All Categories

History

This section provides an overview for contour measuring machines as well as their applications and principles. Also, please take a look at the list of 19 contour measuring machine manufacturers and their company rankings. Here are the top-ranked contour measuring machine companies as of February, 2026: 1.Willrich Precision Instruments, 2.Unimetro Precision Machinery Co., Ltd, 3.Chotest Technology Inc..

Table of Contents

Categories Related to Contour Measuring Machines

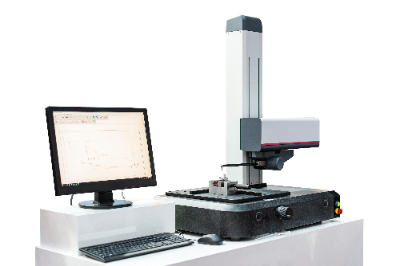

Contour measuring machines are devices that trace the contours of objects and accurately record, analyze, and measure their shapes.

Contour measuring machines are devices that trace the contours of objects and accurately record, analyze, and measure their shapes.

Contour measuring machines that use a stylus to directly trace the surface of the object to be measured and accurately trace its movement are called contact-type contour measuring machines. On the other hand, a non-contact type traces the surface by capturing reflected light from the surface with a laser or other means.

While non-contact contour measuring machines are relatively easy to use, their disadvantage is that the condition of the reflected light varies greatly depending on the material and properties of the object's surface. For this reason, contact-type measuring machines, which are not affected by conditions, are widely used.

Contour measuring machines are widely used mainly for the development, production, and quality control of metalworking products. In addition, they are sometimes used for automatic measurement on the production line by programming a series of measurement operations.

Since the stylus-type contour measuring machines may scratch the surface, they are often used for spot-checking when the appearance of the product is important. Contour measuring machines can accurately measure shapes and dimensions at a fine pitch, so they can also be used for reverse engineering.

This section describes the principle of widely used contact-type contour measuring machines. Contact contour measuring machines consist of a detector that moves horizontally and a stylus that moves up and down in a large circular arc.

The contour shape can be traced by constantly plotting the coordinates of the stylus tip using a digital scale, with the X coordinate from the horizontal movement and the Y coordinate from the vertical position of the stylus. Note that the arm to which the stylus is attached moves up and down as an arc motion.

In other words, the stylus tip also follows the shape of the object to be measured in a circular arc motion. Therefore, to plot the XY coordinates accurately, the error in the X direction caused by the arc motion must be compensated. Also, if the digital scale used to measure the vertical motion of the stylus can only measure linear motion, a mechanism is required to convert the arc motion into linear motion.

Accurate positioning is critical for detectors, so ball screws and stepping motors are used for this motion. In high-precision machines, electrical components such as the power supply and control board are generally independent as an external box to minimize the effects of thermal expansion.

Contour measuring machines have a stylus at the end which is mounted vertically on the arm, so it cannot measure at right angles.

The angle at which contour measuring machines can measure is called the tracking angle, which refers to both the up and down directions. The angle of follow-up depends on the shape of the stylus, which has limits in both the ascending and descending directions.

If the stylus has a conical or symmetrical shape, the tracking angles are equal in the up and down directions. However, if the stylus has an asymmetrical shape, the follow-up angles for ascending and descending are different, so care must be taken. The tracking angle also varies depending on the measuring speed and measuring force, and the higher the measuring speed, the more difficult it is to track a steep slope.

Contact-type contour measuring machines are subject to wear because the stylus tip is in contact with the surface to be measured. Even if wear is minimal, it is affected by hysteresis and other changes over time due to repeated use.

Therefore, periodic inspections are necessary, but frequent large-scale maintenance is not realistic in terms of man-hours and cost. Therefore, as a routine inspection, important functions and points related to performance are simply corrected.

Daily inspections of contour measuring machines mainly check and correct the following three points:

In most cases, both corrections are automatically calculated by the software from the measured values, so it is important to control the use of the software to remember to perform daily inspections. Furthermore, if you want to obtain and maintain the automotive industry and quality management standards, such as IATF16949 and ISO9001, you must also perform calibration work that ensures traceability on a regular basis.

*Including some distributors, etc.

Sort by Features

Sort by Area

Willrich Precision Instruments is a supplier and distributor of precision measurements headquartered in New Jersey, USA, since 1971. The company offers various instruments, including gauges, micrometers, surface roughness testers, and thread gauges. The company serves multiple industries, including manufacturing, aerospace, automotive, medical, and more. Its instruments are used for quality control, inspection, and precision in various applications. While they work closely with manufacturers to source and distribute devices, the company primarily offers instruments. It provides support and expertise to customers in selecting the right tools for specific needs.

Guiyang Xintian OETECH Co., Ltd, founded in 1966 and situated in Guiyang, China, is a manufacturer of precision optical measurement instruments. The company specializes in crafting a broad line of advanced products, including optical measuring machines, gauge block comparators, microscopes, vision measuring systems, and laser scanning systems. It has obtained ISO 9001:2015 certification, and the products offer numerous advantages, including robust accuracy, repeatability, and efficiency, making them important equipment for industries such as aerospace, automotive, electronics, and medical devices for measurement and inspection needs.

Unimetro Precision Machinery Co., Ltd. is a manufacturer of metrology products that was established in 2007 and headquartered in Dongguan, China. The company produces several categories of metrology products such as Vision Measurement Machines, 3D Coordinate Measuring Machines, Tool Inspection Systems and Image Dimension Measurement. Unimetro’s products include circuit boards, electronic components, plastic/rubber products, stamping parts, clocks and watches as well as connectors, touch screen testing, and bottle blank testing. The company also offers multiple services, including OEM or ODM support, remote online support, on-site installation, technical training, and metrology consulting services for manufacturers or dealers of metrology worldwide.

Metrology Technology Research & Development Co., Ltd., established in 1995 and headquartered in Kaohsiung City, Taiwan, is a manufacturer of precision measuring and calibration instruments. The company offers a wide range of products, including a caliper, dial indicator, measuring gauge, granite master gauge, and more. It also offers an optical microscope, calibrator instrument, hardness testing equipment, and repair services. Its Calipers are built using materials such as hardened stainless steel, making them resistant to damage and corrosion. The company has achieved ISO/IEC 17025:2017 accreditation for its calibration laboratory. It serves industries such as manufacturing, automotive, aerospace, electronics, medical, and more.

Mahr GmbH, Providence, RI, in 1888 is a manufacturer of dimensional metrology equipment from simple handheld gages to technically advanced measurement systems for form, contour, surface finish and length. The company's product portfolio includes electronic precision pointers, Touch control buttons used for sensitive measuring tasks, Length measurement technology & components used for electrical linear encoders and Calibration & setting machines. Their products are used in industries such as Food and Beverage, Pharmaceutical and Biotechnology, Medical and laboratories. The company provides services such as Product Selection Guidance, Engineering Support, New Product Design and Development and Custom Manufacturing.

Tokyo Seimitsu Co. Ltd., established in 1949 and headquartered in Tokyo, Japan, is a manufacturer of semiconductor production equipment and precision measuring instruments. Its product portfolio includes optical measuring instruments, probing machines, polish grinders, X-ray CT systems, and coordinate measuring machines. In 1952, the company developed Japan’s first high-pressure flow-type air micrometer, and in 1958, it created the world’s first germanium pellet automatic thickness sorting machine. It also developed Japan’s first coordinate measuring machine in 1969, followed by Japan’s first wafer-dicing machine in 1970. The company is the industry’s only semiconductor equipment manufacturer with measurement technology.

Kosaka Laboratory Ltd., a company founded in 1950 and headquartered in Tokyo, Japan, is a manufacturer and supplier specializing in the production of precision measuring instruments. The company's product portfolio includes precision measuring instruments, hydraulic equipment, automatic machinery, and food equipment. These products are utilized by various industries, including the packaging industry, electronics, wind-power generation, manufacturing and engineering, and food and beverage. The company holds the ISO 9001 certificate for its Quality Management System (QMS).

ZEISS Microscopy, established in Jena, Germany, in 1846 is a manufacturer of optics and optoelectronics used in Precision Mechanics, Binoculars, Microscopy, and Eyeglass Lenses. Their product portfolio includes precision optics, such as lenses, mirrors, and prisms, laser mirrors used in laser cutting, and medical devices, optoelectronic devices and Coatings and Thin Films. The company also provides solutions including industrial quality, microscopy research, project simulation, sample testing and product development. The company also offers customer services that include support, custom research projects and customized services.

Mitutoyo was founded in 1934 and headquartered in Kawasaki City, Japan. The company is a manufacturer and seller of precision measuring instruments including software, optics, machinery, and electronics. The company is ISO/IEC 17025 accredited for calibration services for measuring instruments. The company’s product lines include Micrometers, Calipers, Calibration Equipment, Vision Measuring Systems, and many others. The company’s coordinate measuring machines and roundness/cylindricity measuring machines are sol in over 60 countries worldwide.

Chotest Technology Inc., founded in 2005, is a manufacturer of precision measuring instruments headquartered in Shenzhen, China. The company offers a range of high-precision measuring equipment, including White Light Interferometer SuperView W1, Laser Tracker GT series, universal length measuring machines, laser interferometer SJ6000, and profilometers SJ5700 series. Its products are manufactured in accordance with ISO9001 and 6S standards, ensuring quality products for its customers. The company's precision measuring equipment is used in various industries, including government metrology and quality inspection agencies, automotive, aerospace, and machinery. Its instruments are employed for accurate measurements in quality control and industrial applications.

AMETEK, Inc. is based in Berwyn, Pennsylvania, USA, and is a manufacturer of testing instruments and electrical utility products established in 1968 following the merger of American Machine and Metals and Pennsalt Chemicals. The company’s products include process analyzers for measuring properties of media in industrial processes, calibration instruments for its process analysis sensors or gauges, and power quality analyzers for diagnosing the reliability of electrical output. The company also provides asset management, calibration and repair, and custom engineering services for client-specific projects.

Smart Solutions, based in Pune, India, is a supplier and distributor of measuring equipment established in 2007. The company specializes in providing technological solutions in metrology, which involves precise measurement and quality control. Its offerings include contour measuring machines, coordinate measuring devices, snap digital, and video measuring systems. These instruments deliver accurate results in various industries. The company also offers alternative solutions, such as providing silent diesel/biodiesel generators and AMF panels. The company caters to manufacturing, engineering and research, power generation, and various industrial sectors.

RB Metrology, founded in 2008, is a supplier and provider of metrology solutions and services based in India. The company offers a range of metrology equipment and machines, including 3D Coordinate Measuring Machines (CMM), Portable Arm CMMs, Roughness Testers, and more. These products are designed to meet quality standards and are suitable for various applications across different sectors, including research institutes, testing labs, and engineering institute laboratories. The company offers these metrology machines and equipment at competitive prices for customers who require precise measurement solutions.

Ranking as of February 2026

Derivation Method| Rank | Company | Click Share |

|---|---|---|

| 1 | Willrich Precision Instruments |

14.3%

|

| 2 | Unimetro Precision Machinery Co., Ltd |

11.8%

|

| 3 | Chotest Technology Inc. |

8.0%

|

| 4 | SMART SOLUTIONS |

7.1%

|

| 5 | Kosaka Laboratory Ltd. |

5.5%

|

| 6 | TOKYO SEIMITSU CO., LTD. |

5.5%

|

| 7 | Guiyang Xintian OETECH Co., Ltd |

5.0%

|

| 8 | Mahr GmbH |

5.0%

|

| 9 | HUST VIETNAM TECHNICAL EQUIPMENT JSC |

4.2%

|

| 10 | Metrology Technology Research & Development Co., Ltd. |

4.2%

|

Derivation Method

The ranking is calculated based on the click share within the contour measuring machine page as of February 2026. Click share is defined as the total number of clicks for all companies during the period divided by the number of clicks for each company.Number of Employees

Newly Established Company

Company with a History

*Including some distributors, etc.

*Including some distributors, etc.

| Country | Number of Companies | Share (%) |

|---|---|---|

Japan

Japan

|

3 | 18.8% |

Vietnam

Vietnam

|

3 | 18.8% |

China

China

|

2 | 12.5% |

India

India

|

2 | 12.5% |

United States of America

United States of America

|

1 | 6.3% |

Taiwan

Taiwan

|

1 | 6.3% |

Germany

Germany

|

1 | 6.3% |

| Deutschland | 1 | 6.3% |

United Kingdom

United Kingdom

|

1 | 6.3% |

Singapore

Singapore

|

1 | 6.3% |

58 products found

58 products

Kosaka Laboratory Ltd.

540+ people viewing

Last viewed: 1 day ago

■Features This is a digital surface shape/roughness measuring machine that enables high resolution and wide dynamic range measurement. - A digital ...

Mahr Inc.

470+ people viewing

Last viewed: 14 hours ago

■Measuring station that combines contour measurement and surface measurement This is a measuring machine that performs contour measurement and roug...

Mahr Inc.

640+ people viewing

Last viewed: 14 hours ago

■Reliable measurement station for contour measurement This measuring station sets a new standard in contour inspection. Significantly improve your ...

7 models listed

Kosaka Laboratory Ltd.

610+ people viewing

Last viewed: 10 hours ago

■Features This is a combination of a surface roughness measuring machine and a contour measuring machine, allowing roughness waviness evaluation an...

Kosaka Laboratory Ltd.

640+ people viewing

Last viewed: 8 hours ago

■Features Equipped with analysis macros to help save labor in complex analysis tasks. This is a measuring device with high portability/installation...

Kosaka Laboratory Ltd.

620+ people viewing

Last viewed: 9 hours ago

■Features A high-performance contour measuring machine with ultra-high speed movement and rich analysis functions. Equipped with a detector overloa...

Kosaka Laboratory Ltd.

610+ people viewing

Last viewed: 17 hours ago

■Features Two types of measurements are possible: "Surface roughness" and "Contour shape". The use of a touch panel provides excellent operability,...

Mahr Inc.

260+ people viewing

Last viewed: 21 hours ago

■Highly reliable contour measuring station This measuring station sets a new standard in contour inspection. Significantly improve your quality ass...

4 models listed

Kosaka Laboratory Ltd.

520+ people viewing

Last viewed: 10 hours ago

Kosaka Laboratory Ltd.

500+ people viewing

Last viewed: 4 hours ago

Yagyu Shokai Co., Ltd.

710+ people viewing

Last viewed: 1 day ago

■Features - A small mobile 3D scanner that is lightweight and easy to carry. -The included turntable rotates automatically, making it easy to use. ...

Meishin Koki Co., Ltd.

810+ people viewing

Last viewed: 1 day ago

■Summary ・3D white interference microscope for measuring nano-level surface properties ・Measure the surface roughness and shape of machined parts...

Kosaka Laboratory Ltd.

480+ people viewing

Last viewed: 16 hours ago

■Features Ideal for measuring cylindrical shapes of large objects. A space-saving type equipped with an automatic table with automatic centering, a...

Meishin Koki Co., Ltd.

630+ people viewing

Last viewed: 2 hours ago

■Summary Both surface roughness and contour shape can be completed with one machine. Features ■If you need to evaluate both surface roughness and ...

Kosaka Laboratory Ltd.

400+ people viewing

Last viewed: 1 day ago

■Features This is a rotary table roundness/cylindrical shape measuring machine that can handle large and heavy objects. Especially suitable for mea...

Kosaka Laboratory Ltd.

490+ people viewing

Last viewed: 1 day ago

■Features Compatible with measurements of all piston shapes. Easily measure piston oval, taper, and ring groove shapes. EC3300P is a high precision...

Kosaka Laboratory Ltd.

580+ people viewing

Last viewed: 1 day ago

■Features You can freely change the position of the detector according to the measurement menu and measure all inner and outer diameters and upper ...

Kosaka Laboratory Ltd.

590+ people viewing

Last viewed: 15 hours ago

■Features It is a fully automatic measuring machine with excellent reproducibility, best in class high precision, high functionality, equipped with...

Kosaka Laboratory Ltd.

650+ people viewing

Last viewed: 1 day ago

■Features This is a highly accurate roundness/cylindrical shape measuring machine that anyone can easily use. Designed to reduce the burden on the ...

Kosaka Laboratory Ltd.

510+ people viewing

Last viewed: 13 hours ago

■Features Equipped with a high-precision automatic table, this is a fully automatic measuring machine that performs everything from tilting/centeri...

Kosaka Laboratory Ltd.

550+ people viewing

Last viewed: 1 day ago

■Features EC1650H, full of ideas for “highly accurate and quick” measurement ・High resolution ・The filter uses 2CR normal type, 2CR, and Gaussian...

Kosaka Laboratory Ltd.

590+ people viewing

Last viewed: 17 hours ago

■Features It is a tabletop type with a cylinder evaluation function that emphasizes operability and boasts a high-precision rotational accuracy des...

Kosaka Laboratory Ltd.

760+ people viewing

Last viewed: 1 day ago

■Features Compact for production sites, easy to operate and quick measurements without the need for a PC. ・Easy operation by anyone with centering...

Kosaka Laboratory Ltd.

480+ people viewing

Last viewed: 1 day ago

■Features Large workpieces with sample sizes up to 2,200 x 2,600 mm can be automatically measured with high precision. There is also an option to l...

Kosaka Laboratory Ltd.

560+ people viewing

Last viewed: 1 day ago

■Features This is a fully automatic micro-shape measuring machine with excellent accuracy, stability, and functionality that is ideal for measuring...

Kosaka Laboratory Ltd.

530+ people viewing

Last viewed: 1 day ago

■Features This is a fully automatic micro-shape measuring machine with excellent accuracy, stability, and functionality that is ideal for measuring...

Kosaka Laboratory Ltd.

570+ people viewing

Last viewed: 22 hours ago

■Features This is a fully automatic micro-shape measuring machine with excellent accuracy, stability, and functionality that is ideal for measuring...

Kosaka Laboratory Ltd.

570+ people viewing

Last viewed: 2 hours ago

■Features Ideal for two-dimensional surface roughness analysis and step measurement, it achieves high accuracy, high resolution, and excellent stab...

Kosaka Laboratory Ltd.

440+ people viewing

Last viewed: 1 day ago

■Features Ideal for two-dimensional surface roughness analysis and step measurement, it achieves high accuracy, high resolution, and excellent stab...

Yagyu Shokai Co., Ltd.

970+ people viewing

Last viewed: 1 day ago

■Features - Foldable, camera and turntable can be stored when not in use. ・You can see the process of data construction during scanning. -Can be s...