All Categories

History

This section provides an overview for pump pistons as well as their applications and principles. Also, please take a look at the list of 12 pump piston manufacturers and their company rankings. Here are the top-ranked pump piston companies as of July, 2025: 1.Sunnda corporation, 2.TSC Manufacturing and Supply, 3.Western Rubber & Manufacturing.

Table of Contents

A pump piston is a device that supplies and transfers liquids and gases through the reciprocating motion of a piston.

The pump piston moves liquid or gas by utilizing the volume change that occurs when the cylindrical piston moves in a linear reciprocating motion inside the cylinder of the pump housing. The simplest pump piston, a combination of a piston and two valves, has long been used for wells and other applications. Due to their high discharge pressure characteristics, they are also widely used in industrial fields.

Pump pistons are considered positive displacement pumps. This category includes gear, vane, screw, scroll, plunger, and diaphragm pumps.

Pump pistons are relatively simple in construction and easy to handle. They have long been used for tasks such as manual well pumps and kerosene pumps. Some specific uses of pump pistons include:

The basic operating principle remains consistent for all pumps: liquids or gases are transferred through repeated suction and discharge actions. Pump pistons incorporate valves at the inlet and discharge ports to prevent backflow and apply pressure.

The capacity of a pump piston is determined by three factors: piston diameter, stroke, and the number of pistons. The flow rate is determined by the number of revolutions. Pump characteristics are represented in a chart with flow rate on the horizontal axis and pressure on the vertical axis. Pump pistons designed for liquid applications exhibit minimal pressure variation concerning flow rate.

Among pump pistons, axial and radial types offer continuous capacity adjustment. Even when the required capacity changes, it can be adjusted without altering the rotation speed, simplifying control and conserving energy.

Pump pistons exhibit superior pressure resistance compared to other pumps and can withstand pressures of up to 50 MPa. They also demonstrate high efficiency.

Axial and radial pump pistons can be easily adapted for use in variable displacement pumps.

Axial and radial pistons can function as motors because their design is fundamentally similar to that of pumps. These pistons and motors can be connected to transmit power.

Pump pistons are broadly categorized into axial, radial, and reciprocating types.

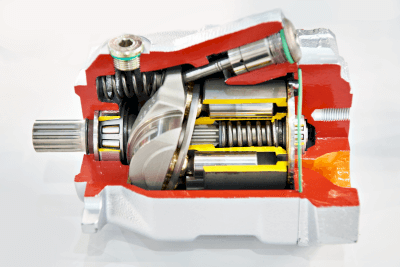

Pistons in axial pumps are arranged close to the drive shaft. They are divided into two types: axial and swash plate, based on the method of piston reciprocation. This structure can also be employed in motors, making it the most commonly used positive displacement pump.

Axial pump pistons can be converted into variable displacement pumps by adjusting the swash shaft or swash plate angle, thereby varying the piston's displacement from zero to maximum continuously.

In radial pumps, multiple pistons are arranged radially around the drive shaft. Eccentric cam rings or cams drive the pistons. In eccentric radial pumps that use an eccentric cam ring, the pistons reciprocate, and the entire cylinder block rotates. This type can also be used as a motor.

Eccentric radial pumps can be adjusted for variable displacement by altering the eccentricity of the cam ring, providing excellent responsiveness.

Reciprocating pistons are driven by a crankshaft or cam. There are various configurations, including single, double, and multiple pistons. Valves at the inlet and discharge ports make them unsuitable for motor applications. Despite their larger size and weight, they can handle relatively high pressures compared to other methods.

*Including some distributors, etc.

Sort by Features

Sort by Area

TSC Manufacturing and Supply LLC (TSC) is an American ISO 9001 certified manufacturer of pumps and related products that was established in 1995. Headquartered in Houston, Texas, the company produces drilling rig supplies and components including mud, uniforce, and centrifugal pumps as well as pulsation dampeners. Its other products include expendable components, such as valves, springs, pistons, and fluid end modules. TSC products are primarily used in the oil and gas, energy, and marine engineering industries.

Sunnda Corporation is an American manufacturer of industrial oilfield equipment that was established in Houston, Texas in 2004. The company divides its products into three categories: oilfield service equipment such as adapter flanges, pup joints, and workover rigs, oilfield production equipment (e.g. casing spools, chokes), and oilfield drilling equipment such as double studded adapters (DSAs) and mud pumps. It also offers custom manufacturing services for unique customer projects. Sunnda Corporation products are used mainly by clients in the mining, construction, and oil and gas industries, including by companies such as Barrick Gold and Weatherford.

Western Rubber & Manufacturing (WRAM) is an American ISO 9001 certified manufacturer of rubber products that was originally established in 1977 as a custom rubber design and manufacturing plant for the oilfield industry. Based in Conroe, Texas, the company specializes in customizing rubber products including drilling swivels, shale traps, circulating heads, and well packers. Its products are used primarily by clients in the well monitoring and servicing, water drilling, oil drilling, and energy sectors. WRAM also offers contract manufacturing for clients with niche specifications, as well as swivel repair services.

Humble Industries Inc. is an American manufacturer of gaskets, seals and pistons established in 1981 and based in Humble, Texas. The company primarily produces custom cast or injection urethane products, tank truck gaskets and seals, rubber or PTFE packing for well service pumps, and mud pump pistons. It also offers mud pump replacement parts, mud cleaning equipment, and washpipe packing. Humble Industries primarily serves clients in the oil and gas, mining, energy, and water well construction sectors.

Premium Oilfield Technologies (POT) is an American manufacturer of oilfield equipment and components that was established in 2003. Based in Houston, Texas, the company offers various oilfield products including centrifugal pumps, mud valves, epicyclic swivels, and drilling equipment. Its products are distributed under seven brand names including CALIBER PISTONS, LOGAN POWER SWIVELS, PATRIOT PRODUCTS, and TRU-FLOW MPD SYSTEMS. POT also offers its clients additional consignment box options and on-site testing services.

Rubber Regenerating and Processing Co. Ltd, established in 1963, and based in Kolkata, India, is a manufacturer and supplier of rubber and metal-bonded products. The product portfolio includes a complete range of oilfield rubber types of equipment which includes desanders, desilters, hydrocyclone replacement cones, gaskets, fluid and power replacement ends, and mud and plunger pumps. The products are used in multiple industries which include railways, defense, oil & gas industry. All the company products are ISO-certified.

Henan Youlong Petroleum Engineering Technology Co., Ltd. (HYPET) is a Chinese manufacturer of oilfield drilling rigs, pumps, and equipment that was established in 2019. Based in Puyang City, Henan, the company designs and produces various oilfield products including plunger and mud pumps, drilling and workover rigs, flowline products, and fracturing equipment. Other products include cementing trucks, intermediate chemicals, and replacement valves or seats. HYPET primarily serves clients in the oil and gas, power generation, mining, and construction industries.

Astarn Engineering and Oilfield Supplies Pvt. Ltd. (AEOS) is an Indian manufacturer of oil drilling equipment that was established in 2021. Based in Kolkata, West Bengal, the company offers various products including casing protectors, mud swivel spares, rubber molded products, and mud pump components. It also provides welding and fabrication, installation, and maintenance services to its customers, as well as additional staffing options. AEOS primarily serves clients in the oil and gas industry, but its products also have applications in food production, pharmaceutical manufacturing, and packaging.

Dezhou Boru Petroleum Machinery Manufacturing Co. (DBP) is a Chinese manufacturer of drilling tools and mud pump components that was established in Dezhou, Shandong in 2010. The company produces various mud pump parts, such as cylinder liners, flanges, and piston rods, as well as drilling tools including drill collars, swivels, and stabilizers. It also offers custom design and engineering, maintenance, and repair services to customers requiring additional support. DBP products are used mainly by its clients in the oil and gas, construction, and mining industries.

GD Energy Products, established in 1989 and headquartered in Houston, Texas, is a manufacturer of OEM parts. The company produces a range of products, including frac pumps, mud pumps, well pumps, hydrostatic pumps, fluid ends, safelock valve covers, tungsten carbide valve seats, plungers, pistons, and liners. It's services include on site field service, pump repairs and parts supplies. The company products are applicable in acidizing, cementing, coiled tubing, electric fracturing, mine dewatering and salt water disposal. The company is API-64 and ISO certified.

UDS International (UDSI) is an Australian ISO 9001:2015 certified custom manufacturer of petrochemical equipment and parts that was established in 2008. Based in Melbourne, the company manufactures various products to customer specifications, including subsea manifolds, subsea intervention skids, and subsea assemblies of valves, sensors, and/or actuators that control the fluids flowing from wellheads. It also provides subsea engineering services such as design, analysis, and installation. UDSI chiefly serves clients in the marine and oil and gas industries, which include companies such as Sapura Energy and Keppel Offshore & Marine.

International Prospering Group S.A. de C.V. was established in 2010 in Villahermosa, Tabasco, and is a supplier of oilfield equipment for many applications. The company designs and produces equipment used for oilfield exploration and development operations, including top drive systems, mud circulating systems & parts, drilling spools, and elevators. It also offers land, trailer-mounted, and truck-mounted drilling rig models. The company's products are used mainly by clients in the oil & gas, construction, and mining industries.

Ranking as of July 2025

Derivation Method| Rank | Company | Click Share |

|---|---|---|

| 1 | Sunnda corporation |

16.7%

|

| 2 | TSC Manufacturing and Supply |

11.9%

|

| 3 | Western Rubber & Manufacturing |

9.5%

|

| 4 | Humble Industries, Inc. |

9.5%

|

| 5 | Premium Oilfield Technologies |

9.5%

|

| 6 | GD Energy Products |

9.5%

|

| 7 | International Prospering Group S.A. de C.V. |

7.1%

|

| 8 | UDS International |

7.1%

|

| 9 | Henan Youlong petroleum Engineering Technology Co.,Ltd. |

4.8%

|

| 10 | Astarn Engineering and Oilfield Supplies Pvt. Ltd. |

4.8%

|

Derivation Method

The ranking is calculated based on the click share within the pump piston page as of July 2025. Click share is defined as the total number of clicks for all companies during the period divided by the number of clicks for each company.Number of Employees

Newly Established Company

Company with a History

*Including some distributors, etc.

*Including some distributors, etc.

| Country | Number of Companies | Share (%) |

|---|---|---|

United States of America

United States of America

|

5 | 55.6% |

India

India

|

2 | 22.2% |

China

China

|

2 | 22.2% |

125 products found

125 products

Fuso Industries Co., Ltd.

270+ people viewing

Last viewed: 6 hours ago

■Features ・The fragile glass oiler has been replaced with a grease injection type. -Grease can now be supplied more directly, improving the lubric...

Graco Inc.

670+ people viewing

Last viewed: 7 hours ago

■Ideal for high viscosity raw materials that are difficult to transfer Graco's powerful series of piston pumps can move high viscosity materials th...

4 models listed

Maximator Fluid Technologies Co., Ltd.

230+ people viewing

Last viewed: 6 hours ago

Due to their robust construction, MSF pumps are particularly suitable for applications in the chemical industry. ■Features ・Single acting type. ...

Maximator Fluid Technologies Co., Ltd.

220+ people viewing

Last viewed: 6 hours ago

Small and lightweight, the S Pump can be used in units that are used in steady-state operation or in applications that require movement. The S Pump...

Maximator Fluid Technologies Co., Ltd.

210+ people viewing

Last viewed: 6 hours ago

The S…D pump operates with lower vibration than the single-acting S pump and has 50% more pump capacity. ■Features ・Double acting type. ・Single ...

Maximator Fluid Technologies Co., Ltd.

210+ people viewing

Last viewed: 6 hours ago

The small and lightweight S…-SS pump is suitable for units used in steady-state operation or applications that require movement. This pump starts ...

Yagyu Shokai Co., Ltd.

200+ people viewing

Last viewed: 6 hours ago

■Features ・Easy to operate by simply moving the handle up and down.Equipped with a ball valve to prevent liquid dripping. ・Can be used with high ...

Maximator Fluid Technologies Co., Ltd.

220+ people viewing

Last viewed: 6 hours ago

With its single-acting design, the M pump features a compact and lightweight construction. ■Features ・Single acting type. ・Single stage air driv...

Maximator Fluid Technologies Co., Ltd.

260+ people viewing

Last viewed: 6 hours ago

With its single-acting design and two-stage air-driven piston, the M…-2 pump reaches twice the working pressure of the single-acting air-driven M p...

Maximator Fluid Technologies Co., Ltd.

210+ people viewing

Last viewed: 6 hours ago

With its single-acting design and three-stage air-driven piston, the M…-3 pump reaches three times the working pressure of the single-acting, singl...

Maximator Fluid Technologies Co., Ltd.

220+ people viewing

Last viewed: 6 hours ago

M…D pumps have lower vibration than M pumps, yet have over 50% higher pump capacity. ■Features ・Double acting type. ・Single stage air driven pis...

Maximator Fluid Technologies Co., Ltd.

270+ people viewing

Last viewed: 6 hours ago

Light and robust MO pumps can be used for a wide range of pressure ratios. Ideal as a portable unit. ■Features ・Single acting type. ・Single stag...

Maximator Fluid Technologies Co., Ltd.

230+ people viewing

Last viewed: 1 hour ago

MO…D pumps operate with lower vibration than single-acting MO pumps and have approximately 50% larger pump capacity. ■Features ・Double acting typ...

Global Parts Co., Ltd.

460+ people viewing

Last viewed: 6 hours ago

A standard piston pump with inverter. Power consumption can be reduced by 77% compared to conventional products.

2 models listed

Global Parts Co., Ltd.

460+ people viewing

Last viewed: 6 hours ago

This is a piston pump with an inverter that allows pressure and flow rate to be changed in two stages. Power consumption can be reduced by 77% comp...

2 models listed

Masaie Co., Ltd.

590+ people viewing

Last viewed: 6 hours ago

■ Features ・ Ideal for cleaning the steam convection oven in the warehouse. ・ Continuous operation is possible ・ Built -in thermal protector ・ ...

2 models listed

Meiwa Co., Ltd.

1320+ people viewing

Last viewed: 6 hours ago

We can even manufacture one unit to order. Other standard models are also available. ■Piston pump - Designed for quantitative transfer, it has a s...

9 models listed

TAIYO Co., Ltd.

320+ people viewing

Last viewed: 7 hours ago

Open circuit swash plate type with through drive for single and multiple pumps. ■Features ・Rated pressure 35MPa, maximum discharge rate 360cc/rev...

TAIYO Co., Ltd.

240+ people viewing

Last viewed: 7 hours ago

Achieves high pressure, high speed rotation, and low noise. ■Features ・Low pulsation, easy maintenance, and resistant to contamination (long life...

TAIYO Co., Ltd.

270+ people viewing

Last viewed: 7 hours ago

■Features ・Long life due to oil-cooled structure and highly rigid bearing structure. - Adopts roller vanes that eliminate the need for a reducer d...

ULVAC, Inc

160+ people viewing

Last viewed: 5 hours ago

Standard type/Two-stage exhaust system/Built-in thermal protector/Power cord (disassembled end) ■Features ・Large displacement and compact size. ...

ULVAC, Inc

150+ people viewing

Last viewed: 5 hours ago

Standard type/1-stage exhaust system/Built-in thermal protector/Power cord (disassembled end) ■Features ・Large displacement and compact size. ・D...

ULVAC, Inc

190+ people viewing

Last viewed: 5 hours ago

Pressure-only type/1-stage exhaust method/Built-in thermal protector/Power cord (disassembled end) ■Features ・Large displacement and compact size...

ULVAC, Inc

200+ people viewing

Last viewed: 5 hours ago

Standard type/1 stage exhaust system/Built-in thermal protector ■Features ・Large displacement and compact size. ・Dry type vacuum pump that does ...

ULVAC, Inc

150+ people viewing

Last viewed: 5 hours ago

Standard type/1-stage exhaust method/Built-in thermal protector/Power cord (discrete end) ■Features ・Large displacement and compact size. ・Dry t...

ULVAC, Inc

160+ people viewing

Last viewed: 5 hours ago

Standard type/Single-stage exhaust system/Built-in thermal protector/With input terminal block (no cord) ■Features ・Large displacement and compac...

ULVAC, Inc

140+ people viewing

Last viewed: 5 hours ago

Standard type/Single-stage exhaust system/Built-in thermal protector/With input terminal block (no cord) ■Features ・Large displacement and compac...

J. Wagner GmbH

190+ people viewing

Last viewed: 5 hours ago

EvoMotion 5-60 low pressure pump can be used for air spray painting up to 40 bar. Low pressure pump suitable for air spray painting on high viscosi...

J. Wagner GmbH

160+ people viewing

Last viewed: 5 hours ago

EvoMotion 5-125 low pressure piston pump is a low pressure piston pump made of stainless steel, suitable for transfers up to 40 bar and 7.5 l/min. ...

J. Wagner GmbH

180+ people viewing

Last viewed: 3 hours ago

Puma 3-600 low pressure piston pump can be used for large supply systems up to 24 bar. Low-pressure piston pump, made of stainless steel, suitable ...