18 Monolithic Ceramic Capacitor Manufacturers in 2024

This section provides an overview for monolithic ceramic capacitors as well as their applications and principles. Also, please take a look at the list of 18 monolithic ceramic capacitor manufacturers and their company rankings. Here are the top-ranked monolithic ceramic capacitor companies as of April, 2024: 1.Vishay Intertechnology, Inc.,, 2.Tokin America, Inc, 3.KYOCERA Corporation.

Table of Contents

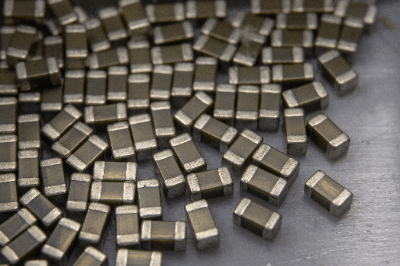

What Is a Monolithic Ceramic Capacitor?

A monolithic ceramic capacitor, also called MLCC (Multi-Layer Ceramic Capacitor), is a chip component type capacitor with multiple layers of internal electrodes and dielectric layers. Further evolution is expected in the capacitor industry, where miniaturization and capacitance increase.

A monolithic ceramic capacitor, also called MLCC (Multi-Layer Ceramic Capacitor), is a chip component type capacitor with multiple layers of internal electrodes and dielectric layers. Further evolution is expected in the capacitor industry, where miniaturization and capacitance increase.

Barium titanate and titanium oxide are mainly used as dielectric, and the inner electrode and dielectric are formed in multiple layers. Increasing the number of layers makes it possible to increase the capacitance, leading to miniaturization of MLCCs.

Recently, the mainstream sizes of MLCCs are 0603 (0.6x0.3mm) and 0402 (0.4x0.2mm). The next generation 0201 size has already been realized in some capacitance values, but it has not yet become widespread in the market due to handling difficulties.

Monolithic ceramic capacitors are available in chip and radial types. Compared to other capacitors, multilayer ceramic capacitors have low high-frequency impedance and ESR (equivalent series resistance) and good high-frequency characteristics.

Types of Monolithic Ceramic Capacitors

Monolithic ceramic capacitors are available in a wide range of characteristics, and the size, withstand voltage, temperature characteristics, and other factors must be taken into consideration when determining the type of capacitor to be used for a particular application. Monolithic ceramic capacitors can be broadly classified into Class 1 and Class 2 in terms of their characteristics.

1. Class 1

Class 1 capacitors are also called temperature compensated capacitors, and can be compensated relatively easily because they have extremely low ESR, little temperature variation in capacitance, and the variation is linear.

However, the capacitance is usually small, ranging from 1pF to 1μF. ESRs are mainly used in applications where changes in capacitance are undesirable, such as oscillator circuits and time constant circuits.

2. Class 2

Class 2 is also called ferroelectric type, and its main material is barium titanate, which provides large capacitance of about 100 μF even in a small size. However, there are many points to keep in mind when using it, such as a large ESR, large temperature fluctuation of capacitance, and a decrease in actual capacitance when a DC bias is applied.

Therefore, when adopting Class 2 monolithic ceramic capacitors, it is essential to design circuits with their characteristics in mind. The main applications of Class 2 multilayer ceramic capacitors are in circuits where slight changes in capacitance have little effect, such as power source smoothing and decoupling capacitors.

Applications of Monolithic Ceramic Capacitors

Monolithic ceramic capacitors have a wide range of applications because their performance can be selected according to the number of layers and their lineup is broad. Monolithic ceramic capacitors are used in cellular phones, televisions, and industrial equipment for decoupling, coupling, and smoothing circuits, in DC/DC converters, in computer power supplies, and for noise reduction.

For automotive applications, long-life and failure-resistant products are selected. For industrial equipment, high capacitance and small capacitors are widely used, and in recent years they have been replacing other capacitors.

Currently, the mainstream monolithic ceramic cCapacitors are quite small, with sizes of 1005 (1.0 x 0.5 x 0.5 mm) and 0603 (0.6 x 0.3 x 0.3 mm), but in the future, ultra-small capacitors such as 0402 (already in use in the market) and 0201 (the next generation) are expected to become mainstream. However, it is expected that ultra-small capacitors such as the 0402 size, which is already in use in the market, and the next-generation 0201 size will become mainstream.

Principle of Monolithic Ceramic Capacitor

The capacitance C of a capacitor is proportional to the dielectric constant ε and the electrode area S, and inversely proportional to the distance d between electrodes. When capacitors are connected in parallel, the overall capacitance is equal to the sum of the capacitances of each capacitor.

Therefore, the key to increasing the capacitance of a capacitor is to use a dielectric with a high dielectric constant, increase the electrode area, and make the distance between electrode plates as small as possible. A monolithic ceramic capacitor has a structure of many layers of very thin electrode plates, which can be considered as many capacitors with close distance between electrode plates connected in parallel.

In other words, the number of layers N is proportional to the capacitance C of the capacitor. Therefore, by increasing the capacitance with the number of layers N, monolithic ceramic capacitors can be made both smaller and larger.

Although barium titanate, which has a very high dielectric constant, is used as a dielectric in most cases, its performance is expected to eventually reach a plateau. Therefore, the development of materials with a superior dielectric constant and less susceptible to wear and tear is expected.

Structure of Monolithic Ceramic Capacitors

Nickel is used for the electrodes and barium titanate is mainly used for the dielectric. Nickel paste, which serves as the internal electrode, is applied to the dielectric in the form of a sheet, and the sheet is then layered and formed under pressure.

It is then cut into small pieces and sintered at about 1000°C. When the external electrodes are attached, the capacitor becomes a monolithic ceramic capacitor. By ensuring that the internal electrodes are connected to the external electrodes alternately on the left and right, the layers are in the same state as if they were joined in parallel.

Since they are produced in sheet form, they have become more efficient, smaller, and thinner. The number of layers can be as many as 1,000. The dielectric materials are classified into two types: low dielectric constant type, which mainly uses titanium oxide, and high dielectric constant type, which uses barium titanate.

Class 1 is used for temperature compensation and low capacitance in signal circuits, etc. Class 2 has a high dielectric constant and a large temperature coefficient, and is used for power supply decoupling and smoothing circuits.

Other Information on Monolithic Ceramic Capacitors

1. Characteristics of Monolithic Ceramic Capacitors

Monolithic ceramic capacitors have a capacitance that varies with temperature. Therefore, when selecting a monolithic ceramic capacitor, you should not only select one based on its capacitance and voltage rating, but also consider the temperature in the operating environment.

Monolithic ceramic capacitors are characterized by low equivalent series resistance (ESR) due to the use of metals such as nickel and copper in the electrodes. Monolithic ceramic capacitors also feature low parasitic inductance (ESL) due to their structure, which makes them suitable for use at high frequencies.

By taking advantage of these features of low ESR and ESL, it is possible to form resonant circuits with high Q-values and low-loss matching circuits, making MLCCs an indispensable component in the field of high-frequency circuit products, as well as in power supply decoupling and noise suppression applications.

By changing the number of layers of electrode plates, it is possible to control the capacitance from small to large. Therefore, a monolithic ceramic capacitor as a product is also characterized by a very wide range of capacitance in the prepared lineup.

2. Basic Technology for Large Capacitance

The capacitance of a capacitor increases in proportion to the area of the internal electrode plates. To achieve high capacitance without changing the size of the monolithic ceramic capacitor, it is important to stack as many electrode layers as possible.

In general, in order to achieve miniaturization and high capacitance, it is necessary to stack electrodes with sub-millimeter order thickness, so thinning electrode layers is an essential technology. For thinning the electrode layer, adjustment of barium oxide, the raw material of dielectric, and printing technology for forming the internal electrode in paste form into a sheet are important.

The dielectric is made of fine particles called grain, which are formed by adding additives to barium oxide, printing it in sheet form, and then sintering it. How the microstructure of the grains is designed is critical to ensure that the thin-layer dielectric functions adequately.

Screen printing technology, such as that used for silk screens, is used to print thin internal electrodes on the paste. By extruding the paste through the micropores, it is possible to form a uniform thin layer of internal electrode.

3. Share of Monolithic Ceramic Capacitors

Monolithic ceramic capacitors are so widely used in the world of electronics that they are now considered the rice of industry. For example, about 200 to 300 monolithic ceramic capacitors are used per TV receiver, and about 1,000 monolithic ceramic capacitors are used per smartphone.

Electric vehicles use more than 15,000 capacitors per vehicle. Japanese companies account for a large share of the production of these multilayer ceramic capacitors. Although the data is a bit old, the top four companies in terms of market share by value in 2017 are as follows, with three Japanese companies accounting for the majority of the global market share.

- Murata: 33.9% (will exceed 40% in 2020)

- Samsung Electro-Mechanics: 18.1

- Taiyo Yuden: 10.3

- TDK: 8.4

High-performance monolithic ceramic capacitors are especially demanded in automobiles, and Murata and TDK dominate the global market. Monolithic ceramic capacitors are expected to be in short supply for the time being, as their use is expected to further increase after 2021, when 5G generation smartphones will be in widespread use.

List of 18 Monolithic Ceramic Capacitor Manufacturers

*Including some distributors, etc.

Sort by Features

- Default

- Company Size: largest first

- Year Founded: oldest first

- Year Founded: earliest first

Sort by Area

- United States of America

- China

- Hongkong

- Japan

- Taiwan

-

-

-

Tokin America, Inc

Multilayer ceramic capacitor

Manufacturer Overview

Tokin America Inc., headquartered in San Jose, California, is a supplier of passive electronic components in North, South, and Central America and is a subsidiary of Tokin Corporation. Its diverse product range includes capacitors, noise countermeasure components, and sensors used in several industries, including telecommunication, automotive electronics, and digital home appliances. The company also provides specialized design support and works with several distributors within the United States, including Future Electronics, WPG Americas, and Bravo Electronics.

-

-

-

-

-

Knowles Capacitors

MLCC

Manufacturer Overview

Knowles Precision Devices, founded in 1985 in the USA, is a specialty component manufacturer of a wide variety of capacitors, microwave to millimeter wave components, thin film capacitors, and substrates. The company's performance microelectronics products include multi-layer ceramic capacitors, single-layer capacitors, trimmers, mm-wave filters, and resonators for use in critical applications in the military, medical, electric vehicle, and 5G market segments. Examples include radar, pacemakers, MRI equipment, electric vehicles, and mobile phone base stations.

-

-

-

-

-

CalRamic Technologies

High voltage multilayer capacitor

Manufacturer Overview

CalRamic Technologies LLC, founded in 2002 with headquarters in the USA, is a specialist manufacturer of ceramic capacitors. The company's range of products includes HV MLC leaded capacitors for space applications, HV leaded disc capacitors for commercial applications, HV leaded disc capacitors for military applications, and HV chip capacitors for military applications. CalRamic Technologies LLC serves the military, telecommunications, consumer products, and many other industries. The company also provides customized design, engineering, and production of custom products to meet client-specific requirements.

-

-

-

-

-

Vishay Intertechnology, Inc.,

Ceramic Multilayer

Manufacturer Overview

Vishay Intertechnology, Inc. (Vishay) was incorporated in 1962 and is headquartered in Malvern, Pennsylvania. The company serves the industrial, automotive, telecommunications, consumer products, and medical end markets and sells its products under numerous brand names inlcuding Siliconix, Draloric, Beyschlag, UltraSource, and Applied Thin-Film Products. The company manufactures and sells discrete semiconductors and passive electronic components in globally while operating in six market segments: MOSFETs, diodes, optoelectronic components, resistors, inductors, and capacitors.

-

-

-

-

-

NIC Components Corp.

Multilayer ceramic chip

Company Overview

NIC Components Corp., and Nippon Industries Co. Ltd. have collaborated for over 37 years to design and manufacture passive components, including capacitors, resistors, and magnetics. Established in the USA in 1982, NIC has expanded its business to the custom speciality that meets the demands of today’s emerging and latest technology. Their regional offices can be found in Canada, Malaysia, India, Mexico, China, etc. All of their products are built with more features and are certified with different ISO certifications. They also assist their customers in component selection through live support.

-

-

-

-

-

Guangdong South Hongming Hong Kong Electronic Science And Technology Co.,Ltd

monolithic ceramic capacitor 104K

Manufacturer Overview

South HongMing was founded in 1988 and is headquartered in Guangdong, China, as a manufacturer of electronic components for various industries. The company's product chart consists of ceramic capacitors, film capacitors, varistors, thermistors, and electronic devices that are applied for all kinds of electronic circuits and electronic products including high and low-voltage power supply, communications equipment, energy and power facilities, computer and peripheral products, and audio-visual devices. The company has obtained DNV ISO9001, China CEPREI GB / T19001-2000, ISO14001:2004, and Chinese Military Products Quality System Certifications and the products meet GB, U.S. EIA, and the International Electrotechnical Commission IEC standards.

-

-

-

-

-

HVC Capacitor Manufacturing

High voltage MLCC

Manufacturer Overview

HVC Capacitor Manufacturing, founded in 1999 and headquartered in Shenzhen, China, stands as a manufacturer of high voltage ceramic capacitors and resistors. Its product range includes high voltage ceramic capacitors for power supplies and motors, high voltage resistors for surge protection, doorknob capacitors for switchgear applications, screw terminal capacitors for circuit connection, and custom capacitors tailored to specific needs. These solutions cater to diverse sectors such as power, energy, transportation, medical, and industrial. The company has an international distribution channel in industrial countries, such as Germany, France, the U.K., the U.S.A, Japan, as well sa in Korea, India, and Russia.

-

-

-

-

-

Murata Manufacturing Co., Ltd.

Ceramic capacitor

Manufacturer Overview

Murata Manufacturing Co., Ltd. (Murata Manufacturing) was founded in 1944 and is headquartered in Nagaokakyo, Japan. Murata Manufacturing designs, manufactures, and sells ceramic-based passive electronic components and solutions globally. The company operates through components, modules, and others segments, serving communications, mobility, industrial, healthcare, and personal electronics customers. They company's product offerings include noise suppression products, quartz devices,RFID devices, phase shifters, and wireless connectivity platforms. Services such as webinars and video library are also available for existing and potential customers alike.

-

-

-

-

-

Viking Tech Corporation

SMD capacitor

Manufacturer Overview

Viking Tech Corporation, established in 1997, is a Taiwanese manufacturer and supplier of electronic components, headquartered in Hukou, Hsinchu. The company’s product lineup comprises resistors, inductors, capacitors, and supercapacitors. These products, particularly the resistors, find applications in various industries. In the medical sector, these resistors are integrated into hospital equipment like X-ray machines, ultrasonography devices, portable defibrillators, and more. Similarly, in the automotive industry, resistors are integrated into electric vehicle (EV) engine control and body control systems, car navigation systems, and other applications. Additionally, the communication industry uses resistors for smartphones and similar devices.

-

-

-

-

-

YAGEO

MLCC

Manufacturer Overview

YAGEO Group, a global supplier of passive components, including chip resistors, MLCC, through-hole resistors, wireless components, inductors and coils, established in 1977 and is based in Taiwan. The Group serves multiple industries, including automotive, telecommunications, smart manufacturing, and power and energy. They offer complete solutions for body and convenience, powertrain and safety, comfort and infotainment, and e-mobility in the automotive industry. They have established a strong global presence with 29 sales offices, 51 production sites, 20 research and development centers, and 40,000 employees worldwide.

-

-

-

-

-

-

-

Walsin Technology Corporation

MLCC

Manufacturer Overview

Walsin Technology Corporation (also known as WTC and Passive Component), founded in 1970 and incorporated as Walsin Technology Corporation in 1992 with facilities in Taiwan and China, is a manufacturer of passive components. The company's products include MLCC, Chip-R, RF, DISC, varistors (VZ, VH, and SR series), and inductor parts used in the mobile communications, networking, automotive, green energy, and IoT industries, among others. Walsin Technology Corp.’s products are REACH-certified, and the company holds ISO 9001, IATF 16949, IECQ HSPM certifications, and an Authorized Economic Operator Certification.

-

-

-

-

-

Exxelia

Microwave ceramic capacitor

Manufacturer Overview

Exxelia was born in Paris, France in 2009 from the merger of five companies, the oldest of which was SIC-SAFCO, founded in France in 1921. The combined conglomerate is a manufacturer of electronic components to electronics manufacturers worldwide. The conglomerate’s entities are organized into 3 global business units: Capacitors, Magnetics, and Resistors & Subsystems. Capacitors are divided into basic materials such as aluminum electrolytic, ceramic, film, and tantalum. Magnetics are divided into functions with inductors, transformers, and rotors as subsections. Resistors & Subsystems are also divided by function and design with resistors, filters, position sensors, and mechanics & subassembly.

-

-

-

-

-

Prosperity Dielectrics Co., Ltd.

Multilayer ceramic capacitor

Manufacturer Overview

Passive System Alliance Properity Dielectric Co. Ltd. is a passive component manufacturer established in 1990 and headquartered in Yang-Mei, TaoYuan, Taiwan. In 2005, the company entered into a strategic alliance with WTC, and in 2008, it formally merged with Hongdian Electronics, expanding its sales scope from dielectric ceramic powder, semiconducting ceramic capacitor tiles, multilayer ceramic capacitors, and chip resistors to inductors. The company is capable of meeting market demands by initiating material research and development and integrating and developing electronic components as required by customers.

-

-

-

-

-

KYOCERA Corporation

Multilayer ceramic chip capacitor

Company Overview

Kyocera Corporation was incorporated in 1946 in Kyoto, Japan as Kyoto Ceramics, but the name was later shortened to Kyocera. Kyocera is a multinational manufacturer and distributor of consumer products as well as industrial components including ceramic and electronic components used in the semiconductor, wireless communications, electronics, and wireless communications markets. Kyocera’s consumer products line includes smartphones and kitchenware such as ceramic knives, cookware, and drinkware. Ceramics are used in semiconductors, solar photovoltaic modules, as well as cutting tools. Kyocera’s electronics cameras, LCDs, medical products, and more.

-

-

-

-

-

SAMSUNG ELECTRO-MECHANICS

MLCC

Company Overview

SAMSUNG ELECTRO-MECHANICS, established in 1973 and based in Suwon, South Korea, is a manufacturer and supplier of MLCCs (Multilayer Ceramic Capacitors). The company's product portfolio includes chip resistors, camera modules, and MLCCs with high bending strength. These products are used in various industries, including consumer electronics, automotive, and telecommunications. The company is ISO 9001, ISO 14001, and ISO 45001 certified for its quality, safety, and environmental management, with a global network in various countries including the United States, Singapore, and India.

-

-

-

-

-

-

-

Kingtronics International Company

MLCC capacitor

Distributor Overview

Kingtronics International Company was established in 1990 in Hong Kong and has several factories across China manufacturing electronic components such as bridge rectifiers. The company is ISO 9001:2015 certified and works with several distributors around the world including KORE, Prod. El, DTDS, and others. The company produces two kinds of electronics components: passive components such as aluminum electrolytic capacitors including radial type and axial type, and active components such as diodes, transistors, and bridge rectifiers.

-

-

Monolithic Ceramic Capacitor Manufacturer Ranking

*Including some distributors, etc.Ranking as of April 2024

Derivation Method| Rank | Company | Click Share |

|---|---|---|

| 1 | Vishay Intertechnology, Inc., |

12.6%

|

| 2 | KYOCERA Corporation |

8.4%

|

| 3 | YAGEO |

8.4%

|

| 4 | Knowles Capacitors |

8.4%

|

| 5 | Murata Manufacturing Co., Ltd. |

8.4%

|

| 6 | Tokin America, Inc |

8.4%

|

| 7 | Semec Technology Company Limited |

6.3%

|

| 8 | Viking Tech Corporation |

6.3%

|

| 9 | CalRamic Technologies |

6.3%

|

| 10 | MARUWA CO., LTD. |

6.3%

|

Derivation Method

The ranking is calculated based on the click share within the monolithic ceramic capacitor page as of April 2024. Click share is defined as the total number of clicks for all companies during the period divided by the number of clicks for each company.Number of Employees

- KYOCERA Corporation: 83,001

- Murata Manufacturing Co., Ltd.: 77,581

- YAGEO: 40,000

Newly Established Company

- HVC Capacitor Manufacturing: 2012 (12 years ago)

- Semec Technology Company Limited: 1999 (25 years ago)

- Walsin Technology Corporation: 1992 (32 years ago)

Company with a History

- Murata Manufacturing Co., Ltd.: 1944 (80 years ago)

- KYOCERA Corporation: 1959 (65 years ago)

- MARUWA CO., LTD.: 1973 (51 years ago)

Monolithic Ceramic Capacitor Manufacturers in United States

*Including some distributors, etc.

- Tokin America, Inc

- Knowles Capacitors

- CalRamic Technologies

- Vishay Intertechnology, Inc.,

- NIC Components Corp.

Global Distribution of Monolithic Ceramic Capacitor Manufacturers by Country

*Including some distributors, etc.

| Country | Number of Companies | Share (%) |

|---|---|---|

United States of America

United States of America

|

5 | 38.5% |

Japan

Japan

|

3 | 23.1% |

China

China

|

2 | 15.4% |

Taiwan

Taiwan

|

2 | 15.4% |

| Hongkong | 1 | 7.7% |