All Categories

History

This section provides an overview for centrifugal pumps as well as their applications and principles. Also, please take a look at the list of 61 centrifugal pump manufacturers and their company rankings. Here are the top-ranked centrifugal pump companies as of July, 2025: 1.CORNELL PUMP COMPANY, 2.Franklin Electric Co., Inc., 3.Graymills.

Table of Contents

Categories Related to Centrifugal Pumps

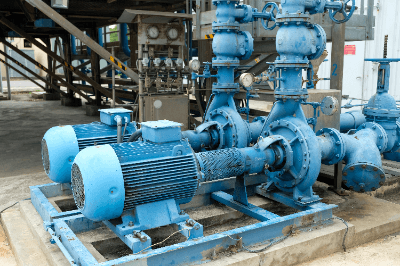

A centrifugal pump is a type of pump that has an impeller-like impeller inside the pump casing. The casing has a volute shape and is also called a volute pump.

A centrifugal pump is a type of pump that has an impeller-like impeller inside the pump casing. The casing has a volute shape and is also called a volute pump.

Liquid enters the impeller through the suction port at the center, and is propelled outward at high speed by the centrifugal action of rotation. As it passes through the volute chamber, it is gradually decelerated and converted to pressure.

There are two types of centrifugal pumps: single-stage with one impeller and multi-stage with two or more impellers. The multistage type increases pressure with each stage and is used when high pressure is required.

Centrifugal pumps are often used when a high flow rate and low pressure are required. They are widely used in industrial applications such as drainage, boiler water supply, water supply and sewage, mining, and chemical industry. They are also used in agriculture, such as for irrigation, and for water supply and drainage of air conditioning units.

Centrifugal pumps are often used for relatively low viscosity solutions with a solids volume concentration of 20% or less in the liquid. Those with improved vane shapes and materials to resist wear and corrosion are used for transporting muddy water, sewage, slurries, and pulp mixtures, sand and gravel, coal, and other liquids. Furthermore, by reducing the number of blades and increasing the flow path area, they can be used to transport fish, oranges, etc. along with water.

Centrifugal pumps use centrifugal force to impart pressure and velocity energy to a fluid by rotating an impeller in a casing. It is then decelerated in the volute-shaped casing and the velocity energy is converted to pressure energy. This phenomenon is known as Bernoulli's theorem.

There are two types of impellers: a radial flow form with a two-dimensional curved surface in which the fluid flows in the radial direction, and a mixed flow form with a three-dimensional curved surface that changes from axial to radial in an incremental manner. This is an important element for efficiently converting velocity energy into pressure.

The casing is installed to form a spiral-shaped chamber outside the impeller. As the cross-sectional area gradually increases in the direction of rotation, the high-speed fluid ejected from the impeller by centrifugal force is gradually decelerated and the pressure (static pressure) increases.

There is a limit to the pressure that can be generated by a single impeller. If higher pressure is required, a multi-stage pump is used. In a multi-stage pump, the fluid leaving the first impeller is sucked into the second impeller to further increase pressure. This can be repeated several times to obtain high pressure.

Pump construction is closely related to flow rate and head, and is an important selection criterion when choosing a pump. Centrifugal Pumps consist of an impeller and volute casing, shaft, bearings, drive coupling, and suction and discharge couplings, shaft sealing device, and if necessary, a pressure gauge, pressure sensor, and pressure switch.

There are pumps with non-rotating fixed guide vanes arranged around the periphery of the impeller. They are called diffuser pumps or turbine pumps and are part of the centrifugal pump family. The mechanism is similar to that of centrifugal pumps, but the fluid leaving the impeller is efficiently decelerated as it passes through the guide vane and the static pressure increases, resulting in higher overall efficiency.

Since the pump structure is designed to convert liquid to pressure, problems can occur if gases are introduced into the pump or if gases are generated inside the pump. One of these problems is cavitation.

Cavitation in pumps is a phenomenon in which the pressure of a liquid drops rapidly inside the pump, and when it reaches saturation vapor pressure, the liquid vaporizes rapidly. Cavitation in centrifugal pumps occurs when the static pressure of the fluid decreases due to the increased velocity of the liquid flowing into the impeller and the static pressure near the inlet falls below the saturation vapor pressure of the fluid.

Repeated cavitation causes damage to the impeller, resulting in cavitation erosion. Vibration and noise are also generated, and performance is reduced. This leads to premature deterioration and destruction of the equipment, not only in the centrifugal pump but also in the pipes and valves.

Cavitation can be prevented by changing operating conditions, reducing resistance on the suction side, and improving the shape and area of the impeller so that the fluid pressure does not fall below the saturated vapor pressure.

*Including some distributors, etc.

Sort by Features

Sort by Area

Price Pump Company, established in 1932 and headquartered in Caldwell, Idaho, United States, is a designer, manufacturer, and supplier of stainless steel industrial pumps. The company's products include horizontal centrifugal pumps, vertical centrifugal pumps, and air-operated diaphragm (AOD) pumps, all with a two-year warranty. It also specializes in the custom manufacture of pumps for industrial and original equipment manufacturer requirements. Its services include product development, system integration, and the supply of evaluation products.

Celeros Flow Technology is based in North Carolina, USA, and is a manufacturer of flow control technology products that was established in 2020 as a spin-off company from the SPX Flow Group. The company markets its products under several brands, including M&J Valve, GD Engineering, and ClydeUnion Pumps. Its product lineup includes filtration systems such as coalescers, valves such as butterfly valve models, and pumps such as reciprocating pump models. The company’s products are used by clients in the oil and gas, power generation, and chemical processing industries.

Magnatex Pumps Inc., established in 1985, is a pump manufacturer located in Houston, Texas, USA. The company holds an ISO 9001:2015 certification and offers a range of pumps including American National Standards Institute (ANSI), American Petroleum Institute (API), and sub-ANSI magnetic drive pumps. It also provides ANSI mechanical seal pumps and small gear pumps. These pumps are constructed from alloy, stainless steel, and fluoropolymer to handle demanding applications such as recovery solvents, heat transfer fluids, and toxic chemicals. They are commonly used in petrochemical and pharmaceutical plants, as well as water treatment facilities.

Haight Pump in Evansville, WI, since 1932, has been a manufacturer of bed plate assemblies and pumps for application in refrigeration, lubrication, filtration, fueling, injection, and thermal systems. The company offer various pumps, including internal gear, custom gear, centrifugal, and external gear pumps manufactured from materials such as iron, stainless steel, and brass. The company is a subsidiary of Baker Manufacturing Company, LLC, has a management system that is ISO 9001 certified, and is listed under NSF Products and Services.

Dry Coolers, Inc., established in 1985 is a manufacturer of industrial cooling solutions headquartered in Oxford, Michigan, USA. The company, which has on-site engineering and fabrication departments offers various cooling technologies and custom solutions such as evaporative cooling towers, mechanical chillers, pump stations, air-cooled heat exchangers, and accessories such as plate heat exchangers, bag filters, controls, sensors, and centrifugal separators. It has passed the ASME, CSA, CE, and UL standards and is ISO 9001:2015 certified to offer products to various industries including aerospace, canning, energy, data centers, and metal treatment.

Graymills, established in 1939 and based in Chicago, United States, is a manufacturer of equipment used in metalworking pumps, ink pumps, filters, and parts washers. The company produces different types of pumps, such as peristaltic, diaphragm, and centrifugal pumps, that are used in different industries, including automotive, aerospace, medical & scientific devices, and military. The manufacturing unit is located in Illinois to manufacture equipment such as laser cutters, fabrication, welding, and CNC machine shops. Initially, the company started with machine tool coolants and later added cleaning equipment to the portfolio of products.

Xylem Inc. was incorporated in 2011 and is headquartered in Washington, District of Columbia. Xylem engages in the design, manufacture, and servicing of engineered products and solutions for the water and wastewater applications across global markets. Xylem operates through three segments: water infrastructure, applied water, and measurement & control solutions. Xylem’s water infrastructure segment offers numerous products such as water pumps, filtration, disinfection, and biological treatment equipment. Xylem’s applied water segment distributes pumps, valves, heat exchangers, controls, and dispensing equipment systems. Xylem’s measurement & control Solutions segment offers devices such as smart meters, networked communication devices, data analytics, test equipment, controls, sensor devices, and software and managed services.

Grundfos Pumps Corporation, established in 1945, and located in Brookshire Texas, is a manufacturer and installer of pumps and pumping systems. The company offers a range of pumps, including CMBE circulator pumps for water circulation in various systems, SCALA2 booster pumps to enhance water pressure, MQ dosing pumps for controlled fluid dispensing, CR pumps for industrial use like water treatment and mining, and SP submersible pumps for well and borehole water pumping. The company holds both ISO 14001, and ISO 9001:2008 in adherance to quality management standards.

Franklin Electric Co. Inc. founded in the year 1946, and based in Indiana, United States is a professional manufacturer and supplier of HVAC, plumping, pools, and hydroponics. Their product portfolio includes different types of pumps, pool, water garden equipment, water pressure multistage pumps, and other accessories. The company also offers a wide range of submersible electric motors and other specialty electric motors with different applications and features. The products are used in many commercial and industrial markets using gasoline dispensers, paint sprays, electric hoists, and livestock feeding machines.

Cornell Pump Company, founded in 1946 in Clackamas, Oregon, USA, is a manufacturer and supplier of robust pumping solutions. The company designs and produces a wide range of pumps, including centrifugal pumps, agricultural pumps, industrial pumps, and more. These pumps find applications in various sectors, such as agriculture, municipal water systems, mining, and food processing. Besides, the company is an great provider of efficient and ideal pumping solutions worldwide. Courtesy of its aim for quality and effectiveness, Cornell Pump continues to meet the diverse needs of its clients across different industries.

Verder was founded in 1959 in Georgia as a manufacturer of pumps. The company produces various pumps for a wide range of applications. These include Veriderflex peristaltic pumps, Verderir diaphragm pumps and Packo pumps. The peristaltic pump has applications in the mining, ad and bio gas and sewage facilities whereas diaphragm pumps help with non liquid pumping. The Packo pumps consist of centrifugal, lobe and twin screw pumps having use in the industrial, food and pharmaceutical applications. There are also Microdos solenoid pumps, SSP Rotary lobe pumps for solids and Verderhus screw centrifugal pumps for low head, high flow pumping.

Blackmer, founded in Grand Rapids, MI, in 1903 is a manufacturer of sliding vane, gear, regenerative turbines and centrifugal pumps. The company's product portfolio includes compressor technologies for the transfer of liquids and gases, Positive Displacement Pumps, and PD Pumps. The company serves industries such as Oil and Gas, Aerospace and Defense, Automotive and Transportation, Construction, and Power Generation. They also provide services including product selection, installation, preventative maintenance, troubleshooting, and repair.

Gorman-Rupp Pumps, founded in the year 1933, and based in Ohio, United States, is a manufacturer and supplier of pumps and pumping systems. Their product portfolio includes different types of pumps self-priming and standard centrifugal, submersible, rotary gear, hydraulic, engine-driven, and booster stations. The products are used in multiple industries which include petroleum, construction, agriculture, sewage, and water stations. The company also offers pump finder technology and pump selector tools on its website.

John Blue Company, founded in 1886 and located in Huntsville, Alabama, is a distributor and manufacturer of agriculture pump products. The company offers a broad range of products, including ground application pumps, hydraulic application pumps, injection pumps, centrifugal pumps, and chemical injection pumps. These products are used in agriculture for tasks like crop spraying, irrigation, fertilization, and chemical injection, enhancing the efficiency and precision of farming operations. The company’s products cater to farmers, crop growers, and agricultural professionals.

Tele-Lite, Inc. is located in Harleysville, Pennsylvania, USA, and is a manufacturer and distributor of emergency services products and utilities, originally founded as Corbett-Steeves Pattern Works in 1914. The company offers LED emergency lighting products including signage, automatic backup lights, and motion-triggered lights. It also stocks a range of Honda brand power equipment including generators, outboard motors, and water pumps. The company mainly serves clients and consumers in the commercial and residential sectors.

Tank Farm Services Ltd is a crude oil sludge management service provider and product manufacturer established in 2011 and based in Nottingham, England, UK. The company’s products include no-entry tank desludging equipment such as standard and live mastir cannons for desludging and resuspending hydrocarbon deposits, and hydraulic dozers for desludging tanks, interceptors, or lagoons. It also offers standard as well as screw-type HSP3 submersible pump models. The company mainly serves clients in the oil and gas industry.

Pumping Solutions, Inc., founded in 1996 and located in Ontario, California, is a distributor of industrial and commercial pumps and process equipment. The company’s diverse product line includes centrifugal pumps, magnetic pumps, sanitary pumps, submersible pumps, and metering pumps. These products are utilized in diverse industries for tasks like fluid transfer, processing, and management. The company’s products find applications in areas such as water circulation, chemical handling, food and beverage, pharmaceuticals, and wastewater management.

Hebei GN Solids Control Co., Ltd, founded in 2007 and headquartered in China, is a manufacturer specializing in separation equipment. Its products serve various industries, and the company has exported them to over 60 countries globally. Key offerings include shale shakers for large solids separation, decanter centrifuges for fine solids separation, mud cleaners combining desander, desilter, and shale shaker functions, oil sludge treatment equipment for recovering valuable components, and industry decanter centrifuges for diverse industrial separation processes.

Salvatore Robuschi e C. SRL, established in 1951 and headquartered in Parma, Italy, is a manufacturer of industrial pumps. The company's products include centrifugal pumps with closed impellers built according to ISO 2858-5199 norms, vertical cantilever centrifugal pumps with vortex and channel impellers, and double-stage with peripheral impeller pumps. These pumps are used for backwashing water, liquid feeding inside the digester of a biogas plant, and extracting concentrated liquid in concentration tanks. It serves industries that include sewage treatment, agriculture, and chemical processing.

Duchting Pumpen Maschinenfabrik GmbH & Co, established in 1938 and headquartered in NRW, Germany, is a manufacturer of centrifugal pumps and related solutions. The company specializes in centrifugal pumps for desalination, flue gas desulphurization, and chemical pigment industries. Its products include single-stage and multi-stage centrifugal pumps such as the MCC, HPXL, and suction dredger. Its retrofit pump series (MCCR) simplifies installation for FGD processes. The company also offers spare parts, mechanical seals, and customized solutions like retrofit designs, addressing specific installation requirements.

Charles Austen Pumps is a manufacturer of specialty pumps founded in 1948 and based in Byfleet, UK. The company produces application-specific pumps for a wide range of industries and applications. These include beverage pumps for fountain drinks, clinical-grade vacuum pumps for ventilators, and wastewater pumps for fish tanks. The company also offers OEM pump design and product customization options for customers requiring additional support. It mainly serves clients in the medical, hospitality, and environmental sectors.

TECALEMIT GMBH & CO. KG, established in 1922 and headquartered in Flensburg, Germany, is a manufacturer and supplier specializing in fluid handling systems. The company's product portfolio includes hand pumps for thin fluids, air-operated diaphragm pumps, and centrifugal pumps. These products find application in various sectors, including manufacturing, agriculture, and transportation and logistics. The company offers various services, including technical support, training, and provision of spare parts. Additionally, the company is ISO 9001 certified for quality management systems.

Andritz AG was initially founded as a much smaller company back in 1852 as an iron foundry, but today the company is a manufacturer and supplier of a wide range of industrial machinery, chemicals, fuels, and textiles, among many more. The company's product portfolio includes over 20 core areas: pulp and paper, metals, cyber security, feeds, and biofuels. Examples include decanter centrifuges, mechanical separation extractors, contact and paddle dryers, and batch helix dryers used in the environment, chemicals, food and beverage, and mining industries. Secondary services include the supply of spare parts, rentals, process consulting, and on-site repairs and upgrades.

Argal Srl, headquartered in Brescia, Italy, is a manufacturer of industrial pumps. The company is engaged in the invention and production of pumps made of thermoplastic material, compounds, and corrosion-resistant metal alloys. The company offers products such as ASTRAevo pumps for broad industrial applications, SATURNsump fiberglass sump pumps, and K2 vertical pumps for solid-laden or moderately abrasive liquids. These pumps are used in industrial applications requiring temperatures ranging from -40°c to +120°c with load capacities up to 1700 m3/h and head over 100 m.

Tapflo is a manufacturer and supplier of diaphragm pumps, pulsation dampeners, centrifugal pumps, and filter units that is headquartered in Kungalv, Sweden and was established in 1980. The company serves industrial machinery where the company offers pumping solutions for markets under chemical and petrochemical, food and beverage, pharmaceutical, and water treatment. Their product catalog includes diaphragm pumps, hose pumps, industrial mixers, Eodd pumps, and pulsation dampeners. The company specifically caters to two specified and categorized sectors which are hygiene and food and industrial purposes.

IWAKI Europe GmbH is a manufacturer and supplier of precision chemical process pumps and fluid handling equipment based in Germany. Established in 1985, the company offers a wide range of products, including magnetic drive pumps, air-operated double diaphragm pumps, metering pumps, and other fluid control equipment. Their pumps are suitable for various applications in industries such as chemical processing, pharmaceuticals, water treatment, and semiconductor manufacturing. One sample product is their MX-F Series Magnetic Drive Pumps. These pumps are designed for handling various chemicals and liquids, offering leak-free performance due to their magnetic drive technology.

Emica Pumps, established in 1899 and headquartered in Abanto, Aragon, Spain, is a manufacturer of residential, commercial, and industrial motor pumps. The company specializes in using various material combinations, flanges, and base plates to produce customized motor pumps. Its standard products include vertical centrifugal pumps for deep wells, various horizontal pumps with open and closed impellers, and multistage high-pressure pumps. The company's services include remanufacturing, the sale of spare parts, and the supply of maintenance programs.

Evoguard GmbH, founded and owned by Krones AG in 2014 and headquartered in Nittenau, Germany, is a manufacturer of valves and pumps used in beverage plant operations. The company's products include hygienic valves, vessel dome fittings, and Evotube heat exchanger systems. Due to its product innovation and independent operations, apart from being used in beverage filling plants and dairy processing plants manufactured by Krones AG, it has expanded its product range to serve the pharmaceutical and biotech sectors.

CKD Corporation, established in 1943 under the name of Japan Aircraft Electric Co., Ltd., is a Japanese manufacturer of automation machinery and manufacturing components, headquartered in Komaki, Aichi. Their diverse portfolio includes pneumatic and fluid control components, fine system components, drive components, and labor-saving components. The company has also developed various types of automation machinery, such as transparent object inspection systems, pharmaceutical products packaging machines, and more. These products find applications in various industries, for example their automated food packaging systems are designed for maintaining food quality and hygienic conditions. Their fluid control components are used in the solar cell manufacturing process.

SPX Flow, established in 1912, is a manufacturer of industrial machinery to solve processing challenges based in Charlotte, North Carolina. The company manufactures various machinery such as mixers, pumps, valves, homogenizers, and heat exchangers. The machinery is used in nutrition, health, mining, construction, and chemical industries. The company provides services such as designing, engineering, and installing turnkey process units or full-scale plants. The SPX Flow brands include Anhydro, Bran+Luebbe, Gerstenberg Schrӧder, Pneumatic Products and Seital Separation.

Asa Technology Produktions und Vertriebs GmbH is based in Vienna, Austria, and is a manufacturer of compact hydraulic products and coolers that was established in 1980 as a subsidiary of Asa Hydraulik GmbH. The company primarily produces a range of thermal systems for cooling liquid, gasses, or electronics. These systems include finned tube, plate and bar, and brazed plate heat exchangers. It also offers pumps for hydraulic systems, metal and rubber hoses, and connection adapters. The company’s products are commonly used in the power generation, renewable energy, and mining industries.

Pierre Guerin SA is a manufacturer of stainless steel products and equipment for the biopharm and food processing industries established in 1949 in Mauzé-sur-le-Mignon, France. The company’s products include agitation and mixing machines for processes such as dispersion or emulsion, and process vessels for cell culturing and fermentation processes. It also offers process accessories and components such as fittings, manways, and valves. The company is ISO 13485-certified, and provides cleaning as well as sterilization-in-place services for customers requiring additional support.

Baker Hughes Co. (BHC) is an American service provider and manufacturer of industrial oilfield equipment that was established in 1987 following the merger of Baker International and Hughes Tool Company. Based in Houston, Texas, the company produces several categories of oilfield products including drilling equipment, pipe and subsea production systems, generators, and storage systems. It also offers process control components and actuators such as pumps, valves and regulators. BHC provides various services for oilfield and liquefied natural gas (LNG) operations, including regasification, well construction, transportation, and storage.

Cryostar Industrial Cryogenics is based in Hésingue, France, and is a manufacturer of cryogenic systems and equipment established in 1967 as a part of the Equans Group. The company offers reciprocating pumps for high pressure applications, centrifugal pumps for unloading or loading of liquid gasses, and expanders for air separation or gas liquefaction processes. It also offers small-scale companders and heat exchangers for LNG distribution or storage. The company is ISO 9001, ISO 14001, and ISO 45001-certified, and chiefly serves clients in the industrial processing sector.

Veolia, founded in Oakland, New Jersey, in 1974 is a manufacturer of water technology products to process water and wastewater. The company's product portfolio includes Condensate Polishers, Filtration Technologies such as Depth Cartridge Filters, Pleated Cartridge Filters and Cartridge Filter Housings, Evaporators & Crystallizers and Sievers Analyzers and Instruments. The company serves industries such as Oil and Gas, Aerospace and Defense, Automotive and Transportation, Construction, and Power Generation. They also offer equipment repair, instrumentation system upgrades and retrofits, preventive maintenance, and warranty service.

ALLWEILER was founded in 1860 and is headquartered in Radolfzell, Germany is a manufacturer of pumps with precision. The company provides an extensive product catalog, which includes screw spindle pumps, eccentric screw pumps, and centrifugal pumps. Additionally, it offers services such as rapid product delivery, the sale of spare parts and consumables, and installation assistance. These products find applications in various industries, including energy generation, water and wastewater treatment, and home and building technology.

Pompe Garbarino S.p.A., established in 1932 and headquartered in Acqui Terme, Italy, is a manufacturer and supplier of pumps. The company's products include centrifugal pumps and positive displacement pumps that are primarily designed for large-scale applications, including offshore petrochemical plants, power stations, and desalination plants. It offers complete consultation and custom manufacturing of turnkey systems to suit clients with specific requirements. Its services include consulting on installation, and it also offers monitoring and maintenance programs. It serves clients that include the military, engineering companies, and ship owners.

Femi S.p.A. is based in Bologna, Italy, and is a manufacturer of cutting and processing machines for metals or wood that was established as a subsidiary of Cometa Srl. The company offers drill presses, portable bandsaws, and semi-automatic bandsaws using hydraulic systems and electronic controls. It also offers drill presses with variable speeds, and metal lathes with digital displays and electronic adjustment controls. The company provides technical assistance and spare parts services, along with custom manufacturing for unique client projects.

Gardner Governor, founded in 1869 and headquartered in Sterling, Illinois, is a manufacturer and provider of precise mechanical governors. The company’s governors are essential control systems used to regulate engine and turbine speeds across industries. Their diverse product portfolio includes mechanical governors tailored for engines, power plants, and industrial machinery, ensuring precise and stable speed control for optimal performance and safety. Gardner Governor's status stems from advanced solutions and excellent customer support. Utilized in power generation, locomotives, and industrial applications, Gardner Governor's products are a major feature in control systems worldwide.

Omnia Della Toffola SpA is based in Signoressa di Trevignano, Italy, and is a manufacturer and supplier of automation technologies established in 2023 after the merger of DT Holding and Bertolaso. The company specializes in automation products for the wine and beverage industry. Its products include bottling lines, distillation plants for producing spirits, and cross-flow filtration system for removing impurities in wine and other beverages. The company also offers installation, engineering, and training services for clients needing additional support.

Shanghai East Pump (Group) Co. Ltd. is a pump manufacturer and supplier based in Shanghai, China. Certified with ISO 9001 and supported by 16 subsidiaries and 8 manufacturing facilities, the company offers a range of pumps, including axial-flow, double-suction, and stamping pumps. It also provides automation and electrical control systems, plate heat exchangers, and pressure vessels. Expanding further, the company offers environmental protection, firefighting, and water supply equipment. These products are utilized in diverse sectors, including agriculture, construction, and heating. The company also collaborates with notable universities such as Tsinghua University at the East Pump Technology Center for scientific research initiatives.

CSF Inox S.p.A., a company established in 1970 and based in Montecchio, Italy, is a manufacturer and supplier specializing in pumps. The company offers various pumps, including volumetric pumps, self-priming centrifugal pumps, and single-stage pumps with volutes. These products are used in various industries, including pharmaceuticals, oil and gas, and the food and beverage industry. The company has both ISO 9001:2015 and ISO 14001:2015 certifications, and it has partnered with various companies, including Bardiani Valvole S.p.A., MBS srl, and OMAC S.r.l.

Enfound Enterprise Co., Lt.d is a manufacturer and supplier of water and wastewater treatment products that was established in Tainan City, Taiwan, in 2000. The company produces aerators for injecting air into water to increase dissolved oxygen levels, UV sterilizers for killing microorganisms in water and preventing waterborne diseases, and diffusers for dispersing air bubbles into water to enhance aeration processes. It also offers related accessories such as pumps and filters. The company’s products are used mainly by clients in municipal water treatment, industrial wastewater treatment, and aquaculture operations.

Atlas Copco UK Holdings Limited, established in 1974 in the UK, is a distributor and supplier of a wide range of industrial tools and machinery used in the aerospace, mobile construction, air motors, and electric motor industries. The company's product portfolio includes air compressors, N2 and O2 generators, tools, and industrial assembly solutions. Atlas Copco UK Holdings Limited also offers a range of products for mobile construction, including power generators, as well as providing clients with 24/7 tool and equipment rental solutions.

Dickow Pump Company, Inc. is the authorized distributor of Dickow Pumpen KG, a respected German pump manufacturer since 1910. Located in Marietta, Georgia, the company supplies sealless metallic centrifugal, multi-stage centrifugal, and side channel pumps with magnetic coupling. These pumps adhere to ANSI, DIN, and API 685 standards, serving industries such as petroleum, heavy-duty chemical, and gas. The company has earned a ISO 9001 certification for its standards. They offer a wide range of customizable options and materials for diverse applications.

Fujian Mindong Electric Corp. Ltd., founded in 1958 and headquartered in Fujian, China, is a power supply equipment and accessories designer, manufacturer, and supplier. The company's products include alternators, portable generators, and various pumps. It also supplies air compressors, three-phase asynchronous motors, and fan motors. These products are used to pump water from agricultural deep wells, as commercial backup power supplies, and in various home appliances. The company accepts direct wholesale orders and also provides OEM services.

Conforto S.r.l. is a water pump manufacturer based in Monselice, Padua, Italy. The company offers various centrifugal pumps featuring single and double impellers, self-priming, and multistage variants. It also provides submersible clean and contaminated water pumps, such as grinder pumps. Other types of submersible pumps are the stainless steel options equipped with floating impellers. The company offers related products such as pressure tanks, pressure sets with integrated pumps, and pressure gauges.

DAB Technology, based in Singapore, has been a supplier and a distributor of vacuum solutions since its incorporation in 1997. Its product range includes palamatic tube lifters, crane systems, dabhandy lifting solutions, and various vacuum components like ejectors, suction cups, and pumps. The company also provides industrial cleaning tools, safety wear, and cleaning equipment. The company is the sole distributor of international brands such as Palamatic, DVP, Hovmand, FBK and more in Asia Pacific, and operates from several branches in Malaysia, Thailand, China, Indonesia, and Vietnam.

Zhejiang YonJou Technology Co., Ltd, established in 1989, is a contemporary corporation based in Zhejiang, China, and it specializes in the production, design, trade, and maintenance of chemical pumps, oil pumps, diaphragm pumps, and diesel water pumps. The organization is devoted to enhancing the technical proficiency of its personnel and is determined to become a frontrunner in the business in terms of quality and innovation. Pumps have applications in various industries, including industrial and mining sectors, among several other utilizations.

Technology Co., LTD, established in 2005, Changsha City, China, is a supplier for high-end micro dc pump solutions. The company’s products portfolio includes micro DC brushless water pumps, DC diaphragm pumps and gear pumps. These products are mainly applied in new energy, home appliances, industrial cooling, medical, and automotive industry, among others. The company is known for its quality and good batch consistency, and cooperative relationship with many world famous brands such as Tesla, Flextronics, Kohler, GE, and Roca, among others.

Cahaba Media Group, Inc., based in Homewood, Alabama, and established in 2002, is a publisher and supplier of various industries' trade publications, websites, and e-newsletters. The firm offers sponsored material, reprints, digital editions, sponsored content, white papers, and webinar promotions. The company has published journals like Pumps & System Media for technical knowledge, Construction Business Owners for contractors, Homecare for professionals in the home health care field, BPN for the butane and propane sectors, and The Shop for auto news.

Ranking as of July 2025

Derivation Method| Rank | Company | Click Share |

|---|---|---|

| 1 | CORNELL PUMP COMPANY |

6.2%

|

| 2 | Franklin Electric Co., Inc. |

4.2%

|

| 3 | Graymills |

4.1%

|

| 4 | Verder Inc. |

3.9%

|

| 5 | Price Pump |

3.9%

|

| 6 | Haight pump |

3.8%

|

| 7 | CELEROS FLOW TECHNOLOGY |

3.6%

|

| 8 | Gorman-Rupp Pumps |

3.4%

|

| 9 | Blackmer |

3.3%

|

| 10 | John Blue Company |

3.0%

|

Derivation Method

The ranking is calculated based on the click share within the centrifugal pump page as of July 2025. Click share is defined as the total number of clicks for all companies during the period divided by the number of clicks for each company.Number of Employees

Newly Established Company

Company with a History

*Including some distributors, etc.

*Including some distributors, etc.

| Country | Number of Companies | Share (%) |

|---|---|---|

United States of America

United States of America

|

17 | 40.5% |

Italy

Italy

|

5 | 11.9% |

China

China

|

4 | 9.5% |

Germany

Germany

|

4 | 9.5% |

Japan

Japan

|

4 | 9.5% |

United Kingdom

United Kingdom

|

2 | 4.8% |

Austria

Austria

|

1 | 2.4% |

Sweden

Sweden

|

1 | 2.4% |

Spain

Spain

|

1 | 2.4% |

Taiwan

Taiwan

|

1 | 2.4% |

Singapore

Singapore

|

1 | 2.4% |

India

India

|

1 | 2.4% |

216 products found

216 products

Nikkora Eiko

3620+ people viewing

Last viewed: 3 hours ago

<Magnet coupling structure without liquid leakage> Handling and maintenance is easy. Connections are possible according to the application, such as...

19 models listed

Maruhachi Pump Manufacturing Co., Ltd.

1000+ people viewing

Last viewed: 32 minutes ago

■Features -Standard impeller is closed type. Semi-open version is also available. ・It is also possible to prevent the fibrous slurry in the liqui...

3 models listed

Torishima Seisakusho Co., Ltd.

660+ people viewing

Last viewed: 3 hours ago

■Features While taking advantage of the features of our conventional pumps, we have adopted a newly developed hydraulic model. This is a single-suc...

Maruhachi Pump Manufacturing Co., Ltd.

1090+ people viewing

Last viewed: 33 minutes ago

■Features -Standard impeller is closed type. Semi-open version is also available. ・Measures can be taken to prevent fibrous slurry in the liquid ...

6 models listed

Sanko Pump Manufacturing Co., Ltd.

340+ people viewing

Last viewed: 12 hours ago

Acid-resistant and wear-resistant pump. ■Applications ・Excellent corrosion-resistant material ・Transfer of chemical solutions containing inorgani...

Torishima Seisakusho Co., Ltd.

470+ people viewing

Last viewed: 9 hours ago

■Features This is a single suction centrifugal pump with a back pullout structure that complies with ISO2858-1975. Widely used for various processe...

Maruhachi Pump Manufacturing Co., Ltd.

910+ people viewing

Last viewed: 1 day ago

■Features ・Since the main parts can be disassembled and inspected while the piping remains the same, the time required is significantly reduced. ...

10 models listed

Sanko Pump Manufacturing Co., Ltd.

300+ people viewing

Last viewed: 12 hours ago

Acid-resistant and wear-resistant pump. ■Applications ・Excellent corrosion-resistant material ・Transfer of chemical solutions containing inorgani...

Matsuda Pump Manufacturing Co., Ltd.

280+ people viewing

Last viewed: 2 hours ago

■Horizontal pump Horizontal centrifugal pumps are the most common industrial pumps. A large number of variations can be planned depending on the co...

Maruhachi Pump Manufacturing Co., Ltd.

680+ people viewing

Last viewed: 10 hours ago

■Features ・A high-performance, high-efficiency pump that incorporates a three-dimensional impeller and achieves a downward characteristic curve. ...

3 models listed

Torishima Seisakusho Co., Ltd.

360+ people viewing

Last viewed: 31 minutes ago

■Features Centerline support hot water and heat medium circulation pump. ■Applications Water supply pumps and circulation pumps in high-temperatur...

Grundfos Pumps Corporation

1910+ people viewing

Last viewed: 1 day ago

85%of the cost of the pump is electricity bill. With a built -in smart pump with a built -in controller, the number of drivers and rotation speed i...

10 models listed

Maruhachi Pump Manufacturing Co., Ltd.

960+ people viewing

Last viewed: 35 minutes ago

■Features -Standard impeller is closed type. Semi-open version is also available. ・Measures can be taken to prevent fibrous slurry in the liquid ...

3 models listed

Matsuda Pump Manufacturing Co., Ltd.

270+ people viewing

Last viewed: 6 hours ago

■Horizontal pump Horizontal volute pumps are the most common industrial pumps. A large number of variations can be planned depending on the combina...

Grundfos Pumps Corporation

860+ people viewing

Last viewed: 1 day ago

NBG that can be used for multiple purposes The NBG is a non -self -absorbed single -stage Uzu -wound pump, with a horizontal intake, a vertical dis...

Maruhachi Pump Manufacturing Co., Ltd.

490+ people viewing

Last viewed: 15 hours ago

■Features ・Since the main parts can be disassembled and inspected without leaving the piping intact, the time required is significantly reduced. ...

3 models listed

Torishima Seisakusho Co., Ltd.

360+ people viewing

Last viewed: 16 hours ago

■Features This pump is manufactured exclusively for heat transfer oil, and the shaft seal and bearing are designed with consideration given to effe...

Maruhachi Pump Manufacturing Co., Ltd.

940+ people viewing

Last viewed: 1 hour ago

■Features ・Low NPSH-Re (compared to our company) ・Can send viscous liquids up to 450mPa・s ・Adopts a fully open impeller to prevent solid matte...

6 models listed

Torishima Seisakusho Co., Ltd.

430+ people viewing

Last viewed: 15 hours ago

■Features This is a non-clog pump with a special impeller that can pass through fixed objects that are approximately 50 to 70% of the pump diameter...

Maruhachi Pump Manufacturing Co., Ltd.

530+ people viewing

Last viewed: 1 day ago

A compact, space-saving, high-performance pump at a reasonable price. It can also be used in environmental protection equipment, waste liquid treat...

4 models listed

Maruhachi Pump Manufacturing Co., Ltd.

620+ people viewing

Last viewed: 18 hours ago

A compact, space-saving, high-performance pump at a reasonable price. It can also be used in environmental protection equipment, waste liquid treat...

4 models listed

Torishima Seisakusho Co., Ltd.

430+ people viewing

Last viewed: 36 minutes ago

■Features This pump has good suction performance and is highly efficient over a wide range. The casing can be divided into two parts, making intern...

Maruhachi Pump Manufacturing Co., Ltd.

620+ people viewing

Last viewed: 21 minutes ago

A compact, space-saving, high-performance pump at a reasonable price. It can also be used in environmental protection equipment, waste liquid trea...

4 models listed

Torishima Seisakusho Co., Ltd.

280+ people viewing

Last viewed: 1 hour ago

■Features The casing is vertically divided in the direction perpendicular to the axis, and a side cover is provided. Suitable for handling relative...

Osmo Co., Ltd.

500+ people viewing

Last viewed: 4 hours ago

Standing multi -dan swirl pump 50Hz/60Hz. All stainless steel specification secure design. Standing design, space saving, 50, 60Hz can be provided....

2 models listed

Cem Corporation Co., Ltd.

510+ people viewing

Last viewed: 5 hours ago

Uses polypropylene with carbon fiber to achieve high corrosion resistance. A self-priming centrifugal pump that is lightweight, compact, highly cor...

2 models listed

SANSHIN MFG.CO.,LTD.

210+ people viewing

■Product description We offer gland packing type and mechanical seal type pumps manufactured in-house. ■Applications ・Various plating solutions ...

SANSHIN MFG.CO.,LTD.

240+ people viewing

Last viewed: 14 hours ago

■Product description We offer gland packing type and mechanical seal type pumps manufactured in-house. ■Features ・In addition to the ground packi...

Masaie Co., Ltd.

440+ people viewing

Last viewed: 18 hours ago

■ Features The Glundfos stand -up multilateral plumbing pump is a centrifugal pump with the same height of the suction port and the exit. It is ide...

Masaie Co., Ltd.

360+ people viewing

Last viewed: 1 day ago

■ Features The SCD -type stainless steel swirl pump is a compatible product that uses stainless steel on the adventional part. Since the main part ...