All Categories

History

This section provides an overview for spindle motors as well as their applications and principles. Also, please take a look at the list of 14 spindle motor manufacturers and their company rankings. Here are the top-ranked spindle motor companies as of February, 2026: 1.NAKANISHI INC., 2.Aerotech, Inc., 3.Pushcorp Inc..

Table of Contents

Categories Related to Spindle Motors

Engaged in research on nitride semiconductor growth using the MBE method at Waseda University Graduate School. After graduating from graduate school in 2016, he joined a non-ferrous metal manufacturer.

Engaged in equipment maintenance and engineering work at metal smelting plants. Moved to a chemical manufacturer in 2022. Engaging in similar tasks.

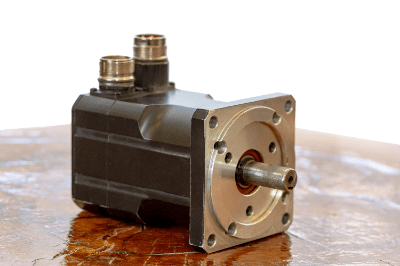

A spindle motor is a motor in which the motor part of the power source and the rotating part are integrated.

A spindle motor is a motor in which the motor part of the power source and the rotating part are integrated.

Since there is only one rotating shaft, the equipment configuration is simplified. A spindle is the rotating shaft of a rotating machine.

It is also called a spindle unit, a term used for machine tools such as lathes. Therefore, a spindle motor refers to a motor integrated with a spindle.

A typical rotation control device consisting of a motor, gears, and belts tends to be complicated to control due to the large number of parts. Spindle motors, however, make it easy to add multiple rotating shafts in parallel in a space-saving manner.

Spindle motors are widely used inside processing machines. The following are examples of spindle motor applications.

A wide range of product lineup exists, from high-torque types to products capable of high-speed rotation. It is possible to select the optimum product from a variety of spindle motors according to the application.

In recent years, spindle motors have also been used in articulated robots, where the axis of rotation of the robot arm is matched with the axis of the spindle motor. Taking advantage of their space-saving characteristics, spindle motors can also be used to drive HDD rotation.

The structure of spindle motors is often very similar to the widely used servo motors. The spindle is installed coaxially with the axis of rotation. There are two types of motors used: synchronous motors and induction motors.

Synchronous motors consist of a rotor made of permanent magnets fixed to a rotating shaft and multiple circular stator units installed around the periphery of the rotor. The stator consists of electric wires wound around an iron core, and when an alternating current flows through it, it acts as an electromagnet and temporarily restrains itself.

Because the phase of the AC current changes from moment to moment, the polarity of the electromagnets also changes with time. Since the polarity of the rotor's permanent magnet is fixed, it can rotate the rotor by alternating attraction and repulsion with the stator.

Induction motors are motors that use a conductor rotor instead of the permanent magnet rotor of synchronous motors. A cage-shaped metal part is often used for the conductor rotor.

The principle is that a rotating magnetic field generated by the stator generates an electric current in the rotor conductor, causing electromagnetic induction action that rotates the shaft. Unlike synchronous motors, this type of motor is not suitable for fine positioning because of an error called "slippage" in the rotation phase. However, they are widely used for high output products because of their low cost and small number of parts.

Spindle refers to the rotary shaft of industrial rotating equipment used for cutting and grinding. Therefore, the main purpose of spindle motors is cutting and grinding. Motors with ultra-high speed rotation and high torque are often used.

In contrast, servo motors are widely used in precision machinery that requires strict positioning accuracy. Assembly robots and automatic packaging equipment are examples. Driving devices such as encoders are used in motors to detect the rotational position and speed of the rotor.

This detection information is communicated with a PLC or driver to implement feedback control, enabling high-speed rotation to be controlled with high precision. Both spindle motors and servo motors of all types can be applied.

However, induction motors are often used for spindle motors and large-capacity servo motors, while synchronous motors are often used for small-capacity servo motors.

*Including some distributors, etc.

Sort by Features

Sort by Area

NAKANISHI, founded in 1930, is a manufacturer and supplier of surgical, dental, and general industrial products applying high-speed rotation technology located in Tochigi, Japan. The products include micro grinders & controllers that are electrically or air-driven, sub-spindle machine tools, high-speed machining spindles, special-purpose machines & robots, and milling machines. The company offers solutions to drilling, milling by endmills, deburring by carbide cutters, grinding by grindstones, and finishing applications in the automotive, medical, mold, micromechanics, and electronics industries.

PushCorp Inc., established in 1993 and based in Garland, Texas, USA, is a manufacturer and supplier of robotic material removal end-of-arm tooling. The company's product range includes AFD310, AFD620, AFD1240, SBS82 Series, and STC1503-BT30. These products are primarily used for grinding, sanding, polishing, routing & cutting, and deburring. They serve industries such as automation machinery manufacturing. In addition to its product offerings, the company provides proof of concept testing, specialized robotic labs, and local support through a sales office in Wixom, Michigan.

AEROTECH creates solutions for motion and positioning of devices. Customers are from industries as diverse as data storage, medical devices, and aerospace. AEROTECH develops controllers, drives, motors, and other parts for motion and positioning devices and offers custom-engineered motion systems. AEROTECH’s serves both manufacturers of individual parts as well as equipment operators offering full range of support rom design to manufacturing to deployment.

Citizen Chiba Precision was established in Chiba, Japan in 1979. Citizen is a leader of miniaturized precision motors and customized products which custom-made to meet specific customer requirements for among others, semiconductor manufacturing equipment, medical equipment, and laser application products. Examples of Citizen’s products include optical scanners, linear actuators, servomotors, gear heads, and control drivers.

FANUC Corporation, established in 1972 and headquartered in Yamanashi Prefecture, Japan, is a manufacturer of factory automation, robomachine, IoT, and robotics. The company offers an extensive and diversified product portfolio including, servomotor, robodrill small cutting machine, roboshot electric injection molding machine, robocut wire electrical discharge machine, and lasers. These cutting-edge products cater to a wide range of industries, spanning from automotive, health care, and aerospace to electronics. The aim of the company is to provide efficient and low-cost products to customers.

URAWA Corporation, established in September 1955 and based in Kuki-shi, Saitama-ken, Japan, is a manufacturer and supplier of micro grinders. The company's product range includes more than 50 different models of micro grinders developed for dental, industrial, and various other uses. These grinders have become essential tools in sectors that require precision grinding. Serving industries such as dental and industrial sectors worldwide, the company emphasizes the importance of creativity, quality, and great design in its product offerings. The company's services include continuous research, development of new products, and technologies.

SUGINO MACHINE LIMITED was established in 1936 and is a manufacturer and supplier of high pressure jet cleaning equipment, water cutting equipment, and industrial devices based in Namerikawa, Toyama, Japan. The company manufactures various products such as water beam machine, ultrasonic cutting machine, gun drill machine, dimple forming tool, and roller burnishing tool. The products are used in various applications such as aerospace, robotic, nuclear power plants, machining manufacture, and biosciences field. The company has obtained the ISO 9001 certification standard in 1998.

MinebeaMitsumi Inc. was incorporated in 1951in Japan and manufactures and supplies machined components, and electronic devices and components globally. It operates through four segments: machined components, electronic devices and components, MITSUMI Business, and the U-Shin business segment. MinebeaMitsumi specializes in bearing products including spherical, roller, rod end, and ball bearings for aerospace. MinebeaMitsumi also produces products including precision mechanical assemblies, fasteners, other special components including clutches and brakes, motors, blowers, sensors and lighting devices. Additionally, MinebeaMitsumi offers its products for use in PCs and peripheral equipment, information and telecommunications equipment, household electrical appliances, automobiles, and aerospace.

BMR GmbH, based in Schwabach, Bavaria, Germany, was founded in 1978 and is a manufacturer of static frequency converters for asynchronous (AC) and synchronous (BLDC) spindles. Its converters are in the power range from 100VA to 3.5 KVA and speed up to 150,000 rpm. Their products are used for grinding, milling, engraving, and dressing. They also produce custom-made industrial electronics for the control of lighting film and lamps for the automotive and advertising industry.

BOBET, a company founded in 2014 and headquartered in Shenzhen, China, is a manufacturer and supplier of DC motors and DC geared motors. The company's product portfolio includes DC planetary gear motors, stepper servo motors, and gearboxes. These products are used in various sectors, including industrial automation, renewable energy generation, and the aerospace and defense industry. The company offers services including technical support, customization, and guidance on product maintenance and repair. The company exports its products to various countries, including the United States, India, and Germany.

MicroLab Precision Technology Co., Ltd., established in 1999 and based in Taichung City, Taiwan, is a manufacturer and supplier of machining spindles. The company's product portfolio includes rotary spindle heads, tapping center spindles, and milling and turning direct drive spindles. These products find applications in various industries, including general manufacturing, automotive, and the defense industry. The company provides services including technical support, customization according to the unique requirements of individual customers, and training. The company sells its products globally to various countries including the United States, Sweden, and China.

FANUC Corporation was established in 1956 and is headquartered in Japan, manufacturing of industrial robots, CNC systems, and related automation technologies. The company produces products that include industrial robots, CRX Cobots, Lasers, IoT Solutions, and various CNC systems for machine tools. These systems and technologies find applications in a broad range of industries, including automotive manufacturing, aerospace and defense, electronics production, and metalworking. They also help with automated repetitive tasks, performing complex assembly operations, and handling hazardous materials for medical device manufacturing, consumer goods products, and many more industrial applications.

Ranking as of February 2026

Derivation Method| Rank | Company | Click Share |

|---|---|---|

| 1 | NAKANISHI INC. |

33.4%

|

| 2 | Aerotech, Inc. |

10.4%

|

| 3 | Pushcorp Inc. |

10.1%

|

| 4 | BMR |

8.8%

|

| 5 | URAWA Corporation |

6.0%

|

| 6 | Citizen Chiba Precision CO.,LTD. |

5.9%

|

| 7 | MicroLab Precision Technology Co., Ltd. |

5.8%

|

| 8 | BOBET |

5.5%

|

| 9 | SUGINO MACHINE LIMITED |

4.3%

|

| 10 | MinebeaMitsumi Inc. |

3.9%

|

Derivation Method

The ranking is calculated based on the click share within the spindle motor page as of February 2026. Click share is defined as the total number of clicks for all companies during the period divided by the number of clicks for each company.Number of Employees

Newly Established Company

Company with a History

*Including some distributors, etc.

*Including some distributors, etc.

| Country | Number of Companies | Share (%) |

|---|---|---|

Japan

Japan

|

7 | 63.6% |

United States of America

United States of America

|

2 | 18.2% |

Germany

Germany

|

2 | 18.2% |

122 products found

122 products

ABC Tech Co., Ltd.

420+ people viewing

Last viewed: 1 day ago

■High-speed motor/spindle Our high-speed motor is compact and generates low heat by using a high-performance, compact built-in motor. Furthermore, ...

TAC TOOL Co., Ltd.

480+ people viewing

Last viewed: 1 day ago

Spindle motors that can be used in a wide range of applications, from general-purpose to dedicated

ABC Tech Co., Ltd.

360+ people viewing

Last viewed: 22 hours ago

■High-speed motor/spindle Our high-speed motor is compact and generates low heat by using a high-performance, compact built-in motor. Furthermore, ...

TAC TOOL Co., Ltd.

580+ people viewing

Last viewed: 1 day ago

High-speed spindle motor with emphasis on precision stability

ABC Tech Co., Ltd.

350+ people viewing

Last viewed: 1 day ago

■High-speed motor/spindle Our high-speed motor is compact and generates low heat by using a high-performance, compact built-in motor. Furthermore, ...

TAC TOOL Co., Ltd.

500+ people viewing

Last viewed: 1 day ago

Small, lightweight, high output spindle motor

ABC Tech Co., Ltd.

360+ people viewing

Last viewed: 1 day ago

■High-speed motor/spindle Our high-speed motor is compact and generates low heat by using a high-performance, compact built-in motor. Furthermore, ...

ABC Tech Co., Ltd.

350+ people viewing

Last viewed: 1 day ago

■High-speed motor/spindle Our high-speed motor is compact and generates low heat by using a high-performance, compact built-in motor. Furthermore, ...

Nidek Drive Technology Co., Ltd.

520+ people viewing

Last viewed: 1 day ago

■Machine tool spindle drive unit that integrates motor, reducer, and spindle [Manufactured by German company DESCH] Application machine tool spindl...

Nidek Drive Technology Co., Ltd.

470+ people viewing

Last viewed: 1 day ago

■ Machine tool spindle reducer unit [Manufactured by German company DESCH] Application machine tool spindle ■Features Compact design with integrat...

Nidek Drive Technology Co., Ltd.

480+ people viewing

Last viewed: 6 hours ago

■ Machine tool spindle reducer unit [Manufactured by German company DESCH] Application machine tool spindle ■Features Can be installed in customer...

URAWA Corporation

1080+ people viewing

Last viewed: 1 day ago

It is designed to be installed on a small automatic machine and a desktop type automatic machine. ・ Replacement of tools is one touch ・ There is no...

ABC Tech Co., Ltd.

320+ people viewing

Last viewed: 10 hours ago

■High-speed motor/spindle Our high-speed motor is compact and generates low heat by using a high-performance, compact built-in motor. Furthermore, ...

K-World Ltd.

180+ people viewing

Last viewed: 1 day ago

8 models listed

ABC Tech Co., Ltd.

320+ people viewing

Last viewed: 1 day ago

■High-speed motor/spindle Our high-speed motor is compact and generates low heat by using a high-performance, compact built-in motor. Furthermore, ...

URAWA Corporation

900+ people viewing

Last viewed: 1 day ago

It is designed to be installed on a small automatic machine and a desktop type automatic machine. ・ Replacement of tools is one touch ・ There is no...

ABC Tech Co., Ltd.

290+ people viewing

Last viewed: 1 day ago

■High-speed motor/spindle Our high-speed motor is compact and generates low heat by using a high-performance, compact built-in motor. Furthermore, ...

ABC Tech Co., Ltd.

320+ people viewing

Last viewed: 1 day ago

■High-speed motor/spindle Our high-speed motor is compact and generates low heat by using a high-performance, compact built-in motor. Furthermore, ...

ABC Tech Co., Ltd.

290+ people viewing

Last viewed: 1 day ago

■High-speed motor/spindle Our high-speed motor is compact and generates low heat by using a high-performance, compact built-in motor. Furthermore, ...

TAC Giken Kogyo Co., Ltd.

390+ people viewing

Last viewed: 1 day ago

Drilling, polishing, chamfering ■Features - Manufactured with a smaller outer diameter than general-purpose motors. Make your equipment more compa...

TAC Giken Kogyo Co., Ltd.

300+ people viewing

Last viewed: 1 day ago

Drilling, polishing, chamfering, deburring, cutting ■Features - Compatible with high speed rotation. ・Variable speed with inverter. - Equipped wi...

TAC Giken Kogyo Co., Ltd.

310+ people viewing

Last viewed: 13 hours ago

Drilling, polishing, chamfering, deburring ■Features - Compact and can handle high-speed rotation. ・Variable speed with dedicated controller. ・U...

TAC Giken Kogyo Co., Ltd.

340+ people viewing

Last viewed: 1 day ago

Drilling, polishing, chamfering, deburring ■Features - Automatic tool exchange allows multiple types of machining. ・High-speed rotation specifica...