All Categories

History

This section provides an overview for parts feeders as well as their applications and principles. Also, please take a look at the list of 21 parts feeder manufacturers and their company rankings. Here are the top-ranked parts feeder companies as of July, 2025: 1.Vibcon Corp., 2.Dixon Automatic Tool, Inc., 3.Visumatic Industrial Products.

Table of Contents

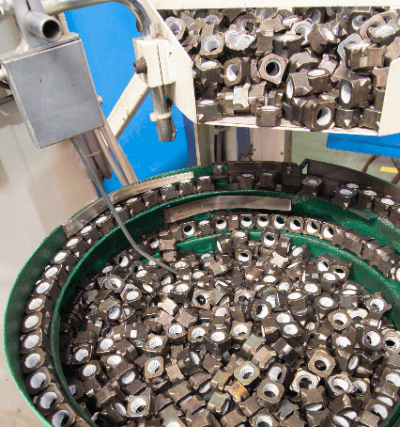

A parts feeder is a device that can automatically supply parts on a factory production line. It is also called an automatic parts feeder. They are used in conjunction with automated systems such as assembly, packaging, cooperative, and inspection machines.

Generally, it vibrates the parts so that each part in a disparate orientation can be fed in the same aligned orientation. This allows various processes, such as assembly, packaging, and wrapping, to be performed efficiently.

Parts feeder can be combined with image processing equipment and artificial intelligence to inspect parts simultaneously or with equipment in the following process to help improve work accuracy and reduce human and installation costs.

Parts feeders are installed to improve the efficiency of factory production. They are used to manufacture mechanical and electronic parts, pharmaceuticals, and food products. Parts feeders are used to increasing work efficiency by automating the supply of parts in combination with image processing equipment and artificial intelligence.

The objective is to automatically supply parts and simultaneously inspect the parts, thereby improving work accuracy and product quality. Some parts feeders supply multiple parts assembled, such as a washer and a bolt together, or disassemble and supply assembled parts.

Parts feeders align parts by vibrating them. The part that vibrates the parts is called the vibrating element or oscillator and is the heart of the parts feeders. The vibration method is mainly electromagnetic, using an electromagnet, and the vibration generated is amplified through a plate spring to generate even greater vibration.

Other methods include the piezoelectric method, which uses piezoelectric elements. The supplied parts are first placed in a bowl, which is a container for parts, and then the bowl is vibrated by a vibrating element to align the parts. The aligned parts are sent to a chute, where they are fed to the machine for the next process.

The parts in the bowl are monitored by a device called a hopper. The hopper detects the number of parts in the bowl and controls the feeding. There are various types of hoppers, including electromagnetic, conveyor, and cylinder hoppers. Hoppers work to stabilize the parts feeders' parts supply capacity by preventing parts from being overfilled or underfilled in the bowl.

Parts feeders are designed to incorporate various sensors and optional parts, allowing them to be customized for different purposes.

Various drive patterns are used in the bowl portion of the parts feeders, and the right parts feeders must be employed according to the parts.

The most common type of parts feeders are the electromagnetic parts feeders, but there are also various other types such as motor type, piezoelectric element type, and compound rotating disk type. Each type has its advantages and disadvantages, so it is essential to select the most suitable parts feeders after understanding the usage conditions and costs.

There are various types of parts feeders, including electromagnetic, motor, piezoelectric (piezoelectric element), and compound rotating disk types, each of which has its characteristics.

Electromagnetic parts feeders include half-wave type, full-wave type, high-frequency part type, and dual motion type.

This type of parts feeder is driven by a motor in horizontal motion only and is characterized by its low noise level.

Driven by a piezoelectric element. This type of parts feeder does not require vibration adjustment and is expected to save energy.

This parts feeder does not use vibration but uses a rotating disk to rotate parts for alignment feeding gently. Low vibration, low noise, and high-speed feeding are possible with this.

*Including some distributors, etc.

Sort by Features

Sort by Area

Visumatic Industrial Products, established in 1966, is a manufacturer of automated fastener feeding and driving equipment for industrial organizations undertaking assembly work, such as clips, bolts, pins, nuts, and specialty fasteners used in machine builders, general manufacturing, medical, and defense industries. The Lexington, Kentucky-based company provides standard and pistol-grip handheld solutions for ergonomic, quality, and speed improvements. The company offers various fully automated fixed systems and robotics, such as Viper 4-axis SCARA robotic screw driving system, dual x-y robot, rotary indexing, customer re-programmable robotic software, and multi-spindle systems.

Mountz Torque, founded in San Jose, CA, in 1965 is a manufacturer of torque products such as Robotic Screwdrivers, Torque Calibration, and Measuring Torque. The company's product portfolio includes Preset Torque Limiters, Torque Sensors, Run Down Adapters, Calibration Equipment and Torque analyzers and Sensor Accessories. Their products are used in the energy sector for wind turbine assembly and maintenance, critical aerospace components and systems and automotive assembly lines and maintenance applications. The company serves industries such as Oil and Gas, Aerospace and Defense, Automotive and Transportation, Construction, and Power Generation.

ASG is a division of Jergens, Inc., was founded in 1976, and headquartered in Cleveland, Ohio. ASG both manufactures and distributes solutions for assembly including precision torque and angle DC electric fastener systems. ASG is ISO 9001:2015 certified. ASG groups include ASG Express, ASG Precision Fastening, ASG Automation, and ASG Integrated Services. Together they specialize in electric and manual screwdrivers, production aides, tool accessories, air motors, pneumatic torque control tools, pulse tools, torque wrenches, current control tool systems, automation systems, auto feed systems, air grippers, torque arms, screwdrivers & nutrunners for automation, and peripheral automation equipment.

Graco Inc. Was incorporated in 1926 and is headquartered in Minneapolis, Minnesota. The company is a designer, marketer, and manufacturer of systems and equipment for the movement, control, dispensing, and spraying of fluid and powder materials to global customers. The company operates in three segments: industrial, process, and contractor. The industrial segment designs proportioning systems for pumping sealants, adhesives, and other coating materials. The process segment designs pumps used in water, wastewater, and petroleum industries. The contractor segment offers paint and viscous coating sprayers.

Dixon Automatic Tool, Inc. was originally founded in 1946 in Rockford Illinois. Dixon Automatic Tool is an automated assembly products and services supplier. Dixon Automatic Tool offerings include automatic screwdrivers, automatic nut-runners, automatic part placers, automatic setting systems, robotic end effectors, assembly work cells, hand-held drivers, feeder bowls and feed systems, and features Stöger products for customers’s automation needs. Dixon Automatic Tool also offers two escapement types that can be tooled to escape and transfer piece parts, as well as electric hand-held screwdrivers.

Vibcon Corp., established in 1982, is a manufacturer of vibratory machines for feeding, separating, and orientation applications, headquartered in Arcadia, Indiana. They manufacture parts feed systems, bowl feeders, hopper feeders, floor feeders, and linear tracks, providing precise handling of small parts and components. Additionally, they offer drive units, escapement, and enclosures. The company has been working with springs, electrical connector bodies, brass, and stainless steel couplings, dealing with shapes that defy typical methods of separation and orientation. Vibcon Corp. also provides installation, troubleshooting, base drive unit tuning, and spare replacement services.

DEPRAG USA is the Lewisville, Texas-based headquarters of DEPRAG, originally founded in 1931. DEPRAG is a distributor of assembly equipment and tools and industrial machinery. DEPRAG’s product lines include advanced screw driving technology with automatic screwdrivers, sequence controllers, measuring technology, accessories, and individual solution offerings. Other product segments include feeding technology including bowl feeders and sword feeders among others, automation including standardized assembly systems and intelligent manual work stations, air motors featuring vane motors and turbine motors, industrial tools, and “Green Energy Turbines segment featuring energy recovery.

ARO Welding Technologies, founded in 1949 and headquartered in Chateau-du-Loir, Le Mans, France, is a manufacturer of welding systems. The company offers a comprehensive product portfolio, including stationary welding machines, welding measuring tools, robotic welding guns, stationary welding tools, and welding controls and software. These products are used in automotive, aerospace, and general industrial applications. It also provides services such as project management, welder training, parameter optimization in the laboratory, and rectifying existing faults.

Nittoseiko Co. Ltd, established in 1938 at Kyoto, Japan is a manufacturer of screw driving components and screw fastening products. The company specializes in manufacturing advanced solutions for fastening, assembly as well as inspection technology. The products list involves loose proof screws, special cold forged parts, automatic screw driving machines, screw driving robots and measuring instrumentation systems. The products are used in applications such as automobiles, home appliances, telecommunications, electronic products and machinery. These fastening and assembly systems make it easier to assemble various components and also bond them together in a robust way.

Futaba, founded in Japan, in 1985 is a manufacturer of vacuum tubes, electronic equipment, and radio control equipment. The company's product portfolio includes OLED Displays, Touch Sensors, Electronic Modules, Radio Control Equipments for Industrial Use, and Radio Control Equipments for Hobby Use. The company serves industries such as Oil and Gas, Aerospace and Defense, Automotive and Transportation, Construction, and Power Generation. The company provides services such as Product Selection Guidance, Engineering Support, and Custom Manufacturing.

SINFONIA TECHNOLOGY CO., LTD., established in 1917 in Tokyo, Japan, is a manufacturer specializing in motion equipment, driven by advanced electromagnetic control technology. The company offers a comprehensive range of products and solutions, including clean transport devices, vital electrical components for space rocket systems, cutting-edge testing systems, advanced vibrating equipment, and electromagnetic clutch systems, among others. These diverse products serve critical functions in sectors such as Aerospace, Industrial Transportation, and Liquid-Crystal manufacturing equipment.

NTN Corporation established in 1918, is a precision machinery manufacturer that researches, develops, and sells bearings and driveshafts (CVJs) based in Japan. Their main products, bearings are essential and precision components that support rotation of machinery. They are used in different types of machinery including automobiles, wind turbines, rolling stocks, and others to support the lives of people around the world. The group has 212 bases in 34 countries around the world (118 sales bases, 72 manufacturing bases, 15 R&D bases, and 7 other bases as of the end of March 2023).

Daishin, a company founded in 1979 and based in Nagano, Japan, is a manufacturer and supplier of parts feeder systems and equipment. The company offers a wide range of products, including piezoelectric stack parts feeders, vibrators, stepping hoppers, and various controllers. These products cater to various manufacturing sectors such as automotive, aerospace, and electronics. Their machinery is utilized in the production of intricate components and parts to ensure accuracy in the manufacturing processes. The company also offers limited services in Japan such as product drawing downloads, manual offers, and public information.

Founded in 1938, Sankyo Seisakusho Co., Ltd. primarily serves the automobile, medical, and aerospace industries. Sankyo Seisakusho’s mane products include precision reducing gears, roller drives, intermittent indexing devices, indexing drives, feeders, motion control, and machine tool related equipment. Sankyo Seisakusho has a global reach with both factories and sales offices in the United States.

Festo Corporation, established in 1925 and headquartered in Esslingen, Germany, is a supplier of automation technology and technical education and is ISO 9001, ISO 13485, and ISO14001 certified. It has around 33,000 catalog products, customized components, and ready-to-install solutions, including grippers, motors, and sensors used in industrial and process automation. The company won the German Future Award in 2010 and serves 300,000 customers worldwide, while its education division provides training solutions for 56,000 industrial companies and educational institutions. It registered €3.81 billion in the 2022 financial year and is available in around 60 countries, with 2,600 patents worldwide.

EXEN Corp., established in 1915 and based in Tokyo, Japan, is a manufacturer of construction equipment and general industrial machinery. The company's main products are concrete vibrator and air knocker to solve material flow problems. Its pneumatic hammering technology in air knockers works against fine powders and sticky or clinging materials in the hopper, chute and pipes. It also offers a range of vibration motors, feeders, manual vibrators and table vibrators for concrete. The company's equipment are used in food and pharmaceutical plant, milling plant, petrochemical plant, paper making factory and civil engineering works.

TNA Australia Pty Limited is based in Sydney, New South Wales, Australia, and is a global supplier of food processing and packaging products that was established in 1982 as a subsidiary of TNA Solutions Pty Ltd. The company’s inventory includes vibratory and vertical conveyors, spray- and slurry model seasoning systems, and weighing equipment including multi-head and linear models. It stocks products from various international brands including Yamato, Baader, and Longford. The company chiefly serves clients in the snack foods, confectionery, and pet food industries.

Ranking as of July 2025

Derivation Method| Rank | Company | Click Share |

|---|---|---|

| 1 | Graco Inc. |

12.2%

|

| 2 | Vibcon Corp. |

11.8%

|

| 3 | Visumatic Industrial Products |

8.8%

|

| 4 | Dixon Automatic Tool, Inc. |

8.4%

|

| 5 | DEPRAG USA |

7.3%

|

| 6 | Sankyo Seisakusho |

5.3%

|

| 7 | Daishin Co.,LTD. |

5.0%

|

| 8 | Mountz Torque |

4.6%

|

| 9 | ASG, Division of Jergens, Inc. |

4.6%

|

| 10 | ARO Welding Technologies SAS |

4.2%

|

Derivation Method

The ranking is calculated based on the click share within the parts feeder page as of July 2025. Click share is defined as the total number of clicks for all companies during the period divided by the number of clicks for each company.Number of Employees

Newly Established Company

Company with a History

*Including some distributors, etc.

*Including some distributors, etc.

| Country | Number of Companies | Share (%) |

|---|---|---|

United States of America

United States of America

|

8 | 47.1% |

Japan

Japan

|

8 | 47.1% |

France

France

|

1 | 5.9% |

229 products found

229 products

Suzuno Manufacturing Co., Ltd.

1270+ people viewing

Last viewed: 1 hour ago

A flexible parts feeder that can handle a wide variety of products and is specialized for robot picking. By combining various industrial robots and...

3 models listed

Sanki Co., Ltd.

330+ people viewing

Last viewed: 8 hours ago

■Summary The piezoelectric parts feeder uses a piezoelectric element made of fine ceramics whose main components are lead titanate and lead zircona...

Kanto Denshi Co., Ltd

1320+ people viewing

Last viewed: 3 hours ago

In the past, separation and alignment of coil springs were very difficult, and it was a failure to operate the automatic manufacturing device. Sin...

8 models listed

Sanki Co., Ltd.

300+ people viewing

■Summary By optimizing our uniquely developed piezoelectric ceramic material and electrode shape, we have achieved durability and conveyance speed ...

Sanki Co., Ltd.

330+ people viewing

Last viewed: 5 hours ago

■Summary Adopts a side-pull method, which allows efficient pulling due to the direction of the leaf spring, generating a large amount of power with...

Daitake Root Industry Co., Ltd.

290+ people viewing

Last viewed: 15 hours ago

The strength of the bit guide bracket has been improved compared to the previous model, making it less likely to tilt. Optionally, a cover can be i...

Murata Seiko Co., Ltd.

1350+ people viewing

Last viewed: 12 hours ago

■Parts feeder body PV (half wave) type This is a general-purpose parts feeder with a half-wave drive method. ■Features - 1 electromagnet (magnet c...

6 models listed

Maehata Seiki Co., Ltd.

330+ people viewing

Last viewed: 15 hours ago

Entangled snap rings, C-rings, retaining rings, etc. are put in, separated one by one using a disassembler, and then fed in an aligned manner.

Shimatec Co., Ltd.

270+ people viewing

Last viewed: 1 day ago

Types ST-1 to ST-4 are full-wave drive. The ST-5 type is available in both full-wave drive and half-wave drive. The ST-6 type is half-wave drive.

Sanki Co., Ltd.

280+ people viewing

Last viewed: 4 hours ago

■Bowl clamp Vibration transmission performance to the bowl is further improved. ■Leaf spring The actual noise level is reduced by nearly 20-30%. (...

Daitake Root Industry Co., Ltd.

230+ people viewing

Last viewed: 1 day ago

The strength of the bit guide bracket has been improved compared to the previous model, making it less likely to tilt. Optionally, a cover can be i...

Murata Seiko Co., Ltd.

820+ people viewing

Last viewed: 20 hours ago

■Parts feeder body PVH (full wave) type This is a high-speed parts feeder using a full-wave drive system. ■Features ・A general-purpose parts feed...

6 models listed

Maehata Seiki Co., Ltd.

380+ people viewing

Last viewed: 1 hour ago

Bolts and washers are fed into one parts feeder at the same time and supplied in an assembled state. (With function to prevent washer assembly defe...

Yamashin Metal Industry Co., Ltd.

210+ people viewing

Last viewed: 1 day ago

■Adsorption conveyance with blower We have developed a magnetic belt feeder that can transport ferrous and non-ferrous materials by combining sucti...

Shimatec Co., Ltd.

210+ people viewing

Vibration adjustment is easy and runs smoothly.Both the front and rear spring angles can be changed, allowing fine adjustment of the workpiece run....

Sanki Co., Ltd.

330+ people viewing

Last viewed: 6 hours ago

■Features ・Power supply 100/200V shared ・Digital display ・Soft start/stop function ■High-speed auto-tuning *High-performance version only The c...

Daitake Root Industry Co., Ltd.

230+ people viewing

Last viewed: 1 day ago

The strength of the bit guide bracket has been improved compared to the previous model, making it less likely to tilt. As an option, a sub-cover ca...

IDEX Co., Ltd.

810+ people viewing

Last viewed: 22 minutes ago

■Quickly arrange all parts. Arrange minute parts while sorting them from front to back. ・The know-how of IDEX, which knows everything about vibrat...

2 models listed

Maehata Seiki Co., Ltd.

220+ people viewing

Separate the intertwined springs one by one, align them, and feed them. Low noise and high speed supply is possible using a motor.

Shimatec Co., Ltd.

220+ people viewing

Last viewed: 17 hours ago

Compatible with faster production lines and inspection machines. Shinko Electric's Dialmotion parts feeder enables high-speed supply of screws, bol...

Sanki Co., Ltd.

290+ people viewing

Last viewed: 9 hours ago

Features ■Digital settings/display Digitally set output voltage and frequency. Setting values can be managed. Soft start/stop function ■Sensor ...

Daitake Root Industry Co., Ltd.

220+ people viewing

Last viewed: 11 hours ago

Features ■One unit supports 8 types of screw diameters One machine can accommodate 8 different screw diameters just by replacing the rail. Supply ...

Maehata Seiki Co., Ltd.

420+ people viewing

Last viewed: 1 hour ago

The tangled springs are fed into the springs, separated one by one by a dismantler, and then fed in a uniform position.

Sanki Co., Ltd.

320+ people viewing

Last viewed: 16 hours ago

■Summary Inline feeders range from small with a total weight of 0.25kg to large feeders with a total feeder weight of 17kg, maximum allowable chute...

Koei System Co., Ltd.

240+ people viewing

Last viewed: 1 day ago

■Alignment Parts feeder parts feeding machines are standard products related to parts that are considered as a major starting point in various fiel...

Shimatec Co., Ltd.

190+ people viewing

Last viewed: 1 day ago

■Features ・Maintenance free ・Easy to dispose of garbage - Strong against impact and load Guide rails and attachments can be attached to the oute...

STARTECHNO COMPANY LIMITED

500+ people viewing

Last viewed: 2 hours ago

■Summary ・New parts feeding system with feeder + vision system. Eliminates feeder clogging and significantly reduces stoppages. ・This is a robot ...

Daitake Root Industry Co., Ltd.

230+ people viewing

Last viewed: 11 hours ago

Features ■It is possible to count the number of screws taken out. A buzzer will notify you when you take out the preset number. ■Quantity set 0 to...

Maehata Seiki Co., Ltd.

290+ people viewing

Last viewed: 1 day ago

A parts feeder called Dexter uses motor rotation to sort and feed workpieces without using vibration. Low noise and high speed supply is possible. ...

CT Takahata Co., Ltd.

180+ people viewing

Last viewed: 1 day ago

■ Significantly improve work efficiency Design and construction of automation equipment and labor-saving equipment ・Automated robot ・Feeding devi...