All Categories

History

This section provides an overview for flowmeters as well as their applications and principles. Also, please take a look at the list of 160 flowmeter manufacturers and their company rankings. Here are the top-ranked flowmeter companies as of July, 2025: 1.Tactical Flow Meter, 2.TA Instruments, 3.Hilman Rollers.

Table of Contents

Categories Related to Flowmeters

Postdoctoral researcher, conducting research on the production of cathode composite particles for solid-state batteries in the Equipment Engineering Group of Osaka Prefecture University.

Belongs to the Resource and Energy Recycling Laboratory, Nagaoka University of Technology, and conducts research on the development of DDR-type zeolite membranes for CO2 separation and the capture of CO2 from digestion gas generated from sewage treatment plants.

https://researchmap.jp/eiji-hayakawa

Thesis

https://doi.org/10.3390/membranes11080623

http://www.ijcea.org/index.php?m=content&c=index&a=show&catid=109&id=1177

https://www.sciencedirect.com/science/article/abs/pii/S1387181119305529?via%3Dihub

https://www.sciencedirect.com/science/article/abs/pii/S138358661833154X?via%3Dihub

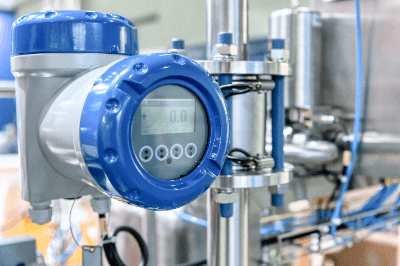

A Flowmeter is a device used to measure the volumetric or mass flow rate of a fluid flowing through a pipe.

Many measurement principles have been developed to properly measure various types of flow depending on conditions such as pressure and temperature. Flow types include gas, liquid, and multiphase flows.

Some products can be installed outside of the piping to measure flow. However, many flowmeters are designed to be installed inside the piping for flow measurement. Therefore, the installation of a flowmeter should be carefully considered either before the piping is installed or during the design phase.

Flowmeters are widely used in manufacturing where fluids are used, including chemical and petroleum plants, automotive, semiconductor, pharmaceutical, and food industries.

More than ten (10) different operating principles have been developed for flow meters, and the appropriate flow meter must be selected according to the fluid being handled.

Flowmeters installed in pipes can disrupt the flow. Therefore, the selection should be based on consideration of the extent of this impact. The frequency, time, and cost of maintenance should also be considered.

The following is a brief introduction to the types of flowmeters and their respective mechanisms, principles, and advantages.

A positive displacement flowmeter consists of a pipe with the same inside diameter as the piping to be measured, a rotor, and a rotation detector. The fluid flowing through the pipe rotates the rotor, and the flow rate is measured by detecting the rotation speed.

The structure is simple and highly accurate, but the use of gears can lead to problems such as entanglement.

It is used for for measuring the flow rate of fluids like fuel oil and lubricating oil, which have relatively stable densities. Due to its high accuracy, it is well-suited for applications such as fuel oil trading.

The Coriolis flowmeter consists of two U-tubes, a vibrating machine, and a force sensor. The Coriolis flowmeter utilizes the principle of Coriolis force, in which two oscillating U-tubes with fluid flowing through them generate forces in opposite directions to each other.

While the Coriolis flowmeter has the disadvantage of being long due to its measurement principle, it does well at directly measuring mass flow. It has high accuracy and responsiveness, and is widely used when the density of a fluid is also to be measured at the same time.

On the other hand, it is less effective in environments with vibrations or when measuring fluids that contain bubbles.

An ultrasonic flowmeter consists of an ultrasonic generator and a measuring instrument. The flow rate is calculated by measuring the propagation time of ultrasonic waves and the Doppler effect caused by the reflection of ultrasonic waves. This flowmeter can measure from the outside of the piping.

It has the advantage of non-contact fluid flow measurement, allowing the flowmeter to be retrofitted onto existing piping. It can also be installed cost-effectively, even on large-diameter piping.

However, it is not well-suited for applications that require highly accurate flow measurement due to errors caused by factors such as pipe wall thickness.

Electromagnetic flowmeter calculates the flow rate by measuring the electromotive force generated by the coil component within the device. This electromotive force is influenced by the velocity of a magnetic material placed inside the fluid to be measured.

Many of these meters do not need to be installed in the pipe, and are used when maintenance costs for in-pipe flowmeters, such as those used for contaminated water, are high.

Electromagnetic Flowmeter is used to measure the flow rate of slurry mixed with solids because it has no moving parts and does not obstruct the flow of fluid. However, it cannot measure non-conductive fluids, such as oil.

A thermal flowmeter consists of two temperature sensors and a heater. It calculates the flow rate by measuring the difference between the fluid's temperature before and after it is heated by the heater. This measurement is then converted into a flow rate. The thermal flowmeter is known for its ability to handle a wide range of temperatures.

Thermal flowmeter can measure corrosive gases since it is a non-contact gas flowmeter. In addition, there is almost no pressure loss and mass flow rate can be measured. However, it may not be suitable for the measuring theflow rate of gases that already contain contaminants.

In an area flowmeter, a float within a vertically tapered tube interrupts the flow from bottom to top, resulting in a pressure difference before and after the float. The meter rests at a position where the weight of the float and the force of the pressure difference are balanced. By reading this position, the flow rate can be determined.

It is used to measure the flow rate of liquids, gases, purge fluids, and more. Its straightforward construction makes it cost-effective, although it does not provide very high measurement accuracy.

The turbine flowmeter is positioned within the flow and calculates the volumetric flow rate based on the number of revolutions of the impeller. It utilizes the fact that the rotational speed of the impeller, which has an axis parallel to the flow, is directly proportional to the flow velocity.

The lightweight design allows for a high degree of freedom in installation. Due its lightweight, inexpensiveness, excellent repeatability, and responsiveness, it is well-suited for measuring large volumes of fluid. However, it has a short-service life due to bearing deterioration.

Differential pressure flowmeter uses an orifice to create a pressure loss and measures the flow rate by utilizing the pressure difference between the primary and secondary sides.

It is characterized by its low-cost and wide range of applications. Actual flow calibration is not required.

The Karman vortex flowmeter consists of an obstacle designed to generate Karman vortex and a vortex measuring instrument. The flow rate is calculated by measuring the Karman vortex.

Karman vortex is a regular vortex generated in the wake of an obstruction.

Karman vortex flowmeter can measure a wide range of fluids since there are no mechanical operating parts or electrodes. However, it cannot be used in high-vibration environments due to the length of straight pipe required and the possibility of malfunctions caused by vibration.

It is used to measure steam and clean water.

A vortex flowmeter is a flowmeter that uses the Karman vortex. A Karman vortex is an alternating sequence of regular vortices that occur downstream of an object (vortex source) placed in the fluid flow.

A flow cell flowmeter is a type of orifice flowmeter that generates differential pressure by installing an orifice in the piping through which water or air flows and measures the differential pressure using a float installed in the tributary stream.

*Including some distributors, etc.

Sort by Features

Sort by Area

TA Instruments, established in 1963, is a manufacturer of machinery for thermal analysis, rheology, microcalorimetry, and mechanical analysis, headquartered in Delaware, USA. Their product range includes rheometers, thermal analyzers, calorimeters, dilatometers, and viscometers which are used in various industries such as biopharmaceuticals, electronics, and pharmaceuticals. Their products provide crucial insights into material properties, enabling quality control, optimizing processes, and facilitating product development. TA Instruments ensures quality and holds certifications such as ISO 9001 for quality management.

Taylor Dynamometer, an American company founded in 1929 and headquartered in Milwaukee, Wisconsin, is a manufacturer and supplier of dynamometer systems. The company’s product portfolio includes water brake engine dynamometers, hydraulic test centers, and electric motor testing systems. These products find applications in various industries, including construction, transportation, and the oil and gas industry. The company provides services including maintenance, installation, and customization, and it exports its products to various countries including the United Kingdom, China, and the Dominican Republic.

Yaskawa America, Inc. - Drives & Motion Division, founded in 1967 and located in Waukegan, Illinois, is a manufacturer of AC inverter drives, servo and motion control, and robotic automation systems. They offer a range of products that include industrial AC drives, HVAC drives, machine controllers, gear motors, and articulated robots. Yaskawa's products are used for precise control, automation, and motion capabilities, enhancing efficiency and productivity in diverse manufacturing, industrial, and automation processes. These applications include factory automation, CNC machining, material handling, packaging machinery, and HVAC systems. The company is also ISO 9001:2015 certified.

Advance Lifts, Inc. is a Saint Charles, Illinois-based manufacturer of load lifting and transfer solutions for industrial applications. The company was founded in 1974, with a network of distributing partners across North America supplying retail chains, government agencies, and mass manufacturers — as well as client companies in the automotive, recycling, and waste management sectors. The company produces various loading and transfer mechanisms including container dumpers, industrial turntables and tilters, dock lifts, reciprocal conveyors, and multistage lifts. Advance Lifts, Inc is ISO 9001:2015 certified, and equipped to handle design as well as engineering operations for custom equipment.

McCrometer Inc., founded in 1955 and headquartered in Hemet, California, is a manufacturer of flow meter solutions and is among the Veralto Water Quality companies. It serves customers’ needs in liquid, gas, and steam fluid processes in diverse markets such as agriculture irrigation, aerospace, and pharmaceutical. The company can test flow meters ranging from ½ to 72 inches in diameter. The company’s Porterville flow lab is one of the largest volumetric test facilities belonging to a meter manufacturer, and it offers accuracy and calibration from 3 to 48-inch diameter with the accuracy assured by ISO 17025 Accreditation.

Macnaught USA, Inc. was founded in Australia in 1948 as a manufacturer of robust industrial flow meters for clean process liquids. Its product line encompasses equipment for fluid handling, fuel transfer, grease, oil handling, including Macnaught OIL Equipment, Macnaught BOP (Battery Operated Oil Pumps), lubrication equipment, high-flow fuel transfer pump systems, retractable hose reels, and Industrial Flow meters, among other offerings.The company supplies equipment for coal handling, lubrication, hose reels with motors, flow meters, and various other products, with its flow meters and fluid handling equipment serving the agriculture, mining, and vehicle repair industries.

Badger Meter, Inc. was founded in 1905 and based in Milwaukee, Wisconsin. Badger Meter is a manufacturer and marketer of flow measurement, quality, control, and communication solutions in the United States and globally. Badger Meter serves several industries including water treatment, water distribution, aviation, concrete production. Badger Meter offers utility water solutions and commercial & industrial solutions product segments. Together they include products such as meters, software, diagnostics, and quality monitoring.

ifm efector (ifm) is a subsidiary of ifm electronic, founded in Germany in 1969. ifm has developed, manufactured and marketed sensors and controls technology to industries that include assembly and robotics, automotive, material handling, metal forming, mobile equipment, plastics, and food and beverage. Ifm produces sensors, condition monitoring equipment, image processing, safety technology, industrial communication, IO-link, systems for mobile machines, displays, software, connection technology, voltage supplies, as well as other accessories.

Sierra Instruments, founded in 1971, is a manufacturer of flow measurement solutions for the gas, liquid, and steam sectors. The product line has incline or insertion mass flow controllers/meters, level switches, flow conditioners, calibration systems, and mass flow sensors. The company provides digital communication protocols to automate flow meters and software upgrades & improvements. The company in Monterey, CA, offers a 12-month limited warranty, is ISO 9001 registered, and is a member of the TASI group.

Walchem, Iwaki America, Inc., expanded and incorporated in 2013 with headquarters in the USA, is a manufacturer of online analytical instruments and electronic metering pumps used for wastewater systems in swimming pools and spas. The company's tangible product line includes treatment controllers to monitor and regulate various aspects of water treatment processes and water treatment sensors and accessories used to detect chemicals and impurities in water bodies. It also provides cloud-based software tools and instrumentation that integrate with its products. The company offers its know-how to assist clients with customized and full-scope chemical control systems.

OMEGA Engineering Inc., founded in Norwalk, CT, in 1962 is a manufacturer of products used to measure temperature and humidity, flow and level, and pressure. The company's product portfolio includes thermocouple probes and assemblies, pressure gauges and switches, and air velocity measurement systems, wireless systems and portable optic sensors. The company serves markets including Automotive and Electric Vehicles, Renewable Energy and Energy Storage and Electronics and IT Infrastructure. The company also offers customer services that include support, custom research projects and customized services.

ERDCO Engineering Corp. is a manufacturer of flow measurement instruments established in 1946 and based in Evanston, Illinois, USA. The company specializes in instruments for measuring liquids and steam in industrial processes. These products include flow switches for flow or no-flow indication, flow rate meters for direct reading of flow rate, and flow totalizers for providing total flow or batch control. The company’s products are mainly used in the industrial processing sector, with additional applications in food and beverage processing and wastewater management.

Xylem Inc. was incorporated in 2011 and is headquartered in Washington, District of Columbia. Xylem engages in the design, manufacture, and servicing of engineered products and solutions for the water and wastewater applications across global markets. Xylem operates through three segments: water infrastructure, applied water, and measurement & control solutions. Xylem’s water infrastructure segment offers numerous products such as water pumps, filtration, disinfection, and biological treatment equipment. Xylem’s applied water segment distributes pumps, valves, heat exchangers, controls, and dispensing equipment systems. Xylem’s measurement & control Solutions segment offers devices such as smart meters, networked communication devices, data analytics, test equipment, controls, sensor devices, and software and managed services.

Endress+Hauser Group Services AG, established in 1953 with headquarters in Reinach, Switzerland, is a global manufacturer, distributor, and integrator of industrial process solutions for flow, level, pressure, temperature, and digital communications. The company's product line includes portable pH meters, Raman spectroscopic analyzers, electromagnetic flowmeters, hydrostatic level sensors, and application managers (devices). These products are available individually, and custom-process manufacturing turnkey systems can be commissioned. The company serves industries including food processing, chemical processing, agriculture, mining, and energy.

Flow Systems Inc., established in 1986, is an American manufacturer located in Berthoud, Colorado, specializing in flow measurement components and test systems. The company offers a range of standard flow controllers, supported by computer software for test automation and data management. It also produces test stands for applications such as vehicle body leakage, mass air flow sensors, and gas turbine air systems. Flow Systems provides on-site calibration, custom test stands, and field engineering services. The company operates across various industries including aerospace, energy, and oil and gas, with a presence in regions like the United Kingdom, Europe, and China.

Universal Flow Monitors Inc was established in 1963 as a manufacturer of flow measurement solutions, but since 2021 it was acquired by Dwyer Instruments and is based in Michigan. The company produces a wide range of flow monitoring and control devices, including flowmeters, flow switches, and flow transmitters. Their products cater to various industries such as oil and gas, chemical processing, water and wastewater, pharmaceutical, and manufacturing. These industries benefit from Universal Flow Monitors' products by ensuring optimized and accurate measurement of fluid flow, helping to maintain regulatory compliance.

Fluke Corporation, established in 1948 and based in Everett, Washington, is a manufacturer of precision calibration solutions. The company provides instrumentation and software tailored for electrical, temperature, pressure, flow, and RF measurements. These instruments are commonly utilized in calibration laboratories and process measurement instrument shops globally, including National Metrology Institutes. The companu also offers services and software solutions for assisting organizations in effectively managing assets and operations, with support ranging from individual to enterprise-level integration.

Headquartered in Everett, Washington, Fluke is an American-born company operating since 1948. Fluke offers a variety of testing equipment including digital multimeters, thermal cameras, solar PV testing equipment, thermometers, oscilloscopes, leak detection devices, as well as testing-equipment related accessories. Fluke offers direct online sales.

TacticalFlowMeter manufactures Gas and Liquid flow meters for industrial and laboratory use. We provide top of the line MAG meters, Vortex Mass Flow Meters, Coriolis Mass Flow Meters, Thermal Mass Flow Meters, Clamp on Ultrasonic Flow Meters, inline Ultrasonic Flow Meters, Turbine Flow Meters as well as modulating ball valves.

Sierra Instruments, Inc. was established in 1973 and has its headquarters in California, United States. The company is a manufacturer of flow instruments for nearly every liquid, gas, and steam application, with locations in Europe and China. Sierra's range of flow instruments includes immersible thermal mass flow meters, vortex flow meters, and thermal mass flow controllers for various applications. The company's flow controllers have applications across global industries such as oil and gas, energy management, biotech, and aerospace.

Superior Products, LLC is based in Cleveland, Ohio. Superior Products is a manufacturer and logistical provider of gas management systems and parts for customers globally, with many customers in industrial, medical, and specialty gas management markets. In addition Superior Products is certified ISO 9001:2008 Superior’s product offerings differ according to industry needs, with parts including couplers, valves, other connectors, gas mixers, and more. Additionally, Superior Products can custom engineer products to custom specifications in stainless steel, aluminum, brass, plastic, and titanium.

CME Inc manufactures standard and custom laminar test equipment for gas flowmeters; oxygen test stands, flow calibrators, and laminar flow elements. Laminar equipment is used to prevent contamination in settings with controlled, smooth airflow, such as cleanrooms. The company’s products include digital, analogue, and portable flowmeters, transducers, calibrators, gages, indicators, totalizers, oxygen systems, and stands. The company, based in Davenport, Iowa, primarily serves the US Military laboratories and has been doing so for the past forty years. They also serve industrial calibration laboratories, and their products are NIST traceable.

Burger & Brown Engineering, Inc., founded in 1978 and based in Grandview, Missouri, is a manufacturer offering a range of engineering services. The company is internationally known for its SMARTFLOW proprietary products for the molding industry. Smartflow products comprise a line of multi-port manifolds for water and non-aggressive liquid applications, flowmeters for monitoring flow, temperature, and pressure, and limit switches for ejector plate, slide retention, and core pull applications. Other services provided by the company include special machines for industrial automation, precision contract machining, custom injection molding, plastic part design, and consulting.

EXAIR was incorporated in 1983 and based in the suburbs of Cincinnati, Ohio. EXAIR is a manufacturer of compressed air-operated products to solve problems in industrial plants. Customer solutions EXAIR addresses include cooling, cleaning, coating, conveying, drying, industrial housekeeping, static elimination, and optimization. EXAIR products include vortex tubes, air amplifiers, air knives, air-operated vacuums, ionizing products, air wipes, static eliminators, vacuum generators, vortex tubes, cabinet coolers for standard and hazardous location, cold gun air coolant systems, and other accessories.

Assured Automation was founded in 1983 and is headquartered in Roselle, New Jersey. Assured Automation is an ISO 9001:2015 certified supplier of automation equipment serving manufacturing, chemical, and pharmaceutical industries among others. Assured Automation offers products in 2 major product lines: valves and flow meters. Valves include compact on/off valves, actuated 2-way and 3-way ball valves, actuated butterfly valves, actuated plug valves, actuated globe valves, manual gate valves, manual valves, lead free brass valves, thermal and remote shutoff valves, valve actuators, and valve & actuator accessories. Flow meters include water meters, fuel meters, industrial flow meters, lube-oil meters, and others.

Rola-Chem Corp., established in St Paul, Minnesota in 1900, is a manufacturer of Peristaltic Pumps, pH/ORP Controllers, Chemical Storage Tanks, and Flow Meters for the commercial swimming pool and SPA markets. Their product portfolio includes Pool Sentry water leveler, Turbo Brush, Corner Brush, Ultrashine leather/vinyl cleaner, and Scumbug oil absorbing sponge. They also offer various services including product selection, installation, preventative maintenance, maintenance, and repair as well as product manuals and customer support.

Envea is a developer and manufacturer of environmental management products that was originally established in Poissy, France, as Environnement SA in 1978 before rebranding in 2022. The company’s product lineup includes emissions monitoring products such as stack emission analyzers, dioxin analyzers, and flue gas analyzers. It also offers air monitoring products such as particulate monitors, and process environment products such as flow meters. The company operates internationally, with manufacturing and R&D locations in Europe, the United States, and Asia.

Eastern Instruments is an American manufacturer of flow measurement equipment and systems that was established in 1984. From their 26,000 sq ft facility in Wilmington, North Carolina, the company produces mass flow meters, feeders, airflow devices, and control systems for air, gas, or solid particles. These are used in various industrial processes within the petrochemical, energy, food, and agricultural sectors. Eastern Instruments also offers clients contract manufacturing and on-site support services such as product installation, maintenance, and repair.

Ohio Medical Parts originated in 1910 as Ohio Chemical and Manufacturing Company in Cleveland, Ohio. Today Ohio Medical is a producer of medical air and vacuum pumping systems as well as medical suction and oxygen therapy devices. Ohio Medical services the medical device, medical gas, construction/renovation, ambulatory surgery center, industrial, and OEM solutions industries. Ohio Medical devices are manufactured in an ISO 13485 registered and FDA regulated medical device manufacturing facility. Product offerings include medical devices such as flowmeters, hoses, gas regulators, and suction regulators, as well as medical gas devices such as medical gas systems, vacuum pumps, air compressors, and medical gas accessories.

Merrick Industries Inc is an industrial equipment manufacturer and supplier based in Lynn Haven, Florida. Established in 1908, the company is the inventor of dynamic weighing and weigh feeding and currently operates in a 50,000-square-foot facility with about 500 employees as of 2023. The privately held company also owns a subsidiary in India that specializes in services for the power generation industry. Merrick’s product portfolio features different weighing and weighs feed solutions, including volumetric feeders, flow meter systems, weigh belt feeders, high-density lime systems, valves, and gravimetric feeders.

Kelly Pneumatics was established in 2004 and is based out of Newport Beach, California. The company is a designer and manufacturer of proportional valves, pressure regulators, and pneumatic control products for numerous industries including medical, alternative energy, test equipment, semiconductor equipment, and gas analyzers. The company’s standard products include proportional valves, pressure regulators, flow controllers, flow sensors and meters, and electronic boards. The company provides custom solutions for pneumatic valves, regulators, and control products to match customers’ needs. These include analyzing, engineering, prototyping, and testing.

Hayward Flow Control was founded in 1923 and operates out of Clemmons, North Carolina. Hayward Flow Control is a manufacturer of industrial thermoplpastic valves and process control products. Hayward Flow Control product lines include thermoplapstic valves such as ball valves and butterfly valves, Hayward Filtration & Straining line, Hayward Actuation line including actuators and actuated valves, pressure & flow control valves, corrosion resistant pumps, instrumentation, bulkhead fittings & tank accessories, end connections, and other parts and accessories.

Hoffer Flow Controls was founded in 1969 and is headquartered in Elizabeth City, North Carolina. The company is an ISO 9001-certified designer and manufacturer of turbine flowmeters and related process instrumentation used in aviation, oil & gas, power generation, and other industries. The company’s product lines include turbine flow meters, electronics, and cryogenic flow meters. Turbine flow meters are further delineated by application, such as those for industrial turbines, oil & gas turbines, and autoclave turbines. Electronics include pressure flow computers, printers, and signal converters. The company also provides full ISO 17025-certified cryogenic field calibration services.

Max Machinery, Inc. (MMI) is an American ISO 9001 certified manufacturer of liquid flow measurement instruments established in 1967 and based in Healdsburg, California. The company offers flow meters for fluids of varying viscosities including gear, helical, piston, and water models. It also stocks flow meter accessories such as filters, digital indicators, vapor eliminators, and level controllers. MMI primarily serves clients in the oil and gas, industrial manufacturing, trucking, and chemical processing industries.

Siemens Process Instrumentation is a service by industrial giant Siemens. Siemens Process Instrumentation offers single-source measurement solutions to increase plant efficiency and enhance product quality. Siemens Process Instrumentation is a designer of instruments designed to seamlessly interplay with existing industrial automation and control systems. Productand design categories include pressure measurement, temperature measurement, flow measurement, level measurement, positioners, weight measurement, process controlling and protection, supplementary components, communication, product solutions for OEM, and digitalization.

Nitto Kohki USA is the US-based subsidiary of Japan-based Nitto Kohki. Nitto Kohki was established in 1956, originally as a manufacturer and marketer of air micrometers and other devices. Nitto Kohki develops products that save on energy and labor while being cleaner for the environment. 4 of Nitto Kohki’s product segments are tools, pumps, CUPLA, and delvo. Tools are used in wood working, aerospace, renewable energy, bridge building, and automotive. Pumps are used in hospital equipment, semiconductors, health and beauty equipment, and medical devices. CUPLA products are used in high purity chemicals, HVAC production, computer and server cooling, and plastic injection. Delvo products are used in door frames, PCBs, home appliances, and lighting.

OMEGA Engineering was originally begun in 1962 as a manufacturer of thermocouples and has grown to over 100,000 products for measurement and control of temperature, humidity, pressure, strain force, flow, level pH, and conductivity as well as customer service including data acquisition, electric heating, and custom-engineered products. Additionally, OMEGA offers tools to serve as reference for engineers around the world. OMEGA Engineering serves the aerospace, automotive, wireless, sanitary, test & measurement, process control, power monitoring, environmental, and laboratory markets.

TSI, headquartered in the United States, is a supplier of instruments and measurements solutions since 1961. The company provides measurement, application guidance, and data analytics solutions that enables customers to make informed decisions in pharmaceutical manufacturing, semiconductor and electronics manufacturing, or cleanroom certification. Their instruments have helped organizations and individuals measure materials, analyze data, and comply with requirements of every kind.They also have product development, manufacturing and customer support facilities on three continents with distributors and manufacturers’ representatives providing local support worldwide.

Clark Solutions, established in 1962 and headquartered in Massachusetts, United States, is a supplier and distributor of fluid handling products. The company offers a wide range of products, including pumps, valves, and instruments, among others, serving industries such as chemical processing, pharmaceuticals, and food and beverage. These industries rely on the company's solutions for precise fluid control in tasks like transferring, mixing, and flow control, ensuring the accuracy and efficiency of operations.

Aalborg Instruments & Controls, Inc., established in 1972 in Orangeburg, New York, USA, is a manufacturer and supplier of precision instrumentation for flow measurement and control. The company's product range includes Mass Flow Controllers, Variable Area Flow Meters, Paddle Wheel Flowmeters, Flow Control Valves, and Peristaltic Pumps, catering to industries requiring accurate flow measurements and controls such as research, industrial processes, and manufacturing. Its services include product manufacturing, flow calibration, and technical assistance. With a long period of experience, the company consistently exceeds expectations in precision and service.

Fluid Components International, founded in San Marcos, CA, in 1964 is a manufacturer of thermal mass flow meters, flow switches and level switches for industrial process measurement applications. The company's product portfolio includes Flow Switch, Flow Conditioners, Gas Flow Meter, Level Measurement Products, and Flow Straighteners. The company serves markets including Medical and Healthcare, Aerospace and Defense, Consumer Goods, Industrial Manufacturing and Construction and Building. The company also provides services including national distribution, product selection, customized services, technical support and customer service.

AW-Lake is based in Oak Creek, Wisconsin. AW-Lake is a distributor of process flow measurement equipment for oil and gas, automotive, hydrogen fueling, chemical, manufacturing, marine, industrial, and aerospace industries among others. AW-Lake is ISO-9001:2015 certified. AW-Lake products include gear & PD flow meters, turbine flow meters, Coriolis mass flow meters, variable area meters, paddle wheel flowstat meters, ultrasonic flow meters, monitors, controllers, flow sensors, pickups, turbidity sensors, and wireless/Bluetooth devices. AW-Lake products are often used in oil, lubricants, water, chemicals, paints, coatings, adhesives, sealants, and sanitary liquids gas.

Eldridge Products, Inc. (EPI), founded in 1988 by Mark Eldridge, is a manufacturer of thermal mass flow meters, switches, and metering software based in Marina, California, USA. The company has distributors in Asia, Pacific Rim, Western Europe, and other countries. Their team of skilled engineers and specialists continuously develop products to meet customer needs, providing unparalleled accuracy and usability. EPI's wide range of certifications, including hazardous location approvals and RFI/EMI certifications, make it the preferred choice for clients seeking flow measurement solutions.

Asahi/America was born in 1971 to be the distributor for Asahi Yukizai Corporation products on the East Coast of the United States. Asahi/America serves the aquarium & entertainment, chemical processing, data center, metal finishing, and the water/wastewater industries. The company offers a selection of valves and actuators including many types of valves, high purity piping, air & gas handling, double containment, and welding equipment. The company alos offers a wide assortment of custom fabrication of parts and components.

CS INSTRUMENTS USA is based in Bluffton, South Carolina, and is the American subsidiary of CS INSTRUMENTS headquartered in Tannheim, Germany. CS INSTRUMENTS was established in 2002 is a manufacturer and distributor of compressed air technology and related products, generally used in industrial and manufacturing settings. CS product lines encompass a complete compressed air monitoring system with individual segments including dew point, compressed air quality, leak detection, chart recording, and software. Many of these components can be used in other capacities, such as flow measurement devices in underwater settings such as marine or water treatment industries.

HydraCheck was established in 1990 and headquartered in West Valley City, Utah. The company is a distributor of diagnostic testing and maintenance for hydraulic systems across North America. The company provides support services for end customers as well as mechanics and technicians. The company’s product lines include testing products, diagnostic kits, and safety devices. Testing products include flanges, gauges, and thermometers while kits include identification kits and test kits. The company's safety devices include goggles, models, and guides.

SebaKMT Megger Germany GmbH, founded in 1951 and based in Baunach, Germany, is a manufacturer of measuring systems for water leak detection and loss reduction. Its product portfolio includes ground microphones, pressure loggers, and noise loggers. Its other products are line location systems, a hybrid correlator for online and offline measurements, and a ferrous metal locator. The company also provides a cloud solution called Poseyedon for leak location and monitoring. The company is a member of the Megger Group, has representatives in 130 countries worldwide, and produces several of its devices in Germany.

NIVUS, based in Germany, is a manufacturer and supplier of measurement technology and automation solutions. Established in 1967, the company provides products and solutions for flow measurement, level measurement, and water quality monitoring. Their products are designed to be accurate, enabling customers to manage and monitor their water and wastewater systems. Some of their product lineup includes Flow Meters, Level Sensors, Water Quality Monitoring, and Data Loggers and Controllers. Some of the industries they serve include Water and Wastewater, Environmental Monitoring, Industrial Processes, Hydropower, Mining, Agriculture, and Infrastructure.

Micro Sensor is a Baoji, Shaanxi, China-based manufacturer of OEM, ODM, and custom-designed transmitters, flowmeters, and sensors used for industrial automation, established in 1993. The production line has level, temperature, and pressure transmitters, pressure sensors, flowmeters, and accessories, including valves, indicators, protectors, and connection boxes for pressure sensors and transmitters used in the HVAC, marine, water, oil, and gas industries. The company has a subsidiary, Micro Sensor GmbH, based in Essen, German.

Pietro Fiorentini S.p.a. founded in Arcugnano, Vicenza, Italy, in 1940, is a manufacturer of oil/gas processing and flow management products. The company manufactures products including pressure regulators, gas meters, gas odorizing systems, and valves. In 2022 it reached consolidated revenues of 500 million euros, an increase of 8% compared to 2021. The company has 2,800 employees spread across 40 international locations, with a strategic commercial presence in 100 countries worldwide. It also provides spare parts for its products and services of data management and custom engineering.

Arthur Grillo GmbH is a manufacturer of building automation control systems that was established in North Rhine-Westphalia, Germany, in 1901. The company produces temperature sensors, differential pressure sensors for measuring and controlling air or gas flow, and venturi tubes for measuring and controlling fluid flow. It also offers control cabinet technology products such as power supplies, switches, and relays. The company’s products are used primarily by clients in the industrial automation, robotics, and semiconductor industries.

CKD Corporation, established in 1943 under the name of Japan Aircraft Electric Co., Ltd., is a Japanese manufacturer of automation machinery and manufacturing components, headquartered in Komaki, Aichi. Their diverse portfolio includes pneumatic and fluid control components, fine system components, drive components, and labor-saving components. The company has also developed various types of automation machinery, such as transparent object inspection systems, pharmaceutical products packaging machines, and more. These products find applications in various industries, for example their automated food packaging systems are designed for maintaining food quality and hygienic conditions. Their fluid control components are used in the solar cell manufacturing process.

VPInstruments, established in 1999 and based in Delft, Netherlands, is a manufacturer and supplier of energy management tools and flow measurement equipment. The company's product range includes Energy Monitoring devices, Flow meters, Dew point sensors, Power meters, and Installation tools. These products assist in detecting leakages, monitoring efficiency, and allocating costs. Primarily, the products serve industries such as the manufacturing of materials, steel, glass production, food & beverage, automotive, and textile. The company's services include energy management, compressed air flow metering, energy savings initiatives, and remote asset monitoring.

Swan, founded in 1991 and based in Switzerland, is a manufacturer of process analytical instruments for monitoring water quality. The company specializes in online water quality measuring analytical systems and offers various solutions for water analysis. Its product portfolio includes solutions for high-purity water, steam and condensate, wastewater, and effluents, addressing the needs of sectors such as pharmaceuticals, oil and gas, and municipal water treatment. The company's instrumentation covers various parameters such as ammonium, chlorine, and dissolved oxygen, catering to diverse industries from semiconductors to food and beverage.

SUTO iTEC GmbH, founded in 2005, is a manufacturer of measurement and monitoring instruments for compressed air and gas systems in Heitersheim, Deutschland. The products are air & gas flow meters, data loggers, air quality analyzers, dew point meters & transmitters, and ultrasonic leak detectors. The products have applications in food & beverage, energy management, quality control, general utilization, and laboratories. The company offers 24/7 services such as exchange services and calibration of dew points, flow, and oil vapor.

E+E Elektronik Ges.m.b.H., established in 1975 in Austria, is a manufacturer and provider of cutting-edge sensor solutions for humidity, temperature, and CO2 measurement. The company’s product portfolio includes humidity sensors, temperature sensors, transmitters, and CO2 sensors. These technologies are broadly employed in industries such as HVAC, automotive, pharmaceuticals, and more. E+E Elektronik's team of experienced engineers and professionals collaborate closely with customers to understand their specific needs and deliver tailored sensor solutions. The company also plays a great role in raising measurement accuracy and enhancing improved environmental monitoring and control systems.

ABSOLUTE OZONE, founded in 1995 in Edmonton, Alberta, is a manufacturer of commercial and residential ozone generators, ozone sensors, monitors, tubes, and fittings. The company's ozone generators are ideal for applications such as drinking water treatment, food disinfection, air purification, soil remediation, and pharmaceutical processes. Its products also include ozone analyzers, ozone spray containers, flow meters, venturi injectors, and air compressors. Industries served include automotive, food, bottling water, agriculture, textile, laundry, and many more. The company is CE certified and RoHS compliant.

Meister Strömungstechnik Gmbh, founded in 1984 and based in Wiesen, Germany, is an ISO 9001-certified manufacturer of flow measuring and monitoring systems for industrial environments worldwide. Its products include flow meters, flow limiters, and accessories for water, oil, and gases. The company uses a modular product design to help it configure and specify the equipment to match the customer’s requirements. Its BA, BB, and BC models of water flow limiters don’t require an external power source and have an operating temperature from -20°C to 200°C. The company has over 1 million devices installed worldwide, and its complaint rate is less than 0.15.

Siemens began in 1847 and is headquartered in Munich, Germany. Siemens focuses in automation and digitalization technology and operates globally. Siemens’s 5 operating segments are digital industries, smart infrastructure, mobility, Siemens Healthineers, and Siemens Financial Services. Siemens Financial Services provides debt and equity investment as well as financing solutions. Siemens Healthineers is a medical devices company that provides products and consulting. Mobility includes passenger and freight transportation. Smart infrastructure includes full solutions for electrification. Digital industries offer both software and hardware for industries and production efficiency.

The Azbil Corporation (formerly the Yamatak Corporation) aims to realize safety, comfort, and fulfillment in people's lives and contribute to global environmental preservation through "human-centered" automation. They provide their customers with timely solutions via an integrated structure that extends from planning and development to maintenance and service, capable of responding rapidly to customer needs.

Casella CEL, Inc., founded in the UK in 1799, is a manufacturer of occupational and environmental monitoring equipment for the benefit of workers' health. The company's product portfolio includes noise monitoring, dust monitoring, vibration monitoring, perimeter monitoring, and boundary monitoring solutions. The company serves industries such as manufacturing, construction, mining, and public facilities to assess exposure levels to improve worker and community health. It uses eminent figures including David Livingstone and Charles Darwin with instrumentation for exploration and scientific work.

Wöhler Technik GmbH, established in 1932 and based in Bad Wünnenberg, Germany, is a manufacturer of measurement instruments. The company produces products such as gas analyzers, soots, inspection cameras, pipe cleaning devices, and temperature-measuring equipment. Apart from this, the company also produces measuring, inspection, and cleaning equipment for building services. Plumbers, chimney sweeps, and installers use the tools manufactured by the company. The company has five subsidiaries in different locations, such as France, the Czech Republic, Austria, Italy, and the Netherlands.

MUNSCH Kunststoff-Schweißtechnik GmbH was founded in 1990 and is headquartered in Baumbach, Germany, as a manufacturer of state-of-the-art plastic welding machines and devices. The MUNSCH plastic welding machines are characterized by their user-friendly and ergonomic design, which enhances ease of use and comfort during operation. Additionally, their aesthetically appealing design adds to their overall attractiveness. These features collectively position the MUNSCH plastic welding machines as dependable and straightforward tools for effectively joining thermoplastics through welding. All goods' development, production, and approval occur in Ransbach-Baumbach in the Westerwald region, with global distribution.

TOFLO CORPORATION was established in 1973 and is a manufacturer of flow sensing and flow control products based in Hino, Tokyo, Japan The company manufactures various flow-related products such as variable area flow meter, flow control valve, vortex flow meter, plastic pressure switch, and metal check valve. The products are used in various applications such as gas management, chemical industries, waste water management, and industrial manufactures. The company had acquired certifications such as ISO 9001 for the Quality Management System and Eco Action 21 for environmental sustainability.

Nittoseiko Co. Ltd, established in 1938 at Kyoto, Japan is a manufacturer of screw driving components and screw fastening products. The company specializes in manufacturing advanced solutions for fastening, assembly as well as inspection technology. The products list involves loose proof screws, special cold forged parts, automatic screw driving machines, screw driving robots and measuring instrumentation systems. The products are used in applications such as automobiles, home appliances, telecommunications, electronic products and machinery. These fastening and assembly systems make it easier to assemble various components and also bond them together in a robust way.

Walsn Enterprises Ltd. was founded in 2006 and is based in Columbia, Canada, and is a manufacturer of instrumentation and measurement equipment for the Automation Machinery Manufacturing industry. The company manufactures Electromagnetic & Coriolis Mass flow meters; Mill & Silo monitors, Flame Detectors, Oxygen Analyzers, and, Acid Dewpoint Temperature Monitors along with Combustion Efficiency Analyzers that have applications in the Oil& Gas, Mining&Metal, Chemical, Power Generation, and Energy optimization industries. They are also equipped with coal-fired power plants for energy conservation & emission reduction and also offer repair&eplace services and technical support.

KROHNE Group began in Duisburg, Germany in 1921 as a producer of variable area flowmeters. Today KROHNE isa a provider of industrial measurement products, solutions, and services. KROHNE services the chemical, food & beverage, life sciences, marine, metal & mining, nuclear, oil & gas, power generation, pulp & paper, water & wastewater, and sustainable energies industries. KROHNE product lines include tools for flow, level, temperature, and pressure measurement as well as process analytics and smart flow control. KROHNE offers full solutions for flow metering, monitoring, and wireless and remote metering applications.

Cubic Sensor and Instrument Co. Ltd., founded in 2003 and based in Wuhan, China, is a manufacturer of gas sensors and sensor solutions and is ISO 9001 certified. It stocks products like spirometers, CO2 sensors, and gas analyzers that serve various fields, including air quality, environmental monitoring, and healthcare. It is a publicly listed company in the SSE STAR Market that has exported its products to more than 80 countries and has obtained more than 100 patents at home and abroad. It has also received ISO 45001, ISO 14001, and Automotive Tier 1 Supplier with IATF16949 certification.

The Endress+Hauser Group are manufacturers and suppliers of instruments, systems, and services for process automation, established in 1953 and headquartered in Reinach, Switzerland. The company supplies a wide range of products, including flow meters, level and temperature sensors, pressure gauges, analytical instruments, and control systems. These instruments enable its clients to make informed decisions, improve quality control, reduce downtime, and minimize operational costs. They cater to various industries, including oil and gas, chemical, food and beverage, water, and wastewater. Power generation, pharmaceuticals, and mining also benefit from the optimization, safety enhancement, and regulation of standards provided by the instruments.

Aplisens S.A., founded in 1992, and headquartered in Warsaw, Mazowieckie, Poland, is a manufacturer of process instrumentation. The company offers a diverse range of control and measurement products, including differential pressure transmitters, hydrostatic level probes, level transmitters, valves, and digital indicators. It also offers power supplies, separators, and gauges. It is certified with ISO 9001:2015 and HART, and also provides Quality Assurance Notifications for ATEX compliance, ensuring product safety in potentially explosive environments.

Azbil Europe NV is based in Germany and was founded in 1906 as a manufacturer and supplier of automation products and solutions. The company designs Industrial Control Communication devices like Digital Controllers, and Flame Safeguard Systems, along with Electromagnetic, Differential Pressure, Vortex Gas, and Thermal Flowmeters. They also deal in sensors and switches and their list of Industrial Automation products includes Field Instruments and Control Valves. Together these components serve the Oil and Gas market, the Pharmaceutical industry, and the Electronics and Electrical equipment industry.

Aichi Tokei Denki Co., Ltd., founded in 1898, is a Japanese manufacturer and supplier headquartered in Atsuta-ku, Nagoya, specializing in measuring equipment. The company offers an array of liquid measuring equipment, including electromagnetic, electronic, and residential water meters, as well as electromagnetic, micro stream, and ultrasonic flow sensors. It also provides a range of gas measuring equipment, including gas meters, pressure-reducing valves, as well as ultrasonic flow meters for compressed air, fuel gas, and nitrogen. These products find applications in residential settings, as well as building and infrastructure management. They cater to a range of industries, including energy, healthcare, and medical sectors.

KOBOLD Messring GmbH, established in 1980 in Germany, is a manufacturer and supplier of new industrial measuring and control equipment. The company's product range includes flow meters, pressure gauges, level sensors, temperature measurement devices, and more, catering to various industries such as oil and gas, water treatment, and manufacturing. KOBOLD's flow meters are utilized to measure and monitor the flow rates of liquids and gases, ensuring precise and efficient process control. With its technological advancement devices, KOBOLD aims to provide ideal and accurate measurement solutions that enhance the success of its customers' operations.

OVAL Corporation, founded in Tokyo, Japan, in 1949 is a manufacturer of metrological control equipment and related systems and measuring devices and environmental control related instruments. The company's product portfolio includes batch controllers, flow computers, peripherals and related instruments, system solutions and calibration equipment. Their products are used in industries such as Food and Beverage, Pharmaceutical and Biotechnology, Chemical and Petrochemical, Environmental Testing and healthcare. The company provides services such as Product Selection Guidance, Engineering Support, and Custom Manufacturing.

ASAHI YUKIZAI CORPORATION, formerly known as Asahi Organic Chemicals Industry, is a Japanese manufacturer headquartered in Taito-ku, Tokyo, and specializes in resins and plastic valves since its establishment in 1945. The company manufactures valve and piping systems, including manual & automatic valves, pipes, fittings, and mixers. It also offers various foundry materials such as resin and sand products for casting, along with functional resins which cater to housing, construction, and industrial applications. The company engages in the design and construction of water utility facilities & reuse of wastewater, industrial water & wastewater treatment, environmental pollution prevention & purification, and public sewage management.

SIKA Dr. Siebert & Kühn GmbH & Co. KG, established in 1901 in Germany, is a manufacturer of industrial measuring and calibration technology. The company has a wide product range that includes dial thermometers, digital thermometers, temperature sensors, digital pressure gauges, and turbine flow sensors. SIKA's products are used or fitted by device manufacturers and can be found in the products or production processes of numerous markets, such as heating, ventilation, automotive engineering, and commercial vehicle construction, as well as industrial technology. SIKA offers customized design, engineering, and mass production of its technology to meet client-specific requirements.

KOFLOC Corporation, established in 1949, is a manufacturer and retailer of standard and off-catalog custom gas generators, precision flow instruments, and engineering devices headquartered in Osaka, Japan. The company manufactures various flow instruments for measuring and controlling fluids, including flow meters, pressure regulating valves, flow control valves, and mass flow controllers and meters. The company’s gas generators are used to generate various gases from the air and water, including nitrogen gas, hydrogen gas, oxygen gas, ozone gas, and clean dry air. KOFLOC is ISO14001: 2006-certified company whose equipment are used in aerospace, water treatment plants, power generation, and refineries.

KRAL GmbH, founded in 1950 with headquarters in Austria, is a manufacturer of screw pumps and flow measurement technology. The company's wide range of products includes screw pumps and flow measurement devices. KRAL also works with clients for custom assembly and production of client-specific equipment. Support services include training, installation, remote support, spare parts, and maintenance for the lifetime of KRAL's products. The company's products are used in various industrial, commercial, and infrastructure applications.

Golden Mountain Enterprise Co., Ltd. (GMEC) is a Taiwanese manufacturer of industrial products and instruments founded in 1980. The company produces various valve, pressure, flow, and temperature system components for use in chemical processing, food processing, pollution control and oil refining. GMEC is an ISO9001 certified company, with an extensive product portfolio including Venturi tubes, butterfly valves, manometers and temperature controllers. These supply industrial processes in sites like breweries, chemical plants and wastewater treatment facilities.

Cosmo Instruments Co., Ltd., founded in 1970 and headquartered in Hachioji, Tokyo, is a manufacturer of sensors and testing equipment, with ISO 14001 and ISO/IEC 17025 certifications. They specialize in manufacturing sensors and testing equipment such as air leak testers, manometers, flow testers, helium/hydrogen leak testers, and pressure flow peripherals. These products are used to detect and measure leaks in various systems and components to ensure their proper functioning and safety.

GEMÜ Group is a manufacturer of valves, measurement, and control systems for liquids, vapors, and gases, founded in 1964, the company is headquartered in Ingelfingen, Germany. The Group serves a wide range of industries, including pharmaceuticals, biotechnology, semiconductors, food and beverage, and chemical technology and more. Their solutions help customers reduce their carbon footprint and improve the sustainability of their operations.They have six manufacturing locations, alongside their manufacturing sites in Germany, they also manufacture their products in Switzerland, France, China, Brazil and the USA. Their worldwide marketing is carried out across 27 subsidiaries, coordinated from Germany.

TLV, established in 1950, is a Japan-based manufacturer and supplier of steam engineering products such as fluid control equipment, system products, and maintenance instruments. The company offers fluid control equipment including cyclone separators, steam traps, automatic check valves, manifolds, and pressure-reducing valves used for steam, air, and water piping. The company offers maintenance instruments such as pocket trapman. The company also offers consultation, engineering, services, and the design and construction of steam and power systems. TLV has achieved ISO9001 and ISO 14001 certifications for standardization allowing their products to be used in logistics, building maintenance, chemicals, refineries, and petrochemical industries.

Arkon Flow Systems, s.r.o. is a Czech ISO 9001 certified manufacturer of control and measurement equipment established in Brno-sever, Česko in 2003. The company primarily produces standard as well as custom flow meters, flow control equipment, and measurement devices. These include ball, paddle, and spinner wheel flow indicators, ultrasonic clamp-on or electromagnetic flow meters, and parshall flumes for measuring open channel flow rates. The company's products are mainly used by clients in the water and wastewater processing, petrochemical, mining, and power generation sectors.

ESAB, founded in 1904 and headquartered in Maryland, United States, is a manufacturer of welding as well as cutting equipment and consumables. It manufactures accessories and consumables, arc welding equipment, cutting automation, filler metals, and gas equipment. Moreover, it offers manual plasma cutting, PPE/Safety, robotics, torches, and welding automation. For arc welding, Fabricator EM 400i, for instance, is ideal for heavy industries due to the use of solid and flux-cored wires together with fabricator feed. ESAB has earned ISO 9001, ISO 14001, and the Occupational Health and Safety Advisory Services 18001 certifications.

Fluidwell Bv. is a Dutch ATEX and IECEx-certified manufacturer of process industry electronics that was established in Veghel, Noord-Brabant, in 1993. The company produces level measurement products such as level transmitters, pressure measurement products such as pressure alarms, and panel mounted instruments such as flow calculators. It also offers explosion-proof instruments for process control applications, including flow rate indicators and data loggers. The company’s products are commonly used in the petrochemical, oil and gas, and wastewater treatment industries.

Liquid Controls is based in Oklahoma City, Oklahoma, USA, and is a manufacturer of control systems and bulk flow meters that was established in 1954 before its acquisition by IDEX Corporation. The company’s product lineup includes its LCMass brand mass flow meters for measuring physical parameters of liquids, its LCMag brand electromagnetic flow meter for analyzing conductive liquids, and positive displacement flow meters. The company’s products are mainly used in fuel refining, chemical processing, and LPG storing operations.

Bijur Delimon International is based in North Carolina, USA, and is a manufacturer of lubrication and cooling systems originally established in 1923 before being acquired by Industrial Manufacturing Company International (IMCI) in 2001. The company produces industrial-grade systems and components for lubrication and cooling purposes. Its products include complete oil and grease pump systems, spray systems for applying coolants and process liquids, and water-oil coolers. The company also offers installation, maintenance, and personnel training services for customers needing additional support. It chiefly serves clients in the steel, automotive, and machine tool industries.

Watts was established in 1874 and is a manufacturer of water management products based in North Andover, Massachusetts, United States. The company offers various water solutions products such as automatic control valves, gas connection systems, pressure reducting valves, water quality parts, and high purity process piping systems. The products have been used for serving various industries such as healthcare, agriculture, hospitality, commercial, and municipal waterworks. The products have been created under compliance of CSA, NSF International, WQA, BSI, and AGA manufacturing standards.

SynQuest Laboratories, Inc. is a manufacturer of specialty chemicals, it was established in 1994, based in the United States. The company specializes in producing a wide range of quality chemicals and reagents for various industries, including pharmaceuticals, research, and manufacturing. The product portfolio includes custom synthesis, rare chemicals, and fine chemicals designed to meet unique client needs. SynQuest Laboratories' aim is to provide chemical solutions that drive scientific advancements and enhance product development.

Hoffer Flow Controls, Inc. is a manufacturer of turbine flow meters and process equipment that was established in 1969 in Elizabeth City, North Carolina, USA. The company primarily produces turbine flow meters for liquids, cryogenic fluids, and gasses. It also offers subsea turbine flow meters for deepwater operations, flow electronics such as converters and amplifiers, and flow accessories such as valves and fittings. The company’s products are used mainly by clients in the pharma-biotech, power generation, and oil and gas industries.

Flux-Gerate GMBH is a manufacturer of drum and container pumps established in 1953 and based in Maulbronn, Germany. The company’s products include eccentric worm-drive pumps for transferring viscous liquids, centrifugal immersion pumps for pumping industrial media, and flow meters for measuring or logging the flow rates in a system or facility. It also offers air-operated diaphragm pumps, and cleaning agents for its portfolio products. The company’s products are commonly used by clients in the chemical, pharmaceutical, and oil and gas industries.

Bürkert Fluid Control Systems, founded in 1946 and headquartered in Ingelfingen, Germany, is a manufacturer of liquid and gas measurement and control systems. Its product range includes solenoid valves for fluid power systems, process and control valves for managing flow, pressure, and temperature, pneumatics and process interfaces for automation control, sensors, transmitters, and controllers for measuring physical and chemical parameters, and MicroFluidics solutions for precise fluid control. Its products serve diverse industries like breweries, labs, medical, and aerospace.

Baker Hughes Co. (BHC) is an American service provider and manufacturer of industrial oilfield equipment that was established in 1987 following the merger of Baker International and Hughes Tool Company. Based in Houston, Texas, the company produces several categories of oilfield products including drilling equipment, pipe and subsea production systems, generators, and storage systems. It also offers process control components and actuators such as pumps, valves and regulators. BHC provides various services for oilfield and liquefied natural gas (LNG) operations, including regasification, well construction, transportation, and storage.

Spirax Sarco is a manufacturer and supplier of steam system solutions, providing products and services to industries, including food and beverage, pharmaceuticals, chemicals, and more. The company was established in the UK in 1888 and has since expanded to over 60 countries worldwide, with its US headquarters based in Blythewood, South Carolina. One of their products is the TD62 Thermodynamic Steam Trap, which offers high efficiency and reliability for condensate removal in steam systems. They received awards like 2019 Innovation Award from the Institute of Chemical Engineers (IChemE) for their EasiHeat engineered system.

Litre Meter Limited, founded in 1975 and headquartered in Aylesbury, England, is a flow meter manufacturer and supplier. The company manufactures rotary piston positive displacement flow meters and pelton wheel turbine flowmeters for the oil and gas sector. It develops custom-designed low-flow and high-pressure flow meters for various applications, including chemical injection and subsea use. It also distributes flowmeters from brands including KEM, Tricor, and Ritter. The company complies with ISO 9001 standards and the RoHS and WEEE directives.

FLEXIM, headquartered in Berlin, Germany, is a supplier and manufacturer of flow measurement solutions since 1990. They offer non-intrusive, ultrasonic flow meters for accurate volume and mass flow measurement of liquids and gases. They also provide PIOX process analyzers and VISOFLOW visualization systems. These products find applications in industries such as industrial processes, energy management, water and wastewater treatment, oil and gas, and chemical processing. FLEXIM is SIL certified and also provides additional services such as on-site measurements, lab analysis, instrument commissioning, rentals, and consulting services.

Drum-Mates Inc. is a designer and manufacturer of industrial liquid processing and container handling equipment established in 1963 in Lumberton, New Jersey, USA. The company’s product lineup includes pumps, mixers, and heaters for drums and intermediate bulk containers (IBCs). It also offers hand dispensing nozzles, custom-engineered lifting equipment, and wholesaling of OEM process equipment. The company’s products are used in industrial processing operations, such as in the food and beverage, chemical, and water treatment sectors.

Turbines Incorporated, founded in 1983 and now a subsidiary of Primary Flow Signal Inc., is a turbine flowmeter manufacturer headquartered in Altus, Oklahoma, United States. The company offers a range of metering devices including cryogenic flowmeters, suitable for low-temperature conditions, gas flowmeters, available in various configurations such as low-flow, high-pressure, and engineered options, as well as liquid turbine flowmeters, typically stainless steel in-line and water-style turbine meters. The company provides these solutions to diverse industries, including food and beverages, oil and gas, military, and power generation. It also delivers custom-engineered solutions for original equipment manufacturers and private labels.

Haimo Technologies (Group) Co. Ltd., established in 1994 and headquartered in Shenzhen, China, is a designer, manufacturer, and supplier of oilfield equipment. The company's products include Exempted Source SP Multiphase Flow Meters, Subsea Multiphase Flow Meters, and a range of fracturing equipment such as joints, valves, and ball injectors. It also supplies its own well refitting and maintenance vehicles, available with equipment that includes skid-mounted cementing units, cement batch mixers, and sand mixers. Its services include well testing, production logging, and the supply of intelligent monitoring systems for oil and gas field operations.

Rototherm Group, established in 1847 and headquartered in Port Talbot, England, is a manufacturer and supplier of measuring and control instruments. The company's product portfolio includes mechanical chart recorders, filled-system thermometers, and flow regulators. These products are used in various industries, including power generation, transportation, and the oil and gas industry. The company provides services including training, repair, and calibration, and some of the company's brands include RTD Products, Canongate Technology, and Micronics.

Höntzsch GmbH & Co. KG, established in 1966 and headquartered in Waiblingen, Germany, is a flow measuring technology and equipment designer and manufacturer. The company's products include fixed and portable ultrasonic equipment, thermal measuring equipment, and vane wheel anemometers for measuring liquid and gas flow rates. Its products are primarily designed for applications with extreme demands and are used in pharmaceutical sterilization tunnels, paint booths, and gas recovery operations. The company's services include instrument calibration, equipment testing, and regular maintenance.

ewo Stuttgart, also known as Hermann Holzapfel GmbH & Co. KG, established in 1914 and headquartered in Stuttgart, Baden-Württemberg, Germany, is a designer, manufacturer, and supplier of air treatment systems and accessories. The company offers thousands of products, including air compressor accessories, welding equipment, and personal protection equipment, all of which are available to buy directly online from its website. These products are used in automotive service and repair centers, industrial situations for cleaning equipment, and spray painting and finishing. Its services include the provision of product warranties, direct shipping, and repairs to damaged products.

ALIA Group Inc., established in 2003 and headquartered in Newark, Delaware, United States, is a manufacturer of gas and liquid measuring and monitoring instruments. The company's products are electromagnetic flowmeters, liquid level transmitters, and paperless panel meters. These products are to measure the velocity of a liquid, calculate volume flow in pipes, and measure and monitor liquid level changes in storage tanks. It also supplies automation instrument products and handheld measurement and testing tools. The company serves industries that include sewage treatment, chemical processing, and pharmaceutical manufacturing.

Bel-Art Products, a company founded in 1946, based in Wayne, New Jersey, USA, is a manufacturer and supplier of labware, glassware, and scientific products. The company offers various products such as bottles, beakers, funnels, flasks, tubes, racks, clamps, thermometers, timers, hydrometers, and safety equipment. Lab equipment, supplies, and glassware are made and sold by the product, which is a major producer and supplier of its things. It has various goods for use in chemistry, biology, physics, and engineering labs, among others. Its goods are known for it quality, accuracy, and how long it last.

Kracht GmbH, established in 1911 and headquartered in Werdohl, Nordrhein-Westfalen, Germany, is a designer and manufacturer of liquid flow equipment and systems. The company's products include gear pumps, flow measurement, and hydraulic valves. These products are used in agricultural machinery, food processing systems, and chemical processing systems. It also works with original equipment manufacturers to produce custom parts and components and complete turnkey systems. It serves sectors that include offshore oil drilling, new energy, and pharmaceuticals.

Honeywell, founded in 1906, in Wabash, Indiana is manufacturer of automotive parts, building technologies, and performance and safety materials for aerospace, The company's product portfolio includes electronic guidance systems, cockpit instrumentation, lighting, automotive parts, and primary propulsion and secondary power turbine engines. The company serves industries such as Oil and Gas, Aerospace and Defense, Automotive and Transportation, Construction, and Power Generation. Their headquartere is located in Carolina and they have global sales offices and distributions channels.

innomatec GmbH, established in 1983 and headquartered in Hessen, Germany, is a manufacturer of leak testing solutions and related equipment. The company specializes in leak test methods, including air, helium, and tracer gas tests. Its products include leak testers, test benches, and quick connectors, offering over 100 test object connections. It also provides standard helium gas recycling solutions for manufacturing lines. The company’s solutions span from laboratory setups to fully automated systems, meeting the testing requirements of industries such as automotive, medical devices, and packaging. It provides repair, maintenance, and calibration services, ensuring compliance with industry standards.

Founded in 1890 in Missouri, Emerson Electric Co., is a technology and engineering company that provides various solutions for customers in industrial, commercial, and consumer markets globally. Business segments include automation solutions, AspenTech, and commercial & residential solutions segments. The Automation Solutions segment offers measurement and analytical instrumentation, industrial valves and equipment, and process control software and systems. The AspenTech segment provides asset optimization software for enhancing performance through a combination of modeling, simulation, and optimization capabilities. The Commercial & Residential Solutions segment offers residential and commercial HVAC products, system protector and flow control devices, and IoT thermostats.

Metal Work S.p.A. is an Italian manufacturer of pneumatic components for automation systems that was established in 1967 in Concesio, Brescia. The company produces various pneumatic motion kits, as well as individual pneumatic automation system components. These products include a wide range of specialized valves, actuators, and fittings. It also offers filter regulator lubricator (FRL) units for ensuring clean air in compressed air systems. The company provides additional support via software downloads, CAD-based circuit design tools, and engineering assistance. Its products are mainly used in the industrial manufacturing, wood processing, and packaging sectors.

TOKYO KEIKI POWER SYSTEMS INC. was founded in 1896 and is a manufacturer of measurement, cognition and control devices based in Ohta, Tokyo, Japan. The company's product portofolio including ultrasonic flowmeter, oil leak detector, fiber optic gyrocompass, ultrasonic rail flaw detector, and solid state power oscillator. The products are used in various industries such as water resources management, railway, communication, ocean transports, and agriculture. The company has obtain certifications such as ISO 14001 standards compliance for the Management System.

Georg Fischer Piping Systems Pvt. Ltd is headquartered in Mumbai, India, and is an ISO 9001-certified manufacturer of plastic as well as metal piping systems that was established in 2007 as a subsidiary of Georg Fischer AG. The company produces piping system components and complete systems for industrial or automation operations. These products include pipes, valves, and fittings made from polyethylene (PE) or polypropylene (PP). It offers automation system components including actuators, sensors, and multi-parameter controllers. The company also offers additional services, such as custom engineering, prefabrication, and installation.

Titan Enterprises Ltd. is an ISO 9001-certified manufacturer of liquid sensors and flow meters established in 1981 in Sherborne, Dorset, United Kingdom. The company’s product lineup includes meters for measuring volumes or flow rates such as ultrasonic flow meters and oval gear flow meters. It also offers displays for controlling or viewing flow data, and spare parts and accessories for its portfolio meters. The company provides R&D, testing, and calibration services for unique projects, mainly serving the industrial processing sector.

Fuji Tecom Inc. is a manufacturer of leak detection and location technology products established in 1972 and located in Chiyoda-ku, Tokyo, Japan. The company specializes in utility inspection equipment for infrastructure maintenance applications. These products include pipeline and cable locators, water leak detectors, and metal detectors. It also offers ultrasonic water pressure recorders and flow meters for data logging and analysis. The company mainly serves clients in Japan’s municipal water utilities, infrastructure, and construction operations.

Datum Electronics Ltd., established in 1989 and headquartered in Oxfordshire, United Kingdom, is a designer, manufacturer, and supplier of torque and shaft power measurement solutions. The company's products include bolt-on static and rotary torque sensors, torque transducers, and torque meters. These products are used in various applications, including monitoring ship propeller shafts, fuel flow, and measuring and verifying heavy-duty torque for the insertion of helical screw piles. It also produces custom sensors that provide customized and modular solutions. It serves industries that include maritime, oil and gas, and automotive. Its notable clients include General Electric, Caterpillar, and Rolls Royce.