8 Ferrite Manufacturers in 2024

This section provides an overview for ferrites as well as their applications and principles. Also, please take a look at the list of 8 ferrite manufacturers and their company rankings. Here are the top-ranked ferrite companies as of July, 2024: 1.Samwha Capacitor Group, 2.Muuntosähkö Oy, 3.Enerdoor Group.

Table of Contents

Categories Related to Ferrites

1987~1991: Engaged in research on wire covering materials at Polymer Materials Laboratory.

1991~1997: Worked as a patent Engineer at Koike International Patent Office.

1997~2005 Worked as an intellectual property member at GE Yokogawa Medical System, currently working as a writer.

Linkedinhttps://www.linkedin.com/in/%E8%A3%95%E5%AD%90-%E9%88%B4%E6%9C%A8-92b21a234/

researchmap

https://researchmap.jp/0315rs2017

What Is a Ferrite?

A Ferrite is a ceramic composed mainly of iron oxide and is used as a magnetic material.

Because it is ceramic, its electrical resistance is higher than that of metallic magnetic materials and is characterized by excellent corrosion and chemical resistance.

Uses of Ferrites

Ferrites are mainly used as a magnet called ferrites magnet. Because it is inexpensive and can be mass-produced, its use fields are diverse, including home appliances, game consoles, and personal computers.

Ferrites are also used as the core of transformers and as a material to block electromagnetic waves in radio wave anechoic boxes and anechoic chambers. Ferrite particles are also used as carriers to carry toner in laser printers, etc. Ferrites are a magnetic material that permeates our daily lives.

Types of Ferrites

There are three types of ferrites as follows.

1. Spinel-Type Ferrites

Spinel-type ferrites are ferrites whose main component is Fe2O4. In the past (because its main component was iron oxide) it had to be heat-treated at a temperature of 800°C or higher to be produced.

In recent years, it has become possible to produce it at temperatures as low as 100°C by conducting the reaction in an alkaline solution. Spinel-type ferrites exhibit soft magnetic properties when mixed with additives such as manganese, cobalt, nickel, copper, and zinc.

2. Hexagonal Ferrites

Hexagonal ferrites are ferrites with the chemical formula M-Fe12O19 (M: Ba, Sr, Pb, etc.). It is hard ferrites that exhibit complex magnetism when barium or strontium is added.

3. Garnet-Type Ferrites

Garnet-type ferrites are ferrites with the same type of crystal structure as natural pomegranate stone and have the chemical formula Mg3Al2Si3O12. Garnet-type ferrites are soft ferrites that exhibit the same mild magnetic properties as spinel-type ferrites.

Other Information on Ferrites

1. Properties of Ferrites

- Hard Ferrites: Hard ferrites have ferromagnetic properties that become magnetic once a strong magnetic field is applied and then remain magnetic.

- Soft Ferrites: Soft ferrites have weak magnetic properties that develop magnetization when a magnetic field is applied and cease to be magnetic when the field is removed. It is characterized by its high magnetic permeability and is used in the cores of coils and transformers.

2. Mechanism of Noise Reduction by Ferrites

Ferrites are also used as a noise-reducing component. For example, EMI (Electromagnetic Interface) is a significant problem in high-speed communication signals such as USB, etc. EMI (Electromagnetic Interference) is not limited to communication lines but refers to unwanted electromagnetic noise emitted by electrical equipment.

In terms of EMI certification and quality assurance, electrical equipment is classified as Class A or Class B, and appropriate EMI countermeasures are required for each product. Usually, EMI countermeasures are taken at the time of circuit and pattern design, but ferrites may be used in the later stages of design and when development time is limited.

By wrapping the ferrites around the noise-generating harness, the impedance of the cable changes according to the magnetization of the ferrites, and as a result, the noise current can be reduced. However, reducing noise current means that high-frequency components are reduced. In other words, the ferrites function as a simple low-pass filter.

Thus, it is essential to keep in mind that reducing high-frequency components leads to signal distortion, which may cause waveform accentuation and, eventually, signal quality degradation. The noise reduction characteristics of ferrites are determined by their impedance, which varies depending on the ferrite's material, size, and number of turns.

When the ferrite material is the same and when the exact size is used, the impedance generally increases with the number of turns N in the harness. Although the increase in impedance results in more powerful noise suppression, the number of turns should be selected according to the frequency band to be suppressed.

The cross-sectional area also affects the impedance, and as a rule, ferrites with a smaller inner diameter and a larger outer diameter have a higher impedance. A wide range of ferrites are available as high-frequency countermeasure components. It is important to understand the characteristics of each and use ferrites with the appropriate characteristics for the frequency band to be counteracted.

List of 8 Ferrite Manufacturers

*Including some distributors, etc.

Sort by Features

- Default

- Company Size: largest first

- Year Founded: oldest first

- Year Founded: earliest first

Sort by Area

- United States of America

- China

- Japan

- Republic of Korea

-

-

-

Tokin America, Inc

Conductive Polymer Tantalum Capacitor NeoCapacitor

Manufacturer Overview

Tokin America Inc., headquartered in San Jose, California, is a supplier of passive electronic components in North, South, and Central America and is a subsidiary of Tokin Corporation. Its diverse product range includes capacitors, noise countermeasure components, and sensors used in several industries, including telecommunication, automotive electronics, and digital home appliances. The company also provides specialized design support and works with several distributors within the United States, including Future Electronics, WPG Americas, and Bravo Electronics.

-

-

-

-

-

NIC Components Corp.

Ferrite Chip Beads

Company Overview

NIC Components Corp., and Nippon Industries Co. Ltd. have collaborated for over 37 years to design and manufacture passive components, including capacitors, resistors, and magnetics. Established in the USA in 1982, NIC has expanded its business to the custom speciality that meets the demands of today’s emerging and latest technology. Their regional offices can be found in Canada, Malaysia, India, Mexico, China, etc. All of their products are built with more features and are certified with different ISO certifications. They also assist their customers in component selection through live support.

-

-

-

-

-

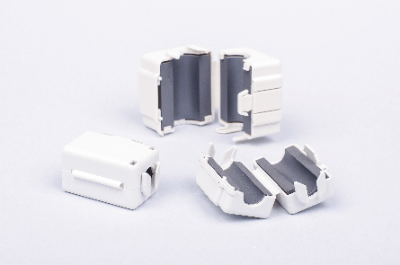

Magengine Co.,ltd

Sintered Ferrite

Manufacturer Overview

Magengine Co.,ltd was founded in 2005 and is a manufacturer of neodymium iron boron, samarium cobalt, ferrite, aluminum nickel cobalt, and magnetic tools based in Xicheng, Beijing, China. The company manufactures various products such as linear motor, casting steel, bonded magnets, soft ferrite, and EV charger products. The products have been used in various industries such as automobile, wind power, servo motors, rail transit, and medical equipments. The company has passed the ISO 9001:2015 certification for the quality management system.

-

-

-

-

-

Nippon Ceramic Co., Ltd.

Products

Manufacturer Overview

NiCera - Nippon Ceramic Co., Ltd. was established in 1975 in Japan as a manufacturer of ceramic sensors. The company designs infrared sensors that have applications in home electronics such as microwaves, air conditioners, heaters, etc. Ultrasonic sensors have been used in automobiles for back and corner sensing and for automatic parking systems. Current sensors are also used in automobiles as well as in industrial equipment along with gas sensors that have applications in the agricultural industry such as controlling CO2 concentration. The modules of human detection sensors and LED power supplies are also part of the production.

-

-

-

-

-

Samwha Capacitor Group

Magnetic powder core

Manufacturer Overview

Samwha Capacitor Group, founded in 1956 in South Korea, is a specialty manufacturer of passive components, specializing in capacitors. The company's products include EMI filters, varistors, chip inductors, power capacitors, and energy storage capacitors used in various applications by original equipment manufacturers, from small consumer batteries, personal device batteries, and industrial-grade batteries to large infrastructure power stations. Samwha Capacitor Group comprises Samwha Capacitor, Samwha Electric, Samwha Electronics, Samwha Tecom, and Korea JCC.

-

-

-

-

-

Glead Electronics

Soft magnetism ferrite material

Manufacturer Overview

Glead Electronics, established in 2000 and headquartered in Jiaxing, China, serves as a manufacturer and supplier of microwave ceramic components and antenna products. Its offerings encompass microwave ceramic materials for diverse temperature applications, RF passive components including filters and couplers, and antenna modules for applications like GPS, Beidou, and 4G. Additionally, they provide ceramic substrates for electronic device mounting and a range of accessories. These solutions are utilized in electronic system design in fields such as satellite navigation, wireless communication, and automotive electronics. The company holds several certifications including ISO 9001, IATF 16949, ISO 14001, OHSAS 18001, and GJB 9001B.

-

-

-

-

-

Enerdoor Group

Toroidal ferrite core

-

-

-

-

-

Muuntosähkö Oy

Ferrite

-

-

Ferrite Manufacturer Ranking

*Including some distributors, etc.Ranking as of July 2024

Derivation Method| Rank | Company | Click Share |

|---|---|---|

| 1 | Samwha Capacitor Group |

22.1%

|

| 2 | Muuntosähkö Oy |

16.9%

|

| 3 | Glead Electronics |

11.7%

|

| 4 | Nippon Ceramic Co., Ltd. |

11.7%

|

| 5 | Enerdoor Group |

10.4%

|

| 6 | Tokin America, Inc |

10.4%

|

| 7 | Magengine Co.,ltd |

9.1%

|

| 8 | NIC Components Corp. |

7.8%

|

Derivation Method

The ranking is calculated based on the click share within the ferrite page as of July 2024. Click share is defined as the total number of clicks for all companies during the period divided by the number of clicks for each company.Number of Employees

- Nippon Ceramic Co., Ltd.: 1,311

Newly Established Company

- Magengine Co.,ltd: 2005 (19 years ago)

- Glead Electronics: 1995 (29 years ago)

- NIC Components Corp.: 1982 (42 years ago)

Company with a History

- Muuntosähkö Oy: 1947 (77 years ago)

- Nippon Ceramic Co., Ltd.: 1975 (49 years ago)

- NIC Components Corp.: 1982 (42 years ago)

Ferrite Manufacturers in United States

*Including some distributors, etc.

Global Distribution of Ferrite Manufacturers by Country

*Including some distributors, etc.

| Country | Number of Companies | Share (%) |

|---|---|---|

United States of America

United States of America

|

2 | 40.0% |

China

China

|

1 | 20.0% |

Japan

Japan

|

1 | 20.0% |

Republic of Korea

Republic of Korea

|

1 | 20.0% |