All Categories

History

This section provides an overview for aluminum electrolytic capacitors as well as their applications and principles. Also, please take a look at the list of 15 aluminum electrolytic capacitor manufacturers and their company rankings. Here are the top-ranked aluminum electrolytic capacitor companies as of July, 2025: 1.JEC, 2.Toshin kogyo CO.,LTD, 3.Exxelia.

Table of Contents

Categories Related to Aluminum Electrolytic Capacitors

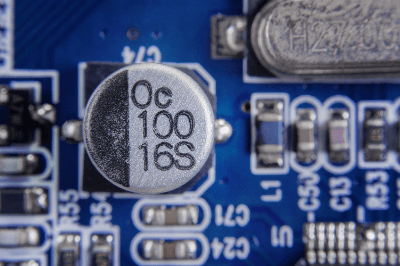

Aluminum electrolytic capacitors are small capacitors with high capacitance that use aluminum oxide as the dielectric.

Aluminum electrolytic capacitors are small capacitors with high capacitance that use aluminum oxide as the dielectric.

Wet type capacitors use an electrolyte as the cathode, but dry type capacitors using solids such as conductive polymers with improved performance are also available. Because of their low price and high versatility, they are used in many products with electronic circuit boards, such as home appliances and personal computers.

Aluminum electrolytic capacitors are used in a wide variety of products with electronic substrates in a wide range of fields, such as automobiles, home appliances, and industrial equipment, because they are smaller, have a larger capacity, and are less expensive than other capacitors.

Specific applications are as follows:

When used as power conditioners for renewable energy, many of them use 10 to 100 aluminum electrolytic capacitors. Due to their high versatility, the performance requirements for aluminum electrolytic capacitors are increasing year by year.

Aluminum electrolytic capacitors use thin aluminum foil for the anode and cathode and aluminum oxide for the dielectric. Aluminum oxide is formed on the surface of the aluminum foil by an electrochemical oxidation process (chemical conversion).

The surface of the aluminum foil is made uneven by an etching process to increase the surface area. The capacitance of a capacitor is expressed by the following equation, which is proportional to the surface area of the dielectric and inversely proportional to its thickness.

Capacitance C = ε × S/d

ε: Dielectric permittivity of dielectric S: Surface area of dielectric d: Thickness of dielectric

A disadvantage of aluminum oxide coatings is that they generate more leakage current than other capacitors because of the minute current flow when voltage is applied. The internal cathode of a wet aluminum electrolytic capacitor uses an electrolytic solution, which can leak in the event of a failure.

Another drawback is that the electrolyte may decrease due to electrolyte leakage or evaporation, resulting in low durability. Dry aluminum electrolytic capacitors, on the other hand, do not evaporate because conductive polymers are used for the internal cathode, and are more durable than wet capacitors.

Among electronic components, wet aluminum electrolytic capacitors are known to have a particularly short life span: while LSIs are required to operate for tens of thousands of hours, a typical aluminum electrolytic capacitor has a life span of 2,000 hours at 85°C and a highly reliable one of 5,000 hours at 105°C.

One of the reasons for the short life expectancy is the structure of aluminum electrolytic capacitors, in which the electrolyte impregnated in the insulating paper gradually leaks out from the rubber sealing section over time. When the electrolyte leaks out, the capacitance decreases and ESR (equivalent series resistance) will increase.

The life of an aluminum electrolytic capacitor is said to follow Arrhenius' law (chemical reaction formula based on thermal energy) when the temperature is below the maximum operating temperature, and the life is approximately doubled when the temperature is 10°C lower. Therefore, an aluminum electrolytic capacitor with a life of 2,000 hours at 85°C will last 4,000 hours if used at 75°C, and 8,000 hours at 65°C.

Compared to other capacitors, aluminum electrolytic capacitors have a large ESR, and when a large current flows during operation, the inside of the capacitor generates heat. This heat generation causes the temperature of the capacitor to rise, which further promotes electrolyte leakage and shortens the life of the capacitor.

Polarized capacitors are always marked with some kind of indication so that the polarity can be easily checked.

It is extremely important to check the polarity indication because if the polarity is incorrectly marked, the capacitor may not only malfunction but may also catch fire.

*Including some distributors, etc.

Sort by Features

Sort by Area

KEMET has a portfolio of over 1,600 patents serving the automotive, aerospace, industrial, telecommunications, computing, consumer, and medical devices. KEMETs devices provide filtering, sensing, energy storage, power conversion, and haptic actuator technology. Among these devices are capacitors, electromagnetic compatibility (EMC) components, resistors, circuit protection devices, inductors, sensors, Piezoelectric devices, release, transformers, and engineering kits.

Vishay Intertechnology, Inc. (Vishay) was incorporated in 1962 and is headquartered in Malvern, Pennsylvania. The company serves the industrial, automotive, telecommunications, consumer products, and medical end markets and sells its products under numerous brand names inlcuding Siliconix, Draloric, Beyschlag, UltraSource, and Applied Thin-Film Products. The company manufactures and sells discrete semiconductors and passive electronic components in globally while operating in six market segments: MOSFETs, diodes, optoelectronic components, resistors, inductors, and capacitors.

CDE, founded in Liberty, SC in 1909 is a manufacturer of optimal power capacitors. The company's product portfolio includes electrolytic capacitors, mica capacitors, AC film capacitors, DC film capacitors and Power Factor Correction Capacitors. The company serves industries such as Oil and Gas, Aerospace and Defense, Automotive and Transportation, Construction, and Power Generation. They also provides services including national distribution, product selection, installation, preventative maintenance, troubleshooting, repair and customer service.

Toshin Kogyo CO., LTD., established in 1951 and headquartered in Tokyo, Japan, is a manufacturer that manufactures, imports and sells electronic components. The company produces electronic components such as aluminum electrolytic capacitors, capacitors for audio equipment, film capacitors, and liquid crystal modules. It also released an aluminum electrolytic capacitor series for acoustic applications called the UTJH series. The UTJH series has a wide temperature range of -40°C to +85°C, which makes it suitable for use in various environments. The company has achieved ISO-14001 and ISO-9001 certification. It serves industries such as electronic components, printing, and fabric industry.

Rubycon Corporation is a Japanese developer and manufacturer of capacitors and related products that was established in Nagano as Nihon Denkai Seisakusho in 1952 before rebranding in 1990. The company’s product lineup includes film capacitors utilizing plastic film as dielectric material, electrolytic capacitors using electrolytic solution or conductive polymer as dielectric material, and power supplies for converting AC input to DC output for various applications including powering industrial equipment, medical devices, or LED lighting. The company is certified to ISO 9001, ISO 14001, and IATF 16949 standards, and offers additional technical support and design assistance services to its clients.

JEC, established in the year 1988 with headquarters in Taipei, Taiwan, is a manufacturer of electronic components, capacitors, and connectors. The company’s diverse range of products includes connectors, capacitors, sockets, cable assemblies, and various electronic accessories. These components play an important role in various industries such as electronics, telecommunications, automotive, and consumer electronics, enabling seamless connectivity and efficient data transmission. The team studies the product's dependability and conducts environmental tests, such as product durability, damp heat resistance, voltage resistance, insulation resistance, temperature characteristics, and flame resistance, to ensure that the products are superior and meet industrial standards.

KLS Electronic, founded in 2002 with headquarters and factories in China, is a manufacturer of electronic components that has expanded to have more than 10 subsidiary companies. The company's extensive product line includes resistors, inductors, wiring accessories, automotive connectors, and heat sinks, which are supplied to the industrial automation, instrumentation, power, transport, shipbuilding, and new energy sectors, among others, across 30 regions worldwide. KLS Electronic also holds ISO 9001 management system certificates.

TDK Corporation, established in 1935, is a manufacturer of electronic solutions for the smart society based in Tokyo, Japan. The company is a part of the TDK Group, which has over 250 locations in more than 30 countries worldwide and employs over 103,000 people. They offer a wide range of products, including sensors, power supplies, and magnetic application products. The robotics industry is evolving at a rapid pace, and they are now offering , a robot development platform equipped with a variety of sensors essential to the accurate operation of robots, enabling more efficiency across a wide range of robot development.

ZONKAS ELECTRONIC CO., LTD., established in 1982 in Taiwan, is a manufacturer of inductors, capacitors, and electrical components. The company's main products include electrolyte capacitors, multilayer leaded ceramic capacitors, transformers, axial fixed inductors, and gas discharge tubes, used by OEM manufacturers worldwide. ZONKAS ELECTRONIC CO., LTD.'s registered brand is ZONKAS, and the company holds ISO 9001 and IS 14001 certifications. The company has its main factory and secondary office located in China.

Murata Manufacturing Co., Ltd. (Murata Manufacturing) was founded in 1944 and is headquartered in Nagaokakyo, Japan. Murata Manufacturing designs, manufactures, and sells ceramic-based passive electronic components and solutions globally. The company operates through components, modules, and others segments, serving communications, mobility, industrial, healthcare, and personal electronics customers. They company's product offerings include noise suppression products, quartz devices,RFID devices, phase shifters, and wireless connectivity platforms. Services such as webinars and video library are also available for existing and potential customers alike.

Polyols and Polymers is an Indian manufacturer and supplier of polyurethane systems, adhesives, and coatings such as including but not limited to aromatic and aliphatic polyisocyanates, polyether polyols, polyester polyols, MDI prepolymers. The company was established in 1991 and has since grown to become a global supplier of polyurethane systems, specialty chemicals, and adhesives. Their products are used in various industries, including automotive, construction, furniture, and insulation. The company's main products include polyurethane foams, coatings, adhesives, and elastomers. In 2019, the company was awarded the Frost & Sullivan Indian Polyurethane Systems Company of the Year Award.

Chiah Sin Industrial Co., Ltd. is a Taiwanese manufacturer and supplier of precision-machined plastic components such as gears, rollers, pulleys, and bearings used in various industries like automotive, electronics, and medical, including aerospace, automotive, and medical. Established in 1978, it expanded its operations to include a wide range of products for various industries. Their products are used in automotive, electronics, and construction. The company's main products include epoxy resins, polyurethane adhesives, and silicone sealants. In 2018, the company was awarded the Taiwan Excellence Award for its performance epoxy resin products.

Taiwan-based NANPAO Resins Chemical Group (NRCG) is a manufacturer and supplier of synthetic resins, speciality adhesives, liquid and powder coatings, and various construction materials including admixtures and grouts. The company was founded in 1963, when its dye and finishing factory was restructured to produce polyvinyl acetate adhesives. Companies in the footwear, automotive, furniture, construction, and technology industries are among the company's core clients. NRCG has factories in multiple countries including China, Vietnam, Indonesia, India, and the Philippines. These produce technologies used in medical and optical devices, as well as renewable energy sources.

Viking Tech Corporation, established in 1997, is a Taiwanese manufacturer and supplier of electronic components, headquartered in Hukou, Hsinchu. The company’s product lineup comprises resistors, inductors, capacitors, and supercapacitors. These products, particularly the resistors, find applications in various industries. In the medical sector, these resistors are integrated into hospital equipment like X-ray machines, ultrasonography devices, portable defibrillators, and more. Similarly, in the automotive industry, resistors are integrated into electric vehicle (EV) engine control and body control systems, car navigation systems, and other applications. Additionally, the communication industry uses resistors for smartphones and similar devices.

Exxelia was born in Paris, France in 2009 from the merger of five companies, the oldest of which was SIC-SAFCO, founded in France in 1921. The combined conglomerate is a manufacturer of electronic components to electronics manufacturers worldwide. The conglomerate’s entities are organized into 3 global business units: Capacitors, Magnetics, and Resistors & Subsystems. Capacitors are divided into basic materials such as aluminum electrolytic, ceramic, film, and tantalum. Magnetics are divided into functions with inductors, transformers, and rotors as subsections. Resistors & Subsystems are also divided by function and design with resistors, filters, position sensors, and mechanics & subassembly.

Ranking as of July 2025

Derivation Method| Rank | Company | Click Share |

|---|---|---|

| 1 | JEC |

11.3%

|

| 2 | Toshin kogyo CO.,LTD |

8.7%

|

| 3 | Exxelia |

8.4%

|

| 4 | Polyols and Polymers Pvt.Ltd. |

7.7%

|

| 5 | KLS Electronic |

7.7%

|

| 6 | NANPAO RESINS CHEMICAL GROUP |

7.1%

|

| 7 | CDE |

6.9%

|

| 8 | Vishay Intertechnology, Inc., |

6.6%

|

| 9 | KEMET |

6.6%

|

| 10 | Viking Tech Corporation |

5.8%

|

Derivation Method

The ranking is calculated based on the click share within the aluminum electrolytic capacitor page as of July 2025. Click share is defined as the total number of clicks for all companies during the period divided by the number of clicks for each company.Number of Employees

Newly Established Company

Company with a History

*Including some distributors, etc.

*Including some distributors, etc.

| Country | Number of Companies | Share (%) |

|---|---|---|

Taiwan

Taiwan

|

4 | 28.6% |

United States of America

United States of America

|

3 | 21.4% |

Japan

Japan

|

3 | 21.4% |

China

China

|

2 | 14.3% |

| Nagano | 1 | 7.1% |

India

India

|

1 | 7.1% |

894 products found

894 products

Nippon Chemi-Con Corporation.

2140+ people viewing

Last viewed: 1 hour ago

Achieving the world's highest class capacity. Ideal for high-output power supplies used in data center servers, etc. *Other model numbers are avai...

10 models listed

SUN Electronic Industries Corporation

800+ people viewing

Last viewed: 8 hours ago

EP-cap is the industry's first aluminum electrolytic capacitor that uses a highly conductive polymer in combination with an electrolyte cathode to ...

5 models listed

Nippon Chemi-Con Corporation.

1530+ people viewing

Last viewed: 10 hours ago

We have a lineup with a maximum rated voltage of 500V and a product height of 80mm for data center servers and new energy power storage devices tha...

10 models listed

SUN Electronic Industries Corporation

1320+ people viewing

Last viewed: 8 hours ago

EP-cap is the industry's first aluminum electrolytic capacitor that uses a highly conductive polymer in combination with an electrolyte cathode to ...

9 models listed

Aisetec

3420+ people viewing

Last viewed: 1 hour ago

Screw terminal -shaped aluminum electrolytic capacitors standard products

5 models listed

Nippon Chemi-Con Corporation.

1650+ people viewing

Last viewed: 2 hours ago

We have a lineup with a maximum rated voltage of 500V and a product height of 80mm for data center servers and new energy power storage devices tha...

10 models listed

SUN Electronic Industries Corporation

730+ people viewing

Last viewed: 4 hours ago

EP-cap is the industry's first aluminum electrolytic capacitor that uses a highly conductive polymer in combination with an electrolyte cathode to ...

4 models listed

Aisetec

950+ people viewing

Last viewed: 2 hours ago

Aluminum electrolytic condenser screw terminal type aluminum electrolytic capacitors high ripple

5 models listed

Aisetec

970+ people viewing

Last viewed: 2 hours ago

Aluminum electrolytic condenser screw terminal type aluminum electrolytic capacitors Large -capacity

5 models listed

Nippon Chemi-Con Corporation.

1500+ people viewing

Last viewed: 2 hours ago

We have created a lineup that assumes harsh usage environments such as the sealed environment of communication base stations, which require high te...

10 models listed

Unielex Co., Ltd.

350+ people viewing

Last viewed: 22 hours ago

■Features ・Surface mounting compatible ・Supplied by carrier taping packaging ・Guaranteed for 2,000 hours at 85℃

SUN Electronic Industries Corporation

590+ people viewing

Last viewed: 7 hours ago

EP-cap is the industry's first aluminum electrolytic capacitor that uses a highly conductive polymer in combination with an electrolyte cathode to ...

4 models listed

Toshin kogyo CO.,LTD

290+ people viewing

Last viewed: 21 hours ago

■Features ・Low ESR, ideal for switching power supplies ・Guaranteed for 4,000~10,000 hours at 105℃ ・High ripple miniaturized product

Nippon Chemi-Con Corporation.

1580+ people viewing

Last viewed: 5 hours ago

This is a lead type input smoothing aluminum electrolytic capacitor designed for ultra-compact size. It has a long life guarantee of 10,000/12,000 ...

10 models listed

Unielex Co., Ltd.

6680+ people viewing

Last viewed: 15 minutes ago

■Features ・Surface mounting compatible ・Supplied by carrier taping packaging ・Guaranteed for 1,000 hours at 105℃

SUN Electronic Industries Corporation

1000+ people viewing

Last viewed: 1 hour ago

EP-cap is the industry's first aluminum electrolytic capacitor that uses a highly conductive polymer in combination with an electrolyte cathode to ...

6 models listed

Toshin kogyo CO.,LTD

200+ people viewing

Last viewed: 6 hours ago

■Features ・A highly stabilized aluminum electrolytic capacitor with a wide operating temperature range of -40℃ to 105℃ and a guaranteed lifespan o...

Aisetec

880+ people viewing

Last viewed: 15 hours ago

Aluminum electrolytic capacitors substrate independent aluminum electrolytic capacitors standard products

4 models listed

Toshin kogyo CO.,LTD

210+ people viewing

Last viewed: 15 hours ago

■Features -This is a series with a nominal height of 5mm and a wide operating temperature range of -40 to +105℃. ・This product is ideal for use in...

Aisetec

730+ people viewing

Last viewed: 1 day ago

Aluminum electrolytic capacitors independent aluminum electrolytic capacitors Long life

3 models listed

Nippon Chemi-Con Corporation.

1390+ people viewing

Last viewed: 2 minutes ago

By developing and using a new electrode foil, we have reduced ESR at high frequencies (kHz band) and improved high frequency ripple current withsta...

10 models listed

Unielex Co., Ltd.

220+ people viewing

Last viewed: 1 day ago

■Features ・Surface mounting compatible ・Supplied by carrier taping packaging ・Guaranteed for 2,000 hours at 85℃

SUN Electronic Industries Corporation

1810+ people viewing

Last viewed: 2 hours ago

EP-cap is the industry's first aluminum electrolytic capacitor that uses a highly conductive polymer in combination with an electrolyte cathode to ...

6 models listed

Toshin kogyo CO.,LTD

180+ people viewing

Last viewed: 8 hours ago

■Features ・This is a series with a nominal height of 7mm and a wide operating temperature range of -40 to +105℃. ・This product is ideal for use i...

Nippon Chemi-Con Corporation.

1330+ people viewing

Last viewed: 14 hours ago

By developing and using a new electrode foil, we have reduced ESR at high frequencies (kHz band) and improved high frequency ripple current withsta...

10 models listed

Unielex Co., Ltd.

200+ people viewing

Last viewed: 12 hours ago

■Features ・Surface mounting compatible ・Supplied by carrier taping packaging ・Guaranteed for 1,000 hours at 125℃

SUN Electronic Industries Corporation

910+ people viewing

Last viewed: 41 minutes ago

EP-cap is the industry's first aluminum electrolytic capacitor that uses a highly conductive polymer in combination with an electrolyte cathode to ...

5 models listed

Aisetec

1200+ people viewing

Last viewed: 4 hours ago

Aluminum electrolytic capacitors board independent aluminum electrolytic capacitors special products

7 models listed

Toshin kogyo CO.,LTD

180+ people viewing

Last viewed: 1 day ago

■Features ・A highly stabilized aluminum electrolytic capacitor with a low leakage current product that has a wide operating temperature range of -...

Nippon Chemi-Con Corporation.

850+ people viewing

Last viewed: 2 hours ago

This series achieves the large capacitance required for input capacitors for automotive applications. By using a large capacity MZT series capacito...

6 models listed