31 Film Capacitor Manufacturers in 2024

This section provides an overview for film capacitors as well as their applications and principles. Also, please take a look at the list of 31 film capacitor manufacturers and their company rankings. Here are the top-ranked film capacitor companies as of October, 2024: 1.Allied International, 2.KEMET, 3.W. L. Gore & Associates, Inc..

Table of Contents

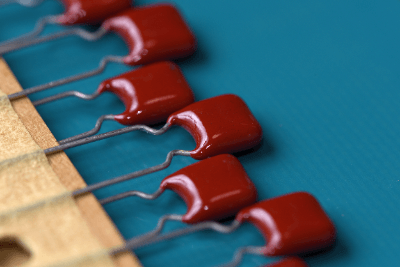

What Is a Film Capacitor?

A film capacitor is a capacitor that uses plastic film as a derivative. The technology traces its roots back to paper capacitors invented in the late 19th century. In paper capacitors, oil or paraffin paper is clipped onto aluminum foil and rolled.

The type that is rolled by depositing metal directly onto paper is called a metalized paper (MP) capacitor. Film capacitor was developed in the 1930s based on these technologies.

Film capacitor is classified into foil electrode type and vapor-deposited electrode type (metalized film type) according to the structure of the internal electrodes, and further into wound type and laminated type, inductive type, and non-inductive type according to the difference in structure.

Uses of Film Capacitors

Film capacitors are used in a wide variety of products from consumer products to industrial equipment. Examples of consumer products are home appliances such as refrigerators and in-car electronic equipment such as car navigation systems, car audio systems, and ETC systems. Examples of industrial equipment include power electronics equipment.

Film capacitors are characterized by high insulation resistance and high safety. They are also non-polarized, have excellent high-frequency characteristics, and have good temperature characteristics. In addition, film capacitors have high capacitance accuracy and a long service life.

However, film capacitors are larger than multilayer ceramic chip capacitors. Therefore, film capacitors tend to be used in voltage and capacitance ranges that cannot be covered by ceramic capacitors, as well as in high-performance and high-precision crises.

Principle of Film Capacitors

Capacitors are electronic components that store and release electricity. When voltage is applied between opposing conductors, electrostatic induction occurs in the insulator or space between them. The electrostatic induction action causes dielectric polarization in the insulator, which charges the battery.

Film capacitors use a film as the inductor. Film capacitors can be classified into several categories according to the construction and structure of the internal electrodes.

1. Foil Electrode Type Film Capacitors

These are wound film capacitors in which a plastic film is wound over a metal foil that serves as the internal electrode. The metallic foil is made of aluminum, tin, or copper.

There are two types of foil-electrode film capacitors: inductive and non-inductive. The inductive type is wound with a lead wire attached to the internal electrode, while the non-inductive type has a lead wire or terminal electrode attached to the end face. The inductance component of the non-inductive type can be smaller than that of the inductive type, resulting in superior high-frequency characteristics.

2. Evaporated-Electrode Film Capacitors

This is a type of film capacitor in which the internal electrode is made by vapor-depositing metal onto plastic film. Aluminum or zinc is used as a metallic material. Since the vapor-deposited film is very thin, this type of capacitor can be made smaller than the foil electrode-type film capacitors.

Other Information on Film Capacitors

1. Polarity of Film Capacitors

Film capacitors do not have polarity. In other words, film capacitors are non-polarized capacitors. There are two types of fixed capacitors: non-polarized capacitors and polarized capacitors.

Non-Polarized Capacitor

A non-polarized capacitor is a capacitor whose terminals do not distinguish between positive and negative. It does not matter which terminal is positive. The polarity of the voltage applied to the terminals is not regulated. Non-polar capacitors can be used directly in AC circuits.

Film capacitors are one of the mainstream nonpolar capacitors. Other non-polar capacitors include ceramic capacitors, paper capacitors, mica capacitors, and air capacitors.

Polarized Capacitors

A polarized capacitor is a capacitor with two terminals, one of which is positive. If the polarity of the terminals is used incorrectly, the capacitor will be damaged.

2. Film Capacitors and Audio

Audio equipment can be self-made or customized to one's taste in sound. Multiple factors affect the quality of sound, but the parts used also affect the sound quality. Capacitors are one of those parts.

The characteristics required of capacitors used in audio amplifiers include the following:

- Good high-frequency characteristics

- Low harmonic distortion

- Low so-called squeal

Compared to electrolytic capacitors, film capacitors are superior in the above characteristics. In terms of sound quality, film capacitors have better sound transparency and resolution than electrolytic capacitors.

List of 31 Film Capacitor Manufacturers

*Including some distributors, etc.

Sort by Features

- Default

- Company Size: largest first

- Year Founded: oldest first

- Year Founded: earliest first

Sort by Area

- United States of America

- China

- Czech Republic

- France

- Germany

- Italy

- Japan

- Nagano

- Spain

- Taiwan

- Turkey

-

-

-

W. L. Gore & Associates, Inc.

High Temperature Capacitors

Manufacturer Overview

W. L. Gore & Associates, Inc., founded in Newark, Delaware, in 1958 is a manufacturer of medical devices and products that reduce emissions, and explore space. The company's product portfolio includes implantable Medical Devices, Electrochemical Devices & Fuel Cell Components, Ozonation Modules, Workwear & Industrial Fabrics, and Fire & Safety Fabrics. The company serves industries such as Oil and Gas, Aerospace and Defense, Automotive and Transportation, Construction, and Power Generation. They have a global distribution and sales channel, customer support center, and R&D center.

-

-

-

-

-

Vishay Intertechnology, Inc.,

CAPACITORS - FILM

Manufacturer Overview

Vishay Intertechnology, Inc. (Vishay) was incorporated in 1962 and is headquartered in Malvern, Pennsylvania. The company serves the industrial, automotive, telecommunications, consumer products, and medical end markets and sells its products under numerous brand names inlcuding Siliconix, Draloric, Beyschlag, UltraSource, and Applied Thin-Film Products. The company manufactures and sells discrete semiconductors and passive electronic components in globally while operating in six market segments: MOSFETs, diodes, optoelectronic components, resistors, inductors, and capacitors.

-

-

-

-

-

KEMET

Film Capacitors

Manufacturer Overview

KEMET has a portfolio of over 1,600 patents serving the automotive, aerospace, industrial, telecommunications, computing, consumer, and medical devices. KEMETs devices provide filtering, sensing, energy storage, power conversion, and haptic actuator technology. Among these devices are capacitors, electromagnetic compatibility (EMC) components, resistors, circuit protection devices, inductors, sensors, Piezoelectric devices, release, transformers, and engineering kits.

-

-

-

-

-

Allied International

Film Capacitor

Company Overview

Allied International, founded in 1930 and based in the US, is a manufacturer, distributor, and purchasing agent of aerospace and related transportation and industrial products that offer solutions to customers. The company offers a wide range of industrial engineering tool applications and products such as Inertia switches, limit & G switches, filters, Chambrelan linear slides, Exxelia, and more. Its industrial tool applications are designed to solve problems in various industries including medical, aerospace, oil & gas, railroad, and military among others.

-

-

-

-

-

Toshin kogyo CO.,LTD

Film Capacitor

Manufacturer Overview

Toshin Kogyo CO., LTD., established in 1951 and headquartered in Tokyo, Japan, is a manufacturer that manufactures, imports and sells electronic components. The company produces electronic components such as aluminum electrolytic capacitors, capacitors for audio equipment, film capacitors, and liquid crystal modules. It also released an aluminum electrolytic capacitor series for acoustic applications called the UTJH series. The UTJH series has a wide temperature range of -40°C to +85°C, which makes it suitable for use in various environments. The company has achieved ISO-14001 and ISO-9001 certification. It serves industries such as electronic components, printing, and fabric industry.

-

-

-

-

-

Xiamen Hongfa Electroacoustic Co.,Ltd.

Polypropylene film capacitor

Manufacturer Overview

Founded in 1984, Xiamen Hongfa Electroacoustic Co., Ltd. is a manufacturer specializing in relays, connectors, precision manufacturing parts, and automation equipment. Headquartered in Xiamen, China, the company has established 30 subsidiaries worldwide, serving over 120 countries and regions. HONGFA offers customized solutions utilizing its electrical appliances and complete equipment. Its wide range of products finds applications in various industries such as smart homes, smart grids, industrial control, automotive and railway transportation, and the Internet of Things. The company has received multiple awards, including the 2023 National Enterprise Culture Outstanding Achievement by China Enterprise Confederation and China Entrepreneurs Association.

-

-

-

-

-

Federal Electric

POWER CAPACITORS

Manufacturer Overview

Federal Electric, established in 1990 and based in Adapazar, is a manufacturer of marble, natural gas metres, lighting, and low-voltage equipment. The company was founded with all national capital on 40,000 square metres of land, of which 25,000 square metres are covered. The company was the 70th organisation in Turkey to be awarded an ISO 9000 quality certificate, and it was also honoured with a quality award in Belgium. The company offers 3250 items, including current transformers, automated transfer switches, small circuit breaker boxes, surge protection devices, and moulded-case circuit breakers.

-

-

-

-

-

AENER ENERGÍA S.L.U.

POWER FACTOR CORRECTION

Manufacturer Overview

AENER ENERGÍA S.L.U. was established in 1994 and is located in Madrid, Spain is a manufacturer of power capacitors, automatic capacitor banks, and equipment. The company offers a comprehensive product catalog, including Uninterruptible power supply, voltage stabilizers, and power factor correction. It also extends services like offering complete software for the calculation of automation capacitors technical training, and pre-sales like installation. These products find applications in automotive, civil engineering, and power supply and distribution industries.

-

-

-

-

-

Enerlux Power srl Via G.Rossa

SINGLE PHASE CAPACITORS

Manufacturer Overview

Enerlux Power SRL, founded in 1979 and headquartered in Viadana, Lombardy, Italy, is a manufacturer of voltage capacitors and power factor correction systems. The company's core products include a range of capacitor banks, reactors, and protection equipment designed for industrial-use applications, operations, and machinery that requires a lossless, harmonized power supply. These products are used in mining excavators, municipal power transformers, and steel rolling mills. In addition to the company's standard products, it specializes in customized solutions, from analysis and design through installation and technical inspection.

-

-

-

-

-

COMAR Condensatori

Capacitors for motor applications

Manufacturer Overview

COMAR Consendatori is manufacturer of capacitors and power factor correction equipment based in Bologna, Italy. Established in 1973, the company offers a wide range of products including motor capacitors, lighting capacitors, power factor correction capacitors, high voltage capacitors and custom capacitors, used for energy storage, signal filtering and power factor correction. Some of the company's capacitors include MKP (metallized polypropylene), EL (electrolytic aluminum), MKS (metallized polyester), and MKT (metallized film) capacitors, each with its own characteristics suited for various applications.

-

-

-

-

-

ZEZ SILKO Ltd

AC Filter capacitors

Manufacturer Overview

ZEZ SILKO Ltd., founded in 1994, is a power capacitor manufacturer based in Zamberk, Czech Republic. The company offers several services, such as electrical device power factor correction (PFC) for low and medium voltage. It also conducts power system evaluation, including measurement of network parameters. The company further provides power electronic capacitors, switchboards, and inducting heating capacitors. These products and services find applications in various industries, including electromobility, railway and public transportation, and power industry.

-

-

-

-

-

ELECTRONICON

Low-inductance DC capacitors

Manufacturer Overview

ELECTRONICON, established in 1952 and based in Gera, Germany, is a manufacturer of capacitors for power electronics and heavy current electrics. Their product includes various capacitors, such as power factor correction capacitors, motor run capacitors, DC-link capacitors, and specialty capacitors, which are vital components in electrical systems, providing energy storage, filtering, and power factor correction functions. The company offers specialty capacitors for various applications, including pulse capacitors for welding equipment and capacitors for railway systems. They serve customers worlwide, providing solutions that ensure efficient operation in electronic systems.

-

-

-

-

-

Blue Jay Technology Co. Ltd.

Power Capacitor for PFC

Manufacturer Overview

Blue Jay Technology Co. Ltd., established in 2013 and headquartered in Chongqing City, China, is a manufacturer of power automation monitoring products and energy meters. The company's product includes DIN rail energy meters and insulation monitoring devices for electric vehicles. It also offers OEM/ODM services such as replacement of UI design (type OEM-I), changes on existing products (type OEM-II), and new designs available on demand (ODM). Its product can display power usage in real-time, helping users understand their power quality and usage, and optimize power usage. It serves industries such as power automation monitoring, mechanical contracting, transportation, and manufacturing.

-

-

-

-

-

Matsuo Electric Co.,Ltd.

Film Capacitors

Manufacturer Overview

Matsuo Electric Co.,Ltd., founded in 1949 in Japan, is a specialty component manufacturer of tantalum capacitors, film capacitors, and circuit protection components. The company's microelectronics products include small size, long life, chip tantalum capacitors, leaded tantalum capacitors, fuses, and PET and PPS-type film capacitors used by original equipment manufacturers in a wide variety of industries, including the automotive, electronics, space, and healthcare markets for fire alarms, personal computers, power tools, hearing aids, automotive navigation, and many more devices. Matsuo Electric Co.,Ltd.'s products are RoHS compliant.

-

-

-

-

-

Rubycon Corporation

Film Capacitors

Manufacturer Overview

Rubycon Corporation is a Japanese developer and manufacturer of capacitors and related products that was established in Nagano as Nihon Denkai Seisakusho in 1952 before rebranding in 1990. The company’s product lineup includes film capacitors utilizing plastic film as dielectric material, electrolytic capacitors using electrolytic solution or conductive polymer as dielectric material, and power supplies for converting AC input to DC output for various applications including powering industrial equipment, medical devices, or LED lighting. The company is certified to ISO 9001, ISO 14001, and IATF 16949 standards, and offers additional technical support and design assistance services to its clients.

-

-

-

-

-

NICHICON

Plastic Film Capacitors

Manufacturer Overview

NICHICON, founded in Kyoto, Japan, in 1950, is a manufacturer of electronic components such as Aluminum electrolytic capacitors and Plastic film capacitors. The company's product portfolio includes Small Li-Ion Rechargeable Batteries, Household energy storage systems, Public and industrial power storage systems, Switching power supplies, and Power sources for medical accelerators. The company serves industries such as Oil and Gas, Aerospace and Defense, Automotive and Transportation, Construction, and Power Generation. NICHICON also offers various services, including product selection, installation, preventative maintenance, troubleshooting, and repair.

-

-

-

-

-

Nippon Chemi-Con Corporation.

Film Capacitors

Manufacturer Overview

Nippon Chemi-Con Corporation. was established in 1931 and is a manufacturer of aluminum-based products, precision mechanical components, and electronics equipment based in Shinagawa, Tokyo, Japan. The company's product portofolio offers various products such as aluminum electrolytic capacitors, multilayer ceramic capacitors, inductors, camera module, and silicon wafer. The products have been used in various application such as electric power steering, direct injection engine control, solar power inverter, switching power supply, and automotive micro computer power supply. The company has passed the ISO 9001, IATF 16949, and ISO 14001 standards certification. The products are manufactured under the compliance of RoHS and REACH/SVHC standards.

-

-

-

-

-

Aisetec

Plastic Film Capacitors

Manufacturer Overview

AIC Tech Inc., established in 2020 and headquartered in Tochigi, Japan, is a manufacturer of electronic and electric equipment along with the related parts and materials. Its main products are power electronic capacitors, including types such as plastic film, aluminum electrolytic, and metalized films. The company also produces deposition products and provides services for designing and supervising contract work related to the installation of electric equipment. The company has six manufacturing sites and serves over 30 countries worldwide, including North America and Germany.

-

-

-

-

-

TDK Corporation.

Film Capacitors

Manufacturer Overview

TDK Corporation, established in 1935, is a manufacturer of electronic solutions for the smart society based in Tokyo, Japan. The company is a part of the TDK Group, which has over 250 locations in more than 30 countries worldwide and employs over 103,000 people. They offer a wide range of products, including sensors, power supplies, and magnetic application products. The robotics industry is evolving at a rapid pace, and they are now offering , a robot development platform equipped with a variety of sensors essential to the accurate operation of robots, enabling more efficiency across a wide range of robot development.

-

-

-

-

-

ZONKAS ELECTRONIC CO., LTD

Film Capacitor

Manufacturer Overview

ZONKAS ELECTRONIC CO., LTD., established in 1982 in Taiwan, is a manufacturer of inductors, capacitors, and electrical components. The company's main products include electrolyte capacitors, multilayer leaded ceramic capacitors, transformers, axial fixed inductors, and gas discharge tubes, used by OEM manufacturers worldwide. ZONKAS ELECTRONIC CO., LTD.'s registered brand is ZONKAS, and the company holds ISO 9001 and IS 14001 certifications. The company has its main factory and secondary office located in China.

-

-

-

-

-

Exxelia

Polypropylene PP

Manufacturer Overview

Exxelia was born in Paris, France in 2009 from the merger of five companies, the oldest of which was SIC-SAFCO, founded in France in 1921. The combined conglomerate is a manufacturer of electronic components to electronics manufacturers worldwide. The conglomerate’s entities are organized into 3 global business units: Capacitors, Magnetics, and Resistors & Subsystems. Capacitors are divided into basic materials such as aluminum electrolytic, ceramic, film, and tantalum. Magnetics are divided into functions with inductors, transformers, and rotors as subsections. Resistors & Subsystems are also divided by function and design with resistors, filters, position sensors, and mechanics & subassembly.

-

-

-

-

Manufacturer Overview

WEG S.A. is an ISO 9001-certified manufacturer of industrial engineering products founded in 1961 and based in Jaraguá do Sul, Brazil. The company produces equipment and products for power generation, control, and coating metal or wood. These include powder coatings for decorative or protective purposes, gas turbines, and dry-type transformers. The company primarily serves clients in the oil and gas, wastewater processing, and mining industries. It also offers maintenance, engineering, and automation services to its customers.

-

-

-

-

People Electric Appliance Group Co., Ltd.

Self-healing Shunt Capacitor

Manufacturer Overview

People Electric Appliance Group Co., Ltd., headquartered in Yueqing, Zhejiang, China, is a manufacturer of electrical equipment. Its diverse product range includes circuit breakers, contactors, disconnectors, switchgear, and control panels. These products find applications in power generation and transmission, industrial automation, and commercial and residential construction industries. The company's equipment is designed to safeguard and regulate electrical circuits, ensuring safe and efficient operations. The company also holds certifications such as ISO 14001 Environmental Management System, ISO 45001 Occupational Health & Safety Management System, and ISO 9001 Quality Management.

-

-

-

-

-

CEFEM GROUP

FILM CAPACITORS

Manufacturer Overview

Cefem Group, founded in 1987 and headquartered at its headquarters in La Chapelle, Saint Michel de Boulogne, France, is a manufacturer of electrical equipment and industry-scale measuring solutions. The company specializes in passive components for power modulation, power conversion, industrial efficiency, and safety equipment. Its products include transformers, safety switches, and photovoltaic inverters. These products are used in renewable solar photovoltaic power systems, environmental quality measurement systems for municipal water supply infrastructure, and high-speed electrical rail systems.

-

-

-

-

-

ISKRA, d.o.o.

Capacitors

Company Overview

ISKRA, d.o.o., founded in 1946 and headquartered in Ljubljana, Slovenia, is a manufacturer and supplier of intelligent industrial solutions and electrotechnical products. Its extensive product line includes energy sector solutions, electrotechnical components, efficient installations, traffic solutions, and telecommunications solutions. These items are deployed across multiple sectors, utlized in process automation, communications, and security systems for power distribution, transmission, and railway and road traffic. Its products are instrumental in software solutions within the energy sector and logistics.

-

-

-

-

-

DAITRON CO., LTD

Film Capacitors

Company Overview

Daitron Group, is an electronics engineering manufacturer, founded in 1952 and headquartered in Tokyo, Japan. The company is involved in the sales, import, and export of electronic components, assembly goods, semiconductors, embedded systems, power supply equipment, and image-related equipment and components. Its product line encompasses a diverse array of independently developed products, including production and inspection equipment for silicon wafers, ICs, LSIs, and flat panels. The company merged with domestic subsidiaries Daito Denso Co., Ltd. and Daitron Technology Co., Ltd. in 2017, resulting to the change of its trade name.

-

-

-

-

-

-

-

-

-

-

-

Jiande Chang Sheng Power Capacitor Co., Ltd.

Capacitor

-

-

-

-

-

Grid Solutions

High Voltage Capacitors

Distributor Overview

Grid Solutions, established in 1892, is a global producer and distributor of GE Renewable Energy solutions headquartered in Boulogne-Billancourt, France. The company is a part of GE Vernova with over 12,000 employees offering equipment, systems, and services to power utilities and industries, ensuring efficient power delivery from generation to consumers. These include Power Electronics, High Voltage Equipment, Automation & Protection, Software Solutions, and Projects & Services. Addressing the challenges of the energy transition, Grid Solutions provides safe integration of renewable and distributed energy into the grid using HV/MV equipment, gas-insulated substations, and more.

-

-

Film Capacitor Manufacturer Ranking

*Including some distributors, etc.Ranking as of October 2024

Derivation Method| Rank | Company | Click Share |

|---|---|---|

| 1 | Allied International |

13.1%

|

| 2 | KEMET |

6.1%

|

| 3 | ZONKAS ELECTRONIC CO., LTD |

4.9%

|

| 4 | W. L. Gore & Associates, Inc. |

4.6%

|

| 5 | TDK Corporation. |

4.6%

|

| 6 | Xiamen Hongfa Electroacoustic Co.,Ltd. |

4.6%

|

| 7 | Vishay Intertechnology, Inc., |

4.2%

|

| 8 | Matsuo Electric Co.,Ltd. |

4.2%

|

| 9 | Rubycon Corporation |

3.9%

|

| 10 | Nippon Chemi-Con Corporation. |

3.9%

|

Derivation Method

The ranking is calculated based on the click share within the film capacitor page as of October 2024. Click share is defined as the total number of clicks for all companies during the period divided by the number of clicks for each company.Number of Employees

- TDK Corporation.: 116,808

- Nippon Chemi-Con Corporation.: 6,045

- NICHICON: 5,408

Newly Established Company

- Aisetec: 2020 (4 years ago)

- Blue Jay Technology Co. Ltd.: 2013 (11 years ago)

- AENER ENERGÍA S.L.U.: 1994 (30 years ago)

Company with a History

- ZEZ SILKO Ltd: 1930 (94 years ago)

- TDK Corporation.: 1935 (89 years ago)

- ISKRA, d.o.o.: 1946 (78 years ago)

Film Capacitor Manufacturers in United States

*Including some distributors, etc.

Global Distribution of Film Capacitor Manufacturers by Country

*Including some distributors, etc.

| Country | Number of Companies | Share (%) |

|---|---|---|

Japan

Japan

|

6 | 26.1% |

United States of America

United States of America

|

4 | 17.4% |

China

China

|

3 | 13.0% |

Spain

Spain

|

2 | 8.7% |

Italy

Italy

|

2 | 8.7% |

Turkey

Turkey

|

1 | 4.3% |

Czech Republic

Czech Republic

|

1 | 4.3% |

Germany

Germany

|

1 | 4.3% |

| Nagano | 1 | 4.3% |

Taiwan

Taiwan

|

1 | 4.3% |

France

France

|

1 | 4.3% |

List of Film Capacitor Products

15 products are listed.

Aisetec

Film Condensor Power Electronics Film Condenser MLC Series

20+ people viewing

Film Condensor Power Electronics Film Condenser MLC Series

Aisetec

Film Condensor Power Electronics Film Condenser E Series

20+ people viewing

Last viewed: 3 hours ago

Film Condensor Power Electronics Film Condenser E Series * There are other part numbers.

Aisetec

Film Condensor Power Electronics Film Condenser MKC Series

20+ people viewing

Film Condensor Power Electronics Film Condenser MKC Series