All Categories

History

This section provides an overview for spindles as well as their applications and principles. Also, please take a look at the list of 35 spindle manufacturers and their company rankings. Here are the top-ranked spindle companies as of March, 2026: 1.Dynomax, Inc., 2.NAKANISHI INC., 3.UNIST, Inc..

Table of Contents

Categories Related to Spindles

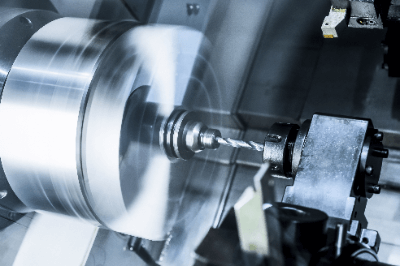

A spindle is a rotating shaft.

The original meaning of spindle relates to the shaft used for winding yarn in a spinning machine. However, in engineering, it primarily denotes the shaft that rotates within a machine tool. Tool blades are attached to this axis to perform machining.

When the blade is fixed and the workpiece rotates, such as on a lathe, it is the shaft on which the workpiece is mounted that rotates. The tool blade and workpiece are attached to the end of the shaft, which is sometimes referred to collectively as the spindle. The rotating object itself or the rotating device itself is also called a spindle unit, or spindle for short.

Other uses of spindles include the center shafts of the rear wheels of FWD cars and the front wheels of RWD cars in automobiles, hard disk drives and storage devices such as DVDs in PCs, and parts of water taps.

Spindle is a device that rotates an object with high precision. Tool knives and workpieces are attached to and detached from spindles, causing misalignment between the axis of rotation and the center axis of the workpiece. This misalignment is called runout and is directly related to errors in machining accuracy.

In addition, if the spindle rotation accuracy is poor, the surface quality of the workpiece after machining will also deteriorate, which will affect the appearance of the workpiece. In addition to the rotational error of the spindle itself, a spindle that rotates stably and with minimal misalignment when attaching and detaching tool knives and workpieces is indispensable for precision machining.

Lathes and milling machines are typical examples of machine tools. Lathes use a spindle to rotate the object. Milling machines, on the other hand, use a spindle to rotate the tool.

Since a spindle is a mechanism or device that performs rotary motion, it requires power to generate rotary motion. Electric motors are mainly used to generate the rotary motion, although some spindles also use pneumatic power.

In most cases, rotational speed and torque are controlled by gears or pulleys, rather than by a motor directly connected to the power transmission in order to process the workpiece under optimum processing conditions. Spindles also generally use bearings to maintain stable and high rotational accuracy.

Some spindles use non-contact bearings such as air bearings or hydraulic bearings to further improve accuracy. Since spindles are structured like the rotating shaft of a machine tool, deterioration is inevitable due to vibration and pressure caused by machining. Therefore, it is necessary to maintain a certain level of rotational accuracy at all times through periodic maintenance and parts replacement.

The most common method of inspection is to attach an inspection tool to the spindle, rotate around of a cylindrical object, and compare the difference in roundness.

Spindles can be classified into several types according to their drive system, structure, and accuracy.

This method is used in combination with other power to rotate by an external motor or other power. Also called a pulley spindle. Speed is increased or decreased to a specific rotational speed.

The motor and spindle are integrated into a single unit, also called a motor spindle. The shaft of the motor serves as the spindle, making it compact and enabling high-precision machining. It is used in various machine tools and is also used in robot hands.

Air spindles are spindles supported by hydrostatic air bearings or powered by compressed air. Hydrostatic air bearings support spindles without contact, resulting in low bearing loss, quiet operation, and no contamination by oil. They are suitable for applications where oil cannot be used.

Air spindles that use compressed air have the advantages of high rotational accuracy and minimal thermal deformation of the spindle. An air turbine or similar device is used to drive the spindle. The disadvantage is that the rotational speed is easily affected by cutting resistance due to the low torque. Also called air turbine spindle.

Air motor spindles driven by an air motor are used for low-speed applications. It is suitable for high-torque machining at relatively low speeds.

This is a spindle with a high-frequency motor built into the spindle. It is used to increase rotation speed or to control rotation speed and torque.

*Including some distributors, etc.

Sort by Features

Sort by Area

NAKANISHI, founded in 1930, is a manufacturer and supplier of surgical, dental, and general industrial products applying high-speed rotation technology located in Tochigi, Japan. The products include micro grinders & controllers that are electrically or air-driven, sub-spindle machine tools, high-speed machining spindles, special-purpose machines & robots, and milling machines. The company offers solutions to drilling, milling by endmills, deburring by carbide cutters, grinding by grindstones, and finishing applications in the automotive, medical, mold, micromechanics, and electronics industries.

UNIST, Inc., situated in Grand Rapids, Michigan, has been a manufacturer of fluid application systems for industrial markets since 1957. The company provides solutions for reducing fluid consumption in manufacturing processes, thereby saving money. Its Minimum Quantity Lubrication (MQL) solutions, apply minute amounts of lubricant directly into the cutting tool/work piece interface. This approach results in reduced fluid usage, cleaner and safer work environments, improved cut quality, and enhanced tool life. Additionally, it facilitates the generation of clean, dry chips for more efficient recycling, eliminates the need for costly coolant treatment equipment and disposal, and result in increased production rates.

Visumatic Industrial Products, established in 1966, is a manufacturer of automated fastener feeding and driving equipment for industrial organizations undertaking assembly work, such as clips, bolts, pins, nuts, and specialty fasteners used in machine builders, general manufacturing, medical, and defense industries. The Lexington, Kentucky-based company provides standard and pistol-grip handheld solutions for ergonomic, quality, and speed improvements. The company offers various fully automated fixed systems and robotics, such as Viper 4-axis SCARA robotic screw driving system, dual x-y robot, rotary indexing, customer re-programmable robotic software, and multi-spindle systems.

SCHUNK, founded in 1945 and based in Morrisville, USA, is a manufacturer of automation technology. The company provides technologies like gripping, tool holding and automation technology for modern manufacturing and robot systems. It also supplies complete solutions for robot systems as well as for a wide variety of production and automation processes. The company has received several awards for its technologies, which includes Engelberger Robotics Award in 2010 and Red Dot Award for Product Design in 2021.

IBAG North America, founded in Zurich, Switzerland, in 1941 is a manufacturer of precision milling, drilling, and grinding for the watch industry. The company's product portfolio includes IBAG Spindles, Witte Vacuum Products, Freeze Chucks, Round Grid Chucks and Custom Witte Vacuum Solutions. Their products are used for Machining (milling, turning, drilling, grinding), Engraving, Polishing and Deburring metal and plastic materials. The company serves markets including Medical and Healthcare, Aerospace and Defense, Consumer Goods, Industrial Manufacturing and Construction and Building.

Setco Inc. is a manufacturer specializing in precision industrial components founded in 1912 and based in the United States. It works in designing, producing, and servicing precision spindles, milling heads, slides, and spindle/slide combinations. With a wide range of offerings, including belt-driven, geared, motorized, high-speed, and high-frequency spindles, it serves industries such as automotive, aerospace, construction, plastics, woodworking, and more. Notably, its precision linear slides come in various models, catering to diverse applications. Its expertise extends to special products like Spark Erosion Grinding systems, AirShield Bearing Seals, and RotoShield Coolant Unions.

Dapra Corporation, founded in 1955, and headquartered in Bloomfield, Connecticut, USA, is a supplier and a manufacturer of manufacturing tools and equipment. The company offers a broad range of products, including indexable milling tools, workholding vises, pneumatic power tools, dot peen, and lasers. The company also offers DataMatrix reading and verification solutions, as well as high-feed square shoulder button, face ball nose, and back draft tools. These products are widely used across various manufacturing sectors, including aerospace, automotive, mold and die, and firearms. It offers USA certified service in-house for all warranty repairs.

Dynomax, Inc., established in 1997 and headquartered in Wheeling, Illinois, USA, is a manufacturer and supplier of precision machine spindles. The product range includes block spindles, cartridge spindles, standard motorized spindles, specialty spindles, and raised-speed motorized spindles, serving industries like aerospace, automotive, medical, manufacturing, and robotics. Its services entail design and engineering, manufacturing, supply chain management, and technical support. With more than 2 decades of experience, the company holds ISO 9001:2015 certification and consistently exceeds expectations in quality and service.

Sassatelli s.r.l. is an ISO 9001:2015-certified manufacturer of precision mechanical tooling accessories that was established in 1972 in Bologna, Italy. The company’s products include live centers that support rotating workpieces on grinding machines or lathes, dead centers for supporting fixed workpieces, and knurling devices for creating knurled surfaces on conical or cylindrical workpieces. It also offers truncated cone heads, grinding wheel dressers, and flanges for coupling chucks. The company’s products are commonly used by clients in the automotive, coin minting, and toy manufacturing industries.

LANG GmbH & Co. KG is an ISO 9001:2015-certified manufacturer of CNC systems and machines that was established in Hüttenberg, Germany, in 1972. The company primarily produces laser technology products for welding, cutting, or marking operations, and milling technology products for machining or engraving processes. It also offers digitizing systems for recording and replicating the shapes or surfaces of physical objects, along with CAD/CAM software to complement its portfolio products. The company chiefly serves its clients in Europe’s semiconductor, wafer manufacturing, and microscopy industries.

Benz GmbH Werkzeugsysteme, founded in 1946 and part of the Dürr Group, is a manufacturer based in Haslach im Kinzigtal, German, specializing in machine tooling systems and components. The company offers angle heads, multi-spindle heads, and mechanical high-speed spindles for metalworking. It also provides computer numerical control (CNC) machines and modular quick-change systems for wood processing. With a subsidiary in the United States and service centers in China and India, the company serves international customers in the automotive, electric mobility, and mechanical engineering sectors.

DAI-ICHI Sokuhan Works Co, founded in 1944 is based in Ojiya, Japan, and is a manufacturer and supplier of machinery tool accessories. Their product portfolio includes measuring instruments, air micrometers, electronic micrometers, gauges, precision machine parts, spindle units, and kneading dispersibility measurement. The products are manufactured under superior technology and precision with quality control. The products are used in multiple industries which include aircraft, trains, automobiles, and other modes of transportation.

SKF UK is the British division of SKF, originally founded in 1907 and headquartered in Gothenburg, Sweden. SKF designs, develops, and manufacturers bearings, seals, lubrication systems, and services worldwide, with industrial and automotive segments, providing solutions for industries including aerospace, agriculture, transportation, food and beverage, general machinery, material handling, mining, energy, paper, and wind energy. SKF UK offers rolling bearings, mounted bearings, automotive seals, lubrication management, vehicle aftermarket services, waste electric products, and electronic equipment products as well as services including maintenance, remanufacturing, customization, and training.

JTET Machine System, established in 1961 and headquartered in Osaka, Japan, is a manufacturer and supplier of machine tools, FA systems, and precision apparatuses. The company's product portfolio includes FA systems, drive shafts, machine tool grinders, precision mechanical equipment, and intermediate shafts for vehicles. These products find applications in various industries, including the automobile, information technology, home appliances, space technology, and medical devices. The company is ISO 14001 certified and has offices in South Korea, China, Thailand, and Mexico, establishing a global network.

NSK Ltd., based in Japan, is a manufacturer of precision bearings and motion control solutions which started its journey in 1916. The company has established itself as a major supplier for multiple industries, including automotive, industrial machinery, and aerospace. Their extensive product portfolio encompasses ball bearings, roller bearings, and linear motion components. Their Motion & Control products and technologies support the motion that brings comfort and convenience in cars, planes, wind turbines, satellites, and almost anything with moving parts.

GMN was founded in 1908 as a manufacturer of high-precision components and systems, in Nuremberg, Germany. Their product list includes Ball Bearings, categorized as special and standard, and ready-to-use bearing systems. The spindles manufactured by the company have applications in grinding, milling, and drilling and the freewheel clutches are available in different forms, such as sprag type and etc. They also develop non-contact seals such as the labyrinth, gap, and face seals and the Electric Drives are also part of the production which has applications in the manufacturing industry along with Aeronautics, Machine Components, and Tool and Die construction.

COLONIAL TOOL GROUP INC, established in 1929, is a manufacturer of CNC broaching and special machines, broaching tools, precision spindles, and work-holding fixtures based in Windsor, Canada. The spindle types are motorized, gear-driven, cluster, belt-driven, specialty, and CNC machined. The broaches are key seaters, keyway, spline rolling, cold forming, and surface broaching tools. The company offers machine tools such as boring tools, milling solutions, valve seat tooling, actuated tooling, and broach services such as sharpening, repair, regrinding, inspection audit test, and heat treatment.

Amtru AG, established in 1985 and headquartered in Wiesendangen, Switzerland, is a manufacturer of deburring tools and components. The company offers customized tools, component designs, and process analysis. It supports system design, pneumatic component selection, and programming of machining processes. In sales, it assists with tool selection along with customer site discussions and provides marketing materials. The company excels in robot applications for deburring, grinding, and polishing, offering various pneumatic and electric tools and accessories like flexicut, swingcut, and scraper tools for aerospace, automotive, and general industries.

Rotork Controls Inc, established in 1957 in New York, USA, is a manufacturer of industrial actuation and flow control equipment. The company offers customized and advanced actuation solutions for valve automation and flow control management. Their product line comprises Electric actuators, fluid power actuators, gearboxes and valve accessories, pneumatic valves and manifolds, and instrumentation and control products. These equipment are used in applications such as oil and gas, water and wastewater, power generation, and industrial automation for precise operation, enabling seamless regulation of fluid flow and process control in critical applications.

Zollern GmbH & Co. KG, founded in 1708 and headquartered in Baden-Wurttemberg, Germany, is a manufacturer of industrial solutions. The company's industrial solutions include drive technology, such as gear boxes, investment casting, and steel profiles. It also provides custom automation solutions for industries that include aviation, new energy, and large-scale railways. Its brands include Zollern, Dorstener, and Ruckle. Its services include project management, custom design, engineering, and manufacture of equipment, as well as the supply of parts.

Schick GmbH, established in 1963 and based in Schemmerhofen, Germany, is a manufacturer and supplier of CNC and machining centers. The company’s product portfolio includes micromotors, handheld electric spindles, and motor handpieces for deburring, grinding, and polishing. These products are used in various applications, including sculpting, carbon fiber processing, and engraving. The company offers customized solutions tailored to meet the specific needs of its clients across different industries, and holds ISO 9001:2015 certification.

HANN KUEN Machinery & Hardware Co., Ltd., a company founded in 1936, based in Taichung, Taiwan, is a manufacturer and supplier of power transmitting and motion control components for automation and engineering. The company offers various products such as slewing ring bearings, oscillating mountings, tensioner devices, spiral bevel gearboxes, servo gears and electromechanical actuators. These products are designed to meet the needs of the customers in various sectors such as aerospace, defense, marine, food and power. The company also offers customer services that include system solutions, digital printing, graphic design and engineering support.

KEBA, founded in 1968 and headquartered in Linz, Austria, is a manufacturer and supplier of industrial machinery automation. The company's primary areas of focus include industrial automation, handover automation, and energy automation. These offerings aim to provide solutions in various industries, striving for sustainable competitive advantages for its clients. Besides, it serves industries that bridge the physical and digital world, emphasize renewable energy, and require tailored industrial solutions. Furthermore, the company offers specialized solutions in banking and service automation, e-mobility, and heating automation.

Seiko Inn Sur was established in 1937 and headquartered in Chiba-shi, Japan is a manufacturer of electronic components, mechanical precision parts and printing devices. The company boasts an extensive and diversified product portfolio including miniature ball bearings, thermal printers, superior performance Co-Ni alloy products, and rare earth magnets among others. These products span a wide spectrum of industries and sectors including commercial printing companies, healthcare facilities, automotive, household appliances, and in the production of musical instrument accessories.

Kenturn Co., Ltd., established in 1983 and headquartered in Changhua County, Taiwan, is a manufacturer and supplier of machine tool spindles. The product range includes CNC machining center spindles, turning center spindles, grinding center spindles, wire EDM spindles, and built-in motor spindles, serving industries like aerospace, automotive, medical, manufacturing, and robotics. Its services entail design and engineering, manufacturing, testing and certification, supply chain management, and technical support. Devoted to quality results, the company holds ISO 9001:2015 certification. With more than four decades of experience, it consistently exceeds expectations in quality and service.

Rototrans d.o.o., a company located in Ljubljana, Slovenia, is a manufacturer and supplier specializing in the design and production of rotary transfer machines. The company's product portfolio includes direct-drive rotary tables, hydraulic indexing rotary tables, and straight shank collet chucks. These products find applications in various industries, including special machinery manufacturing, the machine tool industry, and the automotive industry. The company provides services including customization of products tailored to customers' needs, technical support, and spare parts supply.

Ranking as of March 2026

Derivation Method| Rank | Company | Click Share |

|---|---|---|

| 1 | Dynomax, Inc. |

7.9%

|

| 2 | NAKANISHI INC. |

7.0%

|

| 3 | GMN Paul Müller Industrie GmbH & Co. KG |

6.0%

|

| 4 | UNIST, Inc. |

5.2%

|

| 5 | Visumatic Industrial Products |

4.4%

|

| 6 | IBAG North America |

4.2%

|

| 7 | SCHUNK |

4.0%

|

| 8 | Setco Inc. |

3.9%

|

| 9 | LANG GmbH & Co. KG |

3.1%

|

| 10 | Dapra Corporation |

2.9%

|

Derivation Method

The ranking is calculated based on the click share within the spindle page as of March 2026. Click share is defined as the total number of clicks for all companies during the period divided by the number of clicks for each company.Number of Employees

Newly Established Company

Company with a History

*Including some distributors, etc.

*Including some distributors, etc.

| Country | Number of Companies | Share (%) |

|---|---|---|

United States of America

United States of America

|

7 | 35.0% |

Germany

Germany

|

5 | 25.0% |

Japan

Japan

|

4 | 20.0% |

Italy

Italy

|

1 | 5.0% |

Sweden

Sweden

|

1 | 5.0% |

Canada

Canada

|

1 | 5.0% |

Taiwan

Taiwan

|

1 | 5.0% |

123 products found - Page 1

123 products - Page 1

Wintec Co., Ltd.

220+ people viewing

Last viewed: 1 hour ago

Trapezoidal screw TM30×P6 2-thread right/left thread ~ TM70×P10 2-thread right/left thread

Sunk Japan Co., Ltd.

440+ people viewing

Last viewed: 6 minutes ago

Advantages and benefits ■ Adaptivity high rotation spindle Demonstrate the maximum adaptability when removing Bali ■ Cutting spindle rigidity can ...

6 models listed

Shinken Precision Co., Ltd.

470+ people viewing

Last viewed: 8 hours ago

Highly rigid spindle that delivers performance for BT50 ■Summary ・Belt drive ・Inlet position: outer periphery of flange ・For taper size BT50 ■...

FINESYSTEM Co., Ltd.

570+ people viewing

Last viewed: 16 hours ago

Features ■Ideal for deburring sprues, weirs, membrane burrs, etc. of aluminum die-casting and casting products. A highly rigid rotating tool that u...

SKF

760+ people viewing

Last viewed: 16 hours ago

"SKF Gas Spindle" is an air spindle that has been aged for more than 20 years out of various needs for higher accuracy. These are used not only in ...

TAC Giken Kogyo Co., Ltd.

360+ people viewing

Last viewed: 1 day ago

Drilling, polishing, chamfering, deburring ■Features - Automatic tool exchange allows multiple types of machining. ・High-speed rotation specifica...

Juhara Technos Co., Ltd.

670+ people viewing

Last viewed: 1 day ago

■What is an ultrasonic spindle? ・This is a spindle that can process brittle materials such as glass while rotating it and vibrating it up and down...

ABC Tech Co., Ltd.

310+ people viewing

Last viewed: 1 day ago

■High-speed motor/spindle Our high-speed motor is compact and generates low heat by using a high-performance, compact built-in motor. Furthermore, ...

SIGA MACHINE TOOL CO.,LTD.

590+ people viewing

Last viewed: 7 hours ago

■Innovative ultra-compact spindle S-CUBE condenses advanced technology into a compact body measuring only approximately 60 mm square, achieving a m...

DAI-ICHI SOKUHAN WORKS CO.

720+ people viewing

Last viewed: 16 hours ago

It matches the use of the basic rolling bearing type to the air spindle of submichron accuracy. The rotating spindle unit is an indispensable prod...

Sunk Japan Co., Ltd.

350+ people viewing

Last viewed: 7 minutes ago

Advantages and benefits ■ Correction power can be adjusted by compressed air. Achieves high quality burr removal at any mounting position ■ Flexib...

2 models listed

Shinken Precision Co., Ltd.

490+ people viewing

Last viewed: 16 hours ago

Compact type for space-saving applications, 2 model numbers ■Summary ・Belt drive ・Inlet position: Select from the outer periphery of the flange ...

FINESYSTEM Co., Ltd.

280+ people viewing

Last viewed: 16 hours ago

Features ■Ideal for deburring parting lines of aluminum die-cast and cast products. A highly rigid rotating tool that uses angular bearings. It is ...

2 models listed

SKF

790+ people viewing

Last viewed: 16 hours ago

"SKF oil static pressure spindle" is a spindle that has the advantages of both rolling bearing spindles and gas spindles. In the past, it has devel...

Miniter Co., Ltd.

320+ people viewing

Last viewed: 1 day ago

Achieves high-spec high-speed machining.

Marushin Co., Ltd.

580+ people viewing

Last viewed: 5 minutes ago

Automatically attaches and detaches “all the tools” the user imagines ■Ashura Infinity's biggest features ・Equipped with spindle orientation func...

DAI-ICHI SOKUHAN WORKS CO.

820+ people viewing

Last viewed: 1 day ago

It matches the use of the basic rolling bearing type to the air spindle of submichron accuracy. The rotating spindle unit is an indispensable prod...

TAC Giken Kogyo Co., Ltd.

320+ people viewing

Last viewed: 1 day ago

Drilling, polishing, chamfering, deburring, cutting ■Features - Compatible with high speed rotation. ・Variable speed with inverter. - Equipped wi...

DAI-ICHI SOKUHAN WORKS CO.

790+ people viewing

Last viewed: 1 day ago

It matches the use of the basic rolling bearing type to the air spindle of submichron accuracy. The rotating spindle unit is an indispensable prod...

SKF

800+ people viewing

Last viewed: 16 hours ago

"SKF rolling bearing spindle" provides customers specified products according to your needs. Based on the axle receiving technology for one century...

ABC Tech Co., Ltd.

340+ people viewing

Last viewed: 1 day ago

■High-speed motor/spindle Our high-speed motor is compact and generates low heat by using a high-performance, compact built-in motor. Furthermore, ...

Coretech Co., Ltd.

290+ people viewing

Last viewed: 16 hours ago

High speed spindle for small diameter high speed micro machining and grinding. We also design and manufacture special spindles. Ball bearings, gre...

TUNGALOY CORPORATION

430+ people viewing

Last viewed: 16 hours ago

■Achieving high-speed rotation and high-efficiency machining using existing machines - An original mechanism that uses coolant pressure to rotate a...

Sunk Japan Co., Ltd.

530+ people viewing

Last viewed: 7 minutes ago

Advantages and benefits ■ The rigidity of the spindle can be adjusted by air pressure Achieves high quality burr removal at any mounting position ...

Shinken Precision Co., Ltd.

440+ people viewing

Last viewed: 16 hours ago

Standardized all 12 model numbers for machining centers ■Belt drive Choose from 2 types of pulleys ■Inlet position Select from the outer peripher...

SKF

670+ people viewing

Last viewed: 16 hours ago

"SKF rolling bearing spindle" provides customers specified products according to your needs. Based on the axle receiving technology for one century...

DAI-ICHI SOKUHAN WORKS CO.

1440+ people viewing

Last viewed: 16 hours ago

It matches the use of the basic rolling bearing type to the air spindle of submichron accuracy. The rotating spindle unit is an indispensable prod...

TAC Giken Kogyo Co., Ltd.

410+ people viewing

Last viewed: 1 day ago

Drilling, polishing, chamfering ■Features - Manufactured with a smaller outer diameter than general-purpose motors. Make your equipment more compa...

Coretech Co., Ltd.

400+ people viewing

Last viewed: 16 hours ago

High speed spindle for small diameter high speed micro machining and grinding. We also design and manufacture special spindles. ■Features ・Built-...

TAC Giken Kogyo Co., Ltd.

320+ people viewing

Last viewed: 1 day ago

Drilling, polishing, chamfering, deburring ■Features - Compact and can handle high-speed rotation. ・Variable speed with dedicated controller. ・U...