All Categories

History

This section provides an overview for engineering plastics as well as their applications and principles. Also, please take a look at the list of 8 engineering plastic manufacturers and their company rankings.

Table of Contents

Categories Related to Engineering Plastics

A plastic engineering compound is an engineering compound, which is a plastic with higher performance than the plastics used in everyday products.

When plastics were first developed, industrial equipment, production parts, and tools required a certain level of strength and heat resistance, which was difficult to achieve with plastics, so metals were used.

However, during the period of rapid economic growth, there was a growing demand for lightweight materials that could be easily processed, and plastic engineering compound with various functions were developed.

Plastic engineering compounds are still very much in use today as product materials in various industries.

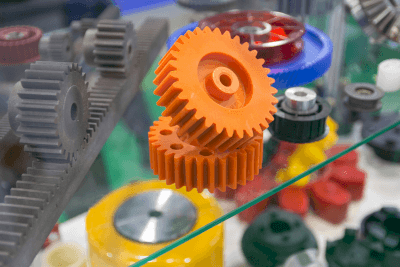

In the automotive industry, its applications include headlights, internal plastic parts, cylinders, gears, and connectors. They are also used in machinery, fans, impellers, and hydraulic tubes; and in the electrical industry, various cables, covering materials, sockets, and rotary switch parts.

The common point is that they are used in parts subject to severe wear and tear and are required to have various types of strength and heat resistance more than ordinary plastics.

Plastic engineering compounds are characterized by higher strength and heat resistance than ordinary plastics.

Although there is no definition of what features plastic engineering compounds must exhibit, it must meet the following criteria: tensile strength of 40 MPa or higher and resistance to heat of 100°C or higher.

However, there is a standard that it can withstand a tensile strength of 40 MPa or higher and heat of 100°C or higher.

Plastic engineering compounds include polycarbonate, polyamide, polyacetal, and polybutylene terephthalate.

Super plastic engineering compounds, commonly known as super engineering compounds, are plastics that are stronger and more heat resistant than plastic engineering compounds.

Super plastic engineering compounds, commonly called "super plastic engineering compounds," have a higher strength and higher heat resistance than plastic engineering compounds.

Like plastic engineering compounds, there is no clear definition, but they are generally defined as plastics with a heat resistance temperature of 150°C or higher.

Because of its increased strength and heat resistance, it is applied to parts that are subject to more intense wear and tear.

It is often used as a material for parts that accumulate damage on a daily basis, such as the inside of equipment, rather than for parts that are visible from the outside.

There are many types of plastic engineering compounds, and each has its advantages and disadvantages. However, they are all characterized by their high cost, so it is not necessary to use plastic engineering compounds when designing a product.

It is necessary to consider whether the product needs to be strong enough to use plastic engineering compounds when designing the product.

*Including some distributors, etc.

Sort by Features

Sort by Area

GUNZE Limited was founded last August 1896, in Meiji, Japan, and first started in the clothing industry. This company has an Engineering and Plastics Division established last 1958 in their Gangnam Plant and what was known as Engineering Business Plastic Center. This division of GUNZE Limited was in charge of manufacturing and selling automation equipment like copiers and printers, and functional parts used in the manufacturing processes in the industrial field. Presently, the company has two offices specializing in plastics engineering, one local affiliate office, and one international overseas affiliate office for this division located in Hong Kong.

Mitsubishi Chemical Corporation was founded in 1933 and has a head office in Tokyo, Japan. Mitsubishi Chemical Corporation provides products including chemicals, industrial gases, and health care products to customers globally. Mitsubishi Chemical Group’s performance products division manufactures and distributes. functional food materials, electronic and electrical components, specialty chemicals, and other products. Mitsubishi Chemical health care products include pharmaceuticals, drug discovery solutions, diagnostic reagents, and instruments for medical use. Mitsubishi Chemical Corporation also provides other services such as engineering, information systems, logistics, and consulting.

Asahi Kasei Corporation, founded in 1931 and headquartered in Tokyo, Japan, is a manufacturer specializing in chemicals and materials science. Its diverse product portfolio spans various industries, including polystyrene and Saran Wrap plastics, acrylonitrile for acrylic fiber production, construction materials, medical devices, and electronics. The company has a history of notable recognition, receiving The Nobel Prize in Chemistry in 2019 for the development of lithium-ion batteries. Its products plays a pivotal role in advancing materials and technologies across multiple sectors, contributing in plastics, healthcare, construction, and electronics.

Sirmax North America, Inc., was founded in 2015 and is based in Anderson, Indiana, US, is a manufacturer and supplier of resin and plastic compounds. The ISO 9001:2015 and IATF-registered company provides Biocomp, Isoter, Xter S, Sertene PP, and Isostyr used in furniture, power tools, packaging, automotive, and home appliances. The products have excellent electrical and thermal conductive features, making them ideal for electrical and electronic applications. Also, the products have thermal insulation, flame, and weather resistance, which make them suitable for the building and construction sector.

Buss AG, founded in Switzerland, in 1901 is a manufacturer of reciprocating Co-Kneader technology and compounding solutions to set the standard for heat or shear critical applications. The company's product portfolio includes PCS Compounder for Powder Coatings, LR Compounder for Foodstuffs, KX Compounder for Anode Paste and Shear and Temperature Sensitive Compounder machines. Their products are used in chemical products, powder coatings and toners, pharmaceutical products, adhesives, anode paste and foodstuffs.

Number of Employees

Newly Established Company

Company with a History

*Including some distributors, etc.

| Country | Number of Companies | Share (%) |

|---|---|---|

Japan

Japan

|

3 | 42.9% |

Italy

Italy

|

1 | 14.3% |

Switzerland

Switzerland

|

1 | 14.3% |

India

India

|

1 | 14.3% |

Thailand

Thailand

|

1 | 14.3% |

137 products found

137 products

Kotec

280+ people viewing

Last viewed: 8 hours ago

"KOTEX" has been established in various fields as a high -quality recycled recycled carbonate resin brand. We offer a wide variety of grades to sup...

3 models listed

Ensinger

370+ people viewing

Last viewed: 8 hours ago

■Summary Compression molded PAI (polyamide-imide) material using Solvay Torlon®PAI. It has the best properties among meltable thermoplastic resins,...

Yumoto Electric Co., Ltd.

350+ people viewing

Last viewed: 1 day ago

■Advantages It is more transparent than glass, has excellent weather resistance, chemical resistance, and optical properties, and is low cost. It i...

Ensinger

510+ people viewing

Last viewed: 8 hours ago

■Summary A white polyacetal copolymer (POM-C) material with no porosity. Engineering plastics used in many fields and applications. It has high str...

Yumoto Electric Co., Ltd.

350+ people viewing

Last viewed: 1 day ago

■Features ABS is a general-purpose plastic with excellent balance of mechanical properties. It is used for exterior parts because of its shiny and ...

Yumoto Electric Co., Ltd.

560+ people viewing

Last viewed: 1 day ago

■Features POM is a highly versatile engineering plastic with excellent mechanical strength, wear resistance, and chemical resistance. It is used in...

Yumoto Electric Co., Ltd.

660+ people viewing

Last viewed: 1 day ago

■Features PMP (polymethylpentene) is a high molecular weight hydrocarbon classified as a polyolefin. It is similar to PP (polypropylene) and has ne...

Ensinger

500+ people viewing

Last viewed: 8 hours ago

■Summary A white polyacetal homopolymer (POM-H) material made with Delrin® resin. It has excellent sliding properties and wear resistance. Compared...

Ensinger

520+ people viewing

Last viewed: 8 hours ago

■Summary A gray polyacetal copolymer (POM-C) material that is metal detector compatible. Contains fillers that are compatible with metal detectors ...

Ensinger

510+ people viewing

Last viewed: 8 hours ago

■Summary Polyacetal copolymer (POM-C) material containing solid lubricant. Low friction coefficient and wear resistance avoid stick-slip phenomenon...

Ensinger

530+ people viewing

Last viewed: 8 hours ago

■Summary This is an antistatic POM-C material with a surface resistivity of 1011Ω that contains an antistatic agent. Excellent wear resistance, che...