All Categories

History

This section provides an overview for cnc measuring systems as well as their applications and principles. Also, please take a look at the list of 19 cnc measuring system manufacturers and their company rankings. Here are the top-ranked cnc measuring system companies as of March, 2026: 1.Fagor Automation Corp., 2.THOME Präzision GmbH, 3.Future Technology Systems S.A.

Table of Contents

Categories Related to CNC Measuring Systems

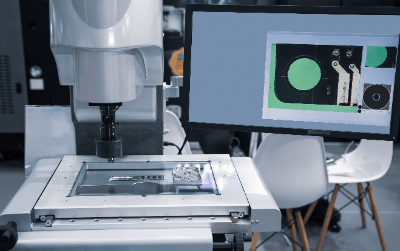

A CNC measuring system is a system that uses a CCD camera to magnify the object to be measured to observe its dimensions, shape, and surface properties.

A CNC measuring system is a system that uses a CCD camera to magnify the object to be measured to observe its dimensions, shape, and surface properties.

The system can move the object to be measured and the CCD camera to any desired position at high speed and with high accuracy and also perform a non-contact measurement without damaging the object to be measured. In addition, the system enables high-precision focusing by laser and image processing autofocusing, and image processing can find flaws and defects that cannot be observed with the naked eye.

The CNC measuring system is used to perform continuous automatic measurement at high speed and high accuracy. The system is suitable for measurements of very small, identical patterns, such as pattern measurements of substrates and electronic components.

Because humans can become confused and fatigued when they lose track of where they have measured due to the succession of the same pattern, a CNC measuring system that always performs the same operation with high accuracy is indispensable in semiconductor production lines. It is also suitable for items that are not suited for manual measurement, as slight variations in positioning have a large impact on error when measured by humans.

CNC measuring system uses a CCD camera to magnify the object to be measured in order to observe its dimensions, shape, and surface properties, and requires a system to display the image obtained by the CCD camera, to measure the dimensions and surface properties from the image, and to process the image itself.

The installation and use of a CNC measuring system requires a dedicated, temperature-controlled measurement room. This is due to the high precision of the device and the fineness of the object to be measured, which means that temperature fluctuations can have a significant impact on measurement errors.

CNC measuring systems can be operated manually, but most of the work is done through a dedicated controller or PC application software. For fast response and highly accurate positioning, the system uses a mechanism that combines a stepping motor and ball screw with a digital scale to read coordinates and perform feedback control.

CNC control is an abbreviation for "computer numerical control" and refers to the use of computers to control machine tools and other equipment. By automating machine movements such as movement direction and speed through programming, high precision and high-speed operation can be achieved.

CNC control is written using two types of programming languages, G code and M code, in which G code describes the conditions and sequence of machining and movements, such as positioning, while M code serves as a supplement to G code.

A CCD camera, which is also used in the CNC image recognition system, consists of a microlens, a color filter, and a photodiode, each of which has the following functions.

Microlens

Microlenses are responsible for focusing the light that has passed through the lenses to deliver it to the photodiode efficiently.

Color Filter

Color filters break down light into RGB (red, green, and blue) or CMY (cyan, magenta, and yellow) and deliver the light to the photodiode.

Photodiode

When light is received, photoelectric conversion is performed to generate an electric charge, which is transferred vertically and horizontally. The transferred charge is converted to a voltage at the output of the CCD, and an image is output for each pixel.

Since R, G, and B are assigned to each photodiode, the resolution is reduced to about 1/3 of the original CCD pixel count. The image processing engine complements the image to produce an image with the original pixel count. The RAW format saves the data extracted from the photodiode without any composite processing.

*Including some distributors, etc.

Sort by Features

Sort by Area

Fagor Automation Corp. is a manufacturer of machine automation and control products and equipment established in 1972 and headquartered in Rolling Meadows, Illinois, USA. The company offers CNC systems for lathes, milling machines, cutting, grinding, and bending under the CNCelite, QUERCUS, and Optima brands. It also offers feedback systems for machine tools such as CNC machines and conventional machines as well as for various applications such as metrology, semiconductors, large scientific facilities, and additive manufacturing.

Future Technology Systems S.A was founded in 1996 and is a manufacturer of advanced CAD/CAM software systems and mechatronic products based in Volos, Greece. The company offers various products such as optical measuring machine, portable arm cmms, handheld 3D scanner, CNC milling machines, and structured light 3D scanner. The company also provides services related to the products such as product design, rapid prototyping, reverse engineering, 3D inspections, and virtual 3D presentations. The company has participated in research projects such as Greek Research Network PENED and BIOMINY.

THOME Präzision GmbH, established in 1993, is a manufacturer of coordinate measuring machines based in Darmstadt, Germany. The company’s products include manual measuring machine SMART, CNC measuring machine RAPID-Plus, CNC measuring machine TETA and stand CMM dimension for quality control in manufacturing, aerospace and automotive industries. In 2013, the company came up with measuring software called "ThomControl", which is installed in THOME measuring machines. The company coordinates, maintains and calibrates measuring machines in accordance with ISO 10360 or VDI 2617.

ATQ Metro Private Limited was established in 2011 based in Pune, Maharashtra, India and it is a manufacturer of vision measuring machines. The company manufactures products such as vision measuring machines, horizontal vision measuring machines, one-touch vision measuring machines, amalgam vision measuring machines, cutting tool vision measuring machines, profile projectors, digital microscopes and metrology fixtures. It's products are applicable for both contact and non-contact measurements, production, quality control and research. The company is ISO 9001 certified.

Walter Maschinenbau GmbH, located in Tübingen, Germany, is a manufacturing company that started in 1919 and makes CNC machines for eroding or grinding wood, metal, and PCD tools. The company was initially called Walter Montanwerke, but after partnering with others and producing more products, it changed its name to Walter Maschinenbau GmbH in 2004. Walter Maschinenbau GmbH produces machines for eroding, grinding, and measuring tools. The company serves global clients in industries like transport and heavy machinery, precision engineering, medical, machine manufacturers, and automotive.

CARMAR ACCURACY CO., LTD, established in 1987 and based in Taichung, Taiwan, is a manufacturer and designer of non-contact and contact measurement systems. The company produces products such as linear scale, profile projectors, video measuring systems and machines, coordinate measuring machines, and white light scanners. All the measuring systems made by the company will inspect the metal, plastic, and rubber components like wafers and PCBs and supply them to different customers in Southeast Asia, China, Europe, America, and Japan.

NIKON CORPORATION was founded in Japan in 1917 and is a global manufacturer of imaging products, optics, precision equipment, and instruments. The company's main product offerings include the Nikon Z series of mirrorless cameras, digital SLR cameras, and COOLPIX. It also offers consumer and professional accessories such as NIKKOR brand optics, Speedlights, system accessories, and software products, along with premium sports and recreational optical products, including full-line binoculars, Fieldscopes, and rangefinders. The company complies with international standards such as ISO 14001:2015 and ISO 45001:2018, catering to industries such as photography and videography, healthcare, manufacturing, and research.

Sinowon Innovation Metrology Manufacture Limited, founded in 2006 with facilities in China, is a manufacturer of geometric dimension measurement instruments and precision devices. The company's products include automatic vision measuring machines, 2D optical measuring machines, profile projectors, video microscopes, and precision displacement platforms. Sinowon Innovation Metrology Manufacture Limited's products are used for measuring dimensional and positional tolerances such as flatness, perpendicularity, and position. The company serves various industries, including 3C consumer electronics, new energy vehicles, medical health, home appliances, and solar photovoltaics.

Asimeto is a German-based manufacturing and supply firm that was established in 2007 and its headquarters are located in Germany. The company specialize in measurement tools, offering a diverse product range including calipers, micrometers, and gauges. Asimeto's precision instruments find application in industries such as manufacturing, engineering, and quality control, aiding accurate measurements. They play a vital role in ensuring dimensional accuracy and quality assurance. With an attention on precision and reliability, Asimeto subsidizes significantly to the field of metrology and measurement technology.

WuXi SenQian Mechanicl Instruments Co.Ltd, founded in China, is a supplier of optics, mechanisms, electricity, and software program. The company's product portfolio includes high-quality optical components, including lenses, mirrors, filters, and prisms, for applications in imaging, laser systems, and precision mechanical components. It also offers control software solutions that allow for efficient operation and monitoring of systems and customized programs. The company has ISO9001:2008 Certification and its products are CE certified.

Insize Co., Ltd., established in 1995 and headquartered in Jiangsu, China, is a supplier that specializes in supplying measuring instruments. The company offers a wide range of products, including calipers, depth-measuring instruments, height-measuring instruments, and more. It also offers comparison instruments, micrometers, and bore gauges. Its calipers can provide measurements in metric (mm) and/or imperial (inch) units, allowing users to work with their preferred measurement system. The company has achieved ISO 45001:2018 and ISO/IEC 17025:2017 certifications. It serves a range of industries, including automotive, aerospace, oil and gas, government, and more.

Ranking as of March 2026

Derivation Method| Rank | Company | Click Share |

|---|---|---|

| 1 | Fagor Automation Corp. |

10.3%

|

| 2 | THOME Präzision GmbH |

9.2%

|

| 3 | Future Technology Systems S.A |

7.7%

|

| 4 | Walter Maschinenbau GmbH |

7.7%

|

| 5 | HOMMEL ETAMIC |

6.2%

|

| 6 | Nikon Corporation |

6.2%

|

| 7 | LaserTherm s.r.o |

5.6%

|

| 8 | Asimeto |

5.6%

|

| 9 | Optimax Imaging Inspection & Measurement Ltd |

5.1%

|

| 10 | ATQ Metro Private Limited |

5.1%

|

Derivation Method

The ranking is calculated based on the click share within the cnc measuring system page as of March 2026. Click share is defined as the total number of clicks for all companies during the period divided by the number of clicks for each company.Number of Employees

Newly Established Company

Company with a History

*Including some distributors, etc.

*Including some distributors, etc.

| Country | Number of Companies | Share (%) |

|---|---|---|

China

China

|

6 | 37.5% |

Germany

Germany

|

2 | 12.5% |

India

India

|

2 | 12.5% |

United States of America

United States of America

|

1 | 6.3% |

Greece

Greece

|

1 | 6.3% |

Japan

Japan

|

1 | 6.3% |

United Kingdom

United Kingdom

|

1 | 6.3% |

Czech Republic

Czech Republic

|

1 | 6.3% |

Malaysia

Malaysia

|

1 | 6.3% |

40 products found

40 products

Corporation Noge Electric Industry

1130+ people viewing

Last viewed: 2 hours ago

■ About the exterior inspection device ・ Automatic exterior inspection is a product that automatically uses a camera and image processing technolog...

C.C.D. Co., Ltd.

440+ people viewing

Last viewed: 1 day ago

The GK-2000 visual inspection system is an online visual inspection system that consists of a CCD line camera, image input board, image processing ...

Mitani Shoji

1450+ people viewing

Last viewed: 14 hours ago

Cosmofinder is an automatic exterior inspection device made by Mitani Corporation, a professional for image processing and image measurement. The h...

2 models listed

CHUO ELECTRIC WORKS L.T.D

640+ people viewing

Last viewed: 19 hours ago

One-click measurement with no teaching required, just set and scan. OK up to A3 size. Batch measurement of multiple workpieces This is a device th...

Osaka Precision Machinery Co., Ltd.

590+ people viewing

Last viewed: 13 hours ago

Speedy and fully automatic measurement of tooth profile, tooth lead, pitch, and eccentricity of gears used in high-load power transmission devices ...

Nidek Power Train Systems

1170+ people viewing

Last viewed: 1 day ago

3D scanner technology in -line inspection Inline non -contact 3D scanners using light cutting methods using line lasers. Automatically tested inli...

YAC GARTER CO .,LTD

610+ people viewing

Last viewed: 1 day ago

This equipment is installed in production equipment for semiconductors, electronic components, etc., and performs appearance and dimensional inspec...

Corporation Noge Electric Industry

1290+ people viewing

Last viewed: 1 day ago

■ About the exterior inspection device ・ Automatic exterior inspection is a product that automatically uses a camera and image processing technolog...

Hubrain

1010+ people viewing

Last viewed: 1 day ago

・ This device is a multifunction device that has a both sides of the front and back imaging and the tray stuffing function. ・ Equipped with a high ...

CHUO ELECTRIC WORKS L.T.D

790+ people viewing

Last viewed: 2 hours ago

This is a custom size compatible version of the large dimension measuring device. We have a track record of delivering various sizes from 500mm up ...

C.C.D. Co., Ltd.

660+ people viewing

Last viewed: 14 hours ago

■Summary ・Automatic inspection of sheet products using CCD line camera ・Detects defects such as scratches, dirt, and unevenness ・Supports inspec...

Skylogic Co., Ltd.

660+ people viewing

Last viewed: 11 hours ago

Automate box sizing and weight measurement. It outputs the width, depth, height, and weight in 2 seconds after placing the box. Output includes rec...

Jutsu Japan Co., Ltd.

1340+ people viewing

Last viewed: 1 day ago

◼︎Features Combined inspection of 2D inspection and 3D inspection

Ryokosha Co., Ltd.

570+ people viewing

Last viewed: 22 hours ago

■Summary iNEXIV VMA series wide field of view type. High performance iNEXIV VMA series with ultimate ease of use. Achieves both high measurement ac...

Hexagon AB

440+ people viewing

Last viewed: 1 day ago

Camera-based 3D optical measurement systems provide highly accurate data to any user.

Ryokosha Co., Ltd.

480+ people viewing

Last viewed: 3 hours ago

■Summary iNEXIV VMA series wide field of view type. High performance iNEXIV VMA series with ultimate ease of use. Achieves both high measurement ac...

CHUO ELECTRIC WORKS L.T.D

810+ people viewing

Last viewed: 2 hours ago

This is an automatic two-dimensional dimension measuring device that automatically measures the dimensions of thin objects such as films and sheets...

5 models listed

C.C.D. Co., Ltd.

450+ people viewing

Last viewed: 1 day ago

■Features ・Latest CCD color camera ・Telecentric lens optical system ・Driven by a notebook PC / Image processing ・XY stage 100×100mm

Ryokosha Co., Ltd.

540+ people viewing

Last viewed: 5 hours ago

■Summary iNEXIV VMA series wide field of view type. High performance iNEXIV VMA series with ultimate ease of use. Achieves both high measurement ac...

Ryokosha Co., Ltd.

660+ people viewing

Last viewed: 1 hour ago

■Summary The evolved 4th generation NEXIV series. Automatically measures dimensions and shapes of various three-dimensional parts at higher speed a...

Ryokosha Co., Ltd.

520+ people viewing

Last viewed: 1 day ago

■Summary The evolved 4th generation NEXIV series. Automatically measures dimensions and shapes of various three-dimensional parts at higher speed a...

Ryokosha Co., Ltd.

610+ people viewing

Last viewed: 4 hours ago

■Summary The evolved 4th generation NEXIV series. Automatically measures dimensions and shapes of various three-dimensional parts at higher speed a...

Ryokosha Co., Ltd.

370+ people viewing

Last viewed: 9 minutes ago

■Summary The combination of NEXIV and automatic wafer transfer system enables full automatic measurement of one cassette of wafers.

Ryokosha Co., Ltd.

450+ people viewing

Last viewed: 21 hours ago

■Summary Confocal NEXIV VMZ-K series. The VMZ series enables even minute height measurements by selecting the objective lens. Two stage strokes ava...

Ryokosha Co., Ltd.

510+ people viewing

Last viewed: 1 day ago

■Summary Confocal NEXIV VMZ-K series. The VMZ series enables even minute height measurements by selecting the objective lens. Two stage strokes ava...

Ryokosha Co., Ltd.

550+ people viewing

Last viewed: 1 day ago

■Summary Confocal NEXIV VMZ-K series. The VMZ series enables even minute height measurements by selecting the objective lens. Two stage strokes ava...

Ryokosha Co., Ltd.

510+ people viewing

Last viewed: 1 day ago

■Summary Confocal NEXIV VMZ-K series. The VMZ series enables even minute height measurements by selecting the objective lens. Two stage strokes ava...

Ryokosha Co., Ltd.

440+ people viewing

Last viewed: 1 day ago

■Summary Achieves the highest measurement accuracy among the NEXIV series. Precise stage movement and high-performance engineering ensure ease of u...