30 3D Printer Manufacturers in 2024

This section provides an overview for 3d printers as well as their applications and principles. Also, please take a look at the list of 30 3d printer manufacturers and their company rankings. Here are the top-ranked 3d printer companies as of April, 2024: 1.3 AXIS Development, Inc., 2.Electroimpact, Inc., 3.MakerBot Industries, LLC.

Table of Contents

Categories Related to 3D Printers

What Is a 3D Printer?

A 3D printer is a device that produces three-dimensional objects by layering printed cross sections based on 3D data.

A 3D printer is a device that produces three-dimensional objects by layering printed cross sections based on 3D data.

3D printers can be produced using a variety of methods, including the FDM (fused deposition modeling) method, SLA (stereo lithography) method, SLS (selective laser sintering) method, inkjet method, inkjet powder laminate method, and inkjet powder laminate method.

For home use, two types of 3D printers are often used: "thermal melting lithography method" and "optical lithography method."

Applications, Principles, and Advantages of Each Type of 3D Printer

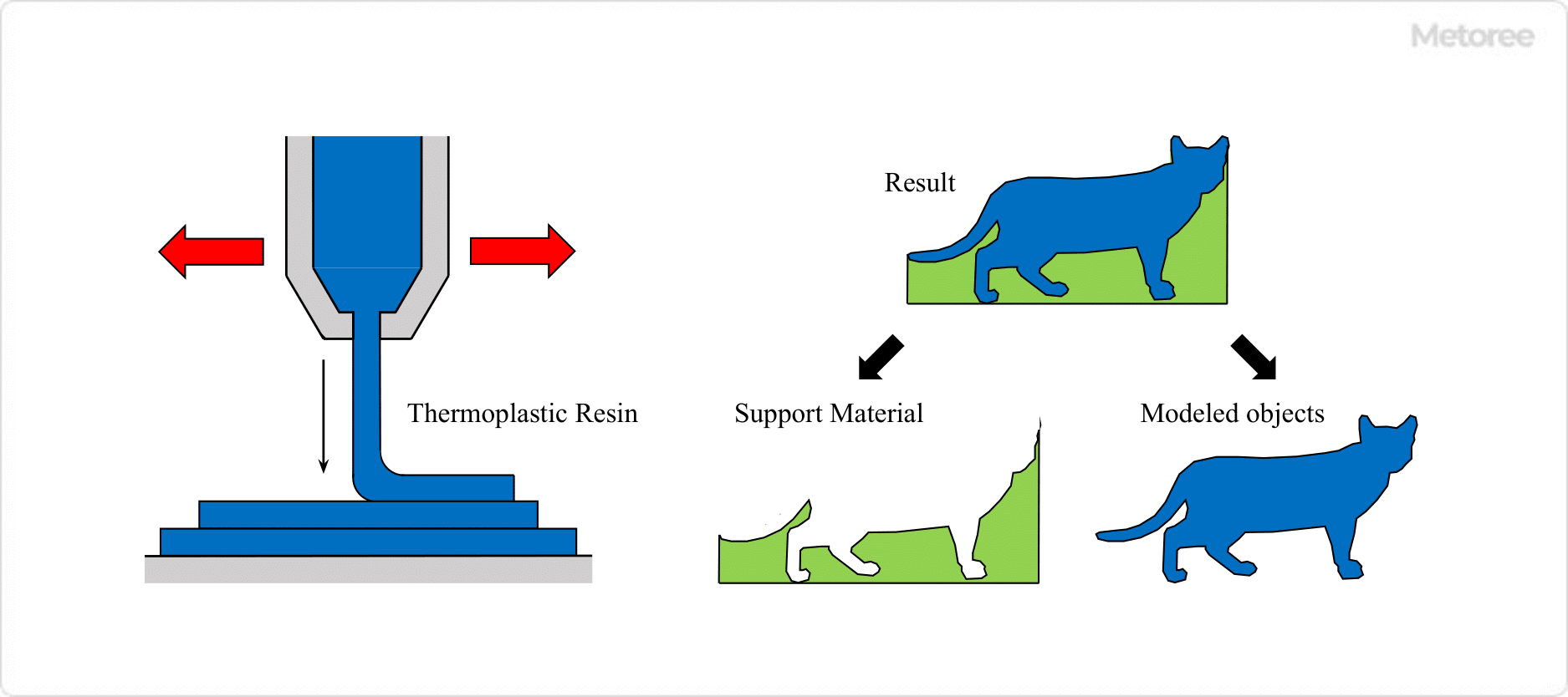

1. Fused Deposition Modeling Method (FDM)

Uses

Production of figures, models, etc.

Principle

Thermoplastic resin is ejected through a thin nozzle of around 0.5mm to print.

Advantages

- Inexpensive main unit

- Printing is possible at low cost due to inexpensive materials

- Mainstream as 3D printer for general use

Disadvantages

- Requires support materials

- Appearance of the modeled object deteriorates due to stacking marks generated during printing

Printable Materials

PLA resin, ABS resin, etc.

Figure1. Thermal Melting Lamination Method

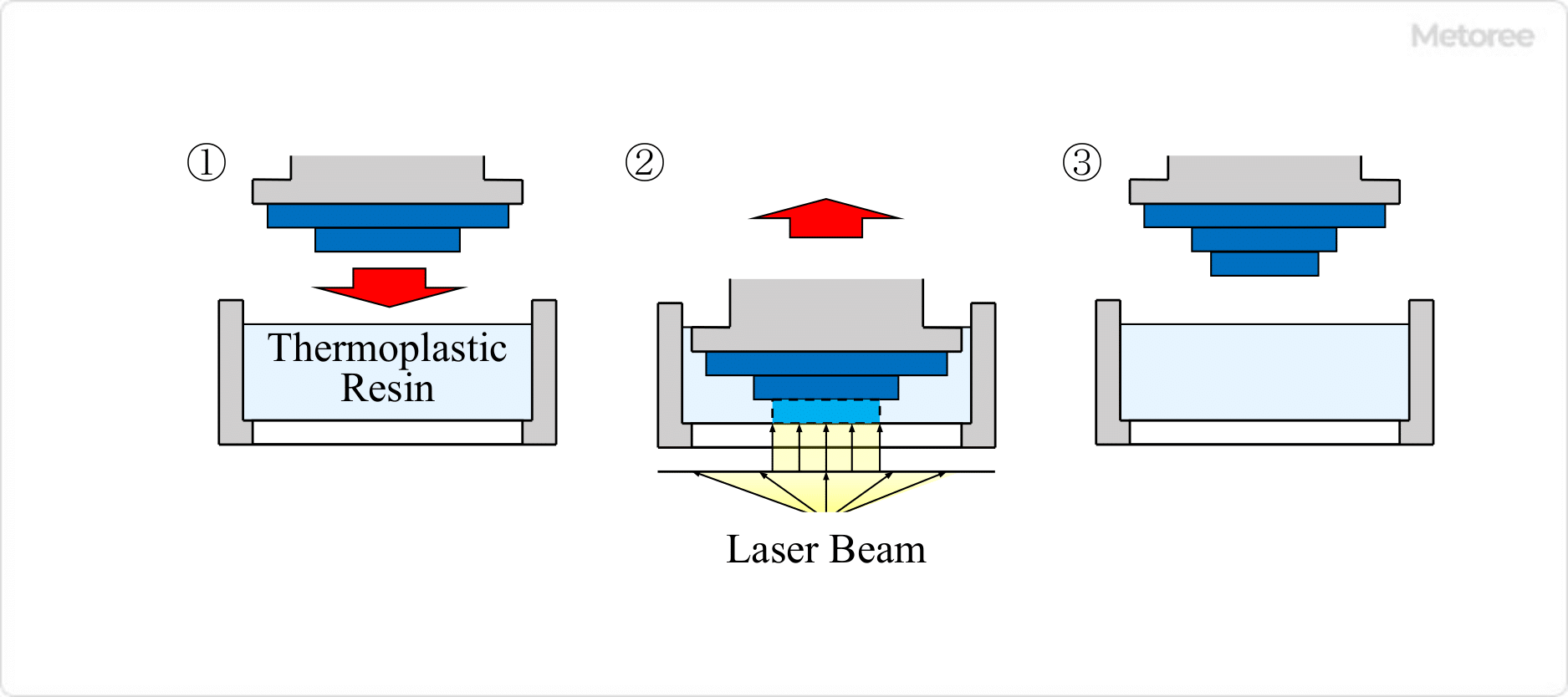

2. Stereolithography Method (SLA)

Uses

SLAs are used for the creation of mock-ups, stage props, etc.

Principle

Printing is performed by exposing a light-curing liquid resin to light to cure it.

Advantages

Easy to process after modeling, and transparent printed materials can be created.

Disadvantages

- Printed materials are vulnerable to sunlight

- Time-consuming post-processing of printed materials

Printable Materials

Epoxy resins, acrylic resins, etc.

Figure2. Optical fabrication method

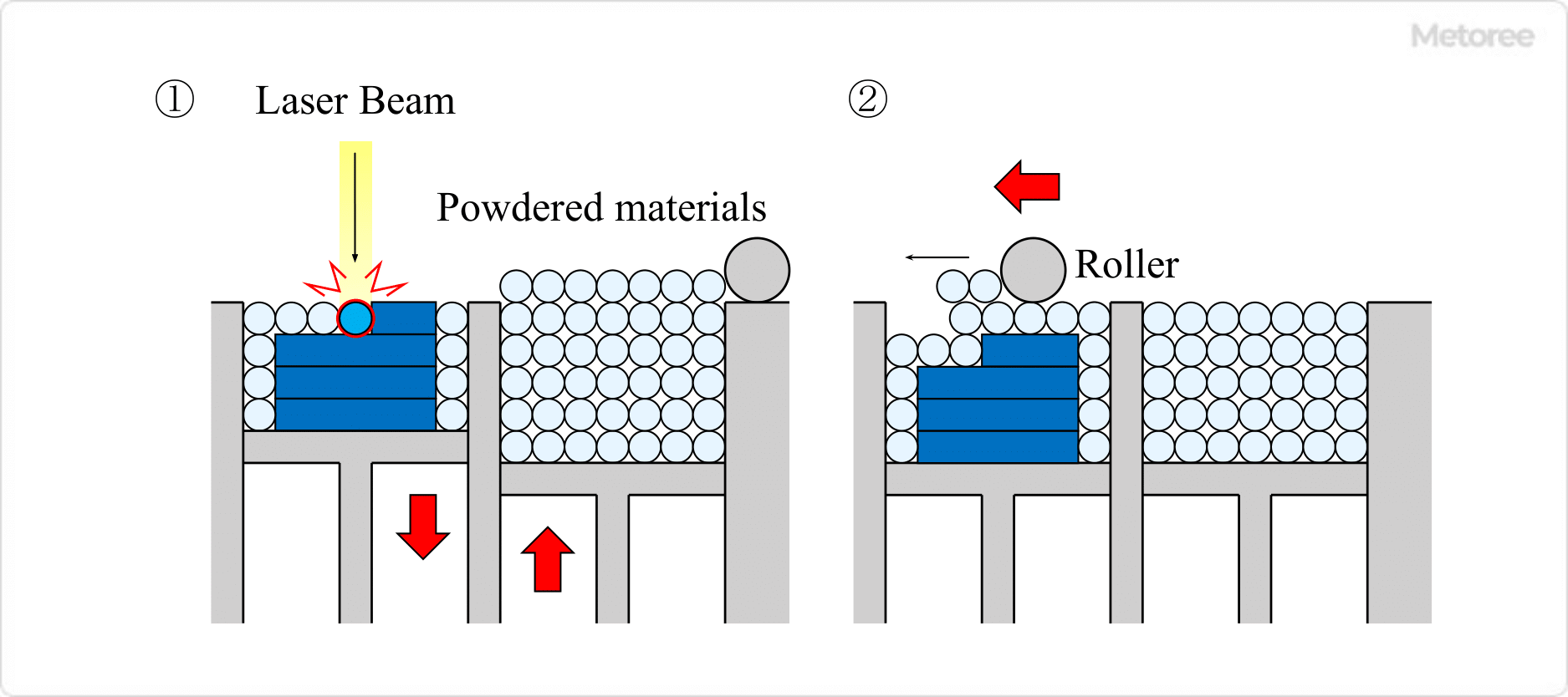

3. Selective Laser Sintering Method (SLS)

Uses

Parts for industrial equipment and medical implants

Principle

Printing is performed by repeating selective heating and sintering of powdered materials one layer at a time.

Advantages

Large-scale, strong structures can be printed without the need for support materials

Disadvantages

- Equipment, including the printer itself, is expensive

- Printed materials have rough surfaces.

Printable Materials

Nylon, metal materials such as titanium, etc.

Figure3. Powder Sintering Additive Manufacturing Method

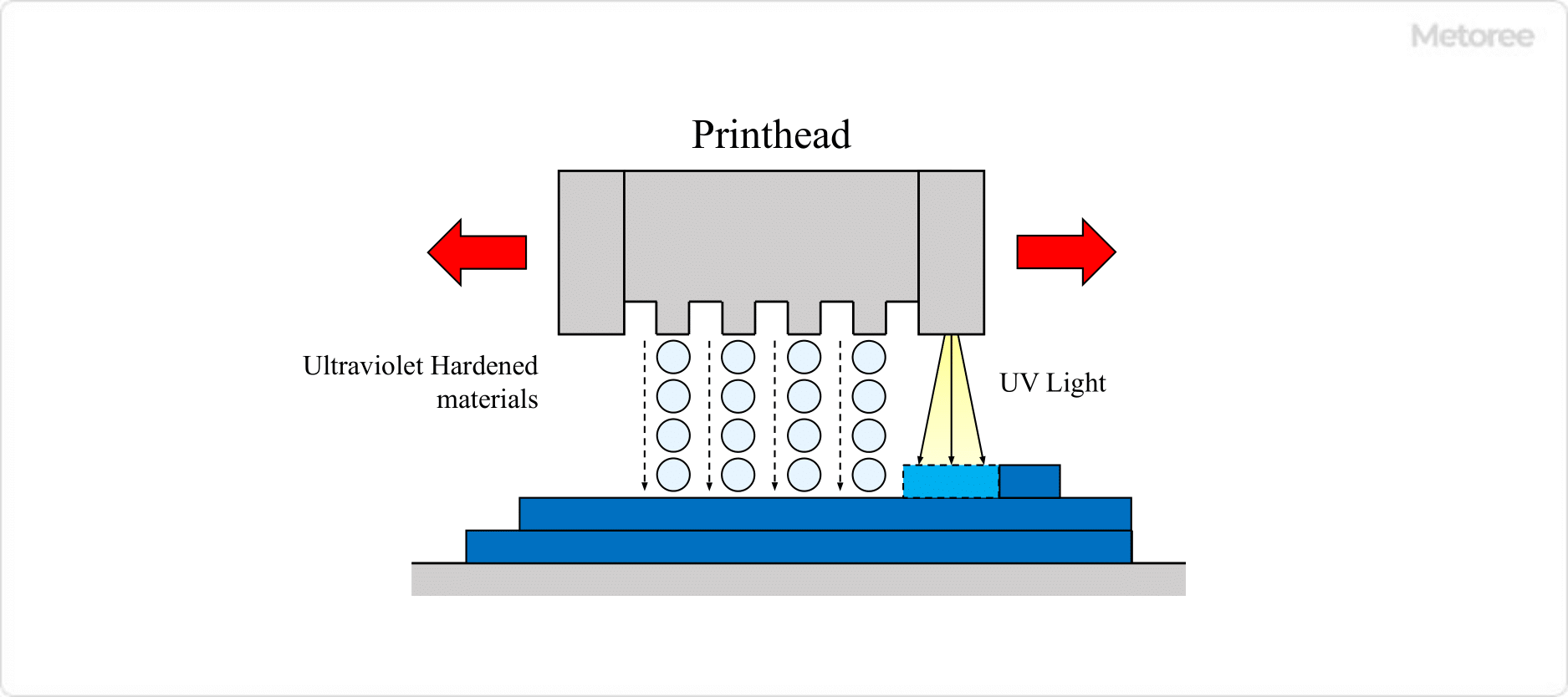

4. Inkjet Method

Uses

Manufacture of medical parts and small-lot products

Principle

UV-curable material is placed on a two-dimensional surface as if it were printed by an ordinary printer and then cured by UV irradiation to produce a print.

Advantages

Easy installation and high-resolution printing

Disadvantages

Printed materials are brittle and vulnerable to sunlight.

Printable Materials

Epoxy resin, acrylic resin, ABS resin, etc.

Figure4. Inkjet method

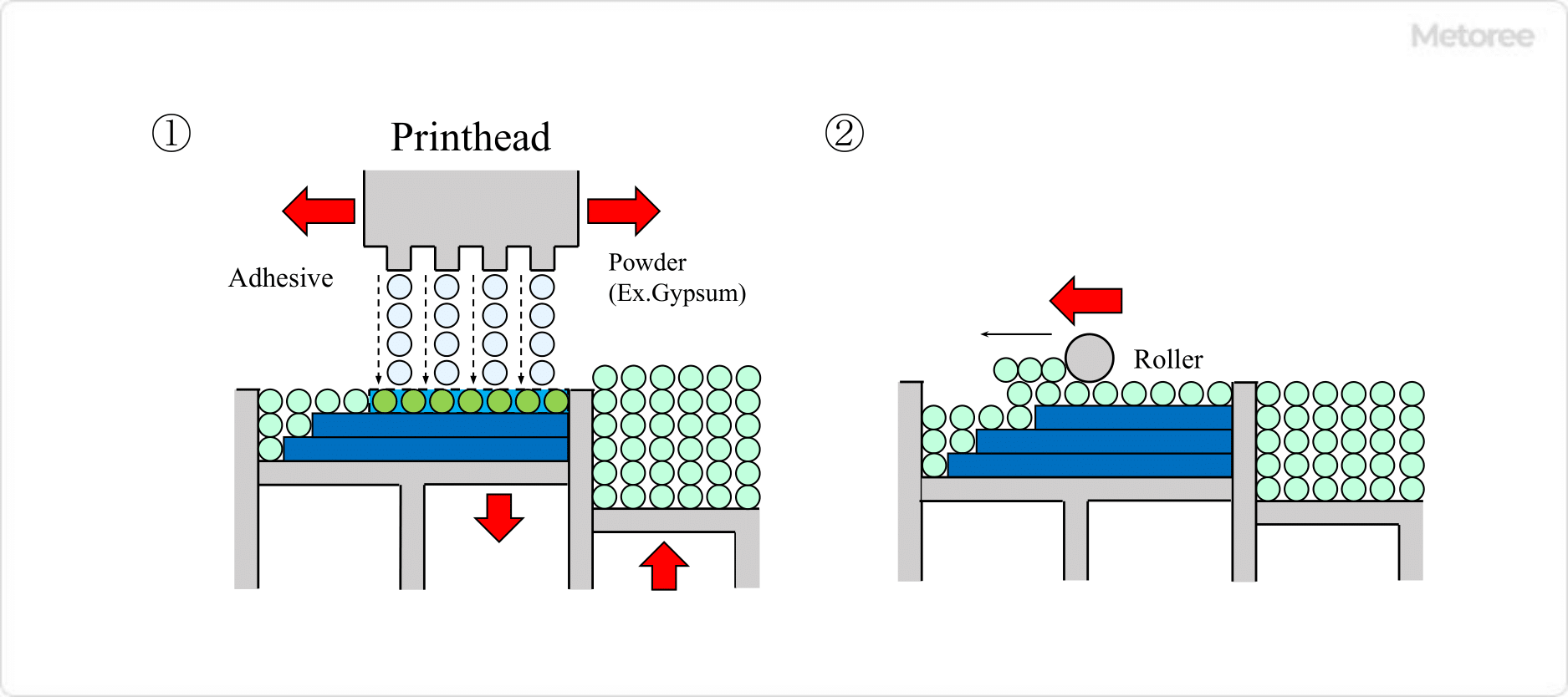

5. Inkjet Powder Lamination Method

Uses

Medical parts, small lot product manufacturing

Principle

Printing is performed by placing an adhesive on plaster and allowing it to cure. Color structures can be created by using colorants.

Advantages

Easy installation and high-resolution printing

Disadvantages

Printed materials have low strength

Printable Materials

Plaster, resin, metal, sand, etc.

Figure 5. Inkjet powder lamination method

How to Use a 3D printer

3D printers can be used to layer the designed structure by melting the resin.

This section explains what you need to prepare and the actual procedure.

What You Need to Prepare

- Personal computer

- 3D printer

- 3D CAD software for designing three-dimensional CAD drawings

- Slicing software

Slicing software has the ability to convert 3D data into tool path data. - Filament

Filament is a material to be laminated; its type varies depending on the 3D printer's lamination method, but PLA resin and ABS resin are most commonly used by beginning users.

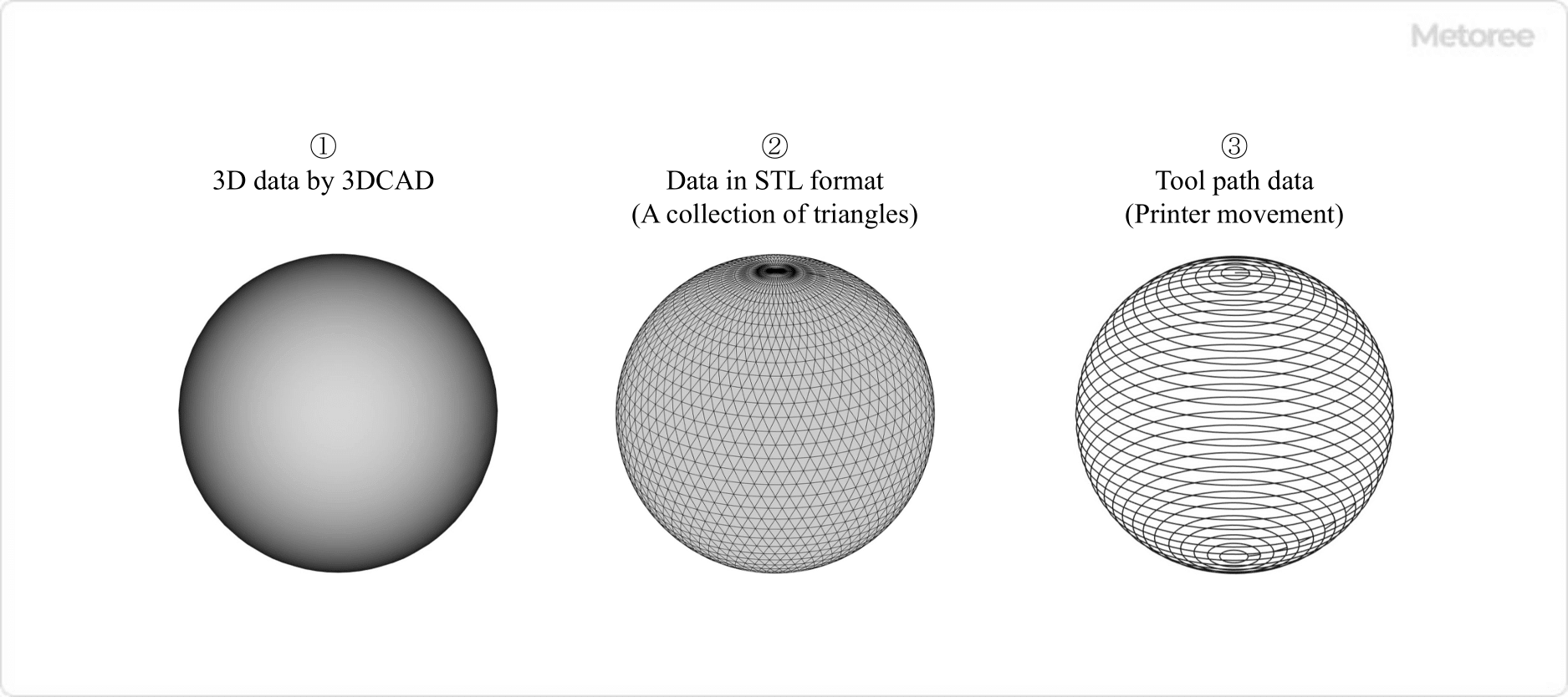

Steps to Layering a Structure on a 3D Printer

-

- To laminate a structure, create 3D data by using 3D CAD software.

- Convert the 3D data to STL format so that the 3D printer can read the data.

- Convert STL data to tool path data.

- Activate the 3D printer.

- Remove secondary materials that are welded to the structure as support materials.

- Surface treatment of burrs, etc. for a smooth finish.

Figure 6. Conversion from 3DCAD data to tool path data

Filament Materials That Can Be Handled

3D printers are limited in the materials they can handle, depending on the type of equipment and the melting method of the material.

For example, a 3D printer that can handle resins can handle both general soft and hard resins. Some types of 3D printers can handle a wide range of materials.

Here, we will focus on resin and metal as filament materials that can be handled.

Resin Filament

The most commonly used types of resin filaments for both beginners and advanced users are PLA and ABS resins.

Other resin materials include nylon, plaster, rubber, and epoxy-based materials.

- PLA Resin

This resin is synthesized from recycled materials consisting of polylactic acid, which is mainly made from corn, etc. - ABS Resin

A synthetic resin composed of acrylonitrile, butadiene, and styrene.

Metal Filament

Types of metal filaments include stainless steel, brass, titanium, platinum, silver, and gold.

Other special materials include filaments containing bronze as a powder.

List of 30 3D Printer Manufacturers

*Including some distributors, etc.

Sort by Features

- Default

- Company Size: largest first

- Year Founded: oldest first

- Year Founded: earliest first

Sort by Area

- United States of America

- China

- Germany

- Italy

- Japan

- Poland

- United Kingdom

-

-

-

Electroimpact, Inc.

3D Printers

Manufacturer Overview

Electroimpact, Inc., established in Mukilteo, Washington, in 1986, is a manufacturer of aerospace tooling and automation. Their product portfolio includes precision machining tools, designed to enhance efficiency and precision in aircraft manufacturing, and automation solutions for composite manufacturing processes, ensuring optimal quality and consistency in composite aircraft components. The company's products find application in Commercial Aviation, Defense and Military Aerospace, and Space Exploration. The company also provides services, including global distribution, product selection, installation, preventative maintenance, and customer service.

-

-

-

-

-

3 AXIS Development, Inc.

3D Printers

Manufacturer Overview

3Axis Development was founded in 2005 and is headquartered in Boynton Beach, Florida. 3Axis is a manufacturer of custom machinery, equipment, and tools. 3Axis offers prototyping services such as stereolithography, FDM, SLS, DMLS, 3D architectural modeling, and 3D printing. 3Axis also offers numerous manufacturing services such as injection molding, plastic prototype extrusions, waterjet cutting, precision sand castings, sheet metal fabrication, vacuum & pressure forming, Swiss CNC machining, carbon fiber prototypes, 3D custom signage, fiberglass fabrication, and medical device engineering.

-

-

-

-

-

LulzBot (Fargo Additive Manufacturing Equipment 3D, LLC)

3D Printers

Manufacturer Overview

LulzBot (Fargo Additive Manufacturing Equipment 3D, LLC), established in Fargo, North Dakota in 2011 is a manufacturer of Desktop 3D Printers. The company's product range includes 3D Printers, 3D Printer Parts, 3D Printer Filaments, Libre Hardware, and Open Source hardware. The company serves markets including Automotive and Electric Vehicles, Renewable Energy and Energy Storage, and Electronics and IT Infrastructure. The company has a global distribution network. technical service and a customer support center.

-

-

-

-

-

Terrafilum

3D Printers

Manufacturer Overview

Terrafilum, established in 2010 in the United States, is a manufacturer specializing in sustainable packaging solutions. Terrafilum manufactures protective packaging solutions that are effective at safeguarding products during transit and are also biodegradable. The company provides customizable containers made from mycelium-based bioplastics. These containers can be tailored to meet specific size, shape, and branding requirements, making them ideal for businesses looking to create unique and sustainable packaging solutions.The company produces plant-based utensils, such as cutlery and straws, made from mycelium-based bioplastics. Terrafilum's compostable tableware includes plates, bowls, and cups that are not only biodegradable but also compostable.

-

-

-

-

-

Nexa3D

3D Printers

Manufacturer Overview

Nexa3D is an American 3D printing systems and product manufacturer founded in 2016 and based in Ventura, California. The company produces various 3D printers, resins, software for controlling or monitoring the 3D printing process, and accessories for improving printer performance. These products have applications in the jewelry, automotive, and aerospace industries, as well as in the medical and dental fields for anatomical models and implants. Nexa3D also provides consultation, training, and support services to clients with niche specifications.

-

-

-

-

-

3D Systems

3D printer

Manufacturer Overview

3D Systems is an American manufacturer specializing in 3D printing solutions founded in 1986 and headquartered in Rock Hill, South Carolina. The company's product inventory includes 3D printing systems with various customization options, printing materials such as metals, ceramics, and composites, and software for creating printing workflows or applications. They also offer niche services to customers in the healthcare industry, such as bioprinting, surgical planning, and anatomical modeling. 3D Systems facilities can also accommodate on-demand prototype manufacturing for customers in other client industries, which include the aerospace, automotive, and industrial sectors.

-

-

-

-

-

Raise 3D Technologies, Inc.

3D printer

Manufacturer Overview

Raise 3D Technologies, Inc., founded in 2014 and located in Irvine, California, is a professional designer and manufacturer of professional 3D printers and associated accessories. Its product line includes a range of professional 3D printers such as the Pro3 Series, E2CF, E2, and Pro2 Series, as well as industrial-grade models like the RMF500 and the MetalFuse System for metal 3D printing. The company also develops RaiseCloud, a web-based platform for managing the 3D printing process. The company holds various certifications, including ISO 9001 and ISO 14001 for its factory, ensuring compliance. Its products serve various fields like additive manufacturing and prototyping.

-

-

-

-

-

MakerBot Industries, LLC

3D printer

Company Overview

Established in January 2009, MakerBot is a global 3D printer manufacturing company specializing in designing and providing user-friendly 3D printing solutions for various applications. The company’s products are designed for personal and professional use, with various types catering to everyone’s needs and budgets. Also, the company’s printers rely on software enabling users to create objects or download designs from online archives. In addition, MakerBot sells accessories like filament materials and extruders to boost its printers’ capabilities. The company has released six generations of 3D printers since 2009.

-

-

-

-

-

Aero 3Ds

3D Printers

Distributor Overview

Aero3ds is an American online supplier of various 3D printing solutions and accessories established in 2021 and based in West Springfield, Massachusetts. The company stocks a wide range of 3D printing devices, parts, filaments, and software from different brands, which supply both enterprises and individual buyers. They also provide consulting, product education and technical support services via remote troubleshooting or online chat. Aero3ds serves clients across the United States and Canada, including the Pioneer Valley Planning Commission, Holyoke Gas & Electric, and Springfield Museums.

-

-

-

-

-

Renishaw plc

Metal 3D printing

Manufacturer Overview

Renishaw is a British manufacturer and supplier of engineering technology products and solutions established in 1973 and based in Gloucestershire, United Kingdom. The company primarily produces equipment for metrology, spectroscopy, and healthcare, including coordinate measuring machines (CMMs), dental scanners, and Raman spectrometers. They also offer long-term support services, such as calibration, refurbishment, repair, and upgrades. Renishaw has more than 5,000 employees across its network of subsidiaries and sales offices in over 36 countries.

-

-

-

-

-

Sodick Co., Ltd

Precision Metal 3D Printer

Manufacturer Overview

Sodick Co., Ltd, founded in 1976 and headquartered in Yokohama, Japan, is a manufacturer and supplier of machine tools, injection molding machines, food machines, and LED products. The company's product portfolio includes nano-level precision machines, magnesium alloy injection machines, noodle steam sterilizers, LED products, and electronic components. These products are utilized in various industries, including food processing, electronics, LED and lighting, manufacturing and machining, and the plastics and injection molding industry. The company has development, production, and service locations in different countries, including the United States, China, Thailand, India, and Singapore.

-

-

-

-

-

MITS Electronics

3D printer

Manufacturer Overview

MITS Electronics, founded in 1984, and located in Koganei, Tokyo, is a manufacturer of electronic prototyping and manufacturing solutions. Their product range includes PCB prototyping machines, software for conversion and CAM, through-hole plating solutions, and tools for electronic prototyping. These products are utilized to facilitate the development, production, and testing of electronic components and printed circuit boards. MITS Electronics serves a broad range of industries including universities, industrial research institutes, guitar manufacturers, and electronics corporations.

-

-

-

-

-

HP Inc UK Limited

3D printer

Manufacturer Overview

HP Inc. provides personal computing and other access devices, imaging and printing products, and related technologies, solutions, and services in the United States and internationally. The company operates through three segments: Personal Systems, Printing, and Corporate Investments. The Personal Systems segment offers commercial and consumer desktop and notebook personal computers, workstations, commercial mobility devices, thin clients, retail point-of-sale systems, displays and peripherals, software, support, and services. The Printing segment provides consumer and commercial printer hardware, supplies, solutions, and services, as well as focuses on graphics and 3D imaging solutions in the commercial and industrial markets. The Corporate Investments segment is involved in the HP Labs and business incubation, and investment projects. It serves individual consumers, small- and medium-sized businesses, and large enterprises, including customers in the government, health, and education sectors. The company was formerly known as Hewlett-Packard Company and changed its name to HP Inc. in October 2015. HP Inc. was founded in 1939 and is headquartered in Palo Alto, California.

-

-

-

-

-

BigRep GmbH

3D printer

Manufacturer Overview

BigRep, headquartered in Berlin, Germany and established in 2014, is a manufacturer and retailer of 3D printers used for rapid prototyping, production tooling, and manufacturing processes. The 1m3 3D printers enable various manufacturing processes, including the manufacture of end-use parts, factory tooling, forms, and molding in e-mobility, automotive, universities, research institutes, and art industries. The BigRep’s FLOW, CONNECT, and BLADE software solutions can be integrated into their 3D printers to control printing processes, including design and print monitoring, allowing manufacturers to create products that meet their specifications.

-

-

-

-

-

Zortrax S.A.

3D printer

Manufacturer Overview

Zortrax, established in 2013, is a Poland-based 3D printer manufacturer for personal and professional use. The company’s products have gained a worldwide reputation as one of the high-quality printers. Zortrax’s printers are well-known for being user-friendly and delivering world-class output. Those printers are widely used in various industries, from engineering to healthcare. The company uses proprietary software and filaments for its products, aiming to deliver a consistent and seamless printing process. Some of the company’s premium printers are Zortrax M300, M200, and M300 Plus (as part of the Zortrax M Series of 3D printers). The products are user-friendly and can deliver pilot prototypes with high-precision results.

-

-

-

-

-

AON3D

AON M2+

Manufacturer Overview

AON3D has been a manufacturer of 3D Printers since 2015 having its headquarters in Quebec, Canada. The company designs 3D printers that can print with a wide range of materials including the strongest thermoplastics in the world, and the use of carbon fiber and glass fiber composites and other affordable materials for prototyping is also possible. The printers are capable of extrusion control, configurable process parameters, and optimized thermal management giving efficient end products which makes them help with Additive Manufacturing for Aerospace and Defense, many Manufacturing Operations, and provide Federal and Military Additive Manufacturing Solutions.

-

-

-

-

-

Desktop Metal, Inc.

X-Series

Manufacturer Overview

Desktop Metal, Inc. is a company established in 2015 and based in Burlington, Massachusetts, as a manufacturer of 3D printing systems. Its specialization is manufacturing binder jet 3D printing, metal binder jetting systems, high-speed metal 3D printing, metal 3D printing systems, and metal fabrication. The company acquired ISO 9001:2015, ISO 13485, and ISO/TS 16949 certification and has partnered with several companies, such as Aerosint, Aidro, and Desktop Labs. Its manufactured products are utilized for automotive, consumer, tooling, and machine design fields across the USA.

-

-

-

-

-

HP 3D

3D Printers

Manufacturer Overview

HP 3D, founded in Palo Alto, California in 2014 is a manufacturer of 3D printing solutions. The company's product portfolio includes plastic 3D printers, metal 3D Printers and custom 3D printers for commercial and industrial usage. Their products are used in markets such as Automotive and Transportation, Telecommunications, Industrial Automation, Healthcare and Medical Devices and Aerospace and Defense. The company also provides services including global distribution, product selection, customized services, technical support and customer service.

-

-

-

-

-

EnvisionTEC

3D printer

Manufacturer Overview

EnvisionTEC (ETEC) is an American manufacturer of 3D printing materials and systems established in 2002 and headquartered in Dearborn, Michigan. The company produces various 3D printers utilizing digital light processing (DLP), P4K, SLCOM and other standard technologies, as well as 3D printing materials suitable for a wide range of industries or applications, and software solutions for different 3D printing workflows or project scales. ETEC also provides technical support, training, and parts-on-demand services for customers in need of low-volume production, as with prototypes or experimental parts. The company's clients include General Electric, the Straumann Group, and Cochlear Ltd.

-

-

-

-

-

Ultimaker

3D printer

Manufacturer Overview

Ultimaker, founded in 2011 and headquartered in the Netherlands, is a manufacturer and supplier in the field of desktop 3D printing. The company offers a wide variety of products including 3D printers, materials, extruders, and accessories. These products are utilized in industries such as engineering, architecture, custom art, and design. They enable users to transform digital designs into physical objects, making prototyping, production, and innovation more accessible. The company also offers technical support to meet clients’ needs.

-

-

-

-

-

XYZprinting, Inc.

3D printer

Manufacturer Overview

XYZprinting, a company founded in 2013 and headquartered in Taiwan, is a manufacturer and supplier in the field of 3D printing technology. The company offers a diverse range of 3D printers, including desktop and industrial models, as well as related accessories and consumables. Their products cater to various industries and applications, including education, prototyping, architecture, and manufacturing. Their 3D printers provide users with the ability to create three-dimensional objects using different materials. The company also offers global customer services including technical support.

-

-

-

-

-

GE Gas Power

3D printer

Manufacturer Overview

GE Gas Power is an American manufacturer and supplier of alternative energy products and solutions established in 2015 as a business unit of the American multinational industrial company General Electric (GE). Headquartered in Schenectady, New York, the company produces steam and gas turbines, standard and heat recovery steam generators (HRSGs), heat exchangers, and power plants for various applications. They also offer after-sale installation, repair, maintenance, and upgrade services for their clients. GE Gas Power runs the world’s largest base of operating gas turbines, with over 7,000 units installed across more than 120 countries.

-

-

-

-

-

MicroJet Technology Co., Ltd.

3D printer

Manufacturer Overview

MicroJet Technology, founded in Taiwan, in 1996 is a manufacturer of thermal Bubble Inkjet Print Cartridges, Full-Color/Ceramic Inkjet 3D Printers. The company's product portfolio includes Piezoelectric micro pumps, Wearable Blood Pressure Modules, small air quality sensors, Printing Inks and Inkjet Printers. Their products are used in industries such as Food and Beverage, Pharmaceutical and Biotechnology, Chemical and Petrochemical, Biomedical and healthcare. The company provides services such as Product Selection Guidance, Engineering Support, and Custom Manufacturing.

-

-

-

-

-

-

-

WASP S.r.l.

4070 ZX

Company Overview

WASP - World’s Advanced Saving Project is a company born in 2012 in Massa Lombarda (Ravenna- Italy) that designs, produces, and sells 3D printers Made in Italy all over the world. The wide range of WASP 3D printers has been developed to answer human needs: food, housing, health, energy, work, art, and culture. Inspired by the Potter Wasp, which builds its own nest with material recovered from the surrounding environment, WASP was born with the aim of developing large-scale 3D printers, to build houses with natural materials available on the territory. The main company's target is to provide effective benefits to humans through technological innovation and research.

-

-

-

-

-

voxeljet AG

3D printing system

Company Overview

Voxeljet, a Friedberg-headquartered firm, is one of the world’s most reputed 3D printing companies. The company was established in 1999 and has opened service centers in India, China, the U.K, and the U.S The company manufactures industrial 3D printers for diverse applications, from aerospace to engineering and film. Voxeljet’s 3D printers can produce parts from various materials such as ceramic, metals, and plastic due to their powder bed binder jetting technology. Besides selling its 3D printers, Voxeljet offers 3D printing services to customers who want to outsource their printing objectives. Voxeljet has been listed on the Nasdaq since 2020.

-

-

-

-

-

INTAMSYS Technology Co.Ltd

3D printer

Company Overview

INTelligent Additive Manufacturing SYStem, or INTAMSYS, established in 2016, is a manufacturing company that caters to several industries such as Aerospace, Automotive, Education, Manufacturing, Gas and Oil, and even Medical Field. Based in Shanghai, China, the company creates additive materials as well as offering 3D printing. Aside from its headquarters, it has two regional sales offices located in Stuttgart, Germany, and Minneapolis, Minnesota, United States. The company does prototype testing, tooling, fixture manufacturing, direct mass production, equipment covering, and several other fabrication services such as software and engineered material manufacturing aside from their 3D printing services.

-

-

-

-

-

Renish

3D printing

Company Overview

Renishaw plc., established in 1973 and based in Wotton-under-Edge, United Kingdom, is a manufacturer of analytical instruments, medical devices, and manufacturing technologies. Some of the products it stocks include additive manufacturing systems, open optical encoders, and neurological products, and it operates in the Americas, EMEA, and APAC regions, with 67 locations in 36 countries. Throughout its history, the company has spent 13% to 18% of its annual sales in R&D and engineering. In 1981, it set up its first international manufacturing facility in Ireland, and in 1984, it was listed in the London Stock Exchange unlisted securities market.

-

-

-

-

-

SLM Solutions

NXG XII 600

-

-

-

-

-

Vector Technology Systems

3D Printers

Distributor Overview

Vector Technology Systems, founded in Phoenix, AZ, is a supplier of 3D solutions in the form of 3D printing, design, scanning, and augmented & virtual reality. The company's product portfolio includes 3D Scanning, 3D Modeling and design, Virtual Reality (VR) and augmented Reality (AR), and 3D software tools that empower users to create, edit, and manipulate 3D content. The company serves markets including automotive, healthcare, manufacturing, architecture, and engineering and also provides industry based custom projects.

-

-

3D Printer Manufacturer Ranking

*Including some distributors, etc.Ranking as of April 2024

Derivation Method| Rank | Company | Click Share |

|---|---|---|

| 1 | 3 AXIS Development, Inc. |

9.1%

|

| 2 | MakerBot Industries, LLC |

8.1%

|

| 3 | Electroimpact, Inc. |

7.1%

|

| 4 | MicroJet Technology Co., Ltd. |

6.1%

|

| 5 | Ultimaker |

6.1%

|

| 6 | BigRep GmbH |

6.1%

|

| 7 | Raise 3D Technologies, Inc. |

5.1%

|

| 8 | INTAMSYS Technology Co.Ltd |

5.1%

|

| 9 | voxeljet AG |

5.1%

|

| 10 | Zortrax S.A. |

5.1%

|

Derivation Method

The ranking is calculated based on the click share within the 3d printer page as of April 2024. Click share is defined as the total number of clicks for all companies during the period divided by the number of clicks for each company.Number of Employees

Newly Established Company

- Nexa3D: 2016 (8 years ago)

- INTAMSYS Technology Co.Ltd: 2016 (8 years ago)

- Raise 3D Technologies, Inc.: 2015 (9 years ago)

Company with a History

- Sodick Co., Ltd: 1971 (53 years ago)

- Renishaw plc: 1973 (51 years ago)

- MITS Electronics: 1984 (40 years ago)

3D Printer Manufacturers in United States

*Including some distributors, etc.

- Electroimpact, Inc.

- 3 AXIS Development, Inc.

- LulzBot (Fargo Additive Manufacturing Equipment 3D, LLC)

- Terrafilum

- Nexa3D

- 3D Systems

- Raise 3D Technologies, Inc.

- MakerBot Industries, LLC

- Aero 3Ds

Global Distribution of 3D Printer Manufacturers by Country

*Including some distributors, etc.

| Country | Number of Companies | Share (%) |

|---|---|---|

United States of America

United States of America

|

9 | 47.4% |

Japan

Japan

|

3 | 15.8% |

United Kingdom

United Kingdom

|

2 | 10.5% |

Germany

Germany

|

2 | 10.5% |

Poland

Poland

|

1 | 5.3% |

Italy

Italy

|

1 | 5.3% |

China

China

|

1 | 5.3% |

List of 3D Printer Products

88 products are listed.

BRULE INC.

Large 3D printer FORMLABS FORM 3L

40+ people viewing

Form 3L is an affordable large 3D printer designed for professionals, and can quickly print industrial quality parts using the advanced LFS (LOW FO...

BRULE INC.

3D Printer Ultimaker S5 Pro Bundle

10+ people viewing

Ultimaker S5 Pro Bundle is an all -in -one desktop 3D printing solution. Large -capacity parts can be used to create accurate and industrial class ...

BRULE INC.

3D Printer Ultimaker S7 Pro Bundle

10+ people viewing

Ultimaker S7 Pro Bundle is an all -in -one desktop 3D printer. Large -capacity parts can be used to create accurate and industrial class parts as m...

BRULE INC.

3D printer Ultimaker S7

10+ people viewing

Ultimaker's flagship model that incorporates all functions and characteristics that have been highly evaluated by users realize unprecedented quali...

BRULE INC.

3D printer Ultimaker S5

20+ people viewing

The large -capacity and easy -to -use desktop 3D printer allows you to shape the industrial grade parts as many times as you want. Ultimaker S5 wit...

BRULE INC.

3D printer Ultimaker S3

10+ people viewing

Last viewed: 14 hours ago

Ultimaker S3 offers professional, stable, 3D prints in an efficient and easy -to -use desktop format. High -quality and beautiful 3D print modelin...

BRULE INC.

3D Printer Zortrax M300 Plus

10+ people viewing

Zortrax M300 Plus is a desktop 3D printer with a wireless connection and a large -scale build volume. It is designed to function as a highly reliab...

BRULE INC.

3D printer FORMLABS FORM 3+

10+ people viewing

FORM 3+ enables 3D prints in the LFS (Low FORCE STEREOLITHOGRAPHY) method on the table, achieving high reproducibility and reliability, achieving i...

BRULE INC.

3D Printer Ultimaker 2+ Connect Air Manager Pro Bandle

10+ people viewing

Ultimaker 2+ Connect Air Manager Pro Bandle is the simplest 3D printer in the Ultimaker lineup. It uses a highly stable single head and can use a r...

BRULE INC.

3D printer Makerbot Sketch Large

10+ people viewing

Last viewed: 21 hours ago

There is an educational resource at all stages to print larger and more boldly. A 3D printer product that contains a printer training, student curr...

BRULE INC.

3D Printer Zortrax M200 Plus

10+ people viewing

The Zortrax M200 Plus is a professional LPD (FFF) 3D printer designed mainly for business clients. The M200 Plus, based on the Zortrax M200, which ...

BRULE INC.

3D printer Ultimaker 2+ Connect

10+ people viewing

Ultimaker 2+ Connect is the simplest 3D printer in the Ultimaker lineup. It uses a highly stable single head and can use a rich Ultimaker material....

BRULE INC.

3D Printer Maketch Classroom Bundle

10+ people viewing

By introducing two printers, you can carry out the classroom print work more quickly, make 3D prints more familiar to students, and increase studen...

BRULE INC.

Metal 3D Printer Desktop Metal Studio System 2

10+ people viewing

Studio System 2 is an office -friendly metal 3D printer, like the conventional Studiosystem ™, and has a simple step of printing and sintering. Wi...

BRULE INC.

Industrial 3D Printer Formlabs FUSE 1

10+ people viewing

Fuse 1 and Fuse Sift bring the industrial power of SLS (selective laser sintering) to the benchtop, enabling prototyping and production at 1/10th t...

BRULE INC.

3D printer for medical professionals FORMLABS FORM 3B+

10+ people viewing

Form 3b+provides higher accurate parts than required in the clinical site, can print highly biological materials, and its use is increasingly expan...

BRULE INC.

3D printer for medical professionals FORMLABS FORM 3BL

40+ people viewing

Form 3BL is an affordable large 3D printer designed for professionals, and can quickly print industrial quality parts using the advanced LFS (Low F...

BRULE INC.

Metal 3D Printer Desktop Metal Shop System

10+ people viewing

SHOP SYSTEM realizes high -quality binder gets into a completely new market called mechanical factory, and can print end -use metal parts with unpa...

BRULE INC.

DLP 3D Printer ETEC Xtreme 8K

10+ people viewing

Xtreme 8K achieves mass production of 3D print parts and can print thousands of parts a day. Xtreme 8K is compatible with a wide range of materials...

BRULE INC.

Industrial 3D Printer ETEC ENVISIONONE XL

10+ people viewing

ENVISION ONE MECHANICAL BUNDLE creates accurate and high -quality parts quickly and reliably. You can create a functional prototype that has a seve...

BRULE INC.

Industrial 3D Printer ENVISION ONE CDLM MECHANICAL

10+ people viewing

ENVISION ONE MECHANICAL BUNDLE creates accurate and high -quality parts quickly and reliably. You can create a functional prototype that has a seve...

BRULE INC.

3D printer for dental NEXA NXD200

10+ people viewing

The NEXA3D NXD200 provides high-speed and industrial quality three-dimensional models in dental engineering and dental clinics on all sizes by the ...

BRULE INC.

3D printer for dental ENVISION ONE DENTAL

10+ people viewing

The Envision One CDLM Dental package offers full solutions to all sizes and dental clinics. By combining intuitive and powerful software with the i...

Hotty Polymer Co., Ltd.

Ultra -low hardness stable molding can be made 3D printer Esdies Ⅰ

■ Overview ・ The modeling size is W250mm x D250mm x H340mm and large size. ・ Filament diameter ф2.85mm is adopted, and the filament can be suppli...

Apple Tree Co., Ltd.

3D printer FX20 ™ compatible with Ultem ™ 9085 material

10+ people viewing

■ Vast modeling area The FX20 ™ has a 84L build chamber, and the maximum maximum modeling size is 525mm x 400mm x 400mm. This is a product with the...

Naroshin Tech Co., Ltd.

Large FDM method 3D printer CREATBOT

10+ people viewing

■ D600 Overview ・ D600 was released in 2016. The print size is a large 3D printer that reaches 600*600*600mm. ・ Suitable for printing large model...

Hotty Polymer Co., Ltd.

Processing with a short printing time, the world's first LAM (liquid laminated modeling method) Silicone rubber 100%3D printer Innovatiq LIQ320

10+ people viewing

■ Characteristics ・ By using various nozzles, fine structures and large objects can be processed in a short printing time. Since the fully automat...

Microboard Technology

Large capacity AFINIA 3D Printer HLF600 with 400 x 500 x 600mm modeling area

10+ people viewing

Last viewed: 20 hours ago

■ Large -capacity modeling area Because it has a modeling area of W400 x D500 x H600mm, it is possible to print a large size that the modeling ar...

Microboard Technology

Afinia 3D Printer H440

10+ people viewing

■ Overwhelming quietness In addition to the ease of use, it has a silent sound of "47db and overwhelmingly low operation sound". In addition, as in...

Microboard Technology

Fusion of multifunctionality and precision Afinia 3D Printer H+1

10+ people viewing

■ Fusion of multifunctionality and precision It is a 3D printer that can be used by any person, such as educational sites, engineers, hobby, etc. T...

Microboard Technology

Infinity 3D Printer IX BOX

10+ people viewing

■ Piled up design When mass production is performed using multiple 3D printers, it is designed to be accumulated, taking into account the location ...

Microboard Technology

Infinity 3D Printer X2 suppresses gaps during modeling

10+ people viewing

Last viewed: 14 hours ago

It is a 3D printer that is assembled using only parts that have passed high -quality and strict inspection without compromising the parts to be use...

Microboard Technology

Compatible with PEEK output Infinity 3D Printer X3 Pro

10+ people viewing

■ Features / functions ・ 30cm x 30cm x 40cm large modeling area ・ Compatible with PEEK output ■ Discerning manufacturing parts ・ Z -axis configura...

Microboard Technology

The latest optical system FORMLABS 3D Printer Form3+

10+ people viewing

The latest optical system maintains accurate and high -density laser spots, ensuring accurate and reproducible printing each time. Easy and smooth ...

Naroshin Tech Co., Ltd.

Ceramics 3D printer Syno Source 3040 for duplication of pottery with the same shape and shortening production time

10+ people viewing

■ Overview Digital pottery manufacturing is an innovative technology that combines a laminated technology and a conventional pottery culture. Potte...

Naroshin Tech Co., Ltd.

Large, high -precision, and high -speed printing realized large industrial class large FDM method 3D printer CREATBOTF1000

10+ people viewing

■ Overview ・ 3D printer F1000 for oversized industrial grade -The CREATBOTF1000 is a super -large industrial FDM3D printer, and can provide large,...

Naroshin Tech Co., Ltd.

Empra-compatible FDM method 3D printer Creatbotpeek-300

■ Overview ・ CREATBOT3D Printer Creatbotpeek-300 is an industrial grade 3D printer and supports high-performance materials such as PEEK, Pekk, and...

Naroshin Tech Co., Ltd.

Completely sealed body FDM method 3D printer CREATBOTF430

■ Overview ・ CREATBOTF430 is a flagship desktop 3D printer with excellent performance using advanced FDM3D printing technology. ・ The F430 can pr...

Naroshin Tech Co., Ltd.

Ceramics 3D printer Synosource 2020 for duplication of pottery with the same shape and shortening production time

■ Overview ・ Digital pottery manufacturing is an innovative technology that combines a laminated technology and a conventional pottery culture. ・...

Apple Tree Co., Ltd.

3D printer X7 ™ that realizes the same strength as aluminum

30+ people viewing

■ High strength modeling with carbon fiber Compatible with four types of long fibers including carbon fiber. Markforged's unique CFR (Continuous Fi...

Marubeni Information Systems Co., Ltd.

FDM method 3D printer that can use real plastic for modeling materials

10+ people viewing

The biggest feature of the FDM system is that real plastic can be used for modeling materials. Since the resin such as ABS and PCs can be used, mod...

Marubeni Information Systems Co., Ltd.

Polyjet 3D printer that can shape high -definition models

10+ people viewing

The biggest feature of the Polyjet system is that a high -definition model with a minimum of 0.014 mm thickness by shooting a liquid light stiffeni...

Hotty Polymer Co., Ltd.

A revolutionary new model SILICOM (Silicom) that enables 3D modeling with silicone rubber

10+ people viewing

■ Overview "SILICOM" is a silicone rubber 3D printer that uses a UV (ultraviolet) hardened liquid laminated model (LAM method) that expands the new...

Hotty Polymer Co., Ltd.

Reproduction to the details of the modeling

"SMAPRI Sonic 4K LL" is an optical modeling 3D printer equipped with a monochrome 4K LCD (LCD panel). With 4K high resolution output, you can faith...

Hotty Polymer Co., Ltd.

Reproduction to the details of the modeling, SMAPRI SONIC 4K LL ID (for industrial)

"SMAPRI Sonic 4K LL" is an optical modeling 3D printer equipped with a monochrome 4K LCD (LCD panel). With 4K high resolution output, you can faith...

Hotty Polymer Co., Ltd.

Reproduction to the details of the modeling, SMAPRI SONIC 8K XM ID (for industrial)

"SMAPRI (Smapri) Sonic 8K XM" is an optical model 3D printer equipped with a monochrome 8K LCD (LCD panel). "Maximum modeling size W330XD185XH400mm...

Hotty Polymer Co., Ltd.

Compact but high -performance, high -quality high -performance business desktop type 3D printer RAISE3D E2

■ Overview A new entry model "RAISE3D E2CF" specialized in high -strength reinforced fibers has been newly added. High -performance, high quality, ...

Hotty Polymer Co., Ltd.

High Performance Comprehensive Rating No.1 Commercial MEX3D Printer RAISE3D Pro

10+ people viewing

■ Overview The highest model of the PRO series. The functions and ease of handling are greatly improved, while reliability and usability remain the...

Hotty Polymer Co., Ltd.

3D print flashforge Creator Pro2 utilizing independent dual heads

■ Characteristics ・ Independent dual head ・ Filament cleaning plate

Hotty Polymer Co., Ltd.

Flashforge Guider2 heated platform compatible with ABS

■ Characteristics ・ Minimum laminated pitch 0.05mm (50 microns) ・ By combining high rigidity body and high -performance XYZ axis motor, high -pre...

Hotty Polymer Co., Ltd.

Removable nozzle Flashforge Adventurer3 with one push

10+ people viewing

■ Safe even if the filament is gone on the way Even if the filament runs out during the modeling, it is possible to resume the modeling by adding t...

Hotty Polymer Co., Ltd.

Compatible with multiple nozzle diameters flashforge Adventurer4

10+ people viewing

■ Characteristics ・ Aluminum -based platform ・ Compatible with multiple nozzle diameter

Hotty Polymer Co., Ltd.

Advanced 3D printer Intamsys Funmat Pro410

10+ people viewing

■ Overview ・ It is an industrial 3D printer that can be used by Super Empar. It can be used as a substitute for metal, and is ideal for using cars...

Hotty Polymer Co., Ltd.

Advanced 3D Printer Intamsys Funmat HT ENHANCED

10+ people viewing

■ Overview ・ It is an industrial 3D printer that can be used by Super Empar. It can be used as a substitute for metal, and is ideal for using cars...