28 Ceramic Substrate Manufacturers in 2024

This section provides an overview for ceramic substrates as well as their applications and principles. Also, please take a look at the list of 28 ceramic substrate manufacturers and their company rankings. Here are the top-ranked ceramic substrate companies as of July, 2024: 1.Ceramic Substrates & Components Ltd, 2.Stanford Advanced Materials, 3.MARUWA CO., LTD..

Table of Contents

1987~1991: Engaged in research on wire covering materials at Polymer Materials Laboratory.

1991~1997: Worked as a patent Engineer at Koike International Patent Office.

1997~2005 Worked as an intellectual property member at GE Yokogawa Medical System, currently working as a writer.

Linkedinhttps://www.linkedin.com/in/%E8%A3%95%E5%AD%90-%E9%88%B4%E6%9C%A8-92b21a234/

researchmap

https://researchmap.jp/0315rs2017

What Is a Ceramic Substrate?

A ceramic substrate is a substrate made of ceramic, which forms the wiring of a printed wiring board or is an insulating board on which components are placed.

Uses of Ceramic Substrates

Ceramic substrates are used in printed wiring boards incorporated in heat dissipation products and high-frequency measuring instruments, etc., as they are used in high-temperature environments and as printed wiring boards become smaller. Specific applications are as follows:

- Heat Dissipation Products

High-power LED lighting equipment, laser processing equipment, deep ultraviolet irradiation equipment

Satellite communication equipment, high-frequency measuring - Equipment

Base station antennas, ETC, RF modules, various radars - Automotive Products

Automotive LED lamps, automotive control components - Electronic Components

Peltier elements, piezoelectric sensors, LEDs, laser diodes, GAN modules, high temperature, acceleration, cycle, SiC power - Semiconductors

High-frequency mobile communication equipment

IoT communication equipment, antennas and filters, voltage controlled oscillators (VCOs), temperature compensated crystal oscillators (TCXOs)

Characteristics of Ceramic Substrates

Ceramic substrate is made of ceramic and its characteristics are similar to those of ceramics. Typical ceramics that form ceramic substrate include alumina substrate, alumina zirconia substrate, aluminum nitride (AlN), and silicon nitride (Si3N4).

These are materials with excellent mechanical strength, electrical insulation, corrosion resistance, heat resistance, and thermal conductivity, and the substrates have the same characteristics.

Types of Ceramic Substrate

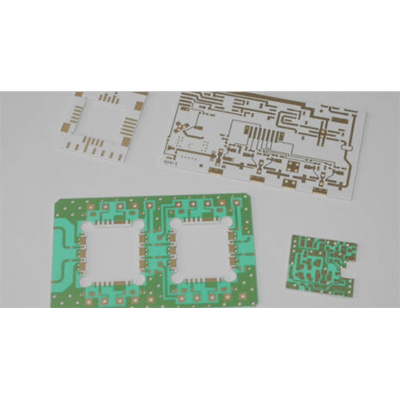

There are three types of printed wiring boards with wiring patterns, etc. formed on insulating substrates made of ceramics: high-temperature ceramic substrate, low-temperature ceramic substrate, and thick film ceramic substrate.

1. High-Temperature Ceramic Substrate

High-temperature ceramic substrate is a substrate on which high-temperature co-fired ceramic (HTCC) circuits are formed. First, an insulating plate, which serves as the substrate, is manufactured using ceramic raw materials formulated for high temperatures. Next, metal circuits such as tungsten and molybdenum are formed on the insulating plate, and the laminated substrate is fired at high temperature to form a High Temperature Ceramic Substrate.

2. Low-Temperature Ceramic Substrate

Low-temperature ceramic substrate is a substrate made of low- temperature co-fired ceramics (LTCC). They are usually manufactured as multilayer substrates.

First, ceramic powder, glass, and binders are mixed to form a sheet. Through holes are made at necessary locations to connect multiple layers, and a wiring pattern is printed and formed to create a single layer. After several layers of different wiring patterns are created and stacked, the LTCC wiring substrate is completed through the firing process.

3. Thick-Film Ceramic Substrate

Thick-film ceramic substrate is a substrate in which electrical circuits are formed by printing conductor or resistor paste on an insulating substrate, and is characterized by the relatively thick film thickness of the conductor.

Other Information on Ceramic Substrate

1 Ceramic Substrate Made of High-Purity Alumina Material

Ceramic substrate is produced by mixing and firing thermally conductive ceramic powder with organic binder and other materials. When high-purity alumina material is used in this process, the fired ceramic has few pores and a very smooth surface because the alumina material is a fine particle.

This means that the material has excellent adhesion to thick films and thin-film materials, and has stable characteristics when used as a printed wiring board. Also, because they are fine particles, their size does not change after firing, and they have very good external characteristics such as dimensional variation, warping, and bending. They also have high heat dissipation and heat resistance, and are physically and chemically stable even under high heat environments.

2. Semiconductor Packages Using Ceramic Substrate

Heat generation associated with the high integration of semiconductor devices is an important issue, and alumina ceramic substrate with high heat dissipation is used. However, this is not always sufficient to meet the high requirements of today's semiconductor devices. In recent years, aluminum nitride and silicon carbide have been attracting attention as new ceramic materials for semiconductor packaging that can replace alumina ceramic substrate.

Aluminum nitride is not a natural ceramic material and has excellent thermal conductivity, with a theoretical value of 320 W/m-K. In reality, however, it is difficult to improve the raw materials, burnout, and heat resistance. In reality, improvements in raw materials, selection of sintering aids, and sintering conditions have resulted in the practical application of a thermal conductivity of about 180 W/m-K.

In silicon carbide ceramics, it has become clear that if beryllium oxide is used as a sintering aid, it can be used as an insulator with high thermal conductivity, and it is now attracting attention as a substrate material.

List of 28 Ceramic Substrate Manufacturers

*Including some distributors, etc.

Sort by Features

- Default

- Company Size: largest first

- Year Founded: oldest first

- Year Founded: earliest first

Sort by Area

- United States of America

- Belgium

- China

- France

- Germany

- Japan

- United Kingdom

-

-

-

Knowles Capacitors

Substrates

Manufacturer Overview

Knowles Precision Devices, founded in 1985 in the USA, is a specialty component manufacturer of a wide variety of capacitors, microwave to millimeter wave components, thin film capacitors, and substrates. The company's performance microelectronics products include multi-layer ceramic capacitors, single-layer capacitors, trimmers, mm-wave filters, and resonators for use in critical applications in the military, medical, electric vehicle, and 5G market segments. Examples include radar, pacemakers, MRI equipment, electric vehicles, and mobile phone base stations.

-

-

-

-

-

Corning Incorporated

Ceramic Substrates

Manufacturer Overview

Corning Incorporated, founded in 1851 and headquartered in Corning, New York, is a manufacturer and supplier of specialty glass, ceramics, and optical fiber. Their offerings include optical fiber for long-distance light signal transmission, specialty glass for applications like displays and lighting, ceramics for various uses, such as cookware and medical implants, and advanced materials like 3D printing powders and ceramic matrix composites. Additionally, Corning provides products for the life sciences industry, such as labware, consumables, and analytical instruments.

-

-

-

-

-

Stanford Advanced Materials

Ceramic Material

Manufacturer Overview

Stanford Advanced Materials was established in 1994 in Lake Forest, California to provide rare-earth products for research and development purposes. Stanford Advanced Materials serves many industries ranging from automotive to fashion to energy to research to sports to textiles. Stanford Advanced Materials manufactures and distributes purified metals, ceramics, composite materials including strips, plates, rods, wires, and bars, as well as laboratory equipment and optical equipment including crystals, lenses, splitters, and windows.

-

-

-

-

-

ORTECH ADVANCED CERAMICS

Ceramic Substrates

Manufacturer Overview

ORTECH ADVANCED CERAMICS, established in 2002, is a manufacturer of advanced technical ceramics, based in Sacramento, California, USA. The company specializes in producing ceramics like Alumina Oxide, Zirconia Oxide, Silicon Carbide, and Silicon Nitride. Their ceramics enhance product performance and offer benefits such as high temperature stability, wear resistance, and anti-corrosive properties. They provide a wide range of ceramic services, from isostatic pressing to ceramic injection molding. They are also ISO 9001:2015 certified and serve multiple industries like electronics, aerospace, and medical equipment. Their expert team leverages CNC machining, grinding, and other techniques to ensure precision.

-

-

-

-

-

CoorsTek, Inc.

Technical Ceramics

Manufacturer Overview

CoorsTek, Inc., founded in 1910, is a family-run manufacturer of technical ceramic material formulations with products such as acetabular liners, baffle chambers, carbon brushes for power, focal plane array components, and precision fixed gauges used in transportation, food & beverage, electronic, chemicals, and semiconductor industries. The company in Golden, CO, USA, has research & development, custom manufacturing, and design assistance capabilities. The company's CIO- Matt Mehlbrech, was awarded the 2023 Colorado ORDIE Award for CIO of the Year.

-

-

-

-

-

High Tech Material Solutions

Ceramic Substrates

Manufacturer Overview

High Tech Material Solutions is based in Auburn, Washington. The company is a supplier of advanced materials and a manufacturer of custom-machined ceramic components to customers globally, with local delivery and in-store pickup also available. The company primarily serves aerospace, medical, government agencies, and energy industries. The company’s services include CNC machining and custom ceramic-based materials fabrication. Additional materials the company provides include crystals, optical materials, nickel foam, and aerospace gels.

-

-

-

-

-

Hybrid Sources, Inc.

Ceramic Substrates

Company Overview

Hybrid Sources Inc., founded in 1985 and located in Wilmington, Massachusetts, is a manufacturer of thick film and hybrid substrates. The company offers a range of products, including aluminum nitride, screened gold, and solder reflow. These products find various applications in industrial packaging equipment, university and research institutions, and automatic testing equipment. Additionally, the company serves as a key supplier of carrier plates for wire bonding to both commercial and military satellite manufacturers.

-

-

-

-

-

Accumet Materials Co.

Ceramic Substrates

Company Overview

Accumet Materials Co. is headquartered in Ossining, New York. The company is a metal and ceramics manufacturer and distributor that provides metal engineering solutions to customers around the world. The company specializes in three primary materials: ceramics, metal, and powders. The company offers custom products based on several materials including ceramics, zirconium, magnesium oxide, crystals, and other metals. The company’s facilities include ceramics fabrication, vacuum & arc melting furnaces, a custom foundry, crystal growing, and powder production systems.

-

-

-

-

-

Xiamen Innovacera Advanced Materials Co., Ltd

Metallized Ceramics

Manufacturer Overview

Xiamen Innovacera Advanced Materials Co. Ltd. is a ceramic material manufacturer based in Xiamen, Fujian. Certified with ISO 9001: 2008 and ISO 14001:2004, the company offers various materials, including aluminum nitride, boron carbide, and boron nitride. Other ceramic material offerings include silicon carbide, silicon nitride, and zirconia-toughened alumina. The company also manufactures ceramic products, including alumina ceramic heaters, cutting blades, and filling pumps. These products find applications in various industries, including aerospace, research, and food processing. The company further extends its services to ceramic processing, offering rapid prototyping, grinding, and metallization to meet various industrial needs.

-

-

-

-

-

JAPAN FINE CERAMICS CO.,LTD.

Products

Manufacturer Overview

Japan Fine Ceramics Co. Ltd, established in 1984 at Sendai City, Japan is a manufacturer of high precision and fine ceramic parts for commercial and industrial uses. The company is a subsidiary of JGC Holdings Corporation and manufactures various advanced ceramic parts for uses in electrical components such as semiconductors, diodes, ICs etc. Their product category has electronic ceramics, engineering ceramics, metal matrix composites and glass ceramics. The products are used in automotive, machinery, electrical, telecommunications and energy applications. These components are heat-resistant, corrosion, wear resistant and have lighter weight with more rigidity. They enhance performance and eliminate damping properties.

-

-

-

-

-

Toshiba Materials Co., Ltd.

Silicon nitride ceramics: Plain substrates

Manufacturer Overview

Toshiba Materials Co., Ltd is a Japanese-based manufacturer and retailer of fine ceramics, magnetic parts, special metals, and alloys founded in 2003. They manufacture fine ceramics for medical equipment, aircraft engines, fan motor, and machine tools, including aluminum nitride and silicon nitride. A tungsten and molybdenum product line also includes wires, probe pins, rotating anodes, and parts of these metals or their alloys. Toshiba Materials also manufactures materials and coatings, including niobium, titanium, and crAix alloy, used in producing semiconductors.

-

-

-

-

-

KOA Corporation

LTCC substrate

Manufacturer Overview

KOA Corporation, established in 1940 in Minowa-machi, Japan, is a manufacturer of electronic components. The company provides an extensive product range including resistors, current sense shunt resistors, fuses, thermal sensors, and inductors. These quality components find applications in industries such as automotive, ecology, energy conservation, telecommunications, power supply units, and home appliances. Operating under the guiding principles of circulation, finite resources, harmony, and enrichment, it continues to provide sustainable electronic solutions to cater to the ever-changing demands of global industries.

-

-

-

-

-

Ceramic Substrates & Components Ltd

Substrates

Manufacturer Overview

Ceramic Substrates & Components Ltd, a company founded in 1968 and based in Newport, Isle of Wight, is a manufacturer of ceramic products. The company specializes in producing ceramic substrates and components. These materials find wide application in various industries such as electronics, telecommunications, automotive, and aerospace. The company's offerings include industrial ceramic components, technical ceramics, precision ceramics, bespoke ceramics, and other advanced ceramic materials. It holds ISO 9001:2015 certification, ensuring industrial standard quality in its products.

-

-

-

-

-

Best Technology

Ceramic PCB

Manufacturer Overview

Best Technology, founded in 2006 and headquartered in Shenzhen, China, is a manufacturer of printed circuit board assemblies and related solutions. The company specializes in PCB Design, prototype, manufacturing, and assembly services. It offers a range of products, including printed circuit boards, connectors, and sensors. Its products are used in LED Lighting, telecommunications, medical equipment, and industrial control. The company's manufacturing ability has earned it ISO 9001 and ISO13485 certifications, ensuring its products meet industry standards.

-

-

-

-

-

KOA EUROPE GmbH

LTCC substrate

Manufacturer Overview

KAO Corporation has its head office in Nagano, Japan, and was established in 1940 as a manufacturer of resistors. The company deals in various resistors such as SMD, Leaded, Low resistance, and Current Sense Shunts. There are other products as well including thermal sensors. ICs, fuses, inductors, varistors, and more. The use of these components is vast with applications in medical equipment, satellites, automotive, home appliances, power supply units, and similar. Even the Ecology and Energy Saving industry benefit from these tools. the company also provides Design Support Tools in the form of 3D designs, and Technical notes.

-

-

-

-

-

Orbray Co., Ltd.

LTCC

Manufacturer Overview

Orbray was originally founded in 1939 in Japan. Orbray serves the automotive, medical, fashion, information communication, audio, and robotics industries. Orbray develops a variety of products including small motors, fiber optics components, and precision jewelry tools. Applications for Orbray’s products include small robots, diaphragm pumps, inner wall metrology systems, and semiconductors.

-

-

-

-

-

Denka Company Limited

High thermal conductivity ceramic substrate

Manufacturer Overview

Denka Company Limited, founded in 1915, is a Japanese chemical manufacturer headquartered in Chuo City, Tokyo. The company offers a range of products made with the technology of fine ceramics and organic fine chemicals, such as adhesives, fluorescent materials, functional films, and heat dissipation materials. They also produce automotive parts, belts, hoses, electric wires and cables, and rubber gloves using chloroprene rubber. Additionally, Denka provides products made of polymer solutions, such as food packaging materials, building materials, and electric home appliances. In 2022, Denka launched the New Business Development to develop products and technologies in ICT and energy, healthcare, and sustainable living.

-

-

-

-

-

-

-

UNIPRETEC

Al2O3 AlN Ceramic Substrates

Manufacturer Overview

Unipretec is a manufacturer of advanced ceramics components for industrial processing operations founded in 2011 and located in Xiamen, China. The company’s products include wear-resistant alumina ceramic pistons for high pressure washer pumps, abrasion-resistant zirconia ceramic plungers for waterjet cutting operations, and thermal-resistant ceramic cylinder liners for reciprocating pumps. It also offers alumina ceramic furnace plates for sintering processes, and ceramic grinding media such as beads and balls. The company’s products are mainly used in the industrial processing sector, such as in foundry and chemical refining operations.

-

-

-

-

-

Xiamen Wintrustek Advanced Materials Co., Ltd.

Al2O3 AlN DBC Ceramic Substrates

Manufacturer Overview

Xiamen Wintrustek Advanced Materials Co., Ltd., founded in 2014 and headquartered in Xiamen, China, is a manufacturer of technical ceramics. The company's products include Boron Nitride Ceramic Crucible Boxes, Customized Macor Ceramic Isolators, and High-Strength Silicon Nitride Si3N4 Ceramic Extrusion Dies. These products are used for various applications in the power metallurgy, oil and gas, and automotive industries. It also provides solutions such as bullet-proof ceramic plates for bullet-proof vests and zirconia ceramic grinding balls.

-

-

-

-

-

Mitsubishi Materials Corporation

DBA (Direct Bonded Aluminum) substrate

Manufacturer Overview

The Company operates diverse businesses, ranging from nonferrous metals and other fundamental materials to cemented cardide tools/metalworking solutions, the manufacturing of semiconductor-related and electronic components/materials, resource recycling, and renewable energy power generation. In each business, the Company holds the No.1 position in production volume, sales volume, etc.

-

-

-

-

-

Rogers Corporation

Metallized Ceramic Substrates

Manufacturer Overview

Rogers Corporation, founded in 1832 and headquartered in Chandler, Arizona, is a manufacturer of engineered materials that cater to various industries. The company offers solutions including foams, circuit materials, and elastomers. It routinely engages in the process of obtaining information from its metal suppliers concerning the origin of the metals that are used to manufacture its products. it also serves as a supplier of materials used in advanced electronic applications, automotive technologies, renewable energy systems, and more. Its product quality standards are evident through its certifications, providing products for advancement of multiple sectors worldwide.

-

-

-

-

-

Glead Electronics

Ceramic substrate

Manufacturer Overview

Glead Electronics, established in 2000 and headquartered in Jiaxing, China, serves as a manufacturer and supplier of microwave ceramic components and antenna products. Its offerings encompass microwave ceramic materials for diverse temperature applications, RF passive components including filters and couplers, and antenna modules for applications like GPS, Beidou, and 4G. Additionally, they provide ceramic substrates for electronic device mounting and a range of accessories. These solutions are utilized in electronic system design in fields such as satellite navigation, wireless communication, and automotive electronics. The company holds several certifications including ISO 9001, IATF 16949, ISO 14001, OHSAS 18001, and GJB 9001B.

-

-

-

-

-

CERcuits

LASER-CUT CERAMIC SUBSTRATES

Company Overview

CERcuits was founded in 1849 and is headquartered in Geel, Flemish Region, Belgium, as a manufacturer and supplier of ceramic PCBs and substrates. The company provides various products, such as alumina PCB (AL2O3), alumina (Al2O3) substrates, laser-cut alumina (Al2O3), and laser-cut aluminum nitride (AlN). The products are essential in electronics and semiconductor manufacturing, providing thermal conductivity, electrical insulation, and mechanical strength for various applications, ensuring accurate electronic system functionality. The company caters to various industries, including electronics, manufacturing, aerospace, defense, telecommunications, and automotive.

-

-

-

-

-

CeramTec

Substrates

Company Overview

CeramTec, established in 1903, is headquartered in Plochingen, Germany, and is a manufacturer and supplier of technical ceramics, and is active at production sites in Europe, the USA, and Asia with more than 3,680 employees worldwide. The products offered by the company are Bearing Rollers, BIOLOX, BIOLOX delta, Catalyst Carriers, Coil Bodies, and many more. The topics used by the company are largely 3D Printing, BIOLOX Implants, E-Mobility, DENSILOX Dental Implants, Medical Equipment, and more. The application areas of the company include 3D Printing, Bearing & Sealing Technology, Automotive & Mobility, Electronic Circuit Carriers, Dental Solutions, and more.

-

-

-

-

-

Advanced Engineering Materials Limited

Ceramic Substrates

Company Overview

Advanced Engineering Materials Limited in headquartered in Changsha, Hunan, China. The company is a global researcher, manufacturer, and distributor of materials including non-ferrous materials, customized alloys, and other synthetic compounds. The company’s products are often used in optics solar, architecture, and automotive industries. The company’s products include crucibles, evaporation materials, crystal materials, powder products, and sputtering targets. Sputtering targets are mechanisms used to coat substrates with thin films. Sputtering target materials include fluoride targets, pure metal targets, alloy sputtering targets, and nitride sputtering targets.

-

-

-

-

-

Accuratus Corporation

Aluminium Nitride Substrates

Company Overview

Accuratus Corporation is a manufacturer and supplier of glass and ceramic materials and components that was established in 1977 in Washington, New Jersey, USA. The company offers its Accuflect-branded light reflecting ceramic material for infrared or laser applications, and its Macor-branded machinable glass material for mechanical or electrical applications. It also offers ceramic tubes and rods fabricated from materials such as silicon carbide, alumina, and zirconia. The company chiefly serves clients in the semiconductor, defense, and biotechnology industries.

-

-

-

-

-

Final Advanced Materials

Ceramic Substrate

Distributor Overview

Final Advanced Materials was established in 1998, based at Dedenheim France, and the company is a supplier of solutions to companies and research centers for the advancement of the materials. The company offers many materials, such as steel, stainless steel, Inconel, aluminum, bronze, and many more. The company can manufacture custom parts for the client’s projects. The company is able to work with technical ceramics, ceramic powders, high-temperature adhesives, composites & refractories, high-temperature textiles, and more.

-

-

Ceramic Substrate Manufacturer Ranking

*Including some distributors, etc.Ranking as of July 2024

Derivation Method| Rank | Company | Click Share |

|---|---|---|

| 1 | Ceramic Substrates & Components Ltd |

8.2%

|

| 2 | MARUWA CO., LTD. |

7.3%

|

| 3 | Stanford Advanced Materials |

6.8%

|

| 4 | Accumet Materials Co. |

5.4%

|

| 5 | High Tech Material Solutions |

5.4%

|

| 6 | Final Advanced Materials |

4.9%

|

| 7 | Rogers Corporation |

4.9%

|

| 8 | CERcuits |

4.7%

|

| 9 | Corning Incorporated |

4.7%

|

| 10 | ORTECH ADVANCED CERAMICS |

4.2%

|

Derivation Method

The ranking is calculated based on the click share within the ceramic substrate page as of July 2024. Click share is defined as the total number of clicks for all companies during the period divided by the number of clicks for each company.Number of Employees

- Denka Company Limited: 6,358

- Mitsubishi Materials Corporation: 5,450

- CeramTec: 3,500

Newly Established Company

- Best Technology: 2006 (18 years ago)

- Toshiba Materials Co., Ltd.: 2003 (21 years ago)

- Glead Electronics: 1995 (29 years ago)

Company with a History

- Rogers Corporation: 1832 (192 years ago)

- Corning Incorporated: 1851 (173 years ago)

- Denka Company Limited: 1915 (109 years ago)

Ceramic Substrate Manufacturers in United States

*Including some distributors, etc.

- Knowles Capacitors

- Corning Incorporated

- Stanford Advanced Materials

- ORTECH ADVANCED CERAMICS

- CoorsTek, Inc.

- High Tech Material Solutions

- Hybrid Sources, Inc.

- Accumet Materials Co.

Global Distribution of Ceramic Substrate Manufacturers by Country

*Including some distributors, etc.

| Country | Number of Companies | Share (%) |

|---|---|---|

United States of America

United States of America

|

8 | 36.4% |

Japan

Japan

|

6 | 27.3% |

China

China

|

3 | 13.6% |

Germany

Germany

|

2 | 9.1% |

United Kingdom

United Kingdom

|

1 | 4.5% |

Belgium

Belgium

|

1 | 4.5% |

France

France

|

1 | 4.5% |

List of Ceramic Substrate Products

2 products are listed.

Noshimitsu Photo Service Co., Ltd.

Ceramic substrate

30+ people viewing

The ceramic substrate is a printed circuit board using ceramic for the insulating layer. Utilizing the material characteristics of the ceramic, it ...