All Categories

History

This section provides an overview for gear pump as well as their applications and principles. Also, please take a look at the list of 25 gear pump manufacturers and their company rankings. Here are the top-ranked gear pump companies as of February, 2026: 1.Magister Hydraulics, 2.Northern pump, 3.Haight pump.

Table of Contents

Categories Related to Gear Pump

Engaged in research on nitride semiconductor growth using the MBE method at Waseda University Graduate School. After graduating from graduate school in 2016, he joined a non-ferrous metal manufacturer.

Engaged in equipment maintenance and engineering work at metal smelting plants. Moved to a chemical manufacturer in 2022. Engaging in similar tasks.

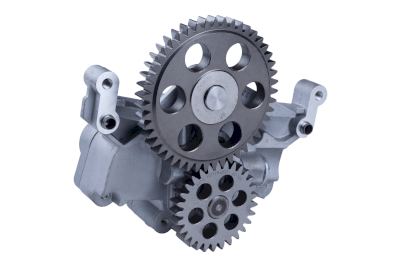

Gear Pumps are used to pump oil and other fluids by utilizing the meshing parts of gears (cogwheels).

A fixed amount of fluid is discharged per gear revolution. The discharge rate does not change much as the pressure rises, and the pump features good metering performance.

When used, the shaft end (shaft) of the Gear Pump is connected to a prime mover such as an engine or electric motor. The power of the prime mover drives the gears to push the fluid out.

One feature of the Gear Pump that is not found in other rotary positive displacement pumps is the structural advantage of being able to switch between forward and reverse rotation to change the suction and discharge directions. Some products can switch between forward and reverse rotation, which is useful when switching directions when transferring fluids.

Pump Gears are widely used in industry.

They are used in equipment with hydraulic systems, such as hydraulic excavators, forklifts, and agricultural machinery. Liquids to be pumped include oils, resins, paints, adhesives, and solvents.

Since there are few points of contact other than the gear and casing, and disassembly is relatively easy, they are also used in the chemical, food, and pharmaceutical industries. They can also be used for liquids containing a certain amount of solids.

A Gear Pump consists of gears, casing, discharge and suction ports, and seals.

The gear consists of an internal gear and an external gear. The pump construction differs depending on the mounting point and number of gears. Liquid entering through the suction port is pressurized by the gears and casing and is discharged through the discharge port.

Oil seals or mechanical seals are used to seal the shaft of the Gear Pump. An oil seal uses the seal's own elasticity to ensure a tight seal, while a mechanical seal uses the force of a coil spring to ensure a tight seal.

In general, mechanical seals have fewer leaks and are easier to maintain. However, maintenance frequency and equipment life can be improved by designing in consideration of the fluid type, pump specifications, and operating conditions. In addition, periodic checks are necessary to ensure that proper clearances are maintained and that there are no changes in leakage.

A Gear Pump is a mechanism that pumps liquid through a gap between gears, and these pumps that sequentially pump a fixed volume are called positive displacement pumps. Gear Pump is a type of rotary positive displacement pump, and similar rotary positive displacement pumps include vane pumps and screw pumps. In a broad sense, rotary pumps are a generic term for all rotary positive displacement pumps. As such Gear Pumps can also be called a type of rotary pump.

In practice, the designation differs depending on the application. In particular, oil rotary pumps for vacuuming are often called rotary pumps. The mechanism of oil rotary vacuum pumps can be of the vane type, cam type, or oscillating piston type.

In addition, there are two types of Gear Pumps: circumscribed gear type and internal gear type.

Two external gears are mounted next to each other inside the pump. When a prime mover such as an engine or an electric motor operates, the shaft of the pump rotates to take in fluid from the pump suction port.

In this type of pump, a small gap is created when the adjacent gears rotate. The gap is filled with fluid, which flows along the inner circumference of the pump and finally flows from the discharge port.

One internal gear and one external gear are mounted inside the casing inside the pump. The internal contact type consists of an internal gear and an external gear with one less tooth. When the external gear is rotated by the drive shaft, the external gear rotates along with the internal gear. This rotation pushes the fluid out through the discharge port.

There are various causes of gear pump failure, but cavitation and air biting are the most common.

Cavitation is a phenomenon that occurs when a partial pressure difference occurs in the casing and the pressure drops to the saturated vapor pressure of the liquid, and is one of the causes of insufficient gear pump discharge pressure. When this phenomenon occurs, a large impact pressure is generated at the time of bubble extinction. This impact pressure causes abnormal noise, and if it continues, vibration will occur, causing failure.

Countermeasures against cavitation include enlarging the pipe inner diameter, shortening the suction side piping, and making the pump suction conditions as push-in as possible. These should be considered at the equipment design stage.

Air bite is a phenomenon in which air is sucked into the pump, causing air to accumulate inside, leading to a decrease in discharge pressure and flow rate. Countermeasures include installing the pump below the fluid level, reducing the number of bends in the piping, and avoiding downward sloping piping. Care should be taken when changing the layout of equipment.

*Including some distributors, etc.

Sort by Features

Sort by Area

Magister Hydraulics is an ISO 9001:2015-certified manufacturer of hydraulic cylinders and related components established in 1998 and located in Belleville, New Jersey, USA. The company primarily offers hydraulic power units, pumps, and valves in a range of operational capacities for hydraulic systems. It also offers single- as well as double-acting hydraulic cylinders, and hydraulic hose kits and corresponding adaptors for equipment connectivity or cross-compatibility. The company’s products are commonly used by clients in agricultural, construction, and waste management operations.

Northern pump, established in 1929 and based in Grantsburg, WI, is a manufacturer of high Pressure heavy duty gear pumps. The company specialises in manufacturing and custom building heavy duty positive displacement gear pumps that can perform in high pressure and severe applications. These pumps are utilised in industries such as oil, gas, chemical, food & beverage. The company provides custom engineered gear pump for specific applications through their modular design. It also provides pump refurbishment, having a team of mechanics to recondition the pump back to its original condition.

Haight Pump in Evansville, WI, since 1932, has been a manufacturer of bed plate assemblies and pumps for application in refrigeration, lubrication, filtration, fueling, injection, and thermal systems. The company offer various pumps, including internal gear, custom gear, centrifugal, and external gear pumps manufactured from materials such as iron, stainless steel, and brass. The company is a subsidiary of Baker Manufacturing Company, LLC, has a management system that is ISO 9001 certified, and is listed under NSF Products and Services.

Gear Motions is a custom gear manufacturer for global OEMs. Founded in 1960 and headquartered in Syracuse, New York, with additional locations in Buffalo and Oliver Springs, Gear Motions has grown significantly since its founding. Initially a ten-man company serving primarily in the New England Area, they have since expanded through acquisitions of companies such as Nixon Gear, Gear Supply and Broaching, and Pro-Gear Co Inc. The company provides custom gear solutions for various custom and precision applications, offering products such as ground helical gears, spur gears, pump gears, timing pulleys, shafts and splines.

Clark Solutions, established in 1962 and headquartered in Massachusetts, United States, is a supplier and distributor of fluid handling products. The company offers a wide range of products, including pumps, valves, and instruments, among others, serving industries such as chemical processing, pharmaceuticals, and food and beverage. These industries rely on the company's solutions for precise fluid control in tasks like transferring, mixing, and flow control, ensuring the accuracy and efficiency of operations.

Fischer Process Industries, founded in 1956 in Loveland, Ohio, USA, is a manufacturer of industrial fluid handling equipment. The product range includes pumps, valves, mixers, and instrumentation equipment that offer efficient fluid handling solutions, ensuring precise control, improved productivity, and reduced downtime for industrial processes. The pumps offer proficient fluid transfer, while their valves enable accurate flow control. Mixers ensure thorough blending and dispersion of liquids and solids. The instrumentation equipment provides accurate monitoring and measurement of fluid processes. These products find applications in industries such as chemical, food and beverage, pharmaceuticals, and water treatment.

FLUID TECH SYSTEMS, founded in 1993 and headquartered in Gujarat, India, is a manufacturer and supplier specializing in rotary gear pumps. The company's product portfolio includes bitumen-jacketed gear pumps, oil gear pumps, and rotary twin gear pumps. These products are used in various industries, including road construction, mining, and the oil and gas industry. The company is ISO 9001:2015 and ISO 9001:2008 certified for its quality management system and serves more than 40 countries, including the United States, India, and New Zealand.

Iwaki Co., LTD was founded in 1956 in Japan. Iwaki is a producer of pumping products and water quality control systems and is the world’s leading pump manufacturer maintaining a global sales and distribution network. Serviced industries include semiconductors, water treatment, surface treatment, food processing, paper production, chemicals and pharmaceuticals.

The Japan Steel Works, LTD., founded in Tokyo, Japan, in 1907 is a manufacturer of plastic machinery products and plastic molding machines, as well as IT and defense products. The company's product portfolio includes Spinning Extruders, Film and Sheet Manufacturing Equipment, Polyolefin Pelletizers, Magnesium Injection Molding Machines and hot presses. The company serves markets including Automotive and Electric Vehicles, Renewable Energy and Energy Storage and Electronics and IT Infrastructure. The company has a national distribution network and a customer support center.

Shanghai Cixi Instrument Co., Ltd., established in 1986 and located in Shanghai, China, is a manufacturer of automation and process control equipment such as flowmeters, level meters, display instruments, analyzers, test equipment, and pumps. The meters include oil oval gear flowmeters, ultrasonic water meters, level transmitters, float level controllers, and radar level meters. Pressure products are transmitters, sensors, pressure switches, and controllers. It also produces paperless recorders, test pens, ultrasonic flaw detectors, temperature transmitters, and float-level switches.

Gear pump Manufacturing, located in Cape Town, South Africa, has been a manufacturer of SAE-mounted cast iron hydraulic pumps and associated commercial components since 1985. The products are flow dividers, valves, and pumps such as bearing gear, PTO dump, bushing gear, and PTO gear pumps used in agriculture, construction, mining, and marine industries. The company holds ISO 9001:2015 and ISO 14001:2015 certification and has expertise in precision casting, gear set manufacture, custom hydraulic pump design, thrust plate manufacture, and pump rebuilding.

Fluid-o-Tech, established in 1948, is a manufacturer of displacement pumps and systems for fluid handling applications, with its headquarters in Milan, Italy. Its product range comprises various pumps, including external and internal gear pumps, solenoid pumps, and peristaltic pumps. Moreover, the company provides valves and sensors for industries such as automotive, foodservice, industrial, and healthcare. Notably, the company has attained the UNI CEI EN ISO 13485:2021 certification for Quality Management Systems - Requirements for Regulatory Purposes in the medical technology market.

Kracht GmbH, established in 1911 and headquartered in Werdohl, Nordrhein-Westfalen, Germany, is a designer and manufacturer of liquid flow equipment and systems. The company's products include gear pumps, flow measurement, and hydraulic valves. These products are used in agricultural machinery, food processing systems, and chemical processing systems. It also works with original equipment manufacturers to produce custom parts and components and complete turnkey systems. It serves sectors that include offshore oil drilling, new energy, and pharmaceuticals.

KOSHIN LTD., established in 1948 in Kyoto, Japan, is a manufacturer specializing in pumps and related products. Its product offerings encompass diverse pumps such as diesel engine pumps for construction, high-pressure pumps for agriculture, semi-trash pumps for construction, clear water pumps for gardening, and grinder pumps for industrial applications. These pumps serve various purposes, including powering construction machinery, irrigating agricultural fields, managing debris-laden water at construction sites, maintaining garden water features, and handling industrial waste efficiently. The company distincts on enhancing convenience, solving problems with technology, and improving social infrastructure.

Camel Precision Co., Ltd. CML, since 1981, is a manufacturer and supplier of hydraulic valves and hydraulic pumps with its headquarters in Taichung City, Taiwan. The company’s product portfolio is composed of variable & fixed displacement vane pumps, internal & external gear pumps, high-back pressure & high-flow type solenoid valves, conventional valves, and modular valves. They also offer various accessories for their valves and pumps such as filters, oil coolers, diaphragm accumulators, air-cooled radiators, and oil-electric pressure switches. These products are used in various machinery industries including shoemaking, rubber & plastic, machine tools, and agriculture.

Nikkora Eiko, a company founded in 1969 and based in Tokyo, Japan, is a manufacturer and supplier of pumps and water treatment technologies. The company's product portfolio includes magnetic drive pumps, bellows pumps, and diaphragm pumps BX series. These products are used in various sectors including power generation, wastewater management, and the food and beverage industry. The company is ISO 9001:2015 certified and has a sales network in various countries, including the United States, China, and the United Kingdom.

Teral Inc., founded in 1918 and headquartered in Fukuyama, Japan, is a manufacturer and seller of pumps, fans, and environmental systems. Its product portfolio includes air conditioning fans, dust collectors, garbage disposal systems, coolant pumps, and firefighting pumps. The products are used in several industries, including fishery, livestock, agriculture, automotive, and shipbuilding. The company is ISO 9001 and ISO 14001 certified and began manufacturing air blowers under the Kyokuta brand in 1956. In 1971, it started developing and selling total heat exchangers, and in 1975, it developed the industry’s first water supply unit.

TSUKASA ELECTRIC CO.,LTD was founded in 1969 in Japan. Tsukasa primarily develops two types of components. First are motors, which are used in vending machines, ATM machines, and amusement machines. These also include gear motors, gear pumps, linear motion units, and rotary actuators. Secondly, Tsukasa develops tube pumps which are generally mounted to the aforementioned motors.

IDEX India is a company established in 1987, situated in Mumbai, India, and specializes as a supplier of diverse range of quality fluid and metering solutions. The company’s product lineup encompasses precision dispensing pumps, fluidic systems, and engineered products catering to industries such as healthcare, food and beverage, and industrial sectors. With the capability of assuring modernization, IDEX India plays a pivotal role in delivering quality solutions that ensure accurate and efficient fluid handling, meeting the intricate needs customers.

Ranking as of February 2026

Derivation Method| Rank | Company | Click Share |

|---|---|---|

| 1 | Magister Hydraulics |

18.5%

|

| 2 | Northern pump |

8.2%

|

| 3 | Haight pump |

7.0%

|

| 4 | Fischer Process industries |

5.5%

|

| 5 | Gear Motions, Inc. |

5.4%

|

| 6 | Fluid-o-Tech |

4.8%

|

| 7 | Gear pump manufacturing |

4.5%

|

| 8 | Clark Solutions |

4.2%

|

| 9 | KRACHT GmbH |

4.1%

|

| 10 | FLUID TECH SYSTEMS |

3.9%

|

Derivation Method

The ranking is calculated based on the click share within the gear pump page as of February 2026. Click share is defined as the total number of clicks for all companies during the period divided by the number of clicks for each company.Number of Employees

Newly Established Company

Company with a History

*Including some distributors, etc.

*Including some distributors, etc.

| Country | Number of Companies | Share (%) |

|---|---|---|

United States of America

United States of America

|

6 | 33.3% |

Japan

Japan

|

6 | 33.3% |

Taiwan

Taiwan

|

2 | 11.1% |

India

India

|

1 | 5.6% |

China

China

|

1 | 5.6% |

South Africa

South Africa

|

1 | 5.6% |

Italy

Italy

|

1 | 5.6% |

125 products found

125 products

Sun Ten Consulting

740+ people viewing

Last viewed: 11 hours ago

The Extreme Series easily pumps difficult liquids, from colored ink to strawberry smoothies. With a flow rate of 1,500 to 5,000ml/min, it can accom...

Hiroshima Seiki Co., Ltd.

410+ people viewing

Last viewed: 6 hours ago

Not only can it be used to quickly evacuate to a safe location as soon as disaster information is issued to prevent oil spills due to factory flood...

Ryu Manufacturing and Automation Gears Co., Ltd.

370+ people viewing

By installing a DEX gear pump on an extrusion molding line, pressure fluctuations at the die can be minimized and resin temperature rise can be sup...

Kyowa Finetech Co., Ltd.

700+ people viewing

Last viewed: 1 day ago

A gear pump that can handle various viscous fluids. This is a precision gear pump that can achieve stable discharge accuracy even when there are f...

Daido Machine Manufacturing Co., Ltd.

720+ people viewing

Last viewed: 4 hours ago

The Daido internal gear pump G series has a proven track record in liquid transfer in the chemical industry and other industries, and is highly rat...

Daido Machine Manufacturing Co., Ltd.

370+ people viewing

The Daido internal gear pump SE series is a series created as a result of many years of research and development, based on the G series, which has ...

Sun Ten Consulting

660+ people viewing

The Optima series is specially designed for small package sizes. Although it has the same structure as the Extreme series, the overall length is mu...

Ryu Manufacturing and Automation Gears Co., Ltd.

450+ people viewing

By installing a DEX gear pump on an extrusion molding line, pressure fluctuations at the die can be minimized and resin temperature rise can be sup...

Daido Machine Manufacturing Co., Ltd.

400+ people viewing

Equipped with an independently developed taocroid tooth profile, it has excellent performance, and is produced at Daido Hailong Machinery (Shanghai...

Tomei Engineering

200+ people viewing

Last viewed: 15 hours ago

feature ■ Lightweight The case is lightweight due to a special aluminum alloy. In addition, the total length dimension is the same as the series, ...

8 models listed

Sun Ten Consulting

580+ people viewing

Last viewed: 1 day ago

Durable, reliable, chemically inert, quiet, leak-free, the silencer series has everything you need in a gear pump. Simplify plumbing with multiple ...

Ryu Manufacturing and Automation Gears Co., Ltd.

380+ people viewing

Last viewed: 1 day ago

By installing a DEX gear pump on an extrusion molding line, pressure fluctuations at the die can be minimized and resin temperature rise can be sup...

Kyowa Finetech Co., Ltd.

570+ people viewing

Last viewed: 1 hour ago

Excellent pressure resistance and stable discharge! Achieves high viscosity, high pressure, high accuracy, and highly durable fixed quantity dispen...

Daido Machine Manufacturing Co., Ltd.

510+ people viewing

The Daido Mag Pump is an internal gear type sealless pump that combines a Taocroid tooth pump and a magnetic coupling using rare earth cobalt magne...

Sun Ten Consulting

600+ people viewing

Last viewed: 19 hours ago

The Precision Series is specialized for applications that require fast and accurate weighing and dispensing. The piston shape separates the outlet ...

Ryu Manufacturing and Automation Gears Co., Ltd.

390+ people viewing

By installing a DEX gear pump on an extrusion molding line, pressure fluctuations at the die can be minimized and resin temperature rise can be sup...

Ryu Manufacturing and Automation Gears Co., Ltd.

370+ people viewing

By installing a DEX gear pump on an extrusion molding line, pressure fluctuations at the die can be minimized and resin temperature rise can be sup...

Nippon Mekuman Co., Ltd.

610+ people viewing

■Product characteristics Gear pump KF is used to pump various fluids. Due to its modular principle, it can be assembled according to requirements a...

Ryu Manufacturing and Automation Gears Co., Ltd.

340+ people viewing

By installing a DEX gear pump on an extrusion molding line, pressure fluctuations at the die can be minimized and resin temperature rise can be sup...

Nippon Mekuman Co., Ltd.

320+ people viewing

Last viewed: 15 minutes ago

High pressure gear pumps can be used anywhere the power generated by high pressure oil is required.

2 models listed

Ryu Manufacturing and Automation Gears Co., Ltd.

410+ people viewing

Last viewed: 13 hours ago

Ryu M&AG handles medium viscosity pumps mainly for 1,000cP to 100,000cP as gear pumps for general industrial use, and provides them at low prices. ...

Yagyu Shokai Co., Ltd.

440+ people viewing

Last viewed: 6 hours ago

■Features ・A small gear pump made of chemical-resistant engineering plastic. -Equipped with an electronically controlled rotation speed control ci...

Nippon Dainisco Co., Ltd.

600+ people viewing

Last viewed: 16 hours ago

PSI's Extrusion Gear Pumps (EGPs) provide superior metering control for polymer and hot melt extrusion and container applications. The pump efficie...

Nippon Dainisco Co., Ltd.

490+ people viewing

Last viewed: 13 hours ago

The PSI Fluoropolymer Gear Pump (FGP) is a pump designed to meet the manufacturing requirements of fluoropolymer moldings such as FEP, ETFE, PTFE, ...

Maruhachi Pump Manufacturing Co., Ltd.

690+ people viewing

This pump uses a "complete single-point contact gear" that does not cause entrapment and does not generate bubbles. We offer gear pumps with low no...

Maruhachi Pump Manufacturing Co., Ltd.

700+ people viewing

Last viewed: 1 day ago

This pump uses a "complete single-point contact gear" that does not cause entrapment and does not generate bubbles. We offer gear pumps with low no...

Maruhachi Pump Manufacturing Co., Ltd.

300+ people viewing

Last viewed: 11 hours ago

This pump uses a "complete single point contact gear" that does not cause entrapment and does not generate bubbles. We provide a gear pump that pro...

3 models listed

Maruhachi Pump Manufacturing Co., Ltd.

260+ people viewing

This pump uses a "complete single-point contact gear" that does not cause entrapment and does not generate bubbles. We offer gear pumps with low no...

3 models listed

Maruhachi Pump Manufacturing Co., Ltd.

780+ people viewing

This pump uses a "complete single-point contact gear" that does not cause entrapment and does not generate bubbles. We offer gear pumps with low no...

TAIYO Co., Ltd.

440+ people viewing

Last viewed: 16 hours ago

A compact set of electric motor and internal gear pump. ■Features Adopts an internal gear pump with a special tooth profile (hypocycloid). Further...