All Categories

History

This section provides an overview for coreless motors as well as their applications and principles. Also, please take a look at the list of 11 coreless motor manufacturers and their company rankings. Here are the top-ranked coreless motor companies as of March, 2026: 1.Sinotech, 2.Motioncontrolproducts., 3.SI Group, Inc..

Table of Contents

Categories Related to Coreless Motors

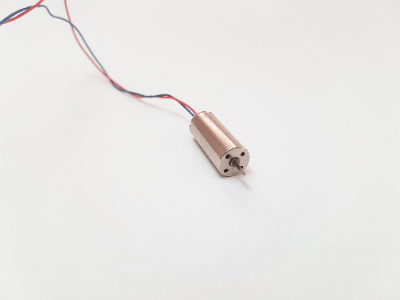

A coreless motor is a small motor without an iron core.

A coreless motor is a small motor without an iron core.

It is also called an iron coreless motor. The advantage of coreless motor is that there is no loss due to iron loss because there is no iron core. There is no vibration due to cogging, and the motor operates quietly.

However, the torque is lower because the magnetic force generated is weaker than that of a normal motor.

Coreless Motors are used in vibration motors that vibrate cell phones and servo motors for radio-controlled vehicles and robots, taking advantage of their small size and low vibration, noise, and electromagnetic interference.

Because of their excellent responsiveness and controllability, they are also used in surveying instruments, camera lens motors, ultrasonic endoscopes, surgical drills, etc., making them indispensable motors, especially for medical applications. Each manufacturer is developing its own unique coil winding method and materials.

An ordinary motor consists of a coil wound around an iron core, with a magnet placed outside the coil. Electric current flows through the coil, and the magnetic field generated by electromagnetic induction is used to cause the magnet to rotate.

In a coreless motor, on the contrary, a permanent magnet is placed inside and the coil is wound around the outside of the magnet in a cup shape using resin or other material, thereby eliminating the iron core. When an electric current is applied to the coil, the coil rotates, subject to Fleming's left-hand rule. Since the coil rotates, it is called a rotor.

Coreless motors have low inductance in their windings and are highly efficient. The electrical time constant of the motor is a parameter that indicates the characteristics of the rising current in relation to the input voltage.

It indicates the time it takes for the current to reach 63.2% of its peak value. Since the electrical time constant is relatively low for coreless motors, the current responds very quickly.

Coreless motors are motors with low inertia due to their reduced weight. Inertia refers to the moment of inertia, which increases in proportion to the mass.

Inertia is proportional to the acceleration/deceleration torque, which is the torque required to accelerate or decelerate to a given rotational speed. In other words, the acceleration/deceleration torque is also smaller in coreless motors, making them suitable for rapid acceleration and deceleration.

The use of powerful rare earth magnets, such as neodymium magnets for the internal magnets, has led to further miniaturization and increased torque. They help reduce size, thickness, and weight.

A coreless motor does not generate iron loss. Iron loss consists mainly of hysteresis loss and eddy current loss. The energy loss caused by a change in the magnetic field report of the iron core is called hysteresis loss.

In addition, changes in the direction of the magnetic field generate electric current inside the iron core. The generated electrical energy is converted to heat and escapes to the outside, and this loss is called eddy current loss.

In the case of coreless motor, the above-mentioned iron loss does not occur, so the motor can operate at high efficiency even at high speeds. Each company's technology is reflected in the way the coils are wound to minimize waste and increase efficiency.

A coreless motor is a motor that does not use an iron core (core) but consists of coils and magnets. A motor with coils wound around a general iron core is called a cored motor.

A brushless motor is a motor that does not use brushes and is rotated by controlling the direction of the electric current by an electronic circuit. DC motors (direct-current motors) are classified according to whether they are controlled by electronic circuits or commutators and brushes, as they need to periodically reverse the direction of the current to keep rotating.

Coreless motors come in two types: brushed and brushless. A motor that is coreless and brushless is called a coreless brushless motor. For brushed motors, the rotor is a coil, and the stator is a permanent magnet. For brushless motors, the rotor is a permanent magnet, and the stator is a coil.

Advantages

The iron core accounts for most of the weight of a motor. The absence of an iron core in a coreless motor allows it to be smaller and lighter. They also have a small moment of inertia (inertia), resulting in excellent responsiveness and controllability, as well as high motor efficiency and high-speed rotation.

In the case of cored motors, the iron core and magnet repeatedly move closer together and farther apart, each time causing cogging, or magnetic force trapping. Coreless motors, however, have the advantage of smooth and quiet rotation because cogging does not occur.

Disadvantages

The disadvantage of coreless motors is that they generally have low torque. The amount of torque is proportional to the current value. To achieve high torque, a large current must be applied, but because the copper wire is thin and there is no iron core, the coil is mechanically weak and a large current cannot be applied.

If a large current is applied to a coreless motor with a small allowable current value, the heat may deform the coil and lead to motor failure.

*Including some distributors, etc.

Sort by Features

Sort by Area

Sinotech is based in Portland, Oregon with offices in China. Sinotech is a distributor for custom-engineered electrical motors, motor components, and mechanical components manufactured in China. Sinotech’s motors include AC motors, DC motors, brushless DC motors, slotless high speed BLDC motors, stepper motors, cordless motors, gear motors, servo motors, and miniature motors. Motor components include laminations, wound coils, armature and field coils, brushes, and communicators. Mechanical components include assemblies, die castings, investment castings, sand castings, shafts, steamed metal parts, tubular metal parts, machined extrusions, plastic parts, rubber parts, and secondary processing.

Citizen Chiba Precision was established in Chiba, Japan in 1979. Citizen is a leader of miniaturized precision motors and customized products which custom-made to meet specific customer requirements for among others, semiconductor manufacturing equipment, medical equipment, and laser application products. Examples of Citizen’s products include optical scanners, linear actuators, servomotors, gear heads, and control drivers.

Motion Control Products Ltd. is a UK-based global supplier and manufacturer of various automation control systems, products, and components for all machinery and systems mechanization requirements. The company offers a range of products including Computer Numeric Control (CNC) and motion controllers which are components used in advanced manufacturing systems, automation, robotics, and aerospace. They also offer Drives and Inverters for use in film & foil converting equipment, printing industries, and to control stepper motors. The company also has offices in China, Hong Kong, and the United States.

Orbray was originally founded in 1939 in Japan. Orbray serves the automotive, medical, fashion, information communication, audio, and robotics industries. Orbray develops a variety of products including small motors, fiber optics components, and precision jewelry tools. Applications for Orbray’s products include small robots, diaphragm pumps, inner wall metrology systems, and semiconductors.

Nidec Corporation was founded in Kyoto, Japan in 1973 and is a conglomerate with over 200 subsidiaries. Primary products are hard-disk drive motors and automotive parts, and specializes motors ranging from miniature to gigantic. Nidec’s products are used in robotics, automotive, home appliances, agriculturel equipments well as molding, cutting, and machining equipment and sensors.

Ion Exchange Limited, established in 1964 in Mumbai, India, is a manufacturer and supplier specializing in ion exchange resins for water treatment applications. The company’s product portfolio includes gel, macroporous, and isoporous ion exchange resins for water, non-water, and specialty applications. Their products are used for water and environmental management in various industries including pharmaceuticals, food and beverage, chemicals, hydrometallurgy, nuclear and more. The company holds ISO 9001:2015 and ISO 14001:2015 certifications, and serves clients across the globe.

C.I. TAKIRON Corporation was founded in 1919 and is a manufacturer and supplier of building materials, plastic plates, and flooring based in Minato, Tokyo, Japan. The company manufactures various products such as polycarbonate corrugated plates, siphon rain gutter system, resin concrete faucet pillar, polyethylene rainwater storage tank, and drainage catch basin. Various industries have used the company's products such as agriculture, semiconductor manufacture, household electical appliances, civil engineering, and urban environment management. The company has obtained various certification such as ISO 9001, ISO 5560, ASTM E1354, and ISO 14001.

SI Group, Inc. is a Texas manufacturer of chemical solutions originally established in 1906. The company specializes in process solutions, chemical intermediates, active pharmaceutical ingredients (APIs), and performance additives for clients in the oil and gas, plastics, pharmaceuticals, and tire industries. The company’s product lineup includes corrosion inhibitors for oilfield production and refining, chain extenders for plastics recycling, rubber modifiers for increasing the performance of industrial goods, and light stabilizers to reduce degradation from UV radiation. With office operations in three continents, SI Group runs facilities in nine countries and provides services to client companies around the world.

Coreless Motor Co. Ltd. is based in Yamato, Kanagawa, Japan, and is a manufacturer of coreless motors and related components that was established in 2017 following the merger of M-Link Co. Ltd., IC Fan V-Tech Co. Ltd., and Coreless Motor Co., Ltd. The company’s product lineup includes coreless AC servo motors, coreless brushless DC motors, and coreless IC fan motors. It also offers custom design and development services, as well as opto-mechanical assembly and optical coating. The company chiefly serves client manufacturers of automobiles, aircraft, and heavy machinery.

Citizen Micro Co. Ltd., founded in 1958 and currently a subsidiary of Citizen Watch Co. Ltd., is a Japanese manufacturer and supplier headquartered in Hidaka City, Saitama, offering electric products. The company introduced industry-standard gear motors, utilizing its ultra-fine machining technology applied in producing watch parts. Its product lineup includes an extensive selection of gear and direct current (DC) motors, gearheads, and rotary encoders. It also engages in joint development projects to create customized products, such as paradox planetary gearheads. The company serves diverse manufacturing sectors, including industrial, housing, and medical equipment.

Ranking as of March 2026

Derivation Method| Rank | Company | Click Share |

|---|---|---|

| 1 | Sinotech |

16.7%

|

| 2 | SI Group, Inc. |

12.6%

|

| 3 | Motioncontrolproducts. |

12.6%

|

| 4 | Ion Exchange Limited |

12.0%

|

| 5 | Coreless Motor Co., Ltd. |

10.1%

|

| 6 | NIDEC SANKYO |

8.8%

|

| 7 | Orbray Co., Ltd. |

8.5%

|

| 8 | Citizen Chiba Precision CO.,LTD. |

6.0%

|

| 9 | C.I. TAKIRON Corporation |

5.7%

|

| 10 | CITIZEN MICRO CO.,LTD. |

4.4%

|

Derivation Method

The ranking is calculated based on the click share within the coreless motor page as of March 2026. Click share is defined as the total number of clicks for all companies during the period divided by the number of clicks for each company.Number of Employees

Newly Established Company

Company with a History

*Including some distributors, etc.

*Including some distributors, etc.

| Country | Number of Companies | Share (%) |

|---|---|---|

Japan

Japan

|

5 | 55.6% |

United States of America

United States of America

|

1 | 11.1% |

United Kingdom

United Kingdom

|

1 | 11.1% |

India

India

|

1 | 11.1% |

Taiwan

Taiwan

|

1 | 11.1% |

81 products found

81 products

Kazumomotion Tech Co., Ltd.

1340+ people viewing

Last viewed: 7 hours ago

■ Reasons for high quality and high performance 1. Coreless motors and brushless motors are made by Japanese manufacturers in the highest class of ...

Techtuit

1000+ people viewing

Last viewed: 7 hours ago

・ Cylinder type, coin type lineup ・ Contributing to long life of product batteries due to low current consumption and expandability of product dev...

CITIZEN MICRO CO.,LTD.

1370+ people viewing

Last viewed: 7 hours ago

Excellent precision processing technology and unique winding technology have made it possible to achieve compact size and high performance. A wide ...

UNO

1760+ people viewing

Last viewed: 7 hours ago

This product is a small generator designed and developed targeting small wind power and micro hydroelectric power generation, and can efficiently c...

UNO

590+ people viewing

Last viewed: 7 hours ago

The output efficiency has been improved than the conventional coreless motor with a coreless motor using a special coil. Because it is small, ligh...

4 models listed

Techtuit

980+ people viewing

Last viewed: 7 hours ago

・ Cylinder type, coin type lineup ・ Contributing to long life of product batteries due to low current consumption and expandability of product dev...

Ally Japan Co., Ltd.

610+ people viewing

Last viewed: 7 hours ago

■Product usage/adoption record Automotive parts, medical precision equipment, robot products, etc.

ISL Products International.

170+ people viewing

Last viewed: 7 hours ago

■Superior Performance ISL Products offers the latest technology when it comes to Coreless Brushless DC Motors. Our Coreless Brushless Motors offer ...

Techtuit

840+ people viewing

Last viewed: 7 hours ago

・ Cylinder type, coin type lineup ・ Contributing to long life of product batteries due to low current consumption and expandability of product dev...

Techtuit

610+ people viewing

Last viewed: 1 hour ago

・ Cylinder type, coin type lineup ・ Contributing to long life of product batteries due to low current consumption and expandability of product dev...

3 models listed

CITIZEN MICRO CO.,LTD.

630+ people viewing

Last viewed: 7 hours ago

A geared motor is a general term for a combination of a motor and a reduction gear.

ISL Products International.

180+ people viewing

Last viewed: 7 hours ago

■High Performance with Less Energy ISL’s coreless brushed dc motors have excellent performance and simple motor control all within a compact size. ...

Techtuit

430+ people viewing

Last viewed: 7 hours ago

・ Cylinder type, coin type lineup ・ Contributing to long life of product batteries due to low current consumption and expandability of product dev...

3 models listed

Techtuit

570+ people viewing

Last viewed: 7 hours ago

・ Cylinder type, coin type lineup ・ Contributing to long life of product batteries due to low current consumption and expandability of product dev...

3 models listed

Techtuit

880+ people viewing

Last viewed: 7 hours ago

・ Cylinder type, coin type lineup ・ Contributing to long life of product batteries due to low current consumption and expandability of product dev...

Techtuit

510+ people viewing

Last viewed: 7 hours ago

・ Cylinder type, coin type lineup ・ Contributing to long life of product batteries due to low current consumption and expandability of product dev...

3 models listed

Techtuit

510+ people viewing

Last viewed: 7 hours ago

・ Cylinder type, coin type lineup ・ Contributing to long life of product batteries due to low current consumption and expandability of product dev...

3 models listed

Techtuit

470+ people viewing

Last viewed: 7 hours ago

・ Cylinder type, coin type lineup ・ Contributing to long life of product batteries due to low current consumption and expandability of product dev...

3 models listed