All Categories

History

This section provides an overview for axial flow pumps as well as their applications and principles. Also, please take a look at the list of 15 axial flow pump manufacturers and their company rankings. Here are the top-ranked axial flow pump companies as of March, 2026: 1.ITT INC., 2.D & D Machine & Hydraulics, Inc., 3.Weir Group PLC.

Table of Contents

Categories Related to Axial Flow Pumps

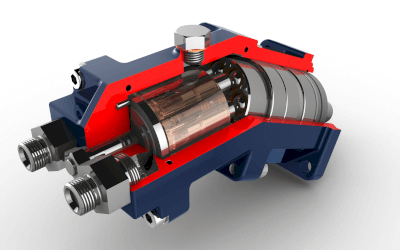

Axial flow pumps are pumps in which the flow discharged from the impeller is concentric with the main shaft.

Multiple impellers are attached to a rotating shaft, and the impellers exert pressure and velocity energy on the fluid through their lifting action. The velocity energy of the fluid exiting parallel to the shaft is then converted to pressure energy by a fixed guide vane.

Axial flow pumps are used for drainage, irrigation, and other applications where large flow rates and little pressure are required.

Axial flow pumps are used in a variety of industrial applications because of their low aerodynamic losses, compact size, and relative ease of handling.

Examples include cooling water in power plants, condensers in steam turbines, water and sewage systems, and water circulation and wastewater in the chemical industry. Other applications include river drainage, irrigation, food and beverage industries, oil and gas, and mining.

Axial flow pumps are classified as turbo type pumps. It has a structure of radially arranged vanes on a cylindrical rotating shaft, and centrifugal force is created by the high-speed rotation of the impeller.

The impeller is similar in shape to the wings of an airplane. In Axial Flow Pumps, the blades are fixed to the impeller and rotate. The lift force acting on the impeller creates an axial flow force and discharges the liquid.

Axial flow pumps consist of a casing, impeller, fixed impeller, main shaft, bearings, and shaft seal.

The casing houses the rotor, which consists of the impeller and shaft, and has a pressure-resistant structure to dispense liquid efficiently.

The impeller has multiple blades that rotate to expel the fluid. The fixed blades change the swirling flow into an axial direction and convert velocity energy into pressure.

The main shaft is the part of the impeller that is attached to and rotates the impeller and transmits the necessary power to the impeller.

The bearing supports the spindle and impeller and is an important component for stable pump operation.

The shaft seal will seal water leakage through the penetration between the shaft and casing.

The major factors that determine pump specifications are flow rate and pressure. Pressure can be converted to m, the same unit of potential energy, and is called head or head. The criteria for selecting which type of turbo pump to use based on flow rate and pressure are generally as follows:

Pumps can experience a problem called cavitation. At the inlet of the pump's impeller, the higher velocity of the fluid increases the velocity energy, which in turn reduces the inlet pressure, i.e., the static pressure.

When the pressure at the impeller inlet drops below the saturated vapor pressure of water at that temperature, the water vaporizes into steam and bubbles are generated. This phenomenon is cavitation.

If the pump continues to operate in this manner, the bubbles repeatedly generate and dissipate, generating shock waves. The shock wave strikes the impeller blade surface, causing gradual erosion of the surface. This is cavitation erosion.

If cavitation continues, the bubbles do not dissipate and the suction area becomes covered with bubbles, making it impossible for the pump to function. Even if there is sufficient margin for cavitation to occur at the rated operating flow rate of the pump, cavitation will occur in the small flow rate range. The countermeasures against cavitation are to increase the minimum operating flow rate or to use a variable pump speed.

*Including some distributors, etc.

Sort by Features

Sort by Area

D&D Machine and Hydraulics was founded in 1980 and is a manufacturer of hydraulically driven, submersible pumping systems in Fort Myers, Florida. Specifically, the company produces electric or diesel-driven Power Units and Axial Flow, Trash, Sludge, Slurry/Digester, and Mixed Flow pump heads. The flow capacity of these pump heads ranges from 450gpm to 55,000gpm and heads of 250 feet are attainable. The company served the Agricultural, Construction, Industrial, Mining, Petroleum and Municipal markets worldwide.

ITT Inc., originally founded in 1920 and headquartered in Stamford, Connecticut, is an American multinational manufacturer specializing in specialty components for a wide range of industries. Through its subsidiaries, the company delivers engineered solutions for specific sectors. In aerospace, it provides custom components to enhance safety and efficiency in passenger and freight transportation. The company also offers electrical penetrator solutions for the oil and gas sector and impact energy absorption technology for automotive and heavy vehicles. Moreover, it supplies pumping solutions for the chemical, food and beverages, medical, and pharmaceutical industries. In infrastructure, the company specializes in shock and vibration isolations.

Sulzer Ltd. is a fluid engineering and chemical processing solutions manufacturer originally founded in 1775. The company has been headquartered in Winterthur, Switzerland since 1834, maintaining a network of 180 manufacturing facilities and service centers around the world. The company has an expansive product portfolio including distillation and absorption columns, agitators, reactors, crystallizers, and polymerization systems. These supply clients in the metals, plastics, chemicals, power, and pharmaceutical industries. Sulzer Ltd. also offers a range of services, such as testing and diagnostics, prototyping, retrofitting, and upgrades, including technical training with long-term support for their customers.

Weir was established in 1871 as a manufacturer and supplier of mining solutions headquartered in Glasgow, Scotland. The company provides Processing equipment for Comminution, Classification, Pumping, and Slurry Transportation and Dewatering along with wear parts, and equipment attachments for similar purposes. There is Feeding, Crushing, and Screening equipment for the processes and wear parts for Face Shovels, Dozers, Motor graders, and more and these products are not just serving the mining industry but also the construction aggregates industry, Food Processing, Recycling, Chemical Processing, and Storage sectors.

Sinoflo is a manufacturer of pumps and related complete fluid transportation solutions established in 2019 and headquartered in Suzhou, Jiangsu, China. The company offers submersible, magnetic drive, canned motor, vertical turbine, and split casing pumps. It also extends its capability to manufacture custom-designed pumps fitted with materials to match specific customer requirements. These pumps are widely used in various industries including municipal building, food medicine, urban water supply, irrigation drainage, and sewage treatment.

Ruhrpumpen, established in 1950 and headquartered in Garza García, Mexico is a manufacturer and supplier of advanced pumping solutions. Their comprehensive product line includes centrifugal and reciprocating pumps, designed to cater to diverse industries such as oil and gas, water treatment, and chemical processing. The company’s engineering excellence, Ruhrpumpen plays a pivotal role in ensuring efficient fluid transport and management globally. With a legacy of invention and reliability, they subsidize significantly to industrial processes, providing modern solutions for fluid handling challenges across various applications.

Mehta Hydraulics, established in 2015 and headquartered in Maharashtra, India, is a manufacturer and supplier of hydraulic components and equipment. The company's products include hydraulic power packs, directional control valves, and mobile control valves. It also provides DC valves, variable pumps, and proportional valves. Its hydraulic cylinders create linear motion and force in mechanical applications, and its hydraulic presses are used for forming, molding, and shaping materials. Its hydraulic and hose fittings facilitate secure and flexible connections, while its accumulators store and release energy to maintain system pressure. The company also offers repair, customization, and refurbishing services for hydraulics.

Sintech Precision Products Ltd., established in 1986 and headquartered in Ghaziabad, India, is an ISO 9001 certified manufacturer and supplier of industrial pumps, pump spares, and related accessories. It has over 100 products, including centrifugal, dynamic sealing, torque flow, vertical turbine, and multistage high-pressure pumps. The pumps are used in various markets and applications, including energy, sugar, water, steel, and process industries. With over 30 years in the industry, the company also undertakes various contract manufacturing activities for complete pumps, sub-assemblies, or single parts. It offers a broad spectrum of materials like nickel and Hastelloy for contract manufacturing.

Flowserve Corporation, founded in 1790 and headquartered in Irving, Texas, is a manufacturer and supplier specializing in fluid motion and control products. The company's product portfolio includes pumps, seals, valves, energy recovery systems, and decoking systems. These products are utilized across various industries, including power generation, chemical processing, water management, oil and gas, and various general industries. The company also provides customer services, including on-site field services, solutions engineering, system assessments, repairs and maintenance, and training and development.

ERG Tech., established in 1994 and based in Zhejiang, China, is a supplier of cooling systems for power generation and distribution and core components of renewable energy. The company distributes various kinds of oil pumps for locomotives, electrical control systems, UHV transformers, wind power generator coolers, and other pertinent gearbox and distribution components. The company’s oil pumps are the preferred product for high-speed railway and bullet trains designated by CRRC. The company is certified with ISO 9000 “Quality Management System Certification” and ISO 3834 “Certification for producers of metallic constructions related to quality requirements for welding”.

AxFlow UK, part of Axel Johnson AB, is a supplier of technical pumps, founded in 1958 and headquartered in the United Kingdom. The company’s pump portfolio includes both positive displacement pumps such as circumferential piston, AODD, metering, as well as centrifugal pumps which embraces DIN, ISO, double suction, magnetically driven and hygienic models. It also provides a range of pump services including installation, monitoring along with comprehensive pump and seal repair capabilities. It is one of the UK and Europe’s largest suppliers of technical pumps with offices and service locations in 26 European countries, New Zealand and Australia.

Ranking as of March 2026

Derivation Method| Rank | Company | Click Share |

|---|---|---|

| 1 | ITT INC. |

12.6%

|

| 2 | D & D Machine & Hydraulics, Inc. |

9.4%

|

| 3 | Flowserve Corporation |

9.1%

|

| 4 | Weir Group PLC |

8.4%

|

| 5 | Ruhrpumpen |

7.4%

|

| 6 | Sintech Precision Products Ltd |

7.1%

|

| 7 | Sulzer Ltd |

7.1%

|

| 8 | Sinoflo |

6.7%

|

| 9 | HCP PUMP MANUFACTURER CO., LTD. |

6.2%

|

| 10 | Jay Ambe Engineering Co. |

5.9%

|

Derivation Method

The ranking is calculated based on the click share within the axial flow pump page as of March 2026. Click share is defined as the total number of clicks for all companies during the period divided by the number of clicks for each company.Number of Employees

Newly Established Company

Company with a History

*Including some distributors, etc.

*Including some distributors, etc.

| Country | Number of Companies | Share (%) |

|---|---|---|

United States of America

United States of America

|

2 | 18.2% |

United Kingdom

United Kingdom

|

2 | 18.2% |

China

China

|

2 | 18.2% |

India

India

|

2 | 18.2% |

Japan

Japan

|

1 | 9.1% |

Switzerland

Switzerland

|

1 | 9.1% |

Taiwan

Taiwan

|

1 | 9.1% |

34 products found

34 products

Torishima Seisakusho Co., Ltd.

570+ people viewing

Last viewed: 1 day ago

■Features This is an axial flow pump that is widely used for low head and large capacity. On the horizontal axis, the casing can be divided horizon...

Matsuda Pump Manufacturing Co., Ltd.

560+ people viewing

Last viewed: 15 hours ago

■Horizontal pump Horizontal centrifugal pumps are the most common industrial pumps. A large number of variations can be planned depending on the co...

Sanmashi Co., Ltd.

470+ people viewing

Last viewed: 4 hours ago

It is also ideal for plants that comply with Trilateral GMP, from utilities to drug substance manufacturing and liquid preparation. ■Pure water/WF...

Fuji Inback Co., Ltd.

290+ people viewing

Last viewed: 13 hours ago

■Application ・High-end electron microscope ・Residual gas analysis ・Optical coating ・Plasma research ・Biotechnology ・Medical technology ・Semi...

Fuji Inback Co., Ltd.

360+ people viewing

Last viewed: 1 day ago

■Application ・Ion implantation ■Features ・Specialized for light gas exhaust ・High durability achieved by nickel coated rotor ・Temperature cont...

Osaka Vacuum, Ltd.

560+ people viewing

Last viewed: 1 day ago

■ST-Compact series ・Introducing the more compact ST series ・Equipped with high compression turbo molecular pump TG70F ・You can choose from two t...

ULVAC, Inc

450+ people viewing

A turbo molecular pump with integrated controller that uses magnetic bearings. By integrating the pump body and controller, wiring and space saving...

Matsuda Pump Manufacturing Co., Ltd.

540+ people viewing

Last viewed: 15 hours ago

Looking at the history of Japan, salt production has been based on evaporation concentration and crystallization techniques. This technology is als...

Fuji Inback Co., Ltd.

260+ people viewing

■Application ・Radiation environment ・High magnetic field environment ■Features By separating the electronic unit from the pump body, it is ideal...

Sanko Ematech Co., Ltd.

600+ people viewing

Last viewed: 18 hours ago

■Product description A high-vacuum exhaust system that compactly includes necessary equipment such as a turbo molecular pump, dry vacuum pump, valv...

Sanko Ematech Co., Ltd.

470+ people viewing

Last viewed: 1 day ago

■Product description A turbo molecular pump with integrated controller that uses magnetic bearings. By integrating the pump body and controller, wi...

4 models listed

Fuji Inback Co., Ltd.

270+ people viewing

Last viewed: 1 day ago

■Application ·coating ・Semiconductor process ・Electron beam welding ■Features ・Kepla® coating applied to pump rotor ・High pumping speed for bo...

ULVAC Sales Co., Ltd.

690+ people viewing

Last viewed: 21 hours ago

■Summary The ULVAC turbo molecular pump UTM series uses a high-performance bearing that is different from general bearings and has excellent featur...

Torishima Seisakusho Co., Ltd.

450+ people viewing

Last viewed: 1 hour ago

■Features By adopting a double suction impeller, it achieves low cut-off head, low NPSH, and high speed, and is used in brine recirculation pumps f...

Fuji Inback Co., Ltd.

280+ people viewing

■Application ·analysis ・Surface observation ·the study ■Features ・Low vibration ・Low leakage magnetic field ・Ideal for analysis equipment such...

ULVAC Sales Co., Ltd.

460+ people viewing

Last viewed: 20 hours ago

■Summary Turbo molecular pump (60L/sec) + dry vacuum pump. Ultimate pressure 10^-5Pa class. This is a small, dry type high vacuum pumping device th...

ULVAC Sales Co., Ltd.

720+ people viewing

Last viewed: 11 hours ago

■Summary The YTP series is a simple high vacuum pumping unit consisting of a ULVAC turbo molecular pump (UTM series), a rotary pump, a forevalve, a...

ULVAC Sales Co., Ltd.

540+ people viewing

Last viewed: 22 hours ago

■Summary YTP series Ver.B is a high vacuum pumping unit equipped with a ceramic ball bearing type turbomolecular pump. Evacuation from atmospheric ...

ULVAC Sales Co., Ltd.

490+ people viewing

Last viewed: 5 hours ago

■Summary This is a desktop high vacuum pumping unit equipped with a ceramic ball bearing type turbomolecular pump. In consideration of the desktop ...

Sakuragawa Pump Manufacturing Co., Ltd.

500+ people viewing

Last viewed: 1 day ago

This is an axial flow type submersible pump designed for low head and large water volume. Designed to be smaller and lighter than those in the same...

Fuji Inback Co., Ltd.

290+ people viewing

Last viewed: 16 hours ago

■Application ·coating ・Semiconductor process ・Electron beam welding ■Features ・Kepla® coating applied to pump rotor ・Can be installed in any d...

ULVAC Sales Co., Ltd.

520+ people viewing

Last viewed: 1 day ago

■Summary This is a composite vane-type turbomolecular pump that uses ceramic ball bearings. Achieves space savings by integrating the controller an...

ULVAC Sales Co., Ltd.

430+ people viewing

Last viewed: 1 day ago

■Summary This is a composite vane-type turbomolecular pump that uses ceramic ball bearings. Achieves space savings by integrating the controller an...

ULVAC Sales Co., Ltd.

350+ people viewing

Last viewed: 1 day ago

■Summary This is a composite vane-type turbomolecular pump that uses digital 5-axis control magnetic bearings. UTM-FH and UTM-FW achieve advantages...

Fuji Inback Co., Ltd.

350+ people viewing

Last viewed: 14 hours ago

■Application ·analysis ・Surface observation ·the study ■Features ・Industry's highest class H2 compression ratio (1×107 *For HiPace300H) ・Specia...

ULVAC Sales Co., Ltd.

400+ people viewing

Last viewed: 1 day ago

■Summary A turbo molecular pump with integrated controller that uses magnetic bearings. By integrating the pump body and controller, wiring and spa...

Fuji Inback Co., Ltd.

300+ people viewing

Last viewed: 1 day ago

■Application ·analysis ・Surface observation ·the study ■Features ・Approximately 20% vibration reduction due to laser balancing (compared to prev...

Fuji Inback Co., Ltd.

300+ people viewing

■Application ·analysis ・Surface observation ·the study ■Features ・Top-level basic performance (pumping speed, light gas compression ratio) ・Use...