All Categories

History

This section provides an overview for coordinate measuring machinery (cmm) as well as their applications and principles. Also, please take a look at the list of 24 coordinate measuring machinery (cmm) manufacturers and their company rankings. Here are the top-ranked coordinate measuring machinery (cmm) companies as of July, 2025: 1.CMMXYZ, 2.WENZEL America, 3.Velocity Machine.

Table of Contents

Categories Related to Coordinate Measuring Machinery (CMM)

A coordinate measuring machine (CMM) is an instrument capable of measuring surface features at the submicron level(smaller than 1/1,000 of a millimeter). 3D coordinate measuring machines can capture the shape of a part in three dimensions and perform a variety of measurements.

A coordinate measuring machine (CMM) is an instrument capable of measuring surface features at the submicron level(smaller than 1/1,000 of a millimeter). 3D coordinate measuring machines can capture the shape of a part in three dimensions and perform a variety of measurements.

They are also used to measure the surface roughness, height, and thickness of electronic component substrates and semiconductors. They are characterized by high speed, high resolution, and high accuracy.

There are also various types of coordinate measuring machinery depending on the installation and measurement methods. There are stationary and portable types in terms of installation method, contact-and non-contact types, laser tracker, layout machine, etc. in terms of measurement method.

Applications of coordinate measuring machinery are as follows:

Coordinate measuring machinery can measure typical surface roughness parameters such as Ra, Rz, etc., as well as a stylus-type surface roughness.

Coordinate measuring machines can measure waviness and steps between surfaces with high accuracy by measuring the entire surface. Examples include washer waviness evaluation and block gauge step measurement.

Coordinate measuring machines are used to measure the distance between two points: straight lines, circular centers, and various other flat surfaces. They are used in all industries, including the medical device, archaeology, molding, and watch industries.

Most coordinate measuring machinery (CMM) uses white light interferometry, a measurement method that uses a white light interferometer. Light interference is a phenomenon that occurs when there is a difference in the phase of light from two sources. Optical interferometers use this phenomenon to measure the state of surface irregularities, for example.

The interference of light causes a stripe pattern to appear due to the optical path difference generated by the unevenness of the sample surface. The number of stripes indicates the height of the unevenness of the sample surface. In actual use, an objective lens with a built-in reference mirror, called an interference lens, is used. White light is irradiated onto the reference mirror and objective lens, and the interference signal is observed by a camera while the objective lens is moved up and down.

Some models are also equipped with a high-sensitivity CMOS, a semiconductor that converts light entering through the lens into electrical signals. A solid-state imaging device using CMOS can capture an external image at the same time as the shape, allowing surface observation and measurement at the same time. The analysis contents are converted into data, such as a 3D model, which can be viewed on a CAD system.

Coordinate measuring machines (CMM) available on the market today use the latest technology and can easily perform measurements that were impossible in the past. The 3D coordinates of a specific point from a virtual origin are considered difficult to measure with common measuring instruments, such as calipers and micrometers.

Also, measurements using virtual points and lines and geometric tolerances are also extremely difficult to conduct with other measuring instruments, but coordinate measuring machinery (CMM) can perform them. Recently, it has become possible to read the shape of a prototype in 3D and create a 3D object using a 3D printer to check the shape in the same way as the actual product.

The efficiency of measurement work has been dramatically improved by the highly accurate measurement technology of coordinate measuring machinery (CMM) and the increased processing speed of measurement data, but there are also the following issues:

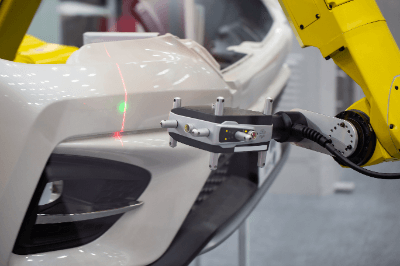

CMM with an articulated arm have emerged as a solution to these problems. Originally developed for manufacturers of prosthetic arms and legs, the technology is now used in transportable CMM.

The ability to move the arm at the will of the operator has further expanded the range of measurements that can be taken. The introduction of non-contact measurement using lasers has also made it possible to measure large objects.

*Including some distributors, etc.

Sort by Features

Sort by Area

Quality Vision International Inc., established in 1992, and based in New York, USA, is a manufacturer and supplier of precision multisensor metrology systems. The product portfolio includes 3D measuring systems, metrology systems, demo units, OPG software, sensors, and other accessories. The products are used in various industries which include aerospace, automotive, energy, medical, and plastics. The company also offers technical support, customer services, and product selector options with ISO certified quality products.

Wenzel America Ltd. is a manufacturer of high-precision measuring machines and metrology solutions that started in 1968 and is headquartered in Wixom, Michigan. Their product range includes coordinate measuring machines (CMMs), optical measuring machines, computed tomography (CT) scanners, gear measurement systems, and surface roughness testers. These products are utilized for quality control and inspection applications in various industries, including aerospace, automotive, medical, and energy. Wenzel America Ltd. has successfully met the requirements of ISO/IEC 17025:2017 in the field of calibration.

Velocity Machine Works LLC is a manufacturer that provides precision machining, welding, mechanical assembly, and packaging solutions, located in Tallahassee, FL. Some of their products include custom machined parts, hydraulic cylinders, hydraulic manifolds, hydraulic power units and hydraulic pumps which provide high response and high efficiency velocity control of a hydraulic injection molding machine (HIMM) for the process of various application such as in CD and DVD disks, plastic optical lens, light guide plates. Velocity Machine Works LLC offers tier one program management for OEM clients worldwide and also holds ISO and IATF certifications.

Dimensional Engineering LLC, established in 2005 and headquartered in Houston, Texas, is an industrial manufacturer specializing in 3D digital metrology and dimensional inspection services. Their comprehensive range of services includes 3D scanning, reverse engineering, dimensional inspection, CMM part inspection, and precision laser alignment. Additionally, they offer tooling and fixture certification, dimensional flange management, virtual build and bolt solutions, custom leak sealing solutions, and dimensional control services, providing precise measurements, quality assurance, and efficient design processes for industries such as automotive, aerospace, and manufacturing. Dimensional Engineering LLC also provides PolyWorks training, and equipment rentals for specialized projects.

Nikon Metrology Inc., a manufacturer based in Brighton, Michigan, United States, specializing in providing solutions for industrial measurement, inspection, and quality assurance needs, was founded in 2010 with the merger of Nikon Instruments Inc.’s industrial instrument business unit and the former Metris NV, a company acquired by Nikon Corporation. The company develops systems for manufacturing operations, including 3D laser scanners, industrial microscopy tools, and laser radar measuring systems. It also provides X-ray and computed tomography (CT) systems, optical manual measuring instruments, and video measuring systems. Furthermore, the company extends its offerings to encompass flat-panel display (FPD) lithography systems and imaging solutions.

Made to Measure, established in 2003 with headquarters in the USA, is a manufacturer of new CMM (coordinate measuring machine) equipment and a distributor of rebuilt CMM equipment and filtration systems. Apart from the supply of CCM equipment, the company also provides CMM maintenance, repair, calibration, retrofitting, upgrades, and software programming services. As a provider of dimensional inspection services, its capabilities include 3D scanning, precision measurement, first article inspection, and reverse engineering, as well as metrology training courses. The company serves clients in various industries, including engineering, aerospace, manufacturing, energy, and healthcare.

THOME Präzision GmbH, established in 1993, is a manufacturer of coordinate measuring machines based in Darmstadt, Germany. The company’s products include manual measuring machine SMART, CNC measuring machine RAPID-Plus, CNC measuring machine TETA and stand CMM dimension for quality control in manufacturing, aerospace and automotive industries. In 2013, the company came up with measuring software called "ThomControl", which is installed in THOME measuring machines. The company coordinates, maintains and calibrates measuring machines in accordance with ISO 10360 or VDI 2617.

LK Metrology Ltd., established in 1963 and headquartered in Derby, United Kingdom, is a developer and manufacturer of coordinate measuring machines. The company's primary products are coordinate measuring machines and portable measuring arms. It also develops and supplies software solutions for process monitoring and statistics, machine tool probing and measurement, and automated control of multiple systems within a single cell for manufacturers. The company's services include custom turnkey system production and onsite installation worldwide through its turn-key solutions division and third-party integrators.

Sinowon Innovation Metrology Manufacture Limited, founded in 2006 with facilities in China, is a manufacturer of geometric dimension measurement instruments and precision devices. The company's products include automatic vision measuring machines, 2D optical measuring machines, profile projectors, video microscopes, and precision displacement platforms. Sinowon Innovation Metrology Manufacture Limited's products are used for measuring dimensional and positional tolerances such as flatness, perpendicularity, and position. The company serves various industries, including 3C consumer electronics, new energy vehicles, medical health, home appliances, and solar photovoltaics.

ZEISS Microscopy, established in Jena, Germany, in 1846 is a manufacturer of optics and optoelectronics used in Precision Mechanics, Binoculars, Microscopy, and Eyeglass Lenses. Their product portfolio includes precision optics, such as lenses, mirrors, and prisms, laser mirrors used in laser cutting, and medical devices, optoelectronic devices and Coatings and Thin Films. The company also provides solutions including industrial quality, microscopy research, project simulation, sample testing and product development. The company also offers customer services that include support, custom research projects and customized services.

Metrol Co.,Ltd. is an ISO 9001-certified manufacturer of precision mechanical sensors and switches for industrial applications that was established in 1976 in Tokyo, Japan. The company produces various mechanical switches and sensors including touch probe contact sensors, tool setters, and precision positioning touch switches. These products have applications in line automation, robotics, and plant safety systems. The company also offers testing, and customization, and certification services for clients with unique project specifications.

Renishaw is a British manufacturer and supplier of engineering technology products and solutions established in 1973 and based in Gloucestershire, United Kingdom. The company primarily produces equipment for metrology, spectroscopy, and healthcare, including coordinate measuring machines (CMMs), dental scanners, and Raman spectrometers. They also offer long-term support services, such as calibration, refurbishment, repair, and upgrades. Renishaw has more than 5,000 employees across its network of subsidiaries and sales offices in over 36 countries.

LT Ultra-Precision Technology GmbH, founded in 2002 and headquartered in Herdwangen-Schönach, Germany, is a manufacturer of optics, optical components, and complete machines. The company's product portfolio includes optical metallic laser optics, metal optics, and beam delivery components. It also offers a range of complex machining machinery, technology components, and interferometric metrology components. The company's services include training and further education, custom manufacturing of metal optics and tools, as well as machine design and engineering.

CMMXYZ, founded in 1986 and headquartered in Mississauga, Canada, is a manufacturer of metrology solutions, specializing in coordinate measuring machines (CMMs) and related technologies. The product portfolio includes high-precision measurement equipment such as dimensional measurement products, marine engineering products, calibration products, and various software products that ensure accurate quality control in industries such as aerospace, automotive, manufacturing, and healthcare. The advanced systems enable companies to enhance product quality, streamline production processes, and maintain compliance with industry standards.

Hexagon AB was established in 1992 in Stockholm, Sweden as a manufacturer, designer, and marketer of digital reality solutions and autonomous technologies. The company offers various products, such as, digital quality inspection, Jovix, LuciadCPillar, REcreate, among others. The solutions offered by the company enhance productivity, efficiency, quality, and safety in various sectors, including manufacturing, infrastructure, industrial, public sector, and mobility applications. It also offers geographic information system (GIS) software for creating 3D models and maps, as well as sensors for satellite location and data collection from the air and ground.

Mitutoyo was founded in 1934 and headquartered in Kawasaki City, Japan. The company is a manufacturer and seller of precision measuring instruments including software, optics, machinery, and electronics. The company is ISO/IEC 17025 accredited for calibration services for measuring instruments. The company’s product lines include Micrometers, Calipers, Calibration Equipment, Vision Measuring Systems, and many others. The company’s coordinate measuring machines and roundness/cylindricity measuring machines are sol in over 60 countries worldwide.

Panasonic Connect Co. Ltd. is based in Tokyo, Japan, and is a manufacturer and service provider specializing in B2B products that was established in 2022 as a spin-off from Panasonic Corporation. The company offers its Zetes brand supply chain manager that utilizes RFID and facial recognition technologies, and its Autonomous Supply Chain brand planning solution which integrates an AI-based supply chain platform. It also offers installation and personnel training services for customers requiring additional assistance. The company mainly serves clients in the retail, transportation, and logistics industries.

ZEISS, established in 1846 in the United Kingdom, is a manufacturer and supplier of optical and optoelectronic technology. The company’s diverse product portfolio includes precision optics, microscopy systems, medical devices, and industrial measurement equipment, serving industries such as healthcare, manufacturing, and research. With a rich history of creativity and global existence, ZEISS is devoted to advancing science, technology, and quality in various fields through its cutting-edge solutions. The company’s emphasis on brilliance has solidified its position as an ideal provider of optical and optoelectronic technology worldwide.

WENZEL Group, founded in 1968 and headquartered in Wiesthal, Bayern, Germany, is a manufacturer of industrial metrology and styling solutions. The company offers a range of products, including coordinate measuring machines (CMMs), gear measuring machines, optical high-speed scanning systems, 3D X-ray measuring technology via computer tomography, and multi-sensor systems. These tools cater to diverse industries such as automotive, aircraft, mechanical engineering, and medical technology for precise measurement and analysis. It holds ISO 9001 and VDA 6.4 certifications for its quality management system, alongside accreditation confirming competence in dimensional measurands as per DIN EN ISO/IEC 17025:2018 standards.

Alicona Imaging GmbH, established in 2001 and headquartered in Graz, Austria, specializes in the manufacturing of optical 3D surface measurement systems and metrology solutions. The company has been part of Bruker since 2019 and now operates under the Bruker Alicona brand and its product catalog includes optical measuring devices, coordinate measuring machines (CMMs), and software for surface metrology. It serves industries like aerospace, automotive, medical technology, and precision engineering. Its products are used for precision quality control, surface roughness analysis, and reverse engineering.

Renishaw plc., established in 1973 and based in Wotton-under-Edge, United Kingdom, is a manufacturer of analytical instruments, medical devices, and manufacturing technologies. Some of the products it stocks include additive manufacturing systems, open optical encoders, and neurological products, and it operates in the Americas, EMEA, and APAC regions, with 67 locations in 36 countries. Throughout its history, the company has spent 13% to 18% of its annual sales in R&D and engineering. In 1981, it set up its first international manufacturing facility in Ireland, and in 1984, it was listed in the London Stock Exchange unlisted securities market.

Zygo Corporation, founded in 1970 and headquartered in Middlefield, Connecticut, is a manufacturer of optical metrology systems and optical components and assemblies. The company manufactures products in several categories, including laser interferometers, 3D optical profilers, and optical components. It serves several industries, including medical, automotive, and consumer electronics, and also provides customizable metrology software to help customers measure. The company holds 750 patents, and in 2014, it became part of the Ultra Precision Technologies division of AMETEK Inc. It is ISO 9001 and ISO/IEC 17025 certified and sells its products under brand names such as Navitar, Special Optics, and Pixelink.

Ranking as of July 2025

Derivation Method| Rank | Company | Click Share |

|---|---|---|

| 1 | CMMXYZ |

17.6%

|

| 2 | Velocity Machine |

9.8%

|

| 3 | WENZEL America |

9.5%

|

| 4 | Nikon Metrology |

8.3%

|

| 5 | Dimensional Engineering |

7.2%

|

| 6 | Mitutoyo Corporation |

6.2%

|

| 7 | Made To Measure Metrology |

6.1%

|

| 8 | ZEISS |

5.4%

|

| 9 | Quality Vision International Inc. |

4.0%

|

| 10 | Hexagon AB |

3.5%

|

Derivation Method

The ranking is calculated based on the click share within the coordinate measuring machinery (cmm) page as of July 2025. Click share is defined as the total number of clicks for all companies during the period divided by the number of clicks for each company.Number of Employees

Newly Established Company

Company with a History

*Including some distributors, etc.

*Including some distributors, etc.

| Country | Number of Companies | Share (%) |

|---|---|---|

United States of America

United States of America

|

6 | 31.6% |

Germany

Germany

|

3 | 15.8% |

United Kingdom

United Kingdom

|

2 | 10.5% |

Japan

Japan

|

2 | 10.5% |

China

China

|

1 | 5.3% |

| Deutschland | 1 | 5.3% |

Canada

Canada

|

1 | 5.3% |

Sweden

Sweden

|

1 | 5.3% |

India

India

|

1 | 5.3% |

Austria

Austria

|

1 | 5.3% |

114 products found

114 products

FARO Technologies, Inc

570+ people viewing

Last viewed: 47 minutes ago

Features of ScanArm ■Laser line probe (LLP) family Achieve high-speed point cloud data acquisition, high-precision acquisition, or both using hot-s...

Meishin Koki Co., Ltd.

460+ people viewing

Last viewed: 1 hour ago

■Coordinate measuring machine = A CNC three-dimensional measuring machine with excellent environmental resistance that overturns common sense in me...

Innovalia Metrology

540+ people viewing

Last viewed: 8 hours ago

■ Overview Measured software that provides solutions that meet various needs. The M3 capture is scanned by scanning the object in a point group. Th...

4 models listed

Tokyo Trade Techno System Co., Ltd.

980+ people viewing

Last viewed: 3 hours ago

The AS1-XL is a combination of Leica laser tracker AT960 and provides unprecedented ultra-high-speed and ultra-large measurements. The scanning lin...

FARO Technologies, Inc

690+ people viewing

Last viewed: 1 hour ago

Vantage Laser Tracker Features ■ActiveSeekTM technology It has the widest field of view in the industry and can track moving targets even when hid...

Meishin Koki Co., Ltd.

570+ people viewing

Last viewed: 42 minutes ago

■Summary The top model of the ZEISS PRISMO® series, achieving the highest level of precision. Features ■Highest level of precision ・Achieved high...

Innovalia Metrology

580+ people viewing

Last viewed: 2 hours ago

■ Overview The CMM arm system is suitable for large -capacity measurement and simple structure measurement. Both the contact type probe and the opt...

Tokyo Trade Techno System Co., Ltd.

2200+ people viewing

Last viewed: 1 hour ago

■ Overview ・ Leica Laser Tracker can measure a wide range of areas with high accuracy. -In addition to the conventional reflector measurement, it ...

5 models listed

FARO Technologies, Inc

520+ people viewing

Last viewed: 44 minutes ago

Features of Gage Max FaroArm ■1.5m (4.9ft) working volume Perform 3D measurements of small parts, molds and assemblies. ■Smart probe function Qui...

Meishin Koki Co., Ltd.

410+ people viewing

Last viewed: 1 hour ago

■Summary Able to focus on a wide range and measure with high precision ■Features ・With in-screen accuracy of ±1.5 µm and repeatability of ±0.7 µm...

Innovalia Metrology

470+ people viewing

Last viewed: 1 day ago

■ Overview The CMM arm system is suitable for large -capacity measurement and simple structure measurement. Both the contact type probe and the opt...

Tokyo Trade Techno System Co., Ltd.

770+ people viewing

Last viewed: 19 hours ago

■ Overview ・ The Leica laser tracker AT500 is the most portable and easy to set up in the existing lineup due to the operation and integrated cont...

Seiko Wave Co., Ltd.

270+ people viewing

Last viewed: 1 day ago

This is a handy type 3D measuring device. Small objects can also be automatically scanned all around using a turntable. A high-speed camera captur...

ARCANA Works

850+ people viewing

Last viewed: 1 day ago

It is a scanner that can be used in an instant 3D scan. You don't have to pose, so you can scan in various poses. Special feature ・ 3D scan in an ...

FARO Technologies, Inc

310+ people viewing

Last viewed: 51 minutes ago

Features of FARO Super 6DoF TrackArm ■Seamless integration Use multiple portable CMMs simultaneously for high-capacity measurement solutions. ■6 d...

Meishin Koki Co., Ltd.

400+ people viewing

Last viewed: 2 hours ago

■Summary Able to focus on a wide range and measure with high precision ■Features ・With in-screen accuracy of ±1.5 µm and repeatability of ±0.7 µm...

Tokyo Trade Techno System Co., Ltd.

990+ people viewing

Last viewed: 4 hours ago

The Leica LaSer Tracker Scanner ATS600 system is a new three -dimensional measurement system made of Leica that seamlessly realizes conventional la...

Innovalia Metrology

410+ people viewing

Last viewed: 1 day ago

■ Overview Consists of horizontal arms and tall rigid structures. ■ Characteristics ・ The main structure is fixed steel. ・ Aluminum Y -axis unit...

Almonicos

650+ people viewing

Last viewed: 18 hours ago

It is a tool that can quantitatively confirm the error by comparing the point group data measured by the 3D scanner to the 3D CAD data to detect an...

FARO Technologies, Inc

520+ people viewing

Last viewed: 58 minutes ago

Features of FARO Orbis ■Lightweight and easy to use Weighing just 3.6 kg (including data logger and battery), Orbis is ideal for scanning large are...

Meishin Koki Co., Ltd.

360+ people viewing

Last viewed: 40 minutes ago

■Summary Able to focus on a wide range and measure with high precision ■Features ・With in-screen accuracy of ±1.5 µm and repeatability of ±0.7 µm...

Innovalia Metrology

420+ people viewing

Last viewed: 32 minutes ago

■ Overview Three axes made of black granite. The Innovalia Metrology bridge type system has a variety of sizes that meet your needs. ■ Characteris...

OptoComb Co., Ltd.

330+ people viewing

Last viewed: 4 hours ago

Combined with an optical comb 3D sensor and 45° mirror, it leverages high-precision measurements and a unique coaxial configuration to inspect inne...

FARO Technologies, Inc

460+ people viewing

Last viewed: 12 hours ago

■Focus on premium and core features ・Scanning range is up to 350m, supporting a wide scanning area for each scanning position ・Smartphone compati...

Meishin Koki Co., Ltd.

310+ people viewing

Last viewed: 1 hour ago

■Summary High precision/high speed CNC three-dimensional coordinate measuring machine Features ■Optimal flexible measurement system to replace pro...

Innovalia Metrology

440+ people viewing

Last viewed: 1 day ago

■ Overview Three axes made of black granite. The Innovalia Metrology bridge type system has a variety of sizes that meet your needs. ■ Characteris...

Meishin Koki Co., Ltd.

310+ people viewing

Last viewed: 11 hours ago

■Summary High precision/high speed CNC three-dimensional coordinate measuring machine Features ■3D measurement system suitable for horizontal mach...

FARO Technologies, Inc

410+ people viewing

Last viewed: 1 hour ago

Freestyle 2 features ■Document important details in 3D Even in small slots and hidden/inaccessible areas, you can rely on highly flexible sensors. ...

Innovalia Metrology

490+ people viewing

Last viewed: 1 day ago

■ Overview Gantry type measuring machines are suitable for high -precision measurement and digitization of large parts. All structures are made of ...

Tokyo Trade Techno System Co., Ltd.

1160+ people viewing

Last viewed: 11 hours ago

■ Overview ・ FLARE system is a non -contact 3D scanner for industrial products. ・ The surface shape can be converted to 3D data quickly and high ...

3 models listed