All Categories

History

This section provides an overview for servo linear motors as well as their applications and principles. Also, please take a look at the list of 26 servo linear motor manufacturers and their company rankings. Here are the top-ranked servo linear motor companies as of July, 2025: 1.Nippon Pulse America, Inc., 2.Beckhoff Automation GmbH & Co. KG, 3.SEW-EURODRIVE GmbH & Co KG.

Table of Contents

A linear servo motor is an electric motor that does not have a built-in rotating shaft and is capable of linear motion for use in servo mechanisms utilized in machine control.

A linear servo motor is an electric motor that does not have a built-in rotating shaft and is capable of linear motion for use in servo mechanisms utilized in machine control.

While general motors perform rotary type motion, linear motors generally perform linear type motion. Linear motors themselves are devices for driving and propulsion widely known as linear motor cars, etc. Servomotors are motors used to control position, speed, etc. in servo mechanisms.

Until recently, rotary servo motors have been the mainstay of linear motion systems for industrial machinery and measuring instruments, but in recent years, linear servo motors, which operate by the action of the magnetic flux generated by a permanent magnet and the current flowing through a coil (Fleming's left-hand rule), have been attracting attention.

Linear servo motors are used in a variety of applications. In particular, applications vary depending on the size.

These are used in desktop-type equipment. Mainly used for observation of industrial products and biotechnology-related products. Shaft motors are required to have high resolution in fields where higher resolution images and image processing are required.

This size is the most widely used in fields that require high thrust, high precision, and high speed, and is widely used for various positioning and moving parts in machine tools and semiconductor equipment.

Other applications include special machines that require large acceleration thrust.

The linear motion of a linear servo motor is based on the principle that a linear motor, which consists of a shaft with a magnet on its axis and a mover containing a coil, generates thrust through the action of the current flowing through the coil and the magnetic flux generated by the permanent magnet, or Fleming's left-hand rule.

The shaft is usually a pipe made of stainless steel filled with magnets at equal intervals, and the mover consists of a three-phase coil wound around the shaft. The mover does not come into contact with the shaft, and its incorporation does not affect the thrust itself, making it easy to install. It operates by generating thrust through the action of the magnetic induction flux generated by the permanent magnet and the current flowing in the coil.

Features of shaft-based motors include high-precision positioning when high-precision linear scales are used, no backlash, and almost no cogging due to the absence of a core. Note that cogging refers to the fine vibration of the magnetic attraction between the shaft and mover in a motor that depends on the angle of rotation.

Since there are no screws, nuts, or other mechanical structures inside, high-speed motion is possible. While the accuracy of motion is excellent, the rigidity is low because the fixed side is not in contact with the moving side, making it unsuitable for heavy-duty cutting where resistance is high. It is used in equipment used to process electronic components such as semiconductors and medical parts. Its small size and simple structure are advantages when incorporated into equipment.

One of the requirements of today's high-performance industrial machinery is to achieve both high-precision machining and high-speed machining. Before linear servo motors were commercialized, linear actuators used a combination of a rotary motor and a ball screw with bearings as a component to convert rotational power into linear power.

With the conventional method, it is technically difficult to achieve both higher accuracy and higher operating speed, and maintenance tends to be more frequent. Linear servo motors, however, are non-contact and have many advantages: they excel in high-speed operation, their positioning accuracy can be easily increased to high precision, and they do not require maintenance.

The challenges in applying linear servo motors to machine tools are their power density and controllability. Compared to conventional rotary motors and ball screws, linear servo motors are difficult to control, and high technology is required to ensure high output density.

Recent technological innovations by manufacturers have overcome these challenges, and linear servo motors are gradually being widely used in machine tools and industrial equipment.

*Including some distributors, etc.

Sort by Features

Sort by Area

Moog Inc. was incorporated in 1951 and is headquartered in East Aurora, New York. The company designs manufactures and integrates precision motion and fluid controls and control systems for customers including OEMS in industries such as aerospace, defense, industrial machinery, motorsports, and construction. The company’s product offerings include both systems and components. Examples of systems include actuation systems, naval systems, turreted weapon systems, and space vehicles. Examples of components include manifolds, slip rings, actuators, and servo actuators.

Nippon Pulse America, Inc. (NPA) is an ISO 9001:2015 and ISO 14001:2015 certified motor manufacturer and supplier of motion control products for OEM applications operating as a subsidiary of Nippon Pulse Motor Co., Ltd. Based in Radford, Virginia, the company provides custom engineering options for their various linear and rotary actuators, linear stages, controllers, and drivers. Their product portfolio includes stepper and shaft motors, belt drive stages, servo controllers, and unipolar drivers, as well as modules for communication or data transfer for various applications in the automation, robotics, defense, and aerospace sectors.

AEROTECH creates solutions for motion and positioning of devices. Customers are from industries as diverse as data storage, medical devices, and aerospace. AEROTECH develops controllers, drives, motors, and other parts for motion and positioning devices and offers custom-engineered motion systems. AEROTECH’s serves both manufacturers of individual parts as well as equipment operators offering full range of support rom design to manufacturing to deployment.

Gimatic Srl was founded in 1985 and headquartered in Roncadelle, Italy as a subsidiary of Barnes Group, based in Bristol, Connecticut. The company is an ISO 9001-certified manufacturer of equipment in the end-of-arm tooling market for manufacturing-based industries. The company’s product categories include automotive manufacturing, tooling & factory automation, food & beverage, home applications, and pharma & medical. Product categories for these segments include vacuums and vacuum pumps, suction cups, sensors, machines, and other components.

FANUC Corporation, established in 1972 and headquartered in Yamanashi Prefecture, Japan, is a manufacturer of factory automation, robomachine, IoT, and robotics. The company offers an extensive and diversified product portfolio including, servomotor, robodrill small cutting machine, roboshot electric injection molding machine, robocut wire electrical discharge machine, and lasers. These cutting-edge products cater to a wide range of industries, spanning from automotive, health care, and aerospace to electronics. The aim of the company is to provide efficient and low-cost products to customers.

Sodick Co., Ltd, founded in 1976 and headquartered in Yokohama, Japan, is a manufacturer and supplier of machine tools, injection molding machines, food machines, and LED products. The company's product portfolio includes nano-level precision machines, magnesium alloy injection machines, noodle steam sterilizers, LED products, and electronic components. These products are utilized in various industries, including food processing, electronics, LED and lighting, manufacturing and machining, and the plastics and injection molding industry. The company has development, production, and service locations in different countries, including the United States, China, Thailand, India, and Singapore.

THK Co., Ltd. was incorporated in 1946 and is headquartered in Tokyo, Japan. THK is a manufacturer and supplier of machine components such as linear motion components for customers globally. THK’s products are used in many industries including electronics, aerospace, industrial robots, and precision instruments. THK’s primary product categories are Linear Motion, Feed Screw, Rotation, Custom Assemblies, and Seismic Isolation. Linear Motion products assist in linear motion and transportation. They include linear motion actuators, guides, and rollers. Feed screws include ball screws, screw nuts, and change nuts. Seismic Isolation includes both large systems and small guides.

SINFONIA TECHNOLOGY CO., LTD., established in 1917 in Tokyo, Japan, is a manufacturer specializing in motion equipment, driven by advanced electromagnetic control technology. The company offers a comprehensive range of products and solutions, including clean transport devices, vital electrical components for space rocket systems, cutting-edge testing systems, advanced vibrating equipment, and electromagnetic clutch systems, among others. These diverse products serve critical functions in sectors such as Aerospace, Industrial Transportation, and Liquid-Crystal manufacturing equipment.

Sumitomo Heavy Industries, Ltd. (SHI) was established in 1888. SHI offers complete solutions for industrial machinery production and operations, heavy machinery for infrastructure, logistics, and construction, power generation systems as well as systems to reduce pollution, water purification, and ship construction. In addition, SHI also offers various software services including IT solutions.

Mitsubishi Electric was established in Japan in 1921 and headquartered in Tokyo. The company’s Semiconductors & Devices division is a manufacturer of products serving several industries ranging from home appliances and automotive to renewable energy and optical fiber communication. The company’s products are divided into 4 product segments: power devices, high-frequency devices, optical devices, and infrared sensors. Power devices encompass motion controls, most home appliances, and SiC applications. High-frequency devices include satellite communications systems, radios, and base transceiver stations. Optical devices include projector light sources and optical fiber communication. Infrared sensing systems include MeIDIR thermal sensors.

SANYO DENKI Europe was established in 1988 in France as the European subsidy of SANYO DENKI CO., LTD of Japan. The company is a manufacturer of components used in mechanization, computing, and public utilities. The company operates in three operating segments: Cooling Systems, Power Systems, and Servo Systems. Cooling Systems develops, manufactures, and sells cooling fans and cooling systems. Power Systems develops and manufactures UPS, engine generators, and solar energy power conditioners. Servo Systems develops, manufactures, and sells servo motors, stepping motors, drive units, and control systems.

SEW-EURODRIVE, founded in 1931 and headquartered in Germany, is a manufacturer and supplier of drive automation solutions. The company offers an extensive product portfolio including gearmotors, frequency inverters, servo drives, industrial gears, and motors, catering to various industries like automotive, food and beverage, mining, and more. SEW-EURODRIVE's drive solutions are utilized in many applications, such as conveyor systems, lifting equipment, agitators, and mixers, contributing to increased efficiency and productivity. The company aims to provide unique and quality solutions that meet the evolving needs of its customers, empowering industries with cutting-edge drive technology.

HIWIN GmbH, established in 1974, is based in Offenburg, Germany, and is a manufacturer and supplier of motion control products and systems. The company's main product portfolio includes linear guideways, ball screws, linear motors, and linear actuators. These precision components and systems are used in various industries, including machine tools, automation, and semiconductor manufacturing. HIWIN's performance motion control solutions enable smooth and accurate linear motion, enhancing the efficiency and productivity of industrial processes. With a great ability on research and development, HIWIN,s aims to provide cutting-edge solutions to meet the dynamic needs of the global market.

Miki Pulley Co., Ltd., founded in 1939, is a manufacturer and provider of solutions for power transmission and control problems, headquartered in Kawasaki City, Japan. They manufacture various products essential for all industries, including couplings for high-precision power transmission, electromagnetic clutches and brakes for power transmission when energized, and speed changers and reducers for controlling the speed of machinery. They also offer inverters, linear shaft drives, rotation speed indicators, torque limiters, and ROSTA rubber springs.

SANYO DENKI CO., LTD. was founded in 1927 and is a manufacturer and supplier of cooling systems, power systems, and servo systems based in Toshima, Tokyo, Japan. The company manufactures various electronic systems such as DC cooling fan, measuring device, power management products, static transfer switch, and AC servo systems. Various field of industry have been using the products, such as electronic manufacturing, financial, solar energy, medical, and robotic industries. The company has certified with ISO 9001:2015, ISO 14001:2015, and ISO 45001:2018. The company has reached various accomplishments such as awarded winner in Good Design Award 2023.

Omron Corporation, started in 1933 and headquartered in Kyoto, Japan, is a manufacturer of automation components, equipment, and systems, and it developed the first contactless proximity switch in 1960. It has four domains, including industrial automation, electronic components, healthcare, and social systems, and it provides products and services in around 120 countries and regions. Some of its products include microsensing devices, access control systems, industrial robots, surveillance cameras, and blood pressure monitors. In 1971, it developed the first online cash machine, and in 1972, it established Japan’s first welfare factory.

Coreless Motor Co. Ltd. is based in Yamato, Kanagawa, Japan, and is a manufacturer of coreless motors and related components that was established in 2017 following the merger of M-Link Co. Ltd., IC Fan V-Tech Co. Ltd., and Coreless Motor Co., Ltd. The company’s product lineup includes coreless AC servo motors, coreless brushless DC motors, and coreless IC fan motors. It also offers custom design and development services, as well as opto-mechanical assembly and optical coating. The company chiefly serves client manufacturers of automobiles, aircraft, and heavy machinery.

Nippon Thompson Co., Ltd. - IKO is based in Japan and was established in 1950 as a manufacturer of bearings. The company designs Linear Motion Rolling guides and Mechatronics series and they were the first to produce Needle Roller Bearings. These products have vast applications in various industries as they are used in Electronics-related Devices and Equipment like semiconductors and for precision devices that are used in laboratory measuring instruments and medical equipment. Textile, printing, construction, transportation, and robotics are also on the list of industries that benefit from IKO products.

Rockwell Automation, Inc. was founded in 1903 and is headquartered in Milwakee, WI. Rockwell Automation provides industrial automation and digital transformation solutions around the world. Rockwell Automation operates through their intelligent devices, software & control, and lifecycle services segments with both hardware and software products and services. The Intelligent Devices segment offers drives, motion, safety, sensing, industrial components, and configured-to-order products. The Software & Control segment provides control and visualization software and hardware, information software, and network and security infrastructure solutions. The Lifecycle Services segment provides consulting, professional services and solutions, and connected and maintenance services through independent distributors.

Beckhoff Automation LLC is the American branch of Beckhoff Automation GmbH & Co. founded in Verl, Germany. The United States headquarters is based in Savage, Minnesota. The company serves industries such as automotive, marine, semiconductors, and alternative energy with hardware and software-based solutions. The company’s five hardware product segments are industrial PCs, fieldbus components for I/O, motion drive systems, MX systems, and system-integrated machine vision products. The company also produces software for automation-related tasks.

FANUC Corporation was established in 1956 and is headquartered in Japan, manufacturing of industrial robots, CNC systems, and related automation technologies. The company produces products that include industrial robots, CRX Cobots, Lasers, IoT Solutions, and various CNC systems for machine tools. These systems and technologies find applications in a broad range of industries, including automotive manufacturing, aerospace and defense, electronics production, and metalworking. They also help with automated repetitive tasks, performing complex assembly operations, and handling hazardous materials for medical device manufacturing, consumer goods products, and many more industrial applications.

OMRON Industrial Automation is the UK branch of OMRON, originally founded in Japan in 1933. OMRON Industrial Automation serves food and beverage industry, panel board design, automotive manufacturing industries among others. OMRON Industrial Automation products categories include automation systems such as industrial PCs and human machine interfaces (HMI), safety such as safety switches and safety logic control systems, switching components such as solid state relays, motion & drives such as motion controllers, sensing such as photoelectric sensors, software, robotics, quality control & inspection systems, as well as control components including power supplies and digital panel indicators.

NIPPON PULSE MOTOR Co., Ltd. established in 1952 and based in Tokyo, Japan, is a manufacturer and supplier of precision motion control products. The company's product range includes controllers, drivers, various motors, industrial fields, and mechatronic systems. These products find their application in valves/fluid control, medical and analytical instruments, industrial machinery, and semiconductor manufacturing. It serves industries such as industrial machines, semiconductor manufacturing, valve mechanisms, and medical analytical instruments. Its services include product design, manufacturing, global distribution, and technical support.

Ranking as of July 2025

Derivation Method| Rank | Company | Click Share |

|---|---|---|

| 1 | Nippon Pulse America, Inc. |

9.1%

|

| 2 | Beckhoff Automation GmbH & Co. KG |

8.3%

|

| 3 | SEW-EURODRIVE GmbH & Co KG |

5.1%

|

| 4 | HIWIN GmbH |

4.7%

|

| 5 | Aerotech, Inc. |

4.7%

|

| 6 | Sumitomo Heavy Industries, Ltd. |

4.7%

|

| 7 | Sodick Co., Ltd |

4.3%

|

| 8 | THK U.K. |

4.3%

|

| 9 | Gimatic Srl |

4.3%

|

| 10 | FANUC |

4.3%

|

Derivation Method

The ranking is calculated based on the click share within the servo linear motor page as of July 2025. Click share is defined as the total number of clicks for all companies during the period divided by the number of clicks for each company.Number of Employees

Newly Established Company

Company with a History

*Including some distributors, etc.

*Including some distributors, etc.

| Country | Number of Companies | Share (%) |

|---|---|---|

Japan

Japan

|

13 | 59.1% |

United States of America

United States of America

|

3 | 13.6% |

Germany

Germany

|

3 | 13.6% |

Italy

Italy

|

1 | 4.5% |

France

France

|

1 | 4.5% |

Belgium

Belgium

|

1 | 4.5% |

102 products found

102 products

TAIYO Co., Ltd.

230+ people viewing

Last viewed: 4 hours ago

Parker's Model MI Linear Motors are products that significantly improve efficiency. Parker's MI type iron core linear motors significantly improve ...

SANYO DENKI CO., LTD.

330+ people viewing

Last viewed: 1 day ago

■Linear servo system Suitable for applications that require high speed and high precision. Ideal for semiconductor manufacturing equipment, liquid ...

GMC Hillston Co., Ltd.

300+ people viewing

Last viewed: 2 hours ago

■Linear shaft motor with simple and versatile features and performance different from conventional linear motors ・High-speed operation (takt incre...

GMC Hillston Co., Ltd.

330+ people viewing

Last viewed: 2 hours ago

■Linear shaft motor with simple and versatile features and performance different from conventional linear motors ・High-speed operation (takt incre...

GMC Hillston Co., Ltd.

340+ people viewing

Last viewed: 2 hours ago

■Linear shaft motor with simple and versatile features and performance different from conventional linear motors ・High-speed operation (takt incre...

Kazumomotion Tech Co., Ltd.

880+ people viewing

Last viewed: 2 hours ago

The ligament -migrated small linear servo actuator MIGHTYZAP is a precision linear position control of motors, gear mechanisms, electronic circuits...

4 models listed

GMC Hillston Co., Ltd.

300+ people viewing

Last viewed: 2 hours ago

■Linear shaft motor with simple and versatile features and performance different from conventional linear motors ・High-speed operation (takt incre...

Kazumomotion Tech Co., Ltd.

530+ people viewing

Last viewed: 1 day ago

A small linear servo actuator, MIGHTYZAP, which is a ligament type that enters and out of the shaft is a servo motor for control of the motor, gear...

GMC Hillston Co., Ltd.

300+ people viewing

Last viewed: 1 hour ago

■Linear shaft motor with simple and versatile features and performance different from conventional linear motors ・High-speed operation (takt incre...

GMC Hillston Co., Ltd.

280+ people viewing

Last viewed: 2 hours ago

■Linear shaft motor with simple and versatile features and performance different from conventional linear motors ・High-speed operation (takt incre...

GMC Hillston Co., Ltd.

300+ people viewing

Last viewed: 2 hours ago

■Linear shaft motor with simple and versatile features and performance different from conventional linear motors ・High-speed operation (takt incre...

GMC Hillston Co., Ltd.

290+ people viewing

Last viewed: 2 hours ago

■Linear shaft motor with simple and versatile features and performance different from conventional linear motors ・High-speed operation (takt incre...

KSS Co., Ltd.

400+ people viewing

Last viewed: 6 hours ago

A high-performance drive unit that integrates a feed screw and stepping motor without a coupling. The motor is directly attached to the shaft end o...

2 models listed

KSS Co., Ltd.

990+ people viewing

Last viewed: 1 day ago

A high-performance drive unit that integrates a feed screw and stepping motor without a coupling. The motor is directly attached to the shaft end o...

10 models listed

KSS Co., Ltd.

1180+ people viewing

Last viewed: 5 hours ago

A high-performance drive unit that integrates a feed screw and stepping motor without a coupling. The motor is directly attached to the shaft end o...

7 models listed

KSS Co., Ltd.

780+ people viewing

Last viewed: 3 hours ago

A compact linear actuator (cylinder type) that combines a 2-phase hollow stepping motor and a ball screw. A wide variety of drive screw types (prec...

10 models listed

KSS Co., Ltd.

700+ people viewing

Last viewed: 3 hours ago

By adopting a precision ball screw + Si-servo, this is a hybrid product that enables "perfectly equal pitch positioning," "no vibration," and "no s...

5 models listed

COMS Co., Ltd.

250+ people viewing

Last viewed: 1 day ago

■Repeat positioning accuracy ±0.0005mm or less This is a direct drive linear servo stage using a shaft motor. Non-contact drive enables speed stabi...

GMC Hillston Co., Ltd.

270+ people viewing

Last viewed: 2 hours ago

■Linear shaft motor with simple and versatile features and performance different from conventional linear motors ・High-speed operation (takt incre...

GMC Hillston Co., Ltd.

290+ people viewing

Last viewed: 2 hours ago

■Linear shaft motor with simple and versatile features and performance different from conventional linear motors ・High-speed operation (takt incre...

SANYO DENKI CO., LTD.

280+ people viewing

Last viewed: 1 day ago

Overview Suitable for applications that require high speed and high precision. Ideal for semiconductor manufacturing equipment, liquid crystal disp...

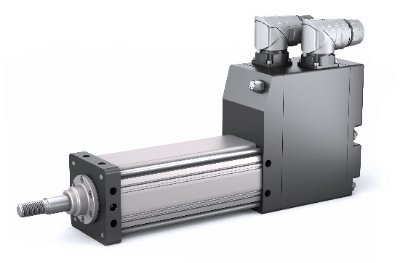

MIKI PULLEY CO., LTD.

500+ people viewing

Last viewed: 1 day ago

■Features Miki Pulley's electric linear actuator is a cylindrical linear motor system that can be driven with a simple system. Position detection u...

GMC Hillston Co., Ltd.

360+ people viewing

Last viewed: 2 hours ago

■Low noise, long life, high performance linear single axis robot with shaft motor ・High thrust, high speed, high response, high precision ・Simple...

GMC Hillston Co., Ltd.

400+ people viewing

Last viewed: 2 hours ago

■Low noise, long life, high performance linear single axis robot with shaft motor ・High thrust, high speed, high response, high precision ・Simple...

GMC Hillston Co., Ltd.

220+ people viewing

Last viewed: 2 hours ago

This is a pressure control unit that uses a shaft motor.

GMC Hillston Co., Ltd.

360+ people viewing

Last viewed: 1 hour ago

■Low noise, long life, high performance linear single axis robot with shaft motor ・High thrust, high speed, high response, high precision ・Simple...

GMC Hillston Co., Ltd.

250+ people viewing

Last viewed: 2 hours ago

■Linear shaft motor with simple and versatile features and performance different from conventional linear motors ・High-speed operation (takt incre...

GMC Hillston Co., Ltd.

250+ people viewing

Last viewed: 2 hours ago

■Linear shaft motor with simple and versatile features and performance different from conventional linear motors ・High-speed operation (takt incre...

GMC Hillston Co., Ltd.

260+ people viewing

Last viewed: 1 hour ago

■Linear shaft motor with simple and versatile features and performance different from conventional linear motors ・High-speed operation (takt incre...

GMC Hillston Co., Ltd.

330+ people viewing

Last viewed: 2 hours ago

■Linear shaft motor with simple and versatile features and performance different from conventional linear motors ・High-speed operation (takt incre...