All Categories

History

This section provides an overview for resin bearings as well as their applications and principles. Also, please take a look at the list of 12 resin bearing manufacturers and their company rankings. Here are the top-ranked resin bearing companies as of February, 2026: 1.Hartford Technologies, Inc., 2.KMS Bearings, Inc., 3.SMB Bearings.

Table of Contents

Categories Related to Resin Bearings

Engaged in research on nitride semiconductor growth using the MBE method at Waseda University Graduate School. After graduating from graduate school in 2016, he joined a non-ferrous metal manufacturer.

Engaged in equipment maintenance and engineering work at metal smelting plants. Moved to a chemical manufacturer in 2022. Engaging in similar tasks.

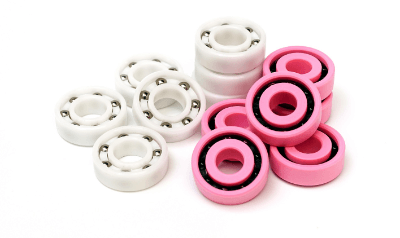

A resin bearing is a bearing fabricated from a plastic material.

A resin bearing is a bearing fabricated from a plastic material.

Resin bearings are also called plastic bearings. A bearing is a component that receives the rotating shaft of a rotating device and facilitates its rotation.

Since resin bearings are made of resin, they are lightweight and can be molded freely. They have high resistance to heat and chemicals, as well as high insulation properties, and can be used in special environments where metals are unsuitable.

Another advantage is that they do not require oil grease or other lubricants, so they require less frequent maintenance. The materials used for resin bearings are mainly synthetic resins, and since there are a wide variety of materials, the optimum material can be selected according to the application.

Resin bearings are used in a wide range of applications, from furniture and other household goods to industrial and commercial equipment. Specific applications are as follows:

Compared to metal bearings, resin bearings have superior chemical and water resistance, and are used in chemicals and underwater because they are non-conductive.

Bearings are made of metal, but resin bearings are made of resin. Resin has excellent corrosion resistance, water resistance, and insulation properties, is lightweight, and can be manufactured at low cost. These advantages are utilized in bearings, which are resin bearings.

Resin bearings are manufactured by using resin materials for sliding parts to effectively demonstrate the characteristics of resin and to design a balance between load and load. Although materials other than resin may be used for the ball portion of a resin ball bearing, the same resin material is generally used for the raceways and cage. The material of each component of the bearing can also be specified according to the intended use.

Bearings can be divided into rolling bearings and plain bearings. In terms of material, they are further classified into metal bearings and resin bearings. Although resin bearings have many advantages over metal bearings, they also have the following disadvantages.

Bearing Strength

Although the performance of engineering plastics is improving, they are not as strong as metal. Therefore, resin bearings cannot be used under heavy loads. Their low strength also results in high deformation, making them unsuitable for high-precision applications.

Heat Resistance of Bearings

Resin cannot be used in high-temperature environments because it softens at temperatures as low as 260°C, even for Teflon materials with high heat resistance. Other disadvantages include difficulty in high-precision machining, difficulty in manufacturing high-precision bearings, and susceptibility to ultraviolet rays and impact loads.

There are various types of materials used for resin bearings. For plain bearings, resin materials such as polyacetal and tetrafluoroethylene with fillers and lubricants are often used.

PEEK (polyetheretherketone), PTFE (Teflon resin), and phenolic resin are often used in rolling bearings.

PTFE has excellent heat resistance and chemical resistance, but its best features are a low coefficient of friction and low adhesion. For this reason, it is used for frying pan coatings. Although its mechanical strength is slightly inferior, it does not absorb water and does not swell with chemicals.

Phenolic resin, also called Bakelite, is characterized by its high insulating and oil resistance properties. It is also resistant to chemicals other than alkalis. Prices are relatively low compared to other materials. Many types of materials are available, including those with conductivity added by adding conductive materials and those partially made of metals.

*Including some distributors, etc.

Sort by Features

Sort by Area

KMS Bearings, Inc. is a manufacturer of plastic and AISI 316 stainless raceway, radial ball bearings. The company is located at Anaheim, California and established in 1979. Their product portfolio includes plastic radial ball bearings out of Engineering Polymers, Thin section ball bearings, 4-Points contact ball bearings, insert bearings, Skate wheel ball bearing, conveyor ball bearing and 316 stainless radial ball bearings. The company provide bearing solutions through the use of Design, Innovation and Material selections that suit the application.

Hartford Technologies was founded in 1926 in Hartford, Connecticut and is currently headquartered in the suburbs of Hartford in Rocky Hill. The ISO 9001 certified company is a manufacturer of custom bearings and assembly solutions for the automotive, agriculture, medical, and other industries. The company has four primary product categories: Custom Bearings & Components, Precision Balls, Bearing Parts, and Precision Pins, Shafts, and Rollers. The company’s manufacturing and service capabilities include prototype development, 3D modeling, technical support including inventor management, and quality control systems.

Senju Metal Industry Co., Ltd. (SMIC) is a manufacturer of soldering systems, factory automation (FA) equipment, and slide bearings based in Adachi-ku, Tokyo. The company was founded in 1938 and produces various soldering solutions and materials for applications in aerospace, electronics, automotive and medical technology. The company's specialized product lineup includes wave, laser, reflow, and micro soldering systems, as well as FA equipment like pureloy wires and spray fluxes. SMIC's client corporations include Intel, Philips, and NASA.

NTN Corporation established in 1918, is a precision machinery manufacturer that researches, develops, and sells bearings and driveshafts (CVJs) based in Japan. Their main products, bearings are essential and precision components that support rotation of machinery. They are used in different types of machinery including automobiles, wind turbines, rolling stocks, and others to support the lives of people around the world. The group has 212 bases in 34 countries around the world (118 sales bases, 72 manufacturing bases, 15 R&D bases, and 7 other bases as of the end of March 2023).

Sugatsune Europe, a company founded in the year 1930, based in Tokyo, Japan is a manufacturer and supplier of industrial components and hardware tools. Their product portfolio includes handles, pulls, knobs, hooks, brackets, shelving products, catches, latches, locks, hinges, lid support, drawer slides, wardrobe, cabinet door hardware, casters, and leveling glides. The company also provides effective solutions to residential, offices, hospitality, education, sports and cultural activities, transportation, and hospital sectors. The products are used in mainly for applications which include architecture, industries and furniture.

Takai Seiki Co. Ltd., established in 1906 and headquartered in Fujisawa City, Japan, is a manufacturer of retainers for miniature to small-sized high-precision ball bearings. The company's offerings include bearing cages (retainers), plastic bearings designed for applications requiring low friction and weight reduction, as well as machining tools and precision metal molds for various manufacturing needs. Certified with ISO 14001 and ISO 9001, the company has received accolades, including the Minister of International Trade and Industry Award in 1984.

Shinwa Kasei Corporation, established in 1986 and headquartered in Osaka, Japan, is a manufacturer specializing in cosmetics and food ingredients. Operating as a raw material trading company, the company supplies fragrances, aroma chemicals, and functional food ingredients. The company facilitates OEM production for various products, offering comprehensive support in raw material procurement, container selection, and label arrangements. The company also supports OEM production involving special ingredients such as CBD and placenta.

SMB Bearings is a supplier of bearings based in Oxon, UK. The company's product portfolio includes miniature, thin-section, stainless steel, plastic and ceramic bearings. The bearings are used in robotics, fishing reels, instrumentation, and drones. In addition, it has a lubrication facility where it offers relubrication for bearings that have problems or require special lubricants. The company delivers its bearings using international post. For heavy parcels, it uses express courier services like FedEx, Parcel force and DPD. For local deliveries, within the UK, the company uses van and motorbike courier services.

Ranking as of February 2026

Derivation Method| Rank | Company | Click Share |

|---|---|---|

| 1 | Hartford Technologies, Inc. |

37.5%

|

| 2 | KMS Bearings, Inc. |

25.0%

|

| 3 | SMB Bearings |

12.5%

|

| 4 | Sugatsune Europe |

12.5%

|

| 5 | TOK Co., Ltd. |

12.5%

|

Derivation Method

The ranking is calculated based on the click share within the resin bearing page as of February 2026. Click share is defined as the total number of clicks for all companies during the period divided by the number of clicks for each company.Number of Employees

Newly Established Company

Company with a History

*Including some distributors, etc.

*Including some distributors, etc.

| Country | Number of Companies | Share (%) |

|---|---|---|

Japan

Japan

|

5 | 50.0% |

United States of America

United States of America

|

2 | 20.0% |

Germany

Germany

|

1 | 10.0% |

China

China

|

1 | 10.0% |

United Kingdom

United Kingdom

|

1 | 10.0% |

669 products found

669 products

TAKAI SEIKI CO., LTD

890+ people viewing

Last viewed: 1 day ago

Detail ■Resin material POM (polyacetal) ■Ball SUS316/SUS304 ■Heat-resistant temperature -20°~105° ■Usage environment ・In the atmosphere ・Unde...

TAKAI SEIKI CO., LTD

830+ people viewing

Last viewed: 21 hours ago

Detail ■Resin material POM (polyacetal) ■Ball SUS316/SUS304 ■Heat-resistant temperature -20°~105° ■Usage environment ・In the atmosphere ・Unde...

TAKAI SEIKI CO., LTD

670+ people viewing

Last viewed: 1 day ago

Detail ■Resin material POM (polyacetal) ■Ball SUS316/SUS304 ■Heat-resistant temperature -20°~105° ■Usage environment ・In the atmosphere ・Unde...

TAKAI SEIKI CO., LTD

590+ people viewing

Last viewed: 4 hours ago

Detail ■Resin material POM (polyacetal) ■Ball SUS316/SUS304 ■Heat-resistant temperature -20°~105° ■Usage environment ・In the atmosphere ・Unde...

Matex Seiko Co., Ltd.

170+ people viewing

Last viewed: 1 day ago

The outer ring is made of polyacetal (Duracon, Delrin, etc.), and the inner ring and ball are plastic bearings made of steel, stainless steel, etc....

10 models listed

TAKAI SEIKI CO., LTD

550+ people viewing

Detail ■Resin material POM (polyacetal) ■Ball SUS316/SUS304 ■Heat-resistant temperature -20°~105° ■Usage environment ・In the atmosphere ・Unde...

Matex Seiko Co., Ltd.

180+ people viewing

The outer ring is made of polyacetal (Duracon, Delrin, etc.), and the inner ring and ball are plastic bearings made of steel, stainless steel, etc....

10 models listed

TOK Co., Ltd.

190+ people viewing

This is a radial ball bearing manufactured based on the extensive know-how unique to a pioneer manufacturer of resin bearings. We offer a variety o...

10 models listed

TAKAI SEIKI CO., LTD

510+ people viewing

Last viewed: 1 day ago

Detail ■Resin material POM (polyacetal) ■Ball SUS316/SUS304 ■Heat-resistant temperature -20°~105° ■Usage environment ・In the atmosphere ・Unde...

Matex Seiko Co., Ltd.

170+ people viewing

The outer ring is made of polyacetal (Duracon, Delrin, etc.), and the inner ring and ball are plastic bearings made of steel, stainless steel, etc....

10 models listed

TOK Co., Ltd.

200+ people viewing

A medium to high load bearing with a steel outer race wrapped in resin using insert molding. It can handle higher loads than the D series and has a...

3 models listed

TAKAI SEIKI CO., LTD

570+ people viewing

Detail ■Resin material POM (polyacetal) ■Ball SUS316/SUS304 ■Heat-resistant temperature -20°~105° ■Usage environment ・In the atmosphere ・Unde...

Matex Seiko Co., Ltd.

180+ people viewing

Last viewed: 3 hours ago

The outer ring is made of polyacetal (Duracon, Delrin, etc.), and the inner ring and ball are plastic bearings made of steel, stainless steel, etc....

6 models listed

TAKAI SEIKI CO., LTD

530+ people viewing

Detail ■Resin material POM (polyacetal) ■Ball SUS316/SUS304 ■Heat-resistant temperature -20°~105° ■Usage environment ・In the atmosphere ・Unde...

Matex Seiko Co., Ltd.

150+ people viewing

Last viewed: 16 hours ago

The outer ring is made of polyacetal (Duracon, Delrin, etc.), and the inner ring and ball are plastic bearings made of steel, stainless steel, etc....

10 models listed

TOK Co., Ltd.

450+ people viewing

The DT series is a JIS standard steel bearing wrapped with polyacetal (POM) by insert molding. It has excellent rotational accuracy and can reduce ...

TAKAI SEIKI CO., LTD

530+ people viewing

Last viewed: 1 day ago

Features of resin (ball) bearing C series ■Polyetheretherketone (PEEK) resin PEEK resin has excellent self-lubricating properties, impact resistanc...

Matex Seiko Co., Ltd.

160+ people viewing

Last viewed: 3 hours ago

The outer ring is made of polyacetal (Duracon, Delrin, etc.), and the inner ring and ball are plastic bearings made of steel, stainless steel, etc....

10 models listed

Fuji Electronics Co., Ltd.

360+ people viewing

■Features of bearing material resin (PEEK: polyetheretherketone) ・Although it is a very expensive thermoplastic resin, it has a rare combination o...

7 models listed

TOK Co., Ltd.

140+ people viewing

We have bearings that meet the special specifications of our customers. ■Chemical resistant bearings ・PE series ・PK series ・C series ■Heat-res...

8 models listed

TAKAI SEIKI CO., LTD

490+ people viewing

Last viewed: 22 hours ago

Features of resin (ball) bearing C series ■Polyetheretherketone (PEEK) resin PEEK resin has excellent self-lubricating properties, impact resistanc...

Matex Seiko Co., Ltd.

160+ people viewing

Last viewed: 43 minutes ago

The outer ring is made of polyacetal (Duracon, Delrin, etc.), and the inner ring and ball are plastic bearings made of steel, stainless steel, etc....

10 models listed

Fuji Electronics Co., Ltd.

320+ people viewing

■Features of bearing material resin (PEEK: polyetheretherketone) ・Although it is a very expensive thermoplastic resin, it has a rare combination o...

7 models listed

TAKAI SEIKI CO., LTD

360+ people viewing

EBB, flat type, low-priced general-purpose type. ■Details ・Products subject to RoHS Directive ・Outer ring resin: Polyacetal ・There is an escape...

TAKAI SEIKI CO., LTD

390+ people viewing

ERB, R type, [low-priced general-purpose type] ■Details ・Products subject to RoHS Directive ・Outer ring resin: Polyacetal ・There is an escape g...

TAKAI SEIKI CO., LTD

450+ people viewing

Last viewed: 1 day ago

The shaft screw is caulked to a bearing made by a Japanese manufacturer (accuracy JIS grade 0 or higher). ■Details Minimum lot 4 pieces ~ type ■H...

TAKAI SEIKI CO., LTD

350+ people viewing

Last viewed: 1 day ago

The shaft screw is caulked to a bearing made by a Japanese manufacturer (accuracy JIS grade 0 or higher). ■Details Minimum lot 4 pieces ~ type ■H...

TAKAI SEIKI CO., LTD

330+ people viewing

Last viewed: 1 day ago

A guide roller made of deep groove resin (POM) with a metal bearing lightly press-fitted and fixed with a retaining ring. Can also be used for deep...

TAKAI SEIKI CO., LTD

310+ people viewing

A guide roller made of deep groove resin (POM) with a metal bearing lightly press-fitted and fixed with a retaining ring. Can also be used for deep...

TAKAI SEIKI CO., LTD

550+ people viewing

Last viewed: 8 hours ago

Features of resin (ball) bearing C series ■Polyetheretherketone (PEEK) resin PEEK resin has excellent self-lubricating properties, impact resistanc...