All Categories

History

This section provides an overview for strain gauges as well as their applications and principles. Also, please take a look at the list of 37 strain gauge manufacturers and their company rankings. Here are the top-ranked strain gauge companies as of February, 2026: 1.GEOKON, 2.Sensing Systems Corporation, 3.Hitec Products, Inc..

Table of Contents

Categories Related to Strain Gauges

1987~1991: Engaged in research on wire covering materials at Polymer Materials Laboratory.

1991~1997: Worked as a patent Engineer at Koike International Patent Office.

1997~2005 Worked as an intellectual property member at GE Yokogawa Medical System, currently working as a writer.

Linkedinhttps://www.linkedin.com/in/%E8%A3%95%E5%AD%90-%E9%88%B4%E6%9C%A8-92b21a234/

researchmap

https://researchmap.jp/0315rs2017

A Strain gauge is a device that measures the strain of an object. They have also been used in pressure gauges and force gauges because they can measure strain and calculate pressure, load, etc.

Strain Gauges are used to measure the strain of products whose strength is directly affected by strain, to measure loads in production plants, and to measure the degree of deformation of molds and other components. However, care must be taken to ensure that the strain cages are installed in the correct orientation, otherwise, measurement errors will occur.

Specific examples of use include the following.

Strain cages are used by attaching them to the object to be measured, which is then strained along with the object to be measured, resulting in a change in the internal electrical resistance. The strain is calculated by measuring the amount of change in the electrical current.

There is a great variety of strain gauge types. The most widely used are foil strain gauges, wire strain gauges, and semiconductor strain gauges.

Other features of strain gauges include those suitable for low and high-temperature environments, those capable of measuring finer strains, and those made of materials suitable for various materials to be measured.

The structure of "foil strain gauges" and "semiconductor strain gauges" are described below.

The structure of foil strain gauges, the most popular type of strain gauges, consists of a metal foil attached in a zigzag pattern on an insulator base, with two wires coming out of the metal foil. These two wires are connected to a circuit called a Hoinston bridge circuit.

The Hoinston bridge circuit is a circuit in which three resistors of known resistance and four strain gauges are arranged in a bridge configuration, and the resistance of the strain gauges can be measured by measuring the potential difference between the center of the resistors and the strain gauges.

When the object to be measured to which the strain gauges are attached is distorted, the foil of the strain gauges attached expands or contracts, resulting in a change in the value of electrical resistance, and the amount of change in resistance is obtained from the potential difference in the Hoisington bridge circuit. Since strain gauges have a gauge factor, which is an intrinsic value of the amount of change in resistance to strain, it is possible to calculate the strain of the object to be measured from the gauge factor and the amount of change in resistance.

Semiconductor strain gauges are strain gauges that utilize a semiconductor in the foil portion of a foil strain gauge. They utilize the property that the electrical resistivity of a semiconductor changes when stress acts on the semiconductor.

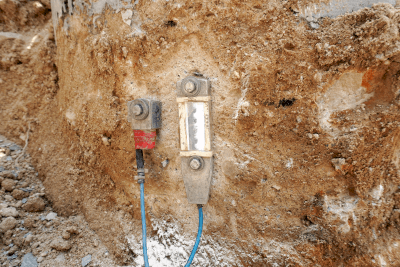

The accuracy of strain measurement using strain gauges strongly depends on the method of gauge installation (adhesion in most cases). Therefore, it must be very careful when attaching strain gauges to a measurement object. The first step is to clean the surface of the measurement target to which the gauge is to be attached.

It is best to use an oil-based detergent to remove oil thoroughly. Failure to do so will allow oil to penetrate deeper into the material when the surface is ground or polished during application. After cleaning, lift the gauge with tweezers and carefully adhere it to the surface to be measured.

At this time, it is important to ensure that all empty bubbles between the surface and the gauge are pushed out so that they can be affixed. In this state, wait a few minutes for the adhesive to harden. After a few minutes have elapsed, finally wrap the entire surface with insulation tape to protect it from damage, and the pasting is complete.

The advantage of strain gauges is that they can easily measure strain simply by bonding them to the object to be measured. In reality, however, there are many complex factors involved that make measurement more difficult. For example, the problem of stress is one of them.

Strain changes due to the material's interaction between externally applied forces and internal stresses. Therefore, analysis of strain in two or three directions requires using "rosette strain gauges," which are a combination of multiple gauges.

In addition, depending on the coefficient of thermal expansion of the material constituting the measurement object, the strain may be determined to have occurred even if there is no actual strain. To prevent this, it is necessary to match the material of the gauge with the material to be measured.

In strain measurement with strain gauges, the best one must be selected from among many types of gauges based on a good understanding of their physical or mechanical characteristics.

The major factors affecting strain gauges bonded to the measurement object are strain caused by external forces and temperature change. When temperature changes occur, the strain gauges are affected by the difference in the coefficient of linear expansion between the measurement object and the strain gauges, and by the change in resistance of the strain gauges due to temperature.

The measurement of strain as if it is caused by temperature change is called apparent strain. The use of self-temperature compensating strain gauges is the most effective countermeasure against apparent strain. Self-temperature compensating strain gauges are strain gauges in which the temperature coefficient of resistance of the strain gauges is adjusted to suit the measurement object to minimize the amount of apparent strain due to temperature.

Selecting the appropriate strain gauges for the measurement object is the best choice, but it may leave some errors. In some cases, they have nonlinear characteristics. In most cases, this error is noted on the data sheet of the strain gauges, and if more precise measurement is required, a compensation calculation can be made to account for the error calculated from the datasheet.

Creep is a phenomenon in which strain increases with time when a constant load is applied under certain temperature conditions. The creep phenomenon is the natural enemy of strain gauges, and if it occurs, it may directly lead to measurement errors.

In most cases, the creep phenomenon of strain gauges is caused by the base material, grid shape, and adhesive. Therefore, a common method is to cancel the effects of creep phenomena on each other by using a strain generator in the opposite phase of the creep caused by these factors as the material creep and attaching strain gauges to it.

The important point is the combination of materials. If the creep phenomena are in opposite phases, but their absolute values are very different, they cannot be canceled, and the effect will be in one direction. Note that, depending on the material, creep phenomena are more pronounced at higher temperatures in most cases. Please remember that the higher the stress applied to the strain gauges, the shorter the time to rupture (life), considering the increase in strain due to the creep phenomenon.

*Including some distributors, etc.

Sort by Features

Sort by Area

Gilson Company, Inc. is an American manufacturer and supplier of construction material testing equipment based in Lewis Center, Ohio. The company was established in 1939 with a primary focus on manufacturing the testing screen, a laboratory-scale screening machine, to cater to the mining and highway construction industries' requirements. Over time, Gilson has expanded its product portfolio and now offers a wide range of equipment, including ovens and furnaces, scales and balances, general laboratory testing equipment, as well as material testing equipment for aggregates, asphalt, concrete, and soils.

PCB Piezotronics, founded in 1967 and headquartered in North Carolina, is a manufacturer of sensors for design engineers and predictive maintenance. They design and manufacture various sensors such as microphones, vibration, pressure, force, and torque sensors. Their products are used for testing, measurement, monitoring, and control requirements in automotive, aerospace, military, and other industries in order to gather accurate data, ensure safety, enable predictive maintenance, and facilitate advancements across multiple industries. PCB Piezotronics is a subsidiary of Amphenol Corporation.

Luna Innovations, founded in 1990, is a manufacturer of fiber optic sensing and non-destructive testing products such as high-definition strain & temperature sensors, interrogators, transmitters & receivers, control units, and accessories. Based in Roanoke, Virginia, the company engages in sensing and non-destructive testing, communications testing, and photonic control. They produce products for photonic control and communication testing, including fiber coils, reflectometers, distributed component analyzers, instruments, and meters.The products are used in the communication, aerospace, automotive, and energy industries.

OMEGA Engineering was originally begun in 1962 as a manufacturer of thermocouples and has grown to over 100,000 products for measurement and control of temperature, humidity, pressure, strain force, flow, level pH, and conductivity as well as customer service including data acquisition, electric heating, and custom-engineered products. Additionally, OMEGA offers tools to serve as reference for engineers around the world. OMEGA Engineering serves the aerospace, automotive, wireless, sanitary, test & measurement, process control, power monitoring, environmental, and laboratory markets.

Sensing Systems Corporation, established in 1972 and located in Rockford, Illinois, USA, is a manufacturer and supplier of sensors and sensor-based systems. The company product range includes a wide range of sensors, including accelerometers, gyroscopes, and magnetometers. These offerings find applications across diverse industries, spanning aerospace, automotive, and defense sectors. Additionally, it specializes in providing various services including crafting and providing sensor-based systems, such as inertial measurement units (IMUs) and navigation systems. Its products adhere to rigorous manufacturing standards and are fortified by a warranty.

GEOKON, established in 1979, and headquartered in located in Lebanon, New Hampshire, is a manufacturer and supplier of geotechnical instrumentation. They manufacture a complete line of geotechnical instruments including extensometers, crack meters, settlement sensors, and dataloggers for applications in industries such as civil engineering, mining, energy, infrastructure, and environmental monitoring. Their offerings enable real-time monitoring and analysis of factors like ground movement, structural integrity, and environmental conditions. GEOKON has been awarded ISO 9001:2015 registration from both ANSI•ANAB, USA, and UKAS of Great Britain.

OMEGA Engineering Inc., founded in Norwalk, CT, in 1962 is a manufacturer of products used to measure temperature and humidity, flow and level, and pressure. The company's product portfolio includes thermocouple probes and assemblies, pressure gauges and switches, and air velocity measurement systems, wireless systems and portable optic sensors. The company serves markets including Automotive and Electric Vehicles, Renewable Energy and Energy Storage and Electronics and IT Infrastructure. The company also offers customer services that include support, custom research projects and customized services.

Hitec Products, Inc. is an ISO 9001:2015 registered manufacturer and supplier of strain gages/gauges for critical strain measurement applications, and hostile environment sensors for automotive, aerospace, and power generation applications. The company is headquartered in Pepperell, Massachusetts, and, offers waterproof weldable strain gages, high-temperature bondable strain gages, high-temperature weldable strain gages, specialty series, and accessories. In addition, HPI offers installation, thermal spray coatings, and structured light services as well as engineering support.

In 1960, Strainsert developed the Internal Strain Gage process, bonding and sealing strain gages inside small holes of load pins, load bolts, load studs and load cells. This innovation facilitated the development of robust and accurate force sensors and their usage in more challenging applications and harsh environments. 65 years later, Strainsert remains an AS9100 certified designer and manufacturer of superior force sensors for many Aerospace, Industrial, Marine, Military and Automotive applications. Visit our website to schedule a consultation on a specific application or help in designing a custom force sensing solution for your company.

Resensys, LLC. is an American manufacturer and supplier of wireless sensor network technology products that was established in 2008 in College Park, Maryland. The company’s product portfolio includes its SENIMAX brand wireless gateway for collecting and transmitting sensor data, as well as its SENSPOT wireless sensors for measuring various physical parameters. It also offers its SENCLOUD brand web-based data visualization and analysis platform, along with its SENBRIDGE data integration software for third-party apps and systems. Aside from its products, the company provides installation, calibration, and personnel training services.

Micro-Measurements, established in 1962 and situated in Research Triangle Park, North Carolina, USA, is a manufacturer and supplier of strain gauges and a range of other sensors. Its product range includes strain gauges, pressure sensors, temperature sensors, and vital components used for measuring strain in materials. The company's offerings find applications across diverse industries, spanning aerospace, automotive, and civil engineering sectors. The company also remains devoted to providing customers with quality strain gauges and other sensors. Its products adhere to stringent manufacturing standards and are fortified by a warranty.

Kinequip, Inc. was founded in 1946 in Buffalo, NY as a distributor of industrial parts, accessories, and kits. Today these offerings have grown to include motors, compressors, blower systems, clams, pumps, various fittings, gauges, and sensors, as well as pneumatic and high-pressure devices. Kinequip also serves as a distributor for individual device and parts manufacturers. Kinequip additionally offers custom-designed solutions ranging from R&D to unique components and special-made parts, as well as value added designs on demand.

As a leading global provider of distributed strain and temperature sensing platforms, Sensuron continues to ensure customer success by providing unparalleled sensing and measurement to applications across industries. What was originally designed to accurately measure the durability and strain of systems is now being utilized to assist in minimally invasive surgeries, cryogenic tank fuel monitoring and 2D deflection sensing for structural health monitoring. Sensuron’s technology continues to meet customers’ needs to replace point sensing solutions with a distributed sensing platform.

Jewell Instruments is headquartered in Manchester, New Hampshire. The company serves industries such as aerospace, geophysical, railroad, laboratory, and data acquisition with various measuring devices and sensors. The company has five product segments: Inertial & Tilt Sensors, GEO Instruments & Sensors, Meters & Avionics, Data Acquisition Hardware, and Triplett Test Equipment Tools. Inertial & Tilt Sensors include accelerometers, inclinometers, and inertial measurement unit devices. GEO Instruments & Sensors includes economical high-precision and ultra-precision sensors. Meters & Avionics include panel meters, avionics, and solenoids.

SensorsONE Ltd., founded in the UK, in 2006 is a manufacturer of measurement instruments and sensors. The company’s product portfolio includes temperature sensors, pressure sensors, proximity sensors that detect the presence or absence of objects without direct contact, level sensors that enable precise monitoring of liquid levels in tanks and containers and motion sensors that detect movement and acceleration. The company serves industries such as Oil and Gas, Aerospace and Defense, Automotive and Transportation, Construction, and Power Generation.

MinebeaMitsumi Technology Center Europe GmbH was established in 1991 and is a manufacturer of motor products based in VIllingen Schwenningen, Germany. The company manufactures various products such as spindle motors, LED backlights, precision components, HVAC actuators, and ball bearings. The products have been used in various applications such as smart city, medical technology, mobility, aerospace, and information technology. The company has obtained certification of IATF 16949:2016, ISO 14001:2015, ISO 9001:2015, and KBA.

BCM SENSOR TECHNOLOGIES bv, established in 2006 and headquartered in Belgium, is a manufacturer of industrial sensors primarily designed for factory automation and process control. The company has a comprehensive product catalog, including those for differential pressure measurement, pressure measurement, torque measurement, force measurement, and strain measurement. These sensors serve vital functions in diverse applications, including stress analysis, signal strength measurement, monitoring machine and product vibrations, and measuring engine emissions, particularly within the automotive sector.

GTM Testing and Metrology GmbH, established in 1988 and headquartered in Bickenbach, Germany, is a measurement technology developer and manufacturer. The company's precision components include force transducers, non-rotating torque transducers, and precision multi-axis transducers. It also provides strain-gauge measuring amplifiers for precision measurement data acquisition. The company's machines include mechanical, force, and multi-axis standard machines providing solutions used in material, component, and structure testing, as well as calibration labs for inter-lab tests. It also offers custom design, engineering, production of custom equipment and complex systems, and calibration services for its clients.

RST Instruments Ltd., founded in 1977, is a manufacturer of geotechnical instrumentation products in Maple Ridge, BC, Canada. The company is part of Terra Insights, together with Measurand, Syscom Instruments, 3vGeomatics, and NavStar. Its product line has pressure cells, signal cables, grout monitors, strain meters, and settlement systems. It also produces tiltmeters, extensometers, load cells, thermistors, and software used in dams, bridges, and tunnels. The establishment offers calibration, repair, rentals, training, inspections, and onsite maintenance services.

Zemic Europe B.V., established in 2006 by the Chinese Aviation Industry, is a supplier, designer, and manufacturer of load cells and force sensors in Etten-Leur, The Netherlands. The company supplies load cells, strain gauges, weighing kits, electronics, and weight transmitters. It also produces elevator indicators, onboard mounts, junction boxes, mounting kits, and feet made from alloy steel, aluminum, and stainless steel. The company serves the consumer electronics, medical, offshores, transportation, and agriculture industries.

Established in 1954, Tokyo Measuring Instruments Laboratory Co., Ltd. (Tokyo Sokki Kenkyujo Co., Ltd.) is a manufacturer headquartered in Tokyo, Japan, specializing in stress measurement equipment. The company has developed a wide range of strain gauge transducers, essential components for stress measurement in general and civil engineering. The company also produces other instruments, such as the portable digital strainmeter for automatic multi-point measurements. With overseas representative offices in China, Germany, and 43 other countries, TML serves global customers, providing solutions for the safety and efficiency of structures.

MinebeaMitsumi Inc. was incorporated in 1951in Japan and manufactures and supplies machined components, and electronic devices and components globally. It operates through four segments: machined components, electronic devices and components, MITSUMI Business, and the U-Shin business segment. MinebeaMitsumi specializes in bearing products including spherical, roller, rod end, and ball bearings for aerospace. MinebeaMitsumi also produces products including precision mechanical assemblies, fasteners, other special components including clutches and brakes, motors, blowers, sensors and lighting devices. Additionally, MinebeaMitsumi offers its products for use in PCs and peripheral equipment, information and telecommunications equipment, household electrical appliances, automobiles, and aerospace.

Gather Technology Co. Ltd, established in 2014 and headquartered in Shaanxi, China, is a manufacturer of load cells, force sensors, and measuring solutions. The company’s products include steel and aluminum load cells, transmitters, and electronic weighing equipment. It provides facilities for strain gauge application, temperature compensation, and testing across various environmental conditions. Its solutions find applications in heavy industries, petrochemicals, and scientific research. The company manufactures products with corrosion resistance, waterproofing, and lightning protection, utilizing laser welding and balancing equipment for precise measurements.

ME systeme was founded in 1995 and is a manufacturer of sensors and measurements electronics based in Hennigsdorf, Brandenburg, Germany. The company manufactures various products such as force sensors, strain gauge, and measuring amplifiers. These products are used in various industries including mechanical engineering, agricultural machinery, and medical technology. Various companies such as Bombardier, Daimler, and Invenio have been part of the company's customer base. The company has obtained certificates of standards such as ISO 9001:2015, CE, and RoHS.

Applied Measurements, a company established in 1991 and based in Aldermaston, West Berkshire, United Kingdom, is a manufacturer and supplier of measuring systems, transducers, and sensors. The product portfolio has pressure sensors, depth sensors, position sensors, LVDTs, and load cells used in industries involved in the production and supply chains making precise measurements and calculations. The ISO 9001-certified company offers various services including calibration, designing, repair, bonding, and custom control of specific products with a 3-annuals warranty.

Founded in Switzerland, Kistler serves both public and private customers in the automotive, aerospace, maritime, transportation, medical, semiconductor, energy and life sciences industries. Products include sensors as well as connectivity, signal, and data acquisition devices as well as software solutions. Applications of these solutions include R&D to safety testing, and condition monitoring. Key technologies include dynamic pressure, force, torque and acceleration measurement technologies.

ALTHEN, established in 1978, headquartered in Kelkheim, Germany, is a manufacturer and supplier that specializes in providing precision sensors and measurement solutions. Their product range includes strain gauges, load cells, pressure transducers, and displacement sensors, catering to industries such as aerospace, automotive, renewable energy, and robotics. ALTHEN's sensors enable accurate data collection, testing, and monitoring of various parameters critical to the performance and safety of industrial processes and structures. They maintain ISO 9001 and ISO 14001 certifications, ensuring the quality of their products for precise measurements across diverse industrial applications.

HBK, formerly named HBM, is a global ISO9001 and ISO14001-certified company founded in 1950. It is known for providing the best technology and expertise in test and measurement. With branches in 30 countries, it provides clients with different solutions ranging from sound and vibration to propulsion efficiency and weighing. Examples of product offerings include transducers, amplifiers, sensors, strain gauges, data acquisition systems, etc. Such products are used in different markets, including aerospace, automobiles, telecom audio, and more. Besides supplying products, they also entertain their customers with after-sales services.

KYOWA ELECTRONIC INSTRUMENTS CO., LTD., founded in 1949 as Kyowa Radio Laboratory Co., Ltd., is a Japanese manufacturer and distributor based in Chofu, Tokyo, specializing in stress measuring equipment with strain gages. Their product offerings include strain gages, bridge boxes or input adapters, transducers, and related accessories. Additionally, KYOWA operates TAMAYA TECHNICS INC., a subsidiary that manufactures navigation, surveying, and meteorological instruments. KYOWA's stress measuring products find applications in various industries. For example, their measurement instruments are used in riding quality evaluation and safety tests of automobiles and railway roads. These devices are also utilized in construction, civil engineering, and healthcare sectors.

RDP Group began in 1966 and is located in Wolverhampton, West Midlands in the UK, and Pottstown, Pennsylvania in the United States. RDP is a designer, manufacturer, and distributor of LVDT displacement transducers, amplifiers, load cells, and pressure sensors for use in manufacturing, power plants, and underwater applications. RDP is ISO 9001:2015 certified. RDP products include LVDT displacement transducers, amplifiers such as rail mounting amplifiers and DC-powered strain gauge transducer amplifiers, digital panel meters and multi-channel signal conditioning, and force sensors such as compression load cells and tension load cells.

Kett US, an American company founded in 1946 and headquartered in Villa Park, California, is a manufacturer and supplier of moisture meters and organic composition analyzers. The company's product portfolio includes laboratory mixers, near-infrared composition analyzers, and moisture determination balances. These products find applications in various industries, including agriculture, construction, and the laboratory and research industry. The company provides services, including technical support and product training to ensure customers can effectively use its products.

MeasureX Pty. Ltd., established in 2010 and headquartered in Melbourne, Australia, is an industrial-type sensor and measuring systems manufacturer and supplier. The company's products include 3-axis load cells, precision spring-loaded displacement sensors, and submersible pressure transducers. These products are used for a range of industrial applications, such as wastewater treatment, liquid level measurement, and vehicle suspension force measurement, as well as components in household appliances. The company's services include the supply of customized measuring, testing, and quality control systems, as well as production for original equipment manufacturers.

Novatest Srl., established in 2010 and based in Ancona, Italy, is a manufacturer and supplier of NDT instruments. The company also distributes tools for precise surveys, monitoring, and non-destructive testing. It adheres to the ISO 9001:2015 standards for the quality management system. In accordance with UNI/PdR 56:2019 and ISO 9712 standards, the company provides training sessions for the certification of individuals participating in non-destructive tests. It offers specific sensors for static and dynamic infrastructure monitoring and geotechnical monitoring. The company provides superior technical tools and devices to ensure geophysical research is as accurate as possible.

Campbell Scientific Inc., established in 1974 and headquartered in Logan, Utah, is a designer and manufacturer of measurement, data acquisition systems, and data loggers. The company sells sensors, measurement devices, and OEM products for water, weather, and soil applications. It also provides software for several purposes, including communication between data loggers and supporting data logger programming. It is ISO 14001, ISO 9001, and ISO 27001 certified, and it marketed its first product, named the CA-9 Path-Averaging Laser Anemometer, in 1974. It introduced its first data acquisition system, the CR5 Digital Recorder, in 1975.

Ranking as of February 2026

Derivation Method| Rank | Company | Click Share |

|---|---|---|

| 1 | GEOKON |

8.4%

|

| 2 | Sensing Systems Corporation |

7.8%

|

| 3 | ALTHEN |

6.7%

|

| 4 | Hitec Products, Inc. |

5.5%

|

| 5 | Hottinger Brüel & Kjær |

5.2%

|

| 6 | Sensuron |

4.5%

|

| 7 | Micro-Measurements |

3.9%

|

| 8 | Tokyo Measuring Instruments Laboratory Co., Ltd. |

3.7%

|

| 9 | Zemic Europe B.V. |

3.6%

|

| 10 | Gilson Company, Inc. |

3.6%

|

Derivation Method

The ranking is calculated based on the click share within the strain gauge page as of February 2026. Click share is defined as the total number of clicks for all companies during the period divided by the number of clicks for each company.Number of Employees

Newly Established Company

Company with a History

*Including some distributors, etc.

*Including some distributors, etc.

| Country | Number of Companies | Share (%) |

|---|---|---|

United States of America

United States of America

|

14 | 53.8% |

Japan

Japan

|

4 | 15.4% |

United Kingdom

United Kingdom

|

2 | 7.7% |

Germany

Germany

|

2 | 7.7% |

Belgium

Belgium

|

1 | 3.8% |

Canada

Canada

|

1 | 3.8% |

Netherlands

Netherlands

|

1 | 3.8% |

China

China

|

1 | 3.8% |

137 products found

137 products

Glocell Co., Ltd.

710+ people viewing

Last viewed: 22 hours ago

The SR300 series (module) is low power consumption and supports various apps such as IoT. There are SRMS300NB tensile compression type, SRMS345NB s...

2 models listed

Pi Crystal Co., Ltd.

540+ people viewing

Last viewed: 17 hours ago

■Characteristics of strain sensor elements ・We are developing a highly sensitive and flexible strain sensor using the strain response of organic s...

Hottinger Brüel & Kjær

480+ people viewing

Last viewed: 12 hours ago

■Moisture resistance and chemical resistance The LE11 is a resistance linear encapsulated strain gauge with stranded standard wire that is resistan...

Hottinger Brüel & Kjær

400+ people viewing

Last viewed: 12 hours ago

■Applicable to high distortion and high compression LD20 is suitable for high strain measurement applications ■LD20: Strain gauge that measures hi...

Hottinger Brüel & Kjær

370+ people viewing

Last viewed: 12 hours ago

■High voltage type PMS40 is a strain gauge that can measure pressure transient phenomena. ■PMS40: Strain gauge that can measure ultra-dynamic pres...

A and Day Co., Ltd.

450+ people viewing

Last viewed: 7 hours ago

This product is a sensor for measuring vehicle wheel load and lateral pressure for the purpose of maintaining safe railway transportation. In rece...

2 models listed

Hottinger Brüel & Kjær

510+ people viewing

Last viewed: 12 hours ago

■Small and robust The LB11 strain gauge has a small cylindrical design, making it especially suitable for measuring strain by incorporating it insi...

Hottinger Brüel & Kjær

590+ people viewing

Last viewed: 4 hours ago

■Piezoelectric strain sensor CST/300: High sensitivity sensor with wide measurement range The piezoelectric strain sensor CST/300 accurately measur...

Hottinger Brüel & Kjær

270+ people viewing

Last viewed: 12 hours ago

■Balanced 2-gauge strain gauge DY for bending beam strain measurement The strain gauge DY has two measuring grids arranged parallel to each other. ...

2 models listed

Hottinger Brüel & Kjær

260+ people viewing

Last viewed: 3 hours ago

■Pre-wired strain gauges: quick delivery, safe, and easy to handle Leave the soldering to HBM. By using pre-wired strain gauges, you can avoid poss...

10 models listed

Hottinger Brüel & Kjær

160+ people viewing

Last viewed: 12 hours ago

■Strain gauge with high durability against alternating loads The M series strain gauges are ideal for frequent load cycles under large strains, use...

6 models listed

Hottinger Brüel & Kjær

440+ people viewing

Last viewed: 12 hours ago

■Small rosette strain gauge for measurements in small spaces such as PCBs Due to its very small size, the miniature strain gauge rosette RF9 is par...

Hottinger Brüel & Kjær

190+ people viewing

Last viewed: 12 hours ago

■Safe and easy residual stress analysis Reliably measure inherent stresses in materials using special strain gauges for residual stress analysis ■...

6 models listed

Hottinger Brüel & Kjær

290+ people viewing

Last viewed: 1 day ago

■Component crack length detection The RDS gauge series is a crack length detection gauge that determines the degree of crack propagation in compone...

4 models listed

Hottinger Brüel & Kjær

410+ people viewing

Last viewed: 12 hours ago

■Temperature measurement with short response time The TT-3/100 is a temperature sensor that is as easy and flexible to use as a classic strain gaug...

Hottinger Brüel & Kjær

420+ people viewing

Last viewed: 12 hours ago

■Ideal for high temperature applications The LS31HT strain gauge is ideal for applications involving weldable objects used in high-temperature envi...

Hottinger Brüel & Kjær

400+ people viewing

Last viewed: 12 hours ago

■Accurate measurement of fiber composite materials The LI66 is a strain gauge designed to be used directly embedded in structures during the fiber ...

Hottinger Brüel & Kjær

670+ people viewing

Last viewed: 10 hours ago

■Strain gauges for sensor manufacturers with excellent cost performance and performance HBM provides sensor manufacturers with strain gauges that a...

Hottinger Brüel & Kjær

180+ people viewing

Last viewed: 12 hours ago

■Summary Strain gauges for experimental stress analysis need to be both high performance and cost-effective. From fatigue testing of aircraft wings...

3 models listed