motors, gear motors, servo motors, and miniature motors. Motor components include laminations, wound coils, armature and field coils, brushes, and communicators. Mechanical components include assemblies, die castings, investment castings, sand castings, shafts, steamed metal parts, tubular metal parts, machined extrusions, plastic parts, rubber parts, and secondary processing.

Founded in Rocklin, CA, Galil is a leading supplier of motion controllers for customers across numerous industries from semiconductors to machinery, to automotive, to the arts. Galil also creates programmable logic controllers (PLC) and specialized multi-axis motion controllers. Galil makes both standard designs as well as custom designs for individual customer needs.

Canon U.S.A., Inc., established as the New York branch in 1955 and then was formally incorporated in 1965, is a supplier of consumer, business-to-business, and industrial digital imaging solutions based in the United States. The company opened their new headquarters in 2013 and continues to realize growth, oversees operations in North, Central and South America. Located off the Long Island Expressway and near the technology corridor of Route 110, the headquarters features modern amenities and a 52-acre campus.

JIANGSU LEILI MOTOR CO., LTD., founded in 1993, is a manufacturer of synchronous, micro-stepping, DC brush motors and micro water pumps. Their products are used in research and development, automotive parts, manufacturing, industrial, and sports health industries, with over 200 million machines shipped annually. The company, located in Changzhou City, Jiangsu Province, is affiliated with businesses including Jiangsu DINGS' Intelligent Control Technology Co Ltd, Anhui Leili Intelligent Technology Co Ltd, Vietnam Leili Motor Co., Ltd, and Changzhou Leili Motor Science and Technology Co Ltd.

maxon, a company established in 1961, based in Sachseln, Switzerland, is a manufacturer and exporter of high-precision drive systems and components. The company advanced product solutions for various industrial and medical applications such as robotics, aerospace, automotive, prosthetics, and surgical devices. It has a range of products such as brushed and brushless DC motors, gearheads, encoders, controllers, and sensors. These products are designed to operate with high performance, quality, and reliability.

Changzhou Fulling Motor Co., Ltd was established in 2001 and is a manufacturer of motor products based in Changzhou, China. The company offers various products such as hybrid stepping motor, outer rotor BLDC motor, and closed-loop brushless servo motor. The products have been applied in various industries such as office automation, bank equipment, and green energy. The company has passed the certification of ISO 9001, IATF 16949, and ISO 14001. The products are manufactured under RoHS and CE standards, and some products are also UL approved.

Johnson Electric, since 1959, is a manufacturer of motors, micro-switches, solenoids, microelectronics, and flexible printed circuits based in Shatin, Hong Kong. Their products include AC motors, automotive switches & subsystems, cargo bikes, EMI-shielded flexible circuits, snap action switches, used in automotive, building automation, digital security, food & beverage, and laboratory equipment. Johnson Electric has been in the Hang Seng Corporate Sustainability Benchmark index since 2018. The Hong Council of Social Service awarded it the 5+ caring company award in 2022-2023 and additionally, it is an Institute of Business Ethics supporter.

3X Motion Technologies Co. Ltd, established in 2002 and headquartered in LuCheng Changzhou, China, is a manufacturer and designer specializing in control motor solutions. The company offers a range of products, such as hybrid stepper motors, brushed DC geared motors, and brushed DC motors. These products are widely used in various applications, including industrial automation, security systems, and automatic doors. Additionally, the company offers unique customization options and complete engineered systems, tailored to meet specific customer needs.

Constar Micromotor Co., Ltd., established in 2000 and headquartered in Shenzhen, China, is a manufacturer specializing in micromotor products and related solutions. The company's product portfolio includes brushless DC motors, 12-volt coreless DC motors, DC gear motors, microservo motors, and more. These products are manufactured in compliance with the IATF16949 Standard, serving various industries, with applications spanning medical equipment, automobiles, robotics, and industrial automation. The company operates from two production bases in Shenzhen and Chongqing, boasting a total area of 70,000 square meters and an annual production capacity of 100 million units.

Citizen Chiba Precision was established in Chiba, Japan in 1979. Citizen is a leader of miniaturized precision motors and customized products which custom-made to meet specific customer requirements for among others, semiconductor manufacturing equipment, medical equipment, and laser application products. Examples of Citizen’s products include optical scanners, linear actuators, servomotors, gear heads, and control drivers.

Orbray was originally founded in 1939 in Japan. Orbray serves the automotive, medical, fashion, information communication, audio, and robotics industries. Orbray develops a variety of products including small motors, fiber optics components, and precision jewelry tools. Applications for Orbray’s products include small robots, diaphragm pumps, inner wall metrology systems, and semiconductors.

MOON’s is headquartered in Shanghai, China. MOON’s is a manufacturer or motion control products. Among these products are stepper drives and motors, brushed and brushless DC motors, servo drives and motors, integrated motors, BLDC drives, lighting drivers and control products, and condition monitoring products. MOON’s has achieved ISO 14001 and ISO 9001 certification.

MinebeaMitsumi Inc. was incorporated in 1951in Japan and manufactures and supplies machined components, and electronic devices and components globally. It operates through four segments: machined components, electronic devices and components, MITSUMI Business, and the U-Shin business segment. MinebeaMitsumi specializes in bearing products including spherical, roller, rod end, and ball bearings for aerospace. MinebeaMitsumi also produces products including precision mechanical assemblies, fasteners, other special components including clutches and brakes, motors, blowers, sensors and lighting devices. Additionally, MinebeaMitsumi offers its products for use in PCs and peripheral equipment, information and telecommunications equipment, household electrical appliances, automobiles, and aerospace.

Nidec Corporation was founded in Kyoto, Japan in 1973 and is a conglomerate with over 200 subsidiaries. Primary products are hard-disk drive motors and automotive parts, and specializes motors ranging from miniature to gigantic. Nidec’s products are used in robotics, automotive, home appliances, agriculturel equipments well as molding, cutting, and machining equipment and sensors.

Assun Motor is based in Shenzhen China, founded in 2003, an innovative manufacturer for advanced DC drive system. Products including DC Coreless Brushed Motor, DC Slot-less Brushless Motor, Planetary Gearbox, Servo Motor and Controller, Encoder and Brake. Assun Motor provide high precision, reliability and efficiency DC drive systems for critical applications.

Koford Engineering LLC is a manufacturer of brushless motors and drives located in Winchester, Ohio, USA. The company offers brushless ironless motors for flywheel energy storage and spotless brushless motors for high-speed or high-efficiency applications. It also offers brushless Hall and sensorless drives for unmanned aerial vehicles, medical machinery, and military robots. The company markets its products internationally, with distribution operations across North, Central, and South America, serving clients in the military, aerospace, and industrial automation sectors.

MTC Industries and Research Carmiel Ltd. is an AS9100D, ISO 9001:2015 and MIL-STD certified manufacturer of subsystems for the defense and aerospace industries established in 1977 in Karmiel, Israel. The company’s product lineup includes servo motors for converting electrical energy into mechanical energy, and servo actuators for providing controlled force and motion in platforms such as UAVs or gliding bombs. It also offers inertial sensors, gyroscopes, and slip rings for transmitting power and signals. The company’s products are mainly used by clients in the aerospace and defense sectors, such as Elbit Systems and Israel Aerospace Industries.

Anaheim Automation, Inc. is a manufacturer and service provider specializing in motion control products established in 1966 in Anaheim, California, USA. The company produces a wide range of motion control products, including linear guides for moving machine tables along an X or Y axis, integrated circuits, and gear motors. It also offers customization services to clients requiring additional support, including wiring, redesign, and private labeling. The company's products are primarily used in the robotics, food processing, and medical diagnostics sectors.

Portescap originated in Switzerland in 1931 as a manufacturer of miniature motors and precision motor control solutions. The company assists its customers in selecting the optimal motion technology for a specific application. The extensive range of products includes linear actuators, gearheads, encoders, miniature DC motors (both brush and brushless), and miniature stepper motors. The miniature stepper motors and DC motor technologies are designed to reduce size and weight while enhancing efficiency. They fulfill the need for precise control in medical devices. robotics, surgical, and industrial power tools, automation and other applications.

Parvalux Electric Motors Ltd., founded in 1947, is a UK-based electric and geared motor manufacturer in Bournemouth, currently a subsidiary of an American company, Maxon Precision Motors, Inc. The company supplies industrial and building automation as well as material handling products to original equipment manufacturers (OEMs). These products include building access control systems, robotic solutions, and automated guided vehicles (AGVs). It also develops mobility solutions like wheelchair ramps and lifts, along with medical devices like air pumps and ventilators. The company further offers products for transportation, logistics, and agriculture, including marine steering systems as well as livestock feed and ventilation systems.

C.I. TAKIRON Corporation was founded in 1919 and is a manufacturer and supplier of building materials, plastic plates, and flooring based in Minato, Tokyo, Japan. The company manufactures various products such as polycarbonate corrugated plates, siphon rain gutter system, resin concrete faucet pillar, polyethylene rainwater storage tank, and drainage catch basin. Various industries have used the company's products such as agriculture, semiconductor manufacture, household electical appliances, civil engineering, and urban environment management. The company has obtained various certification such as ISO 9001, ISO 5560, ASTM E1354, and ISO 14001.

Ametek PDS, headquartered in Woodstock, NY. is an OEM supplier of components and systems used for power generation and distribution, motion control, data acquisition, and cockpit instruments for the aerospace and defense industry. Products consist of custom power supplies, programmable power supplies, and AC/DC power supplies. The company also offers a range of services, such as repair and calibration, to ensure power supply operation. AMETEK PDS is a part of AMETEK Inc., a publicly traded global manufacturer of electronic instruments and electromechanical devices.

Coreless Motor Co. Ltd. is based in Yamato, Kanagawa, Japan, and is a manufacturer of coreless motors and related components that was established in 2017 following the merger of M-Link Co. Ltd., IC Fan V-Tech Co. Ltd., and Coreless Motor Co., Ltd. The company’s product lineup includes coreless AC servo motors, coreless brushless DC motors, and coreless IC fan motors. It also offers custom design and development services, as well as opto-mechanical assembly and optical coating. The company chiefly serves client manufacturers of automobiles, aircraft, and heavy machinery.

Curtiss-Wright Defense Solutions, established in 1930 and based in Ashburn, Virginia, USA, is a manufacturer and distributor of rugged, and safe solutions. The company's product range includes embedded computing modules, processor boards, flight test and monitoring, and networking and communications.These products are used in ensuring optimal performance in defense and space manufacturing. It serves industries such as defense, aerospace, commercial aerospace, and industrial manufacturing. Its services includes obsolescence mitigation, proactive prevention against counterfeit parts, development of product roadmaps, and facilitating the smooth integration of future technological advancements.

AMETEK, Inc., headquartered in Waterbury, Connecticut, and founded in 1930, is a supplier and manufacturer of advanced linear and rotary solutions. The company offers a product portfolio, including multi-axis motion systems, linear rail systems, and lead screw and nuts assemblies. These solutions find applications in various fields, such as playing a key role in purge and trap analysis for gas chromatography sample preparation, ensuring the precise and accurate delivery of dyes and agents in contrast injector systems, and contributing to dialysis pump applications with linear stepper actuators.

Alien Power System, established in 2016 and headquartered in Vancouver, Canada, is a manufacturer and supplier of brushless motors. The company's product range includes different brushless motors, such as outrunner motors, inrunner motors, and sensorless motors. These products cater to diverse industries, including radio-controlled (RC) vehicles, robotics, drones, electric vehicles, and medical devices. The company delivers quality brushless motors, It offers good services, including customization options to meet specific customer requirements, troubleshooting, and training to maximize customer investment. As an ISO 9001:2015 company, the company upholds quality as a dependable partner across industries.

Hacker Motor USA, established in 2004 and located in a suburb of Kansas City, Missouri, is a manufacturer and supplier of performance brushless motors and controllers. The company's product includes brushless motors and controllers, catering to diverse industries such as RC (radio-controlled) aircraft, cars, and boats. The company's services include turning wind turbines and robotics, medical applications such as prosthetics and surgical robots; and scientific applications including particle accelerators and telescopes. The company's passion for quality is reflected in its range of services, including custom design and manufacturing solutions.

Dunkermotoren, established in 1950 and headquartered in Bonndorf, Germany, is a manufacturer specializing in complete motor solutions. We're more than just motor suppliers – we're your trusted partner for comprehensive drive solutions. We take pride in leading diverse industries such as industrial automation, building automation, laboratory and medical technology, and motive applications. Products include brushed DC motors, brushless DC motors, PMDC motors, AC motor, Venetian Blind Drives, Planetary Gearboxes, Angular Gears , Wheel Hub Gear , Controllers, Brakes, Linear Systems, Encoders.

Established in 1996 in Gujarat, India, Alto Motors is a leading BLDC motor manufacturer dedicated to advanced motion technology. We specialize in state-of-the-art BLDC motors and have a strong history in AC motor production. As a top BLDC motor manufacturer in India, our commitment to engineering excellence and innovative technology ensures the highest quality and performance in our products. At Alto Motors, we deliver high-performance, energy-efficient solutions tailored to meet the diverse needs of our global customers. Our focus on continuous improvement and customer satisfaction drives us to stay at the forefront of motor technology, providing reliable and effective solutions for various applications.

Activa Inc, located in Kaoshiung, Taiwan, is a leader of research and development of cooling fans and motors. Examples include cooling fans used in personal computers, cross flow fans, duct fans, DC and stepper motors, Sirocco blowers, ceiling fans, and fan accessories. Additional products include water pumps, air compressors, and AC heating fans.

KING RIGHT MOTOR CO., LTD of Taoyuan City, Taiwan, specializes in the research and development and manufacture of DC brushed motors, servo motors, and DC gears. King Right Motor’s main products include DC motors, planetary gear motors, worm gear motors, spur gears, servo motors and pumps ranging in output power from 10W to 1,000W. These are used in equipment, industrial machinery, garage doors, elevators, elevator doors, mixers, medical equipment, health and welfare equipment, garden equipment tools, stage design and vehicle applications. King Right Motor has passed ISO 9001 certification.

TSUKASA ELECTRIC CO.,LTD was founded in 1969 in Japan. Tsukasa primarily develops two types of components. First are motors, which are used in vending machines, ATM machines, and amusement machines. These also include gear motors, gear pumps, linear motion units, and rotary actuators. Secondly, Tsukasa develops tube pumps which are generally mounted to the aforementioned motors.

WITTENSTEIN SE, a company established in 1949 and based in Bartlett, Illinois, is a manufacturer and supplier specializing in servo gearboxes and motors. The company's product portfolio includes rotative synchronous motors, single-axis servo drives, and integrated system solutions. These products are used in various industries, including the pharmaceutical industry, food and beverage, and nuclear energy generation. The company offers services including technical support, expedited delivery after purchase, and product installation. The company has a global footprint in various countries including China, the Czech Republic, and Sweden.

Ranking as of July 2025

Derivation Method| Rank | Company | Click Share |

|---|---|---|

| 1 | ISL Products International. |

11.6%

|

| 2 | Lin Eng. Inc. |

4.4%

|

| 3 | NMB Technologies Corporation |

3.5%

|

| 4 | Coreless Motor Co., Ltd. |

3.4%

|

| 5 | Sensata Technologies, Inc. |

3.3%

|

| 6 | Regal Rexnord Corporation |

3.2%

|

| 7 | Neutronics Enterprises Inc. |

3.1%

|

| 8 | Aerotech, Inc. |

3.1%

|

| 9 | Allied Motion, Inc. |

2.8%

|

| 10 | Geeplus Inc. |

2.7%

|

Derivation Method

The ranking is calculated based on the click share within the brushless motor page as of July 2025. Click share is defined as the total number of clicks for all companies during the period divided by the number of clicks for each company.Number of Employees

Newly Established Company

Company with a History

*Including some distributors, etc.

*Including some distributors, etc.

| Country | Number of Companies | Share (%) |

|---|---|---|

United States of America

United States of America

|

17 | 44.7% |

Japan

Japan

|

9 | 23.7% |

China

China

|

5 | 13.2% |

Taiwan

Taiwan

|

3 | 7.9% |

Switzerland

Switzerland

|

1 | 2.6% |

Hong Kong

Hong Kong

|

1 | 2.6% |

| United States | 1 | 2.6% |

India

India

|

1 | 2.6% |

319 products found

319 products

Sowa Electric Manufacturing Co., Ltd.

660+ people viewing

Last viewed: 51 minutes ago

■Features ・Inner rotor type brushless motor. - Brushless, long life. ・The rotation direction is specified in one direction. ・There are two types...

CITIZEN MICRO CO.,LTD.

410+ people viewing

Last viewed: 17 minutes ago

This is a revolutionary miniaturized motor with a built-in drive circuit, and is also equipped with a motor lock protection circuit and FG signal o...

2 models listed

Esco Co., Ltd.

320+ people viewing

Last viewed: 16 hours ago

Esco DC brushless motor. It is a small, high-output motor that has the same characteristics as a DC motor, such as the proportional relationship be...

Asahi Engineering Co., Ltd.

370+ people viewing

Last viewed: 21 hours ago

Features ■Brushless motor with external size 60 and hollow diameter φ22 - Hollow brushless motor with external size 60mm, depth 40mm, and hollow di...

Esco Co., Ltd.

620+ people viewing

Last viewed: 20 hours ago

■Features ・Built-in current limit circuit ・FG output possible ・High voltage type (DC60 [V] to 180 [V]) Commercial power can be directly rectifie...

3 models listed

Esco Co., Ltd.

930+ people viewing

Last viewed: 2 hours ago

Covers the voltage normally used as a DC power supply (DC12[V] to 24[V]). The rotation speed can be varied by switching the input voltage. With loc...

6 models listed

Joytech Co., Ltd.

310+ people viewing

Last viewed: 16 hours ago

■Summary We handle brushed and brushless motors and slip rings, which have short delivery times and low costs. Customization according to your desi...

Esco Co., Ltd.

640+ people viewing

Last viewed: 11 hours ago

Compact, lightweight, highly efficient, inexpensive, and suitable for a wide range of applications. ■Main uses ・Copy machine ·printer ·scanner ・...

4 models listed

Shinkoh Electronics

750+ people viewing

Last viewed: 3 hours ago

3 models listed

Esco Co., Ltd.

1400+ people viewing

Last viewed: 1 hour ago

Φ29L45 (including connector) fan. Ultra high speed, ultra static pressure, lightweight and small fan. Drive circuits are also available. ■Main use...

10 models listed

Ally Japan Co., Ltd.

270+ people viewing

Last viewed: 17 hours ago

■Product usage/adoption record Drones, medical equipment, industrial equipment, etc.

CITIZEN MICRO CO.,LTD.

320+ people viewing

Last viewed: 1 day ago

A geared motor is a general term for a combination of a motor and a reduction gear.

Ally Japan Co., Ltd.

280+ people viewing

Last viewed: 11 hours ago

■Product usage/adoption record Drones, medical equipment, industrial equipment, etc.

NPM High Technologies Co., Ltd.

2050+ people viewing

Last viewed: 7 hours ago

■ Overview ・ Manufacturer: CDA Inter Corp ・ Application: Military, space ■ Features ・ CDA Intercorp has been supplied for more than 40 years of...

7 models listed

Kazumomotion Tech Co., Ltd.

660+ people viewing

Last viewed: 19 hours ago

■ Characteristics We handle an inner rotor, outer rotor, brushless driver, built -in driver, and a wide range of brushless motors that can respond ...

5 models listed

Takasago Electric Industry

460+ people viewing

Last viewed: 1 day ago

■Features ・The standard flow rate is 180 mL/min or 200 mL/min, and the pressure range is -30 to 100 kPa. ・Since it is a brushless motor, it has a...

2 models listed

Takasago Electric Industry

330+ people viewing

Last viewed: 1 day ago

■Features ・This pump has a standard flow rate of 300 mL/min and a pressure range of - 30 to 600 kPa. ・Since it is a brushless motor, it has a lon...

Nerve Motor Co., Ltd.

210+ people viewing

Last viewed: 8 hours ago

■Summary - Reduction gears and intermediate reduction gears can be purchased separately. ・When displayed in red, the reducer rotates in the same d...

Nisshinbo Micro Devices Inc.

290+ people viewing

Last viewed: 5 hours ago

■Summary The NA7200 is a three-phase DC brushless motor pre-driver with a 120 degree conduction method using a CMOS process. It receives the rotor ...

Tokushu Denso Co., Ltd.

270+ people viewing

Last viewed: 10 hours ago

■Brushless motors with special electrical equipment for various industrial machines Long life, small size, light weight, high performance, high qua...

Tokushu Denso Co., Ltd.

420+ people viewing

Last viewed: 16 hours ago

■Brushless motors with special electrical equipment for various industrial machines Long life, small size, light weight, high performance, high qua...

Keisei Co., Ltd.

240+ people viewing

Last viewed: 10 hours ago

■Features ・High efficiency, long life, wide range of speed control ・Efficiency and energy saving due to appropriate energization based on detecti...

Keisei Co., Ltd.

240+ people viewing

Last viewed: 1 day ago

■Applications We handle all Nidek Advanced Motor (formerly Nidec Servo) products, so if you cannot find a product in your search, please contact us...

Tokushu Denso Co., Ltd.

290+ people viewing

Last viewed: 7 hours ago

■Brushless motors with special electrical equipment for various industrial machines Long life, small size, light weight, high performance, high qua...

Keisei Co., Ltd.

200+ people viewing

Last viewed: 6 hours ago

■Features ・High efficiency, long life, wide range of speed control ・Efficiency and energy saving due to appropriate energization based on detecti...

Tokushu Denso Co., Ltd.

250+ people viewing

Last viewed: 1 day ago

■Brushless motors with special electrical equipment for various industrial machines Long life, small size, light weight, high performance, high qua...

Tokushu Denso Co., Ltd.

350+ people viewing

Last viewed: 1 day ago

■Summary The motor rotation speed is controlled by a variable resistor (potentiometer) or indicated voltage. We offer controllers as standard produ...

Tokushu Denso Co., Ltd.

270+ people viewing

Last viewed: 1 day ago

■Summary The motor rotation speed is controlled by a variable resistor (potentiometer) or indicated voltage. We offer controllers as standard produ...

Tokushu Denso Co., Ltd.

290+ people viewing

Last viewed: 1 day ago

■Brushless motors with special electrical equipment for various industrial machines Long life, small size, light weight, high performance, high qua...