All Categories

History

This section provides an overview for syringe pumps as well as their applications and principles. Also, please take a look at the list of 14 syringe pump manufacturers and their company rankings. Here are the top-ranked syringe pump companies as of July, 2025: 1.SAE Manufacturing Specialties Corp, 2.Bio-x, 3.Chemyx Inc..

Table of Contents

A Syringe Pump is a machine that continuously pumps or aspirates a precise volume and speed of solution or medicine from a syringe.

A Syringe Pump is a machine that continuously pumps or aspirates a precise volume and speed of solution or medicine from a syringe.

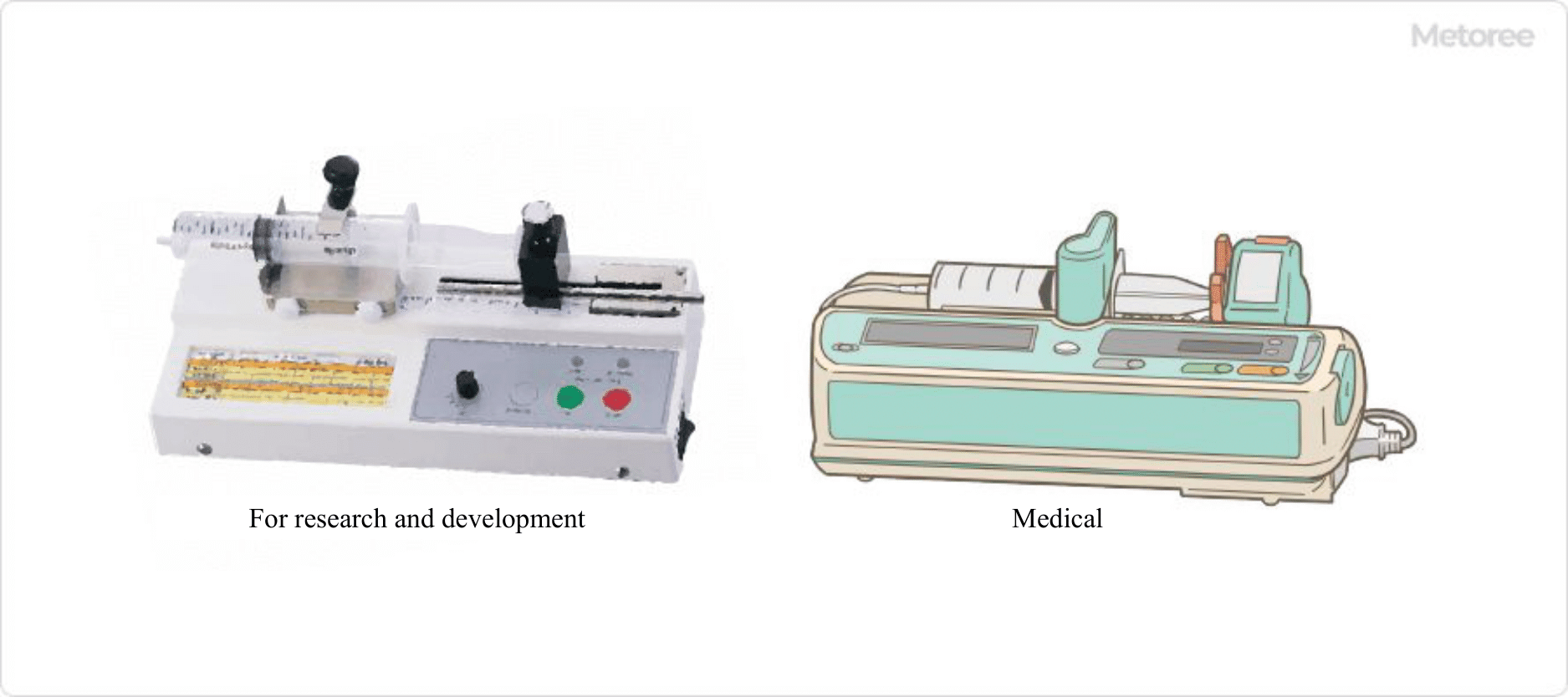

There are two types of syringe pumps: those for medical use and those for research and development.

Syringe pumps move the plunger of a syringe at a constant speed according to the size of the syringe in order to pump or aspirate precisely at a preset volume and time.

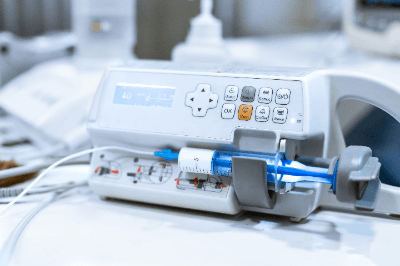

Figure 1. Syringe pump

There are two main types of uses for syringe pumps: medical and research.

The purpose of syringe pumps is to pump or aspirate a precise amount of solution or drug at a constant speed while controlling the flow rate.

Medical syringe pumps are used to administer exact and precise doses of medication in doses of 50 mL or less per dose. Compared to infusion pumps that use elastic tubing, syringe pumps use rigid syringes to ensure accurate infusion.

Syringe pumps for research and development are used in applications that require precise, pulseless, metered volume infusion.

Applications include flow micro-reactions, reagent drops, pharmacological and animal experiments, and injection into analytical instruments.

Fluid volumes may be very small and may have additional characteristics that make them unsuitable for clinical use.

Other applications include the dispensing of various fluids such as adhesives, silver, solder paste, grease, chemicals, liquid crystals, etc., in the manufacture of components and assembly lines in production.

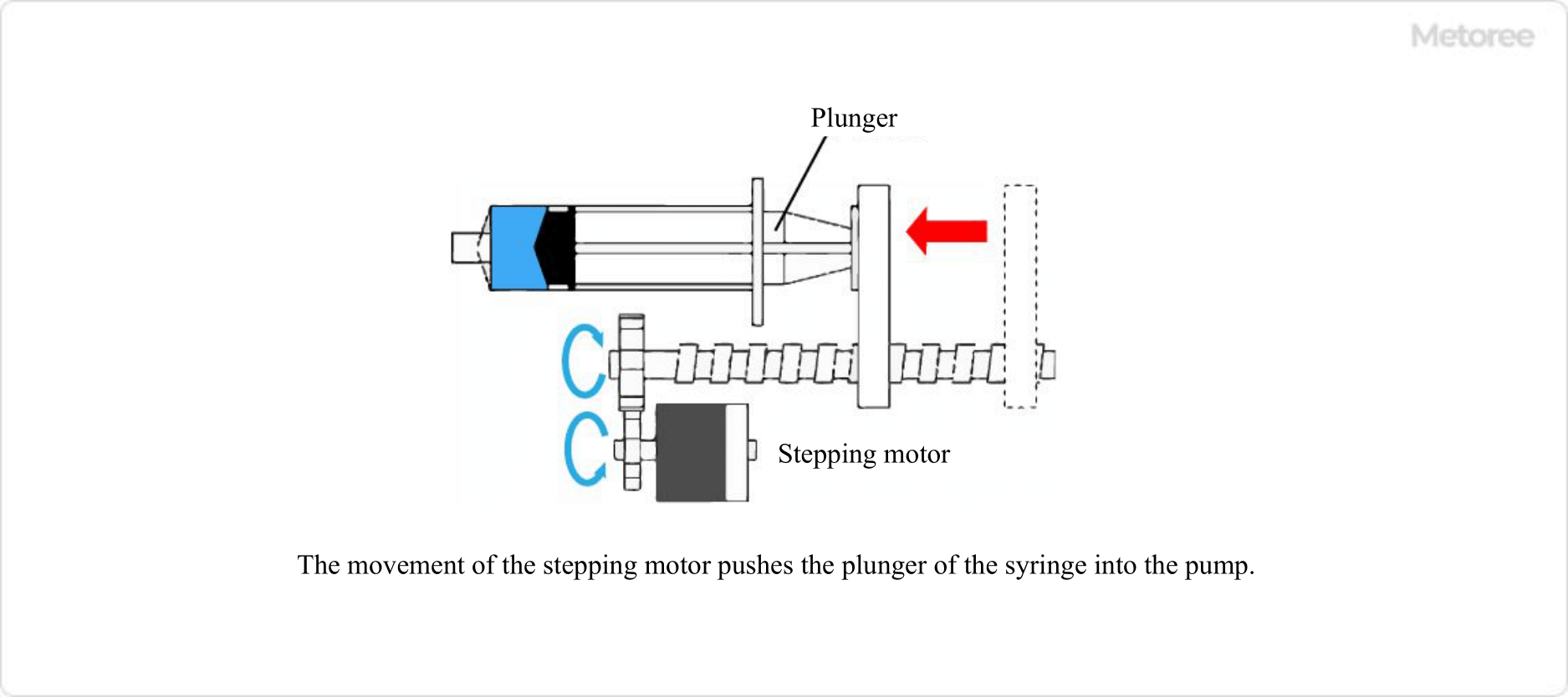

Figure 2. Principle of the syringe pump

A syringe pump pump delivers a constant flow of liquid by fixing the outer cylinder of a syringe and pushing out the inner cylinder with the power of a motor. A stepping motor, which is easily adjustable and can operate at a constant speed, is generally used as the motor.

When syringes are used manually, it is extremely difficult to adjust the flow rate and speed, but with syringe pumps, the motor pushes the syringe at a constant speed, enabling highly accurate flow rate adjustment and pulsation-free pumping.

As mentioned above, you must first select a different medical/research and development pump for your application. Then, according to your purpose, you should use the one equipped with the necessary functions.

Syringe pumps for medical use are available for 5, 10, 20, 30, 50, and 100 mL syringes, respectively. It is necessary to select a product that matches the volume of drug solution to be used and the desired inflow volume.

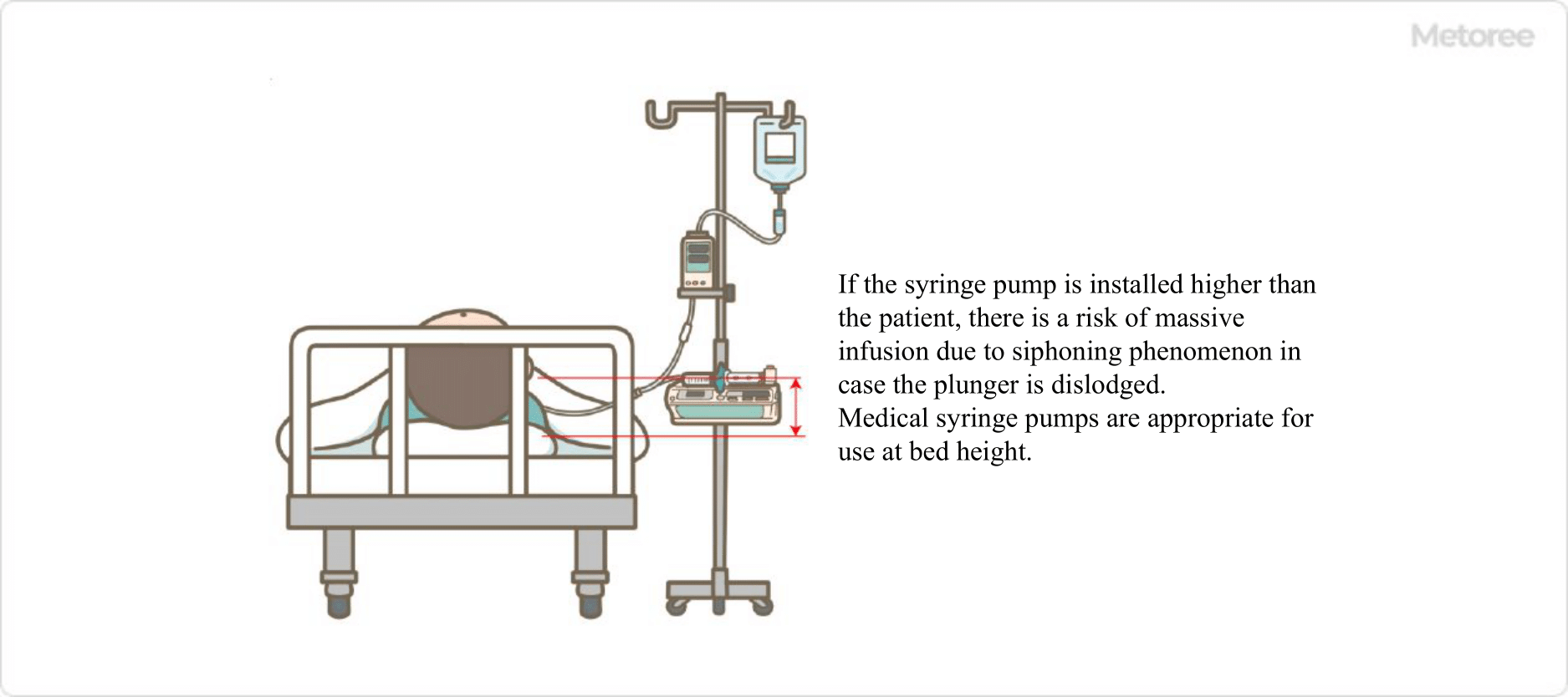

Some products may alert the user with a buzzer sound until the syringe is properly installed as a safety measure. This is to prevent siphoning, a phenomenon in which a large amount of drug is injected into a syringe pump installed at a height higher than the patient's body due to a drop-off if the syringe pusher is not fixed in place.

Others are equipped with wireless LAN for remote monitoring of pump operation, pulse injection (intermittent injection) settings, and display of gamma volume calculations linked to the injection rate value of the Syringe Pump itself. Some products also allow two syringes to be attached simultaneously to administer different drugs or to perform continuous infusion.

Figure 3. Danger of siphoning phenomenon

There are a variety of sizes available, from those for micro-liter liquid volumes to those for 100-mL liquid volumes. First, it is necessary to select the scale that best suits your application. The basic functions also vary depending on the product, ranging from simple pumping-only models to those capable of pumping/aspirating and programmed pumping.

The control unit can be as simple as a dial to set the flow rate, or as sophisticated as a microcomputer-equipped type. The remote control cable can also be added to allow operation via remote control. For example, the drive unit can be installed in a cold room and the flow rate can be controlled from outside.

Other notable features include the ability to pump high-viscosity liquids such as CMC solutions. Some syringe pumps are pre-installed with syringe data from major manufacturers and can be set up so that all you have to do is make a selection.

Incidents related to Syringe Pumps include the following

Incorrect input of pump flow rate setting

Syringe pumps are used to continuously administer medication at a precise volume and rate, and incorrectly entered flow rates can result in serious incidents that can be fatal to patients. Other examples of setting input errors include mistakenly entering the wrong flow rate for Drug A and Drug B, and mistakenly entering the wrong flow rate units.

Failure of the pump's air bubble detector

Syringe pumps are usually designed to detect air bubbles and automatically stop pumping, but there have been reports of cases where the pumps do not stop and air is pumped to the patient side due to equipment malfunction. Even if maintenance and inspections are performed, such cases can still occur, so it is important to enter the expected volume when using the pump.

In addition, as a background or factor in these cases, lack of knowledge and experience of medical personnel was reported in many cases. Familiarization with the procedure manual and reeducation on how to use it are also important to prevent these cases from occurring.

*Including some distributors, etc.

Sort by Features

Sort by Area

New Era Pump Systems, Inc., established in 1996 and headquartered in Farmingdale, New York, is a manufacturer of programmable syringe pumps. The company's products include syringes, plumbing supplies, and accessories for precise fluid dispensing applications. Its pumps offer infusion and withdrawal capabilities, computer interfaces, and programming options. It supports precise fluid dispensing control, which is ideal for automation in various fields. The company's disposable plastic syringes, made from laboratory-grade polypropylene and polyethylene, are latex-free and chemically resistant. Its glass syringes range from 1 mL to 100 mL, with gas-tight variants handling up to 400 psi.

Chemyx Inc. is a manufacturer of high-precision syringe pumps for use in the life science, chemical research, and analytical equipment company. The company was founded in 2000 and is based in Stafford USA. The company made infusion pump to develop the next-generation syringe pump with an interactive LCD interface and integrated syringe database. The company continues to push advancements in the laboratory services industry to facilitate and further the research of the world’s scientists, academics, and manufacturing companies

Hamilton Company is a US-based manufacturer of automation and laboratory equipment including process sensors, precision measuring devices, automated liquid handling workstations, and sample management systems. Hamilton's automation solutions include flexible automated liquid handling platforms and pre-configured Assay Ready workstations that are designed for specialized methods. They also offer small liquid handling devices for temperature control, plate sealing to protect microplate-based samples during critical stop points, and barcode reading. The company is also a supplier of laboratory products such as syringes and needles.

Based in Bayville, NY, SAE Manufacturing Specialties Corp. is an ISO-certified supplier and manufacturer of industrial equipment, chemicals, components, ordinance, electronics, and systems for industries ranging from aerospace to high tech to law enforcement. Examples of product offerings include raw materials, chemicals, and lubricants for industrial purposes to finished products such as security helmets for law enforcement, and military ordnances. SAE also provides research and development as well as technical support for other companies in similar industries.

Suzhou Wenhao Microfluidic Technology Co., Ltd , established in 2012 in Suzhou, Jiangsu, China, is a manufacturer of microfluidic technology products and devices. The company manufactures a diverse range of products, including microfluidic chips, microfluidic devices, and lab-on-a-chip systems for precise sample manipulation, optimal-throughput analysis, and reduced reagent consumption, supporting efficient and accurate lab processes. Industries spanning from life sciences and biotechnology to pharmaceuticals and diagnostics use the products for advanced microfluidic applications. Its specialization in microfluidics offers advantages in miniaturization, automation, and genuine-throughput analysis, making advanced lab processes and scientific discoveries possible.

Bio-X, established in 2010 in Mumbai, Maharashtra, India, is a manufacturer of various medical, diagnostic, and research equipment. The company produces a diverse array of products, including laboratory autoclaves, diagnostic centrifuges, CO2 incubators, LED X-Ray devices, and biosafety cabinets. These solutions offer benefits such as precise sample processing, optimum diagnosis, controlled environmental conditions, and safe handling of biological materials, assisting in accurate research and diagnostics. Industries spanning from healthcare and pharmaceuticals to research institutions and diagnostics rely on the products for advanced equipment solutions. It offers equipment customization that allows for tailored equipment to suit specific research and diagnostic requirements.

Plenum Tech Private Limited , established in 2000 and located in Maharastra, India, is a manufacturer of infusion therapy devices and pumps. The company produces various products, including infusion pumps, syringe pumps, and ambulatory infusion systems, for accurate drug delivery, controlled dosing, and enhanced patient safety, assisting in effective and optimal medical treatment. Industries spanning from healthcare facilities and hospitals to home care and ambulatory settings use the products for precise infusion therapy. The products’ usability and user-friendly interfaces allow for easy operation and accurate medication administration while delivering genuine infusion therapy devices and pumps for medical applications.

Longer Precision Pump Co. Ltd. was founded in 1997, in China, as a manufacturer of fluid transfer and handling devices. The company provides Peristaltic Pumps of various types like Basic, Intelligent, Dispensing and Flow Rate, and OEM Peristaltic Pumps such as the Hemodialysis pump that is used for pumping fluids in dialysis machines. Syringe pumps and Micro Gear Pump have uses in laboratories and the Micro Piston Pump has applications for device fluid sampling. The Longer Precision Pumps serve the pharmaceutical, medical, laboratory, and environmental monitoring industries.

Gardner Governor, founded in 1869 and headquartered in Sterling, Illinois, is a manufacturer and provider of precise mechanical governors. The company’s governors are essential control systems used to regulate engine and turbine speeds across industries. Their diverse product portfolio includes mechanical governors tailored for engines, power plants, and industrial machinery, ensuring precise and stable speed control for optimal performance and safety. Gardner Governor's status stems from advanced solutions and excellent customer support. Utilized in power generation, locomotives, and industrial applications, Gardner Governor's products are a major feature in control systems worldwide.

Syrris is based in Royston, Hertfordshire, United Kingdom, is a manufacturer of chemical reactors and flow chemistry equipment established in 2001 before becoming a subsidiary of Asahi Glassplant Inc. The company offers automated jacketed reactors for batch chemical reactions with controllable automated stirring, and flow chemistry systems designed to increase the scalability and efficiency of continuous flow reactions. It also offers orb jacketed reactors, orb pilot scale-up reactors, and syringe pumps for precise dosing to maintain reaction conditions. The company chiefly serves clients in the industrial processing sector.

Narang Medical Limited is an Indian manufacturer and supplier of medical equipment and hospital products established in 1989 and based in New Delhi, India. The company produces a wide range of products for hospital use such as consumable supplies, medical diagnostic equipment, and rehabilitation aids. Its products include orthopedic implants, hospital beds, and cold-chain vaccine carriers. The company chiefly serves clients in the healthcare, research, and government sectors. It operates within ISO 9001, ISO 13485 and CE certification standards.

Ranking as of July 2025

Derivation Method| Rank | Company | Click Share |

|---|---|---|

| 1 | SAE Manufacturing Specialties Corp |

14.3%

|

| 2 | Bio-x |

12.8%

|

| 3 | Chemyx Inc. |

11.5%

|

| 4 | Longer Precision Pump Co., Ltd, |

9.3%

|

| 5 | Suzhou Wenhao Microfluidic Technology Co., Ltd |

7.2%

|

| 6 | Gardner Governor Company |

7.2%

|

| 7 | New Era Pump Systems Inc. |

6.8%

|

| 8 | Hamilton Company |

6.8%

|

| 9 | Plenum Tech Private Limited. |

6.7%

|

| 10 | Narang Medical Limited |

5.2%

|

Derivation Method

The ranking is calculated based on the click share within the syringe pump page as of July 2025. Click share is defined as the total number of clicks for all companies during the period divided by the number of clicks for each company.Number of Employees

Newly Established Company

Company with a History

*Including some distributors, etc.

*Including some distributors, etc.

| Country | Number of Companies | Share (%) |

|---|---|---|

United States of America

United States of America

|

4 | 36.4% |

India

India

|

3 | 27.3% |

United Kingdom

United Kingdom

|

2 | 18.2% |

China

China

|

1 | 9.1% |

Japan

Japan

|

1 | 9.1% |

68 products found

68 products

Shinagawa Communications Instrumulation Service Co., Ltd.

480+ people viewing

Last viewed: 10 hours ago

It is a space -saving liquid system that does not generate pulse pumps using a syringe pump. Outside operation by PC is easy to control. ■ No puls...

Elteex Co., Ltd.

1350+ people viewing

Last viewed: 8 hours ago

The biggest feature of syring pumps is the stable liquid of low pulsation and small flow rate. Elteex syring pumps are basically custom -made, and...

5 models listed

Elteex Co., Ltd.

500+ people viewing

Last viewed: 1 day ago

The biggest feature of syring pumps is the stable liquid of low pulsation and small flow rate. Elteex syring pumps are basically custom -made, and ...

Elteex Co., Ltd.

520+ people viewing

Last viewed: 13 hours ago

The biggest feature of syring pumps is the stable liquid of low pulsation and small flow rate. Elteex syring pumps are basically custom -made, and ...

Takasago Electric Industry

800+ people viewing

Last viewed: 6 hours ago

Understanding resolution is 0.65 nl at 1/16 at Micro Step. The transmission is smooth due to high resolution. Characteristics of the product -The ...

4 models listed

Takasago Electric Industry

540+ people viewing

Last viewed: 13 hours ago

The SCP series is a palm -sized syringe pump with a built -in motor. Compared to the conventional pump unit, the cost is smaller and lightweight, a...

Yagyu Shokai Co., Ltd.

280+ people viewing

Last viewed: 21 hours ago

■Features - Various settings can be made from the large color touch display while wearing gloves. - Highly rigid stainless steel body minimizes vib...

Yagyu Shokai Co., Ltd.

280+ people viewing

Last viewed: 1 day ago

■Features - Cooling can be performed while stirring on a φ135mm or φ145mm magnetic stirrer (separate cooling substance such as ice is required). ・...

Elteex Co., Ltd.

490+ people viewing

The biggest feature of syring pumps is the stable liquid of low pulsation and small flow rate. Elteex syring pumps are basically custom -made, and ...

Elteex Co., Ltd.

670+ people viewing

Last viewed: 2 hours ago

With the request of a low -priced pump that can send a small flow rate stably, we have removed extra functions to thoroughly simplify them. Functio...

2 models listed

Maximator Fluid Technologies Co., Ltd.

230+ people viewing

Last viewed: 1 day ago

Transparent syringe machined from solid methyl methacrylate with heat-engraved volumetric graduations and treated to avoid deformation and cracking...

Yagyu Shokai Co., Ltd.

270+ people viewing

Last viewed: 1 day ago

■Features ・Only the drive unit can be installed inside a chamber etc. and can be remotely controlled from outside. - Flow rate setting is as easy ...

Yagyu Shokai Co., Ltd.

260+ people viewing

Last viewed: 10 hours ago

■Features ・It is possible to send even high viscosity liquids such as 50,000mP・sCMC solutions. - Syringe data from major manufacturers is pre-ent...

Yagyu Shokai Co., Ltd.

250+ people viewing

Last viewed: 1 day ago

■Features - Syringe data from major manufacturers is pre-entered, making selection easy. ・Multiple conditions such as injection amount, injection ...

Yagyu Shokai Co., Ltd.

210+ people viewing

Last viewed: 11 hours ago

- Flow rate setting is easy, just use the dial. - Conversion software for the "flow rate setting scale table" is included. *This product is not a ...

Yagyu Shokai Co., Ltd.

340+ people viewing

Last viewed: 1 hour ago

Setting the flow rate is easy, just use the dial. *This product is not a medical device. *Syringe is not included. *The feed speed scale is set fo...

Yagyu Shokai Co., Ltd.

310+ people viewing

Last viewed: 23 hours ago

・Multiple conditions such as injection amount, injection time, injection amount per hour, etc. can be set. ・Setting conditions and cumulative inj...

Yagyu Shokai Co., Ltd.

310+ people viewing

Last viewed: 4 hours ago

■Features -90 types of frequently used syringes are stored in memory, so just select the type. ・When you turn on the power, the last used settings...

G -Science

700+ people viewing

Last viewed: 8 hours ago

power consumption Up to 70va

2 models listed

Minato Concept Co., Ltd.

240+ people viewing

Last viewed: 3 hours ago

We are pursuing the features and possibilities of motor-driven syringe pumps. It supports ultra slow speed control to high speed operation and redu...

Minato Concept Co., Ltd.

230+ people viewing

Last viewed: 1 day ago

We are pursuing the features and possibilities of motor-driven syringe pumps. It supports ultra slow speed control to high speed operation and redu...

Minato Concept Co., Ltd.

280+ people viewing

Last viewed: 18 hours ago

We are pursuing the features and possibilities of motor-driven syringe pumps. It supports ultra slow speed control to high speed operation and redu...

Minato Concept Co., Ltd.

260+ people viewing

Last viewed: 15 hours ago

We are pursuing the features and possibilities of motor-driven syringe pumps. It supports ultra slow speed control to high speed operation and redu...

Minato Concept Co., Ltd.

250+ people viewing

Last viewed: 7 hours ago

We are pursuing the features and possibilities of motor-driven syringe pumps. It supports ultra slow speed control to high speed operation and redu...

Minato Concept Co., Ltd.

270+ people viewing

Last viewed: 16 hours ago

We are pursuing the features and possibilities of motor-driven syringe pumps. It supports ultra slow speed control to high speed operation and redu...

Minato Concept Co., Ltd.

210+ people viewing

Last viewed: 19 hours ago

We have a track record of manufacturing in various fields such as semi-automatic machines for production equipment and PC control management system...

Minato Concept Co., Ltd.

220+ people viewing

Last viewed: 7 hours ago

We have a track record of manufacturing in various fields such as semi-automatic machines for production equipment and PC control management system...

Minato Concept Co., Ltd.

230+ people viewing

Last viewed: 1 day ago

We have a track record of manufacturing in various fields such as semi-automatic machines for production equipment and PC control management system...

Kyodo International, Inc.

210+ people viewing

Last viewed: 1 day ago

A programmable, modular, high-precision syringe pump. It consists of a control unit and a pump unit, and up to 8 pumps can be installed. In additi...

Kyodo International, Inc.

220+ people viewing

Last viewed: 15 hours ago

High precision syringe pump. Achieves resolution of 0.015 µL and accuracy of ±0.5%. Up to 8 pumps can be installed.