All Categories

History

This section provides an overview for sputtering equipment as well as their applications and principles. Also, please take a look at the list of 9 sputtering equipment manufacturers and their company rankings. Here are the top-ranked sputtering equipment companies as of February, 2026: 1.Vapor Technologies, Inc., 2.Alliance Concept, 3.Blue Wave Semiconductors.

Table of Contents

Categories Related to Sputtering Equipment

Sputtering equipment is a device that performs sputtering to create a very thin film uniformly on the surface of an object.

Sputtering is a physical vapor deposition (PVD) method, like vacuum evaporation and ion plating. Sputtering is used in various fields, including the deposition of semiconductor and liquid crystal films. It is also used to clean the surface of objects.

Sputtering equipment is used to fabricate thin films for semiconductors, liquid crystals, and plasma displays. Compared to other PVD evaporation systems, sputtering equipment is capable of depositing metals and alloys with high melting points, and thus has a wide range of applications.

Recently, metals have been deposited on the surface of plastic, glass, and film to make them conductive and used as transparent electrodes and wiring for touch panels. This, further expands the range of applications for sputtering equipment.

In addition, medical devices and miscellaneous goods with antibacterial properties coated with photocatalytic titanium dioxide on their surfaces are also available. It is also used in analytical applications, such as sample preparation for scanning electron microscopes (SEM).

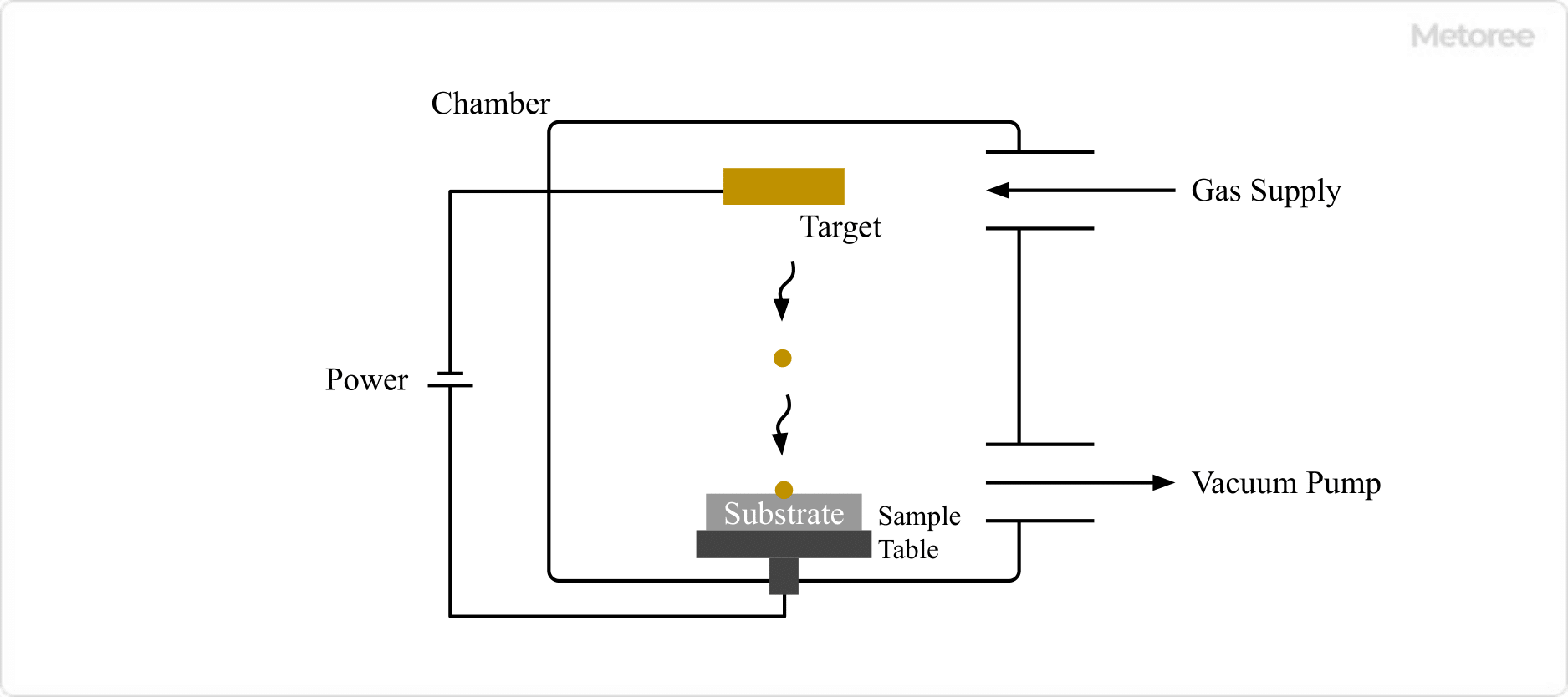

Sputtering equipment mainly consists of the following components:

The vacuum chamber contains a sample stand that holds the substrate and a sputtering target that supplies the sputtering material, while the vacuum pump and gas supply system are connected to the chamber.

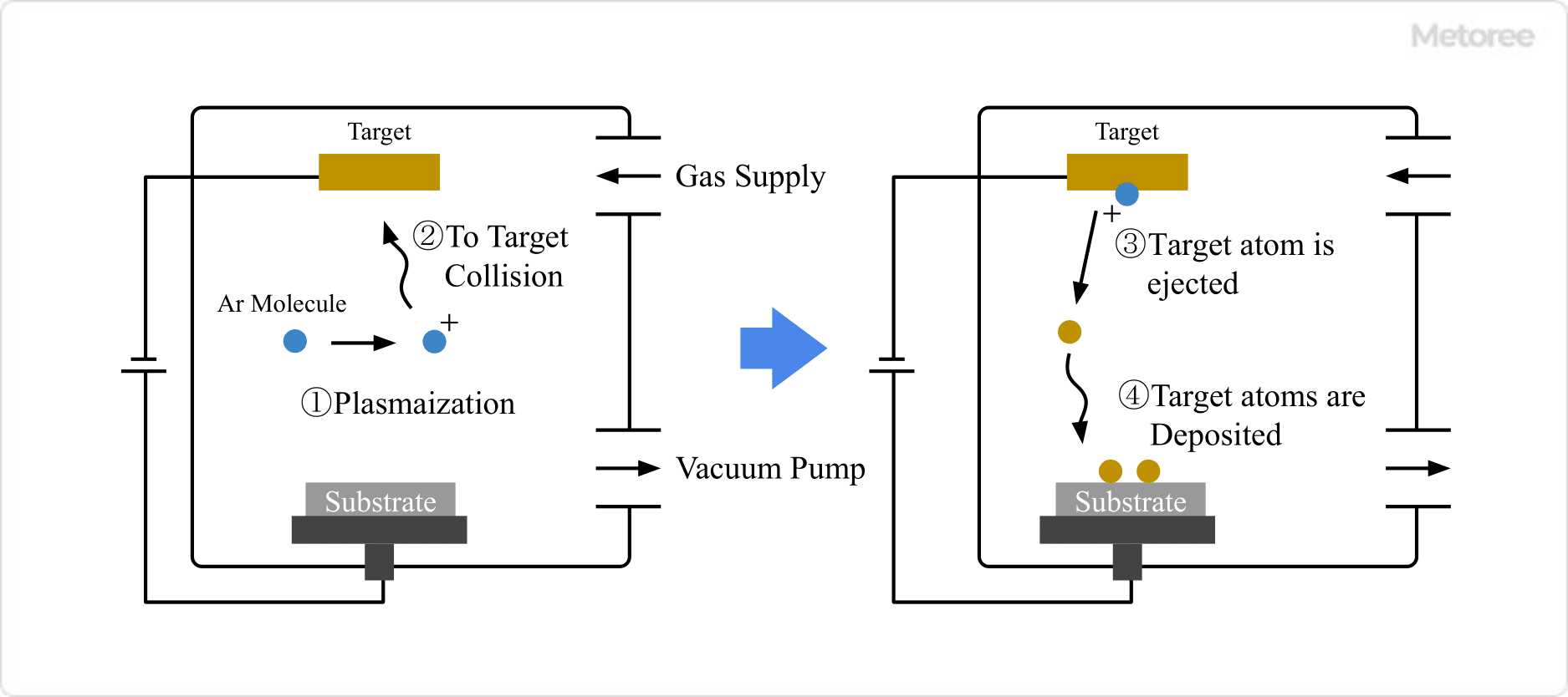

The principle of sputtering equipment is to deposit a film on the surface of an object by applying high voltage under vacuum and repelling the atoms of the film material. First, the chamber is sufficiently depressurized by a pump, and then inert gases such as argon are filled into the equipment at a constant pressure.

When a high negative voltage is applied to the target, which is the material for the thin film, and a glow discharge is generated, the argon filled in the equipment becomes plasma and collides with the target on the cathode, causing the Ions, atoms and molecules on the target to be ejected. The target atoms are then deposited on the surface of the target to which the positive voltage is applied, resulting in the production of a thin film.

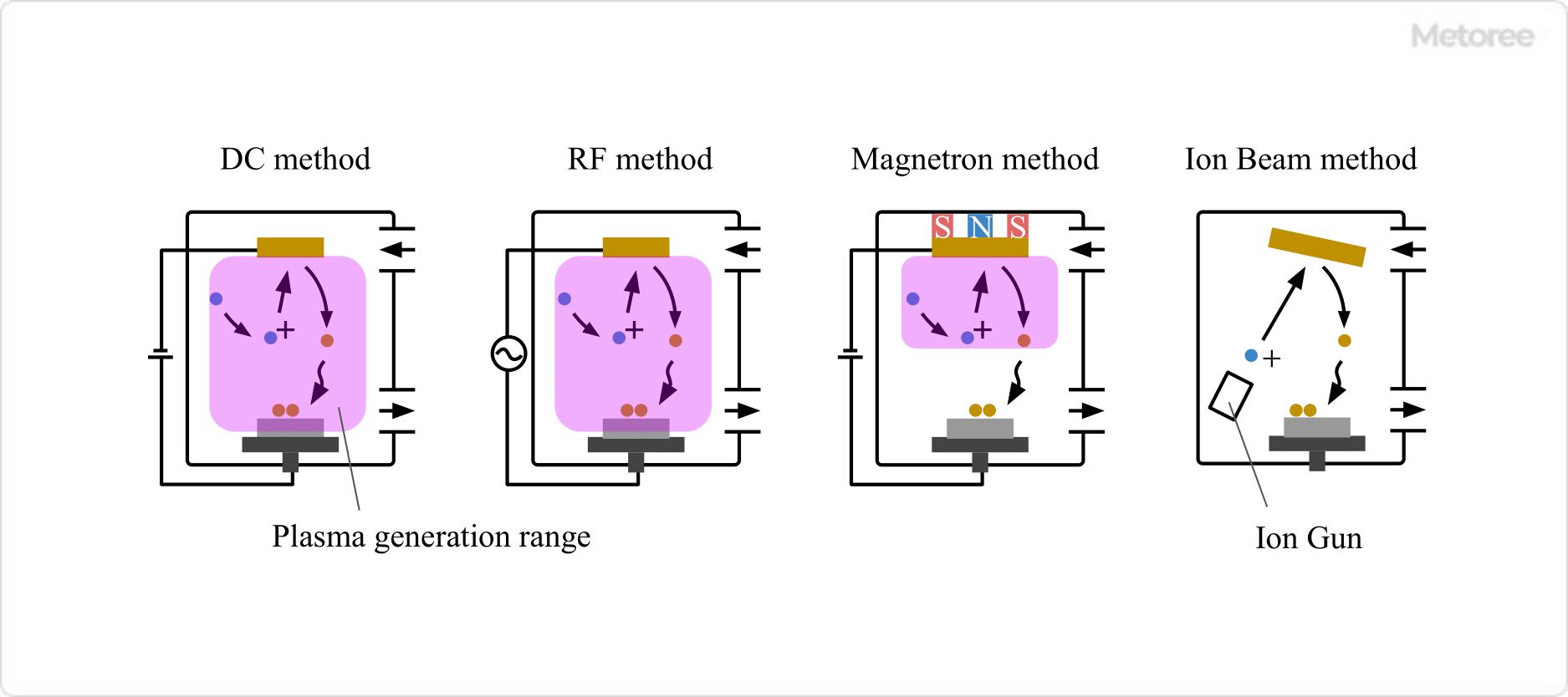

There are various types of sputtering methods.

This method applies DC voltage between electrodes. This method has various advantages, such as a simple structure. However, the disadvantages include the possibility that the sample may be damaged by the high-temperature plasma and the inability to form a film properly if the sputtering target is an insulator.

This method applies a high-frequency AC voltage between electrodes to form films on materials such as ceramics, silica and other oxides, metal oxides, and nitrides, which cannot be formed by the DC method.

This method uses a magnet to create a magnetic field on the target side to keep the plasma near the target. This not only reduces damage to the sample caused by the plasma, but also increases the plasma generation speed, resulting in faster film formation. Various power supply methods are available, including DC, AC, and high-frequency AC. On the other hand, the target is reduced unevenly and the utilization efficiency tends to be low.

Ions are produced at a separate location from the target or sample and accelerated to the target. Since there is no discharge in the chamber, the effect on the sample is minimized and there is no need to consider the adhesion of impurities or the conductivity of the target.

In addition to the above, there are various types of sputtering equipment, such as Electron Cyclotron (ECR), which should be selected appropriately according to the application and budget.

Sputtering equipment can make the film thickness uniform, and since it uses electrical properties, it can increase the strength of the film. It can produce films of high-melting-point metals and alloy materials, which is difficult with other PVD methods. Another method is to fill oxygen instead of argon or other inert gases to deposit oxide films.

However, there are some disadvantages, such as the longer time required for film deposition compared to other PVD methods and the risk of damaging the sputtering target by the generated plasma.

*Including some distributors, etc.

Sort by Features

Sort by Area

VaporTech designs, builds, and services thin-film coating equipment which deposit PVD and PE-CVD coatings to enhance the quality of numerous products. We exhibit a steadfast commitment to our craft, recognizing that a product's finish is a direct reflection of its quality, underlining a brand's dedication to quality and value. For over three decades, VaporTech's PVD coating equipment has been assisting customers in applying stunning and durable hard coatings that not only enhance but differentiate the aesthetics, texture, and functionality of a plethora of items including home hardware, medical devices, automobiles, industrial tooling, consumer electronics, sporting goods, among others. We are located in Longmont, Colorado, extending our sales, service, and support on a global scale.

Semicore Equipment, Inc. is a deposition equipment and custom vacuum systems manufacturer based in Livermore, California since 1996. The company showcases a diverse product catalog, serving multiple fields like the electronics, optical, solar energy, medical, and automotive industries. It produces items such as sputtering, evaporation, PVD coating and custom systems, as well as DLC tribology coaters and magnetron sputtering cathodes. In addition, the venture offers tooling and fixturing, innovative solutions and automation control services.

Blue Wave Semiconductors was established in the year 2000, located in Baltimore, USA and it is a manufacturer and supplier of thin-film deposition systems. The company manufactures products such as deposition equipment, CVD diamond machine systems, and electron beam evaporators. The company also provides services like thin-film coatings, CVD diamond coatings, metal deposition and optical coatings. It's R&D services include CVD diamond coatings on custom structures and parts. The company is ISO certified.

Ulvac Inc., established in 1952 and headquartered in Kanagawa, Japan, is a manufacturer of vacuum equipment, components, peripheral devices, and materials for the solar cell and semiconductor industries, among others. The company operates businesses in six areas, including materials, components, electronic devices, semiconductors, and flat panel display production equipment. Some of its products include roll coaters, semiconductor production equipment, LED production equipment, leak detectors, and vacuum brazing furnaces. It is ISO9001 certified, and its net sales in the 2022 fiscal year were 227.5 billion Japanese Yen, with 34% of this amount coming from semiconductor and electronic device production equipment.

Alliance Concept, based in France, is a manufacturer of vacuum systems and equipment since 1991. The company excels across three distinct sectors: thin film deposition, leak testing, and vacuum technology. The company designs and produces cutting-edge frames or thin film deposition. This technology finds extensive use in various industries, enabling precise and controlled deposition of thin films onto surfaces. The company's proficiency extends to leak testing, a critical process for ensuring the integrity of products that require containment. Furthermore, its expertise in vacuum technology covers a broad spectrum of applications.

CANON ANELVA is a manufacturer and supplier of vacuum deposition systems and related systems headquartered in Kanagawa, Japan. The company was established in 1967 and specializes in producing a wide array of products that cater to sectors such as semiconductor manufacturing, electronics, and beyond. The company's product portfolio includes vacuum deposition systems, spluttering equipment, and other advanced technology solutions designed to meet the demands of modern manufacturing processes. These products play an integral role in enhancing the efficiency and performance of manufacturing processes across a diverse range of applications.

Sputtering Components, a member of the Bühler Group, established in 2001 and headquartered in Owatonna, USA, is a manufacturer of vacuum coating systems and related components. The company offers end blocks, magnetrons, and complete lid systems, enabling the production of windows, smartphones, and automotive components. Using Solidworks for 3D modeling, it employs finite element analysis for magnetic and thermal simulations. The company fabricates components with diameters ranging from 0.1 to 60 inches. Its rotary magnetron technology serves solar cells, touch screen production, and decorative coatings, while its swing-duotm software enhances coating uniformity through optimized magnet bar movement.

Omicron Scientific Equipment was established in the year 2000 based in New Delhi, India and it is a manufacturer, supplier, and exporter of scientific equipment. The company manufactures products like microwaves, radio frequency equipment, DC power supplies, thermal evaporation systems, electron beam gun-based evaporation systems, spin coating systems, scrubbers, semiconductor processing equipment, chemical benches, equipments for research and development and vacuum furnaces. The company is a member of Trade India and is also ISO certified.

Ranking as of February 2026

Derivation Method| Rank | Company | Click Share |

|---|---|---|

| 1 | Vapor Technologies, Inc. |

15.6%

|

| 2 | Alliance Concept |

14.3%

|

| 3 | Blue Wave Semiconductors |

12.1%

|

| 4 | ULVAC, Inc |

11.9%

|

| 5 | Semicore Equipment, Inc. |

10.7%

|

| 6 | CANON ANELVA CORPORATION |

9.8%

|

| 7 | Omicron Scientific Equipment Co. |

9.3%

|

| 8 | Japan Create Co., Ltd. |

9.1%

|

| 9 | Sputtering Components |

7.3%

|

Derivation Method

The ranking is calculated based on the click share within the sputtering equipment page as of February 2026. Click share is defined as the total number of clicks for all companies during the period divided by the number of clicks for each company.Number of Employees

Newly Established Company

Company with a History

*Including some distributors, etc.

*Including some distributors, etc.

| Country | Number of Companies | Share (%) |

|---|---|---|

United States of America

United States of America

|

3 | 37.5% |

Japan

Japan

|

3 | 37.5% |

France

France

|

1 | 12.5% |

India

India

|

1 | 12.5% |

121 products found

121 products

Vacuum device

890+ people viewing

Last viewed: 6 hours ago

Magnetron Patta device is applied to promote ionization on the cathode surface layer using a powerful magnet on the back of the target, and apply a...

Vacuum device

990+ people viewing

Last viewed: 6 hours ago

Magnetron Patta device is applied to promote ionization on the cathode surface layer using a powerful magnet on the back of the target, and apply a...

FKD Factory Co., Ltd.

580+ people viewing

Last viewed: 6 hours ago

Basic specifications: DC1 source sputtering ■Extension options ・Addition of 2-source magnetron cathode ・High vacuum specification (turbo molecul...

ASD Co., Ltd.

540+ people viewing

Last viewed: 5 minutes ago

■About powder sputtering equipment In recent years, there has been an active movement to improve the performance, safety, and cost reduction of sec...

Vacuum device

990+ people viewing

Last viewed: 6 hours ago

Magnetron Patta device is applied to promote ionization on the cathode surface layer using a powerful magnet on the back of the target, and apply a...

Vacuum device

790+ people viewing

Last viewed: 6 hours ago

Magnetron Patta device is applied to promote ionization on the cathode surface layer using a powerful magnet on the back of the target, and apply a...

Vacuum device

740+ people viewing

Last viewed: 6 hours ago

Magnetron Patta device is applied to promote ionization on the cathode surface layer using a powerful magnet on the back of the target, and apply a...

Arios Co., Ltd.

650+ people viewing

Last viewed: 6 hours ago

■Summary Small sputtering equipment SS-DC RF301 This is a film forming equipment that uses sputtering (often abbreviated as sputtering). A feature ...

Vacuum device

930+ people viewing

Last viewed: 6 hours ago

Magnetron Patta device is applied to promote ionization on the cathode surface layer using a powerful magnet on the back of the target, and apply a...

ULVAC Sales Co., Ltd.

700+ people viewing

Last viewed: 6 hours ago

■Summary This is a multi-chamber sputtering system that can have multiple process chambers (up to 3 200E, up to 5 200J, and up to 7 200). ■Applica...

Vacuum device

610+ people viewing

Last viewed: 6 hours ago

Magnetron Patta device is applied to promote ionization on the cathode surface layer using a powerful magnet on the back of the target, and apply a...

ULVAC Sales Co., Ltd.

750+ people viewing

Last viewed: 6 hours ago

■Summary The SRH series backside/mounting sputtering equipment is a mass production equipment intended for metal film formation for power devices, ...

ULVAC Sales Co., Ltd.

530+ people viewing

Last viewed: 38 minutes ago

■Summary The ULDiS series of sputtering systems for optical films is a digital sputtering system that is an advanced version of Metamode® technolog...

ULVAC Sales Co., Ltd.

590+ people viewing

Last viewed: 6 hours ago

■Summary The SCH series is a horizontal in-line sputtering system that forms transparent conductive films, metal films, etc. It is compatible with ...

SHINKO SEIKI CO., LTD.

730+ people viewing

Last viewed: 7 hours ago

This is the latest sputter ring device that can be flexible regardless of the substrate or application, such as SI wafer, glass and ceramics. The ...

3 models listed

Arios Co., Ltd.

490+ people viewing

Last viewed: 6 hours ago

■Summary A film deposition system that uses sputtering (often abbreviated as sputtering). A feature of sputtering film formation is that the partic...

Arios Co., Ltd.

630+ people viewing

Last viewed: 7 hours ago

■Summary In order to uniformly form a film on the surface of the sample, this device places the sample in a drum-shaped sample holder and performs ...

Sanko Ematech Co., Ltd.

300+ people viewing

Last viewed: 45 minutes ago

■Product description It is an ideal device for research and development purposes at universities, research institutes, etc. It is also ideal for hi...

2 models listed

Sanko Ematech Co., Ltd.

510+ people viewing

Last viewed: 6 hours ago

Product Description This is a compact high frequency sputtering device that can be used in a space-saving manner. It is possible to form films of m...

SHINKO SEIKI CO., LTD.

500+ people viewing

Last viewed: 7 hours ago

It is a road rock -type sputtering device that realizes space. The maximum φ270 tray can be set as standard in the cassette room, and continuous sp...

3 models listed

ULVAC Sales Co., Ltd.

1150+ people viewing

Last viewed: 6 hours ago

■Summary This is a device that can be used in a wide range of applications, based on ULVAC's extensive film-forming technology and experience. Achi...

HiSOL,Inc.

630+ people viewing

Last viewed: 6 hours ago

■Easy sputtering with low current without using any inert gas This tabletop sputtering device is ideal for applying antistatic coatings to the surf...

Kitano Seiki Co., Ltd.

470+ people viewing

Last viewed: 6 hours ago

■Summary UVS40A2 is an ultraviolet generator that is compatible with various gases (helium, neon, krypton, argon, hydrogen). The discharge of the U...

Kitano Seiki Co., Ltd.

550+ people viewing

Last viewed: 14 hours ago

■Summary The RS40B1 is a new, high power twin anode (Al/Mg) X-ray source developed for photoelectron spectroscopy. Z-shift is also available as an ...

Kitano Seiki Co., Ltd.

430+ people viewing

Last viewed: 27 minutes ago

■Summary This sputter source is a general-purpose compact magnetron sputter source that is compatible with ultra-high vacuum. Since the main body i...

Kitano Seiki Co., Ltd.

560+ people viewing

Last viewed: 7 hours ago

■Summary The 40C1 ion gun is a compact and simple ion gun for cleaning sample surfaces. The mounting flange is DN40CF (outer diameter 70mm) and can...

Kitano Seiki Co., Ltd.

490+ people viewing

Last viewed: 7 hours ago

■Summary The 40E1 ion gun is a convergent ion gun that uses a two-stage exit lens. The spot size and accelerating voltage (0.15eV to 5keV) can be e...

Kitano Seiki Co., Ltd.

490+ people viewing

Last viewed: 7 hours ago

■Summary EBV40A1 is a device developed for producing films of several atomic layers or as a dopant for multilayer films produced using MBE equipmen...

Kitano Seiki Co., Ltd.

380+ people viewing

Last viewed: 6 hours ago

■Summary The ES40C1 electron gun is a scanning electron gun developed for Auger electron spectroscopy. By using an Einzel lens, a large beam curren...

Kitano Seiki Co., Ltd.

370+ people viewing

Last viewed: 6 hours ago

■Summary FS40A1 was developed as an antistatic electron gun for use in XPS, UPS, and SIMS. Designed with simplicity, ease, and reliability in mind....