10 Stereolithography 3D Printer Manufacturers in 2024

This section provides an overview for stereolithography 3d printers as well as their applications and principles. Also, please take a look at the list of 10 stereolithography 3d printer manufacturers and their company rankings. Here are the top-ranked stereolithography 3d printer companies as of July, 2024: 1.MDPI, 2.Stratasys, 3.Protolabs, Inc..

Table of Contents

Categories Related to Stereolithography 3D Printers

What Is a Stereolithography 3D Printer?

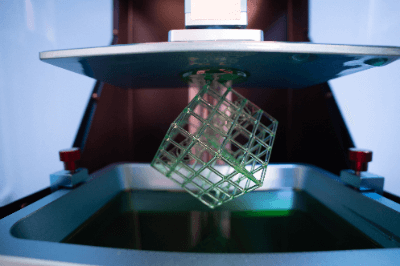

A stereolithography 3D printer is a 3D printer that utilizes the stereolithography method.

The stereolithography method is a technique for creating three-dimensional structures by curing and layering a material, which is cured by exposure to ultraviolet light, layer by layer. The material used is usually a liquid light-curable resin such as epoxy or acrylic resin.

Stereolithography 3D printing is the oldest of all the 3D printing technologies currently in practical use and is the most widely used method in the industry.

Uses of Stereolithography 3D Printers

Stereolithography 3D printers are employed for verifying designs, creating master models, and producing molds.

Due to their capability to produce highly precise, smooth-surfaced objects, stereolithography 3D printers can also be used for manufacturing final products.

The choice of printer types and materials depends on the intended use.

Principles of Stereolithography 3D Printers

In the optical fabrication method, 3D data is loaded into the printer, and the liquid resin is irradiated with ultraviolet light to create the model.

The process begins by creating the first layer, where the resin is cured by irradiating a laser beam onto a tank filled with light-curing resin liquid. Subsequently, the resin is lowered by one layer from the cured stacked surface, and the next layer is cured in the same manner. This process is repeated to build the model layer by layer.

Precise modeling can be achieved by setting a thin layer thickness, while thicker layers allow for faster and more efficient modeling.

Types of Stereolithography 3D Printers

There are several types of stereolithography 3D printers.

Here is a description of typical modeling methods.

1. Classification of Stereolithography 3D Printers Based on Modeling Direction

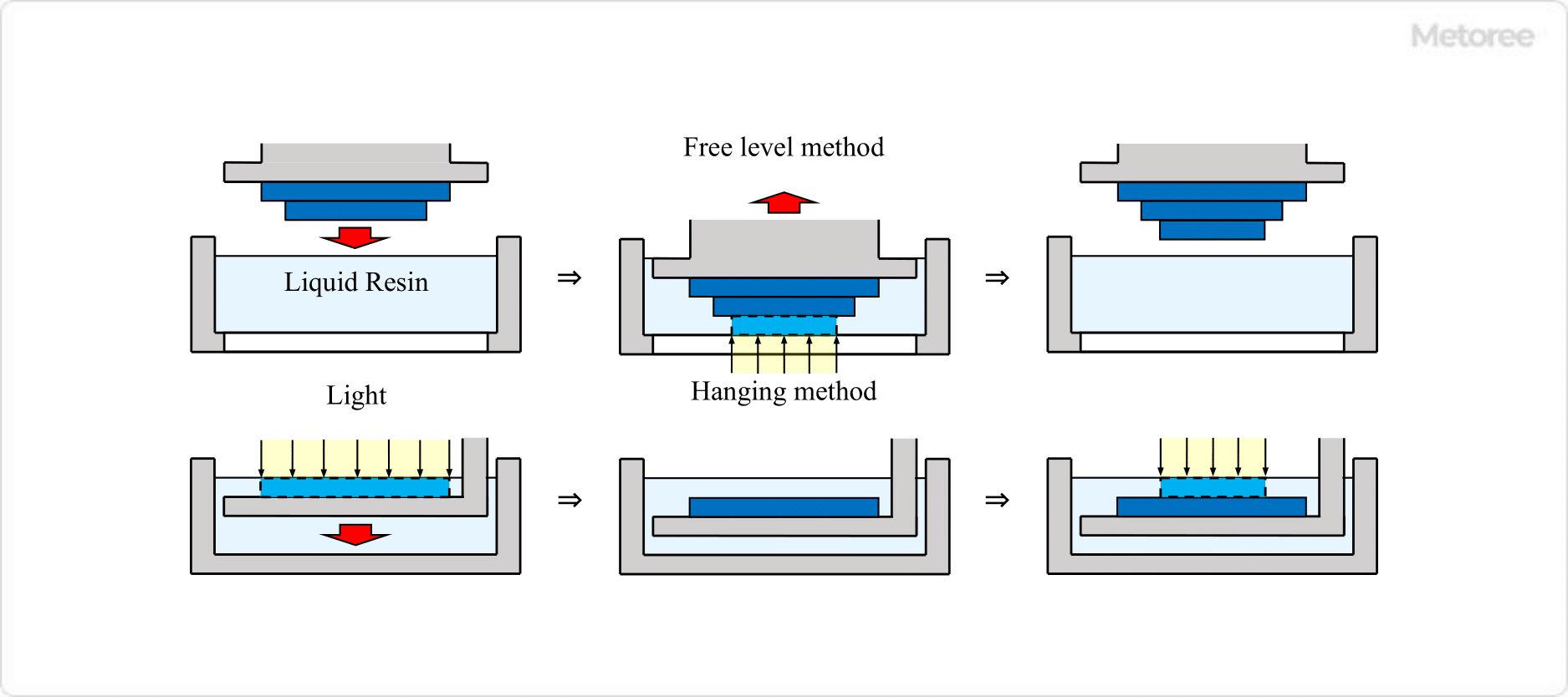

Stereolithography 3D printers can be classified into two types based on the direction in which modeling proceeds:

- Free surface method: Light is directed onto the modeling object from above, and modeling proceeds by stacking cured layers.

- Hanging method: The modeling object is suspended, and light is irradiated from below to advance the modeling.

Figure 1. Classification based on modeling direction

2. Classifications of Stereolithography 3D Printers by the Way Light Is Applied

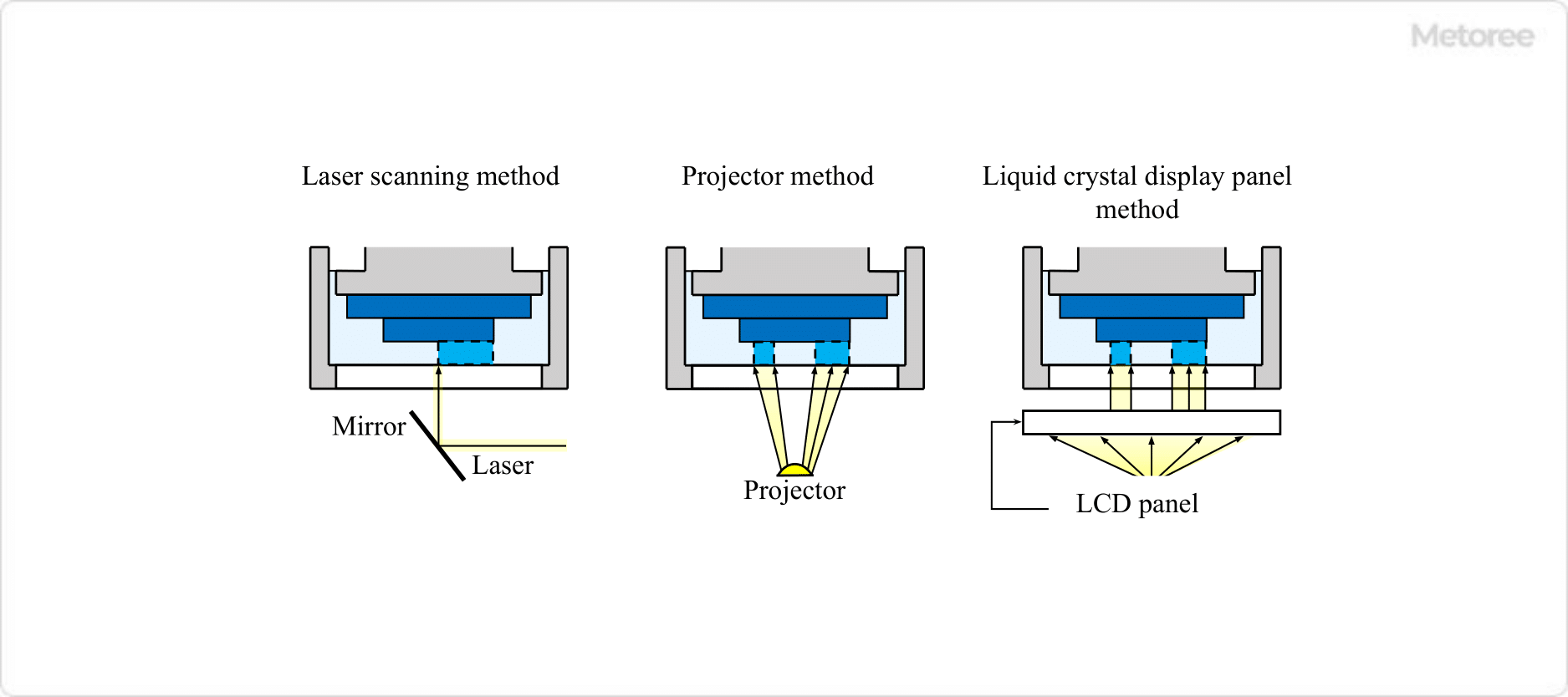

Stereolithography 3D printers can also be classified based on how light is applied. Three representative examples are:

- Laser scanning method: This method employs a laser-pointer-like light to draw lines of light.

- Projector method: A single layer of light is produced with a single irradiation.

- Liquid crystal panel method: Similar to the projector method, light is emitted from a surface, but this method uses a liquid crystal display instead of a projector to irradiate light.

Figure 2. Classification is based on the way light is exposed

Other Information on Stereolithography 3D Printers

1. Features of Stereolithography 3D Printers

Stereolithography 3D printers have their advantages and disadvantages:

- Advantages: They can achieve high-precision modeling with smooth surfaces and are capable of relatively rapid production.

- Disadvantages: Stereolithography equipment and resins are costly, and post-processing is often required.

The light-curing resins used have distinct characteristics, and the choice of resin depends on the intended application. For example, epoxy resin is not resistant to sunlight, while acrylic resin is fragile, making it unsuitable for applications with high forces or durability requirements.

2. Stereolithography 3D Printers Procedure

The use of stereolithography 3D printers typically involves three steps: creation and conversion of 3D data, modeling, and post-processing.

- Creation and conversion of 3D data: 3D data of the object to be modeled is created using 3D CAD or a 3D scanner. This data is then converted into STL data and tool path data compatible with the selected 3D printer, which is subsequently loaded into the 3D printer.

- Modeling: The stereolithography 3D printer is used for the modeling process.

- Post-processing: Immediately after modeling, the surface of the model is cleaned with alcohol or other solvents to remove any uncured resin. Depending on the resin used, secondary curing may be performed to enhance strength. After these processes, support material, which is used to prevent deformation during printing, is removed.

3. Data Handled by Stereolithography 3D Printers

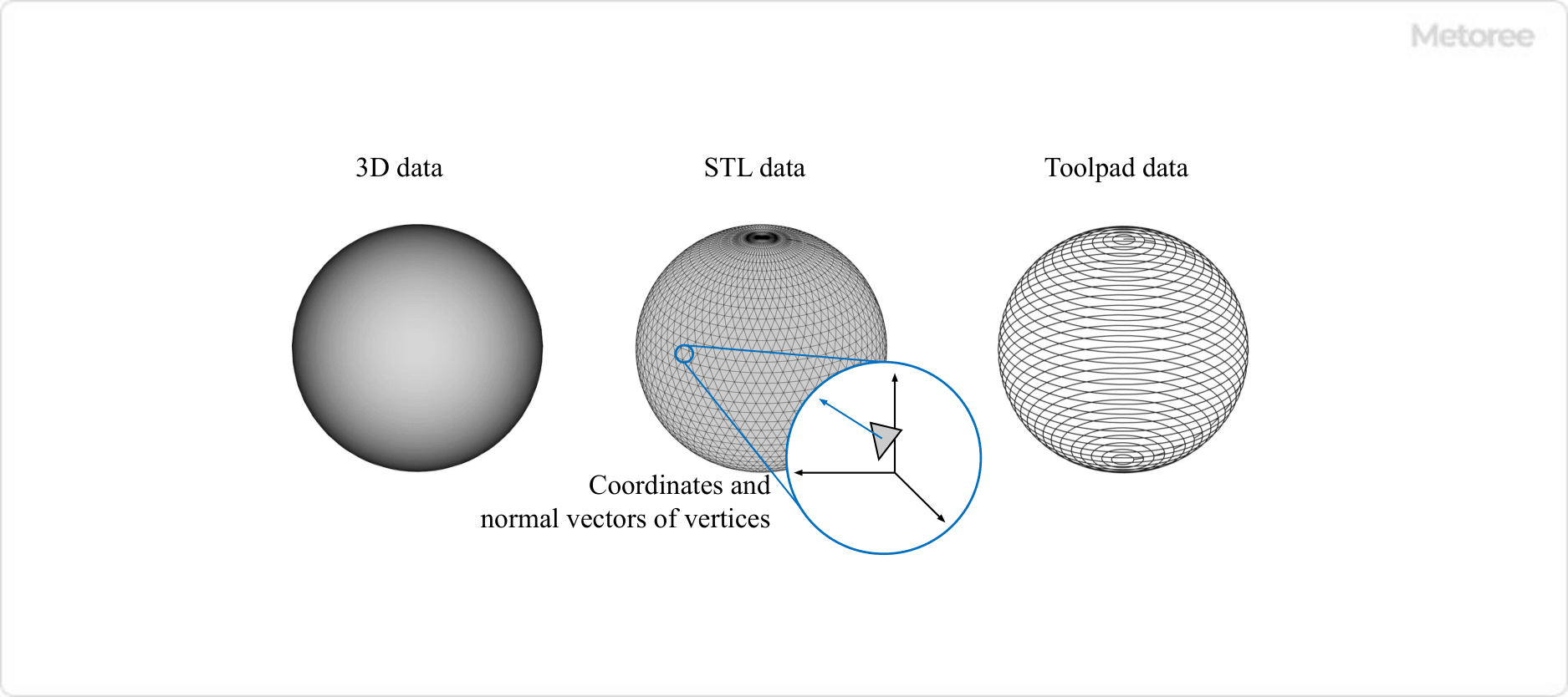

Figure 3. Data handled by stereolithography 3D printers

To proceed with stereolithography 3D printing, three types of data are essential: 3D data, STL data, and toolpath data.

- 3D data: 3D data can be created using 3D CAD software and 3D scanners. 3D CAD generates 3D data by designing the object on a computer. 3D scanners acquire 3D data by scanning physical objects. In recent years, some systems have allowed users to easily scan objects using smartphones and other devices.

- STL data: STL data represents 3D data as a collection of triangles, containing information such as coordinates and normal vectors of the triangle vertices. Many 3D CAD software can output STL data, but when creating STL data, it is necessary to check and correct the model to ensure it is not too flawed to be realistically modeled.

- Toolpath data: Toolpath data contains information on how the 3D printer operates to create the 3D model. The specific toolpath data varies depending on the 3D printer used, and the 3D printer must read this data to model the object.

List of 10 Stereolithography 3D Printer Manufacturers

*Including some distributors, etc.

Sort by Features

- Default

- Company Size: largest first

- Year Founded: oldest first

- Year Founded: earliest first

Sort by Area

- United States of America

- Belgium

- Switzerland

-

-

-

Stratasys

NEO Printers

Manufacturer Overview

Stratasys, established in 1988, and with its headquarters in Los Angeles, California, serves as a manufacturer and supplier of 3D printers, materials, and software solutions. Their product portfolio includes FDM and PolyJet 3D printers, 3D printing, stereolithography technology, and selective absorption fusion (SAF) technology designed for industries such as aerospace, automotive, healthcare, consumer goods, and education. Stratasys' technology enables rapid prototyping, tooling production, and direct manufacturing, maintaining ISO 9001 and ISO 13485 standards.

-

-

-

-

-

3D Systems

Stereolithography

Manufacturer Overview

3D Systems is an American manufacturer specializing in 3D printing solutions founded in 1986 and headquartered in Rock Hill, South Carolina. The company's product inventory includes 3D printing systems with various customization options, printing materials such as metals, ceramics, and composites, and software for creating printing workflows or applications. They also offer niche services to customers in the healthcare industry, such as bioprinting, surgical planning, and anatomical modeling. 3D Systems facilities can also accommodate on-demand prototype manufacturing for customers in other client industries, which include the aerospace, automotive, and industrial sectors.

-

-

-

-

-

MakerBot Industries, LLC

3D PRINTER

Company Overview

Established in January 2009, MakerBot is a global 3D printer manufacturing company specializing in designing and providing user-friendly 3D printing solutions for various applications. The company’s products are designed for personal and professional use, with various types catering to everyone’s needs and budgets. Also, the company’s printers rely on software enabling users to create objects or download designs from online archives. In addition, MakerBot sells accessories like filament materials and extruders to boost its printers’ capabilities. The company has released six generations of 3D printers since 2009.

-

-

-

-

-

Protolabs, Inc.

Stereolithography

Company Overview

Proto Labs, founded in 1999, is a company that provides rapid manufacturing of low-volume 3D printed, CNC-machined, sheet metal, and injection-molded custom parts for prototyping and short-run production, headquartered in the U.S. The company builds strong injection-molded parts by incorporating strategic support features and selecting the right thermoplastics. They offer a wide range of materials and design tips to help customers create stronger molded parts. In 2017, they acquired Rapid Manufacturing to further expand their machining capabilities and introduce sheet metal fabrication into their suite of services. Also, global online manufacturing platform, Hubs, joined their family in early 2021.

-

-

-

-

-

Computer Aided Technology Inc.

Stratasys Neo 3D Printer

Distributor Overview

GoEngineer, established in 1988 and headquartered in the United States, is a supplier of software, hardware, and services for product design and manufacturing. The company offers a broad range of products, including computer-aided design (CAD) software, 3D printers, and training and support services. It serves industries like engineering, automotive, and aerospace, where efficient product development is essential. These industries utilize the company's solutions to streamline design and manufacturing processes, ultimately improving product quality and reducing time-to-market.

-

-

-

-

-

3DEXPERIENCE Company

SLA - Stereolithography

Manufacturer Overview

Dassault Systemes, a technology company established in 1981 in France, is a supplier of the 3DEXPERIENCE (3DX) business and innovation platform and virtual software solutions. The company’s SaaS provides individuals, commercial, industrial, and research organizations with a real-time visualization of their business activity and ecosystem. Dassault Systems' core business is the provision of 3D design software, 3D digital mockups, and product lifecycle management. The 3DX cloud-based platform is available with options that include computer-aided design, project management solutions, and three-dimensional rendering. Dassault Systemes' software is used in the architecture, consumer products, lifestyle, and industrial equipment markets, among many others.

-

-

-

-

Company Overview

MDPI was founded in 1996 and is based in Basel, Switzerland. The company is a pioneer in scholarly, open-access publishing, featuring 417 peer-reviewed journals and 9 conference journals with over 115,000 academic contributors. The company’s journals fall into 10 subjects including biology, economics, medicine, physical sciences, and public health. The company’s pear review system is a dingle-blind assessment with at least two independent reviewers, followed by a final decision of acceptance or rejection by the editor-in-chief. Authors may appeal editorial decisions in case of rejection of articles.

-

-

-

-

-

All3DP

Resin 3D Printing

Company Overview

All3DP is an online platform for 3D printing enthusiasts and professionals that was established in 2014 and is headquartered in München, Ridlerstraße 31A, Germany. The company provides a wealth of information, reviews, and resources related to 3D printing technology and its applications. Its platform offers a wide range of content, including news, tutorials, product reviews, and a vast collection of 3D models. All3DP also runs a magazine for digital makers, which contains content on 3D printing, 3D scanning, CAD, laser cutting/engraving, CNC, and SBCs as well as other ever-evolving stories in the world of 3D printing.

-

-

-

-

-

Materialise

Stereolithography

Distributor Overview

Materialise, established in 1990, is a supplier and service provider specializing in printing software and services based in Belgium. The company primarily provides software solutions that cater to various aspects of 3D printing, including design, simulation, and printing preparation. Professionals and industries worldwide use its software for creating 3D models, optimizing designs, and generating print-ready files. Additionally, the company offers 3D printing services that cater to various industries, including medical, automotive, aerospace, art, and fashion.

-

-

-

-

-

B&H Foto and Electronics Corp.

XYZprinting Nobel 1.0 Stereolithography 3D Printer

Distributor Overview

B&H Foto & Electronics Corporation, founded in 1973 and based in Manhattan, New York City, is a retailer of photo, video, and other technological equipment. B&H is an authorized seller of Sony, Panasonic, Canon, Fuji, and more. The company serves photographers, musicians, and professionals with products related to film, music, photography, audio, art, and technology. The company's main products include photography gear, computers, televisions, drones, surveillance systems, and more. B&H store has nearly 500,000 items in stock for customers who need them.

-

-

Stereolithography 3D Printer Manufacturer Ranking

*Including some distributors, etc.Ranking as of July 2024

Derivation Method| Rank | Company | Click Share |

|---|---|---|

| 1 | MDPI |

23.0%

|

| 2 | Stratasys |

12.2%

|

| 3 | Protolabs, Inc. |

10.8%

|

| 4 | 3D Systems |

10.8%

|

| 5 | MakerBot Industries, LLC |

10.8%

|

| 6 | Materialise |

9.5%

|

| 7 | 3DEXPERIENCE Company |

8.1%

|

| 8 | All3DP |

6.8%

|

| 9 | B&H Foto and Electronics Corp. |

6.8%

|

| 10 | Computer Aided Technology Inc. |

1.4%

|

Derivation Method

The ranking is calculated based on the click share within the stereolithography 3d printer page as of July 2024. Click share is defined as the total number of clicks for all companies during the period divided by the number of clicks for each company.Number of Employees

- 3DEXPERIENCE Company: 20,000

- All3DP: 40

Newly Established Company

- MakerBot Industries, LLC: 2009 (15 years ago)

- Protolabs, Inc.: 1999 (25 years ago)

Company with a History

- Protolabs, Inc.: 1999 (25 years ago)

- MakerBot Industries, LLC: 2009 (15 years ago)

Stereolithography 3D Printer Manufacturers in United States

*Including some distributors, etc.

Global Distribution of Stereolithography 3D Printer Manufacturers by Country

*Including some distributors, etc.

| Country | Number of Companies | Share (%) |

|---|---|---|

United States of America

United States of America

|

5 | 71.4% |

Switzerland

Switzerland

|

1 | 14.3% |

Belgium

Belgium

|

1 | 14.3% |

List of Stereolithography 3D Printer Products

8 products are listed.

Hotty Polymer Co., Ltd.

Processing with a short printing time, the world's first LAM (liquid laminated modeling method) Silicone rubber 100%3D printer Innovatiq LIQ320

20+ people viewing

Last viewed: 5 hours ago

■ Characteristics ・ By using various nozzles, fine structures and large objects can be processed in a short printing time. Since the fully automat...

Hotty Polymer Co., Ltd.

A revolutionary new model SILICOM (Silicom) that enables 3D modeling with silicone rubber

20+ people viewing

■ Overview "SILICOM" is a silicone rubber 3D printer that uses a UV (ultraviolet) hardened liquid laminated model (LAM method) that expands the new...

Hotty Polymer Co., Ltd.

Reproduction to the details of the modeling

20+ people viewing

Last viewed: 5 hours ago

"SMAPRI Sonic 4K LL" is an optical modeling 3D printer equipped with a monochrome 4K LCD (LCD panel). With 4K high resolution output, you can faith...

Hotty Polymer Co., Ltd.

Reproduction to the details of the modeling, SMAPRI SONIC 4K LL ID (for industrial)

20+ people viewing

"SMAPRI Sonic 4K LL" is an optical modeling 3D printer equipped with a monochrome 4K LCD (LCD panel). With 4K high resolution output, you can faith...

Hotty Polymer Co., Ltd.

Reproduction to the details of the modeling, SMAPRI SONIC 8K XM ID (for industrial)

20+ people viewing

"SMAPRI (Smapri) Sonic 8K XM" is an optical model 3D printer equipped with a monochrome 8K LCD (LCD panel). "Maximum modeling size W330XD185XH400mm...

Suzumine Co., Ltd.

High -speed optical modeling machine Part Pro 100XP

20+ people viewing

High -resolution model for jewelry that emphasizes accuracy A long -awaited new model has appeared on a small and low -priced optical aircraft. It ...