All Categories

History

This section provides an overview for x-ray diffractometers as well as their applications and principles. Also, please take a look at the list of 12 x-ray diffractometer manufacturers and their company rankings. Here are the top-ranked x-ray diffractometer companies as of July, 2025: 1.Angstrom Advanced Inc., 2.ALVORD SYSTEMS INC., 3.Verichek Technical Services, Inc..

Table of Contents

An X-Ray Diffractometer is a device that measures the diffraction phenomenon that occurs when a material is irradiated with X-rays.

An X-Ray Diffractometer is a device that measures the diffraction phenomenon that occurs when a material is irradiated with X-rays.

The X-ray diffractometer consists of an X-ray generator to generate X-rays, a goniometer to measure the diffraction angle, and a detector to measure the X-ray intensity.

They are often used to measure materials with crystalline properties, such as single crystals, powders, and thin films. They are utilized in the research and development and analysis of various materials, including organic materials, inorganic materials, alloys, and proteins.

X-Ray Diffractometers are used to measure the diffraction phenomena that occur when a sample is irradiated with X-rays. By analyzing the diffraction patterns obtained, it is possible to evaluate the crystallinity, orientation, and lattice defects of the sample.

X-ray diffractometers are not suitable for measuring non-crystalline materials such as amorphous materials, however they can be used to measure a variety of materials such as crystalline powders, thin films, and alloys.

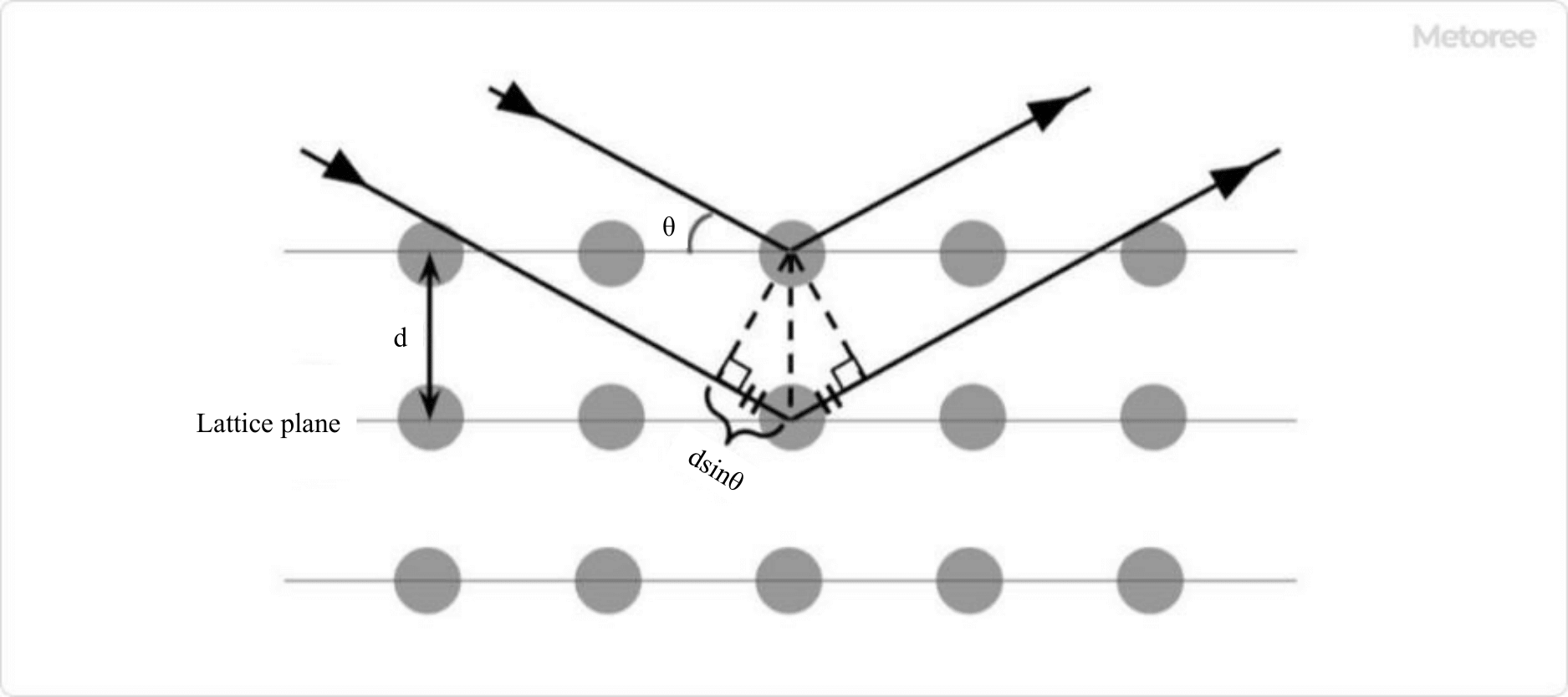

Figure 1. Diffraction conditions of Bragg

X-rays irradiated on a material are scattered by electrons in the material. In the case of crystals and other materials in which atoms are arranged with some degree of regularity, the scattered X-rays interfere with each other, amplifying or attenuating each other, and the scattering intensity increases only in a certain direction. This is called X-ray diffraction.

In X-ray diffraction, it is known that the X-ray scattering intensity increases when the Bragg equation 2d sinθ = nλ (d: lattice spacing θ: Bragg angle n: integer λ: wavelength of the irradiated X-ray) holds. In other words, if the wavelength λ is fixed, the lattice plane spacing d can be determined for various diffraction angles 2θ (angle between incident and diffracted X-rays). In this way, the atomic arrangement of the measured material is clarified from the measured diffraction pattern.

The main types of X-ray diffractometers are powder X-ray diffractometers, single-crystal X-ray diffractometers, and thin-film X-ray diffractometers. These are classified according to the way X-rays are irradiated and detected.

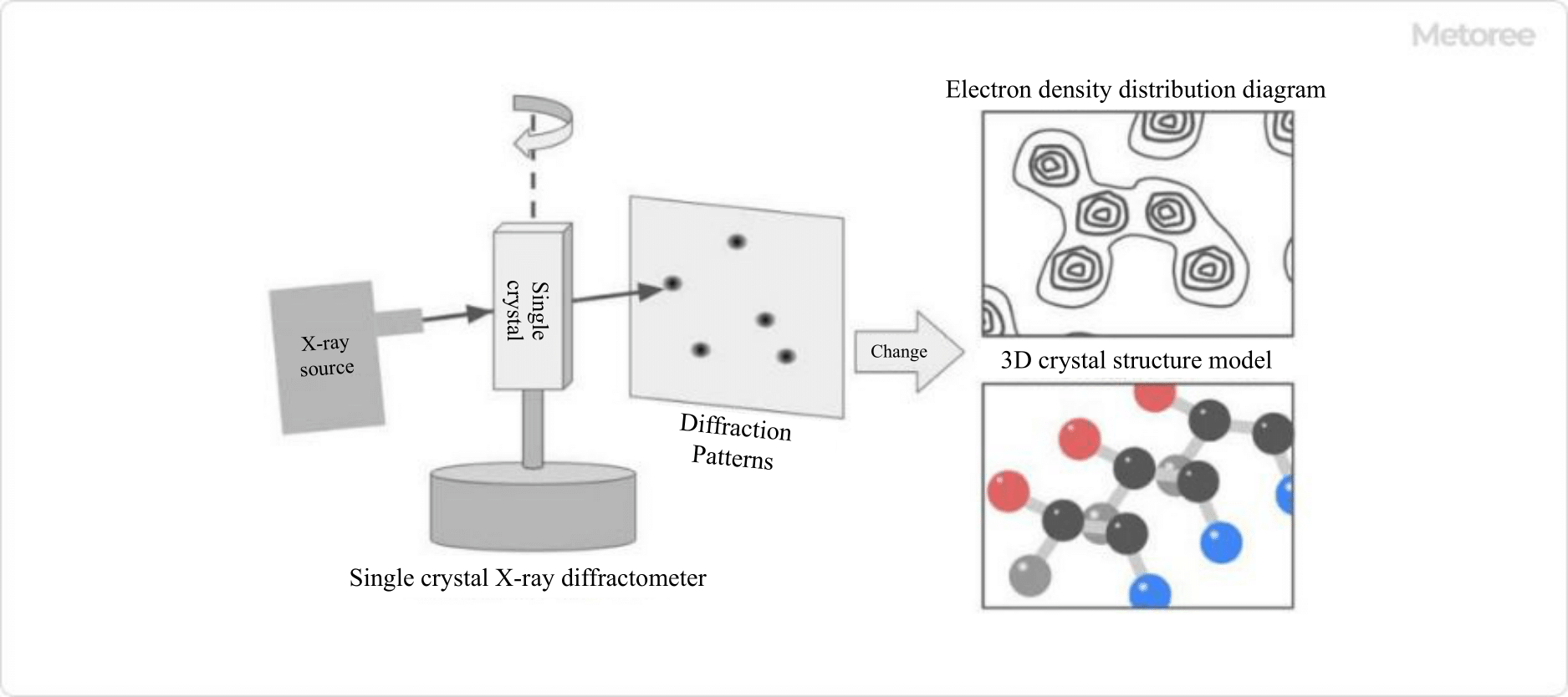

Figure 2. Single crystal X-ray diffractometer

In this method, X-rays are irradiated while the crystal is rotated about a certain axis, and the diffraction pattern is measured as a two-dimensional image. A three-dimensional model of the crystal structure can be obtained by calculating the obtained two-dimensional diffraction pattern using dedicated software.

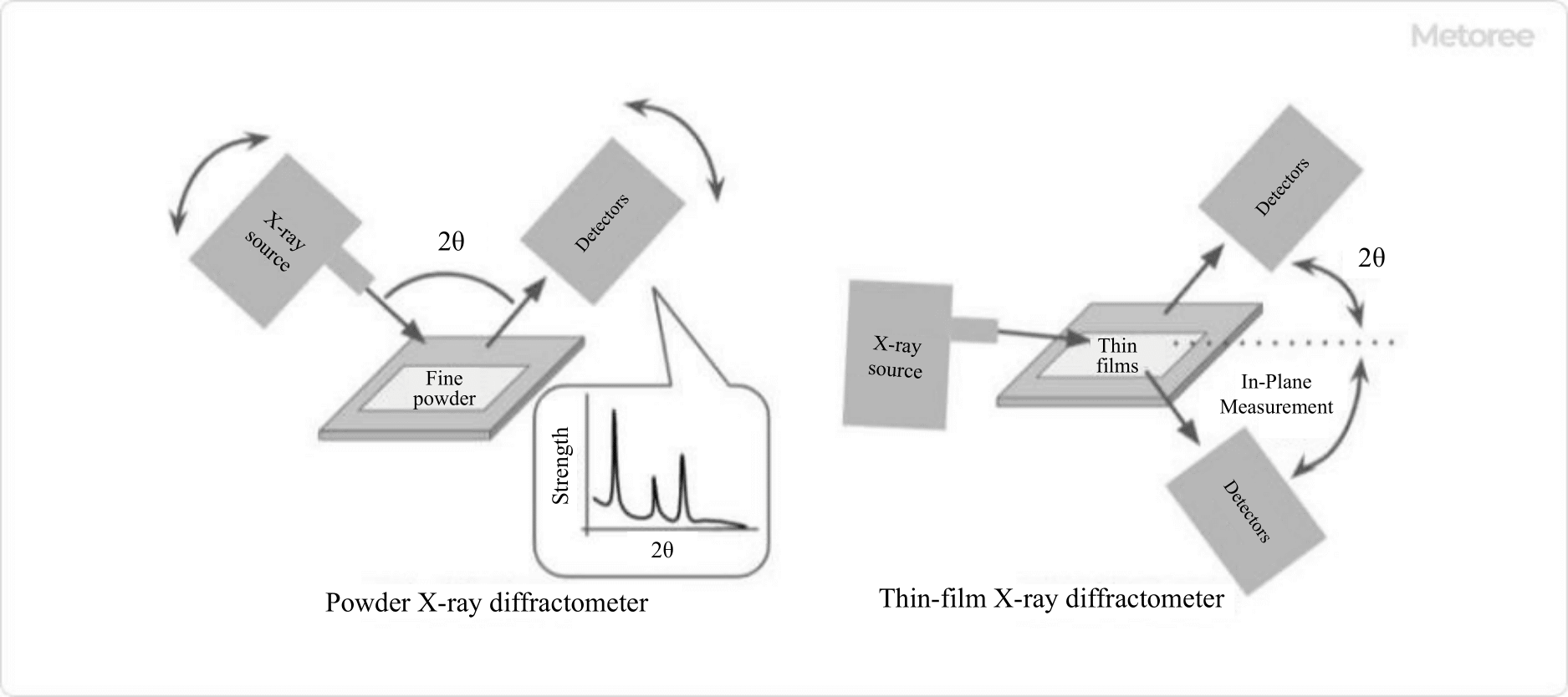

Figure 3. Powder X-ray diffractometer

PXRD is a method of measurement in which the angle of incidence of the irradiated X-rays and the position of the detector are moved to obtain diffraction intensity data for a diffraction angle of 2θ. It is mainly used for identification and qualitative analysis of substances with known diffraction patterns. It is the most commonly used measurement method because it requires a small amount of sample and is easy to adjust the sample.

This is a method of measurement in which the incident angle of the irradiated X-rays is fixed so that it is almost parallel to the substrate surface, and the detector is moved. In-Plane measurement can also be performed by moving the detector in a direction parallel to the substrate surface. Since the influence of the substrate is relatively small and information on the area close to the surface can be obtained, this method is mainly used to identify the crystal structure of thin films and interfaces and for qualitative analysis.

Each of these methods has different characteristics, so it is necessary to select the one best suited to the purpose of use and the sample to be measured. Depending on the purpose of use, it may be better to use an X-ray scattering system, which is a similar measurement system. Other accessory devices can be used to change the type of light source and to change the measurement environment, such as temperature and pressure, while performing measurements.

*Including some distributors, etc.

Sort by Features

Sort by Area

Shimadzu Scientific Instruments, established in 1875 in Japan, is a renowned manufacturer and supplier specializing in analytical instruments and testing equipment. The company offers a wide range of products, including chromatographs, spectrophotometers, and material testing machines. Shimadzu's history reflects a devotion to innovation and precision. Catering to industries such as pharmaceuticals, materials science, and environmental analysis, their products enable accurate research and quality control. Shimadzu's extraordinary products, such as liquid chromatographs used in pharmaceutical analysis and universal testing machines for evaluating material strength, empower scientific exploration and quality assurance across diverse sectors.

Rigaku Americas Corporation is based in The Woodlands, Texas, USA, and is a manufacturer and distributor of industrial as well as scientific instrumentation established in 1951 as a subsidiary of Japan’s Rigaku Corporation. The company’s product lineup includes single crystal diffractometers for determining the molecular or atomic structure of crystals, and x-ray diffractometers for material analysis or characterization. It also offers x-ray fluorescence spectrometers for non-destructive analysis of the elemental composition of different materials. The company is UL, DVGW, and CE-certified, and mainly serves clients in the industrial sector.

Bruker, founded in 1960 and based in Billerica, Massachusetts, is a manufacturer and distributor of scientific instruments and analytical and diagnostic solutions. The company's product range includes analyzers, microscopes, and imaging solutions, which have applications in fields such as life science research, cell biology, and microbiology. In 1969, the company developed the world's first FT-NMR spectrometer system, enabling broadband proton decoupling. In 1997, it further expanded its capabilities by acquiring the analytical X-ray division of Siemens AG. The company holds ISO 9001 and ISO 13485 certifications, and its products are available for sale worldwide.

ALVORD SYSTEMS INC., was founded in 2012, and is based in Clairton, Pennsylvania is a manufacturer of multi-blade packages, assemetery testers, and special aircraft tools for various industries. The company provides X-Ray diffraction single & double piezo goniometers, digital angle transfer sets, X-Ray detectors, and compound sine tables for the aviation, medical instrumentation, and, aerospace sectors. They also offer testing and measurement equipment, process measuring instruments, hand saw blades, and, industrial machinery, as well as comply with the U. S. Food and Drug Administration, American National Standards Institute for Safety, and the Commonwealth of Pennsylvania’s Department of Environmental Protection.

Angstrom Advanced Inc was founded in 2007 in Boston, MA, USA, and is a manufacturer of scientific instruments and Hydrogen plants for academic and industrial applications. The company provides X-ray diffractometers, lab gas generators, atomic force microscopes, hydrogen-generating plants, and scanning probe microscopes that have applications in renewable energy, nuclear power, atomic research, aerospace, and chemical energy sectors. They have received ISO 9001:2015 certification and were awarded in the arena of optical Instruments and Apparatus in the year 2010.

Thermo Fisher Scientific Inc., founded in 1956 and headquartered in Waltham, Massachusetts, is a manufacturer and supplier of life science solutions, analytical instruments, specialty diagnostics, laboratory products, and biopharma services. Through its brand names, including Invitrogen, Fisher Scientific, Patheon, Applied Biosystems, and Gibco, among others, the company provides a wide range of products, which include chromatography systems, thermal cyclers, automated cell counters, fermenters, and DNA polymerases. The company’s annual revenue is over 40 billion USD, and it serves several fields, including customers working in clinical diagnostic labs, research institutions, hospitals, government agencies, and pharmaceutical/biotech companies.

Verichek Technical Services, Inc was founded in 1992 and is based in Bethel Park, PA, is a supplier of metal analysis testing equipment & services to various industries. The company is certified to the ISO/IEC 17025:2005 quality system and provides optical emissions spectrometers, Ernst hardness testers, refurbished metal analyzers, temperature measurement instruments, and, adapters & electrodes for the metalworking, mining, material handling, construction, and, general engineering sectors. They also offer periodic-maintenance services, OES emergency repair, on-site and in-house positive metal identification, hardness testing, and, retained austenite measurement, as well as coating thickness testing, and, metal alloy analysis services.

Anton Paar, founded in 1933 and headquartered in Graz, Austria, is a manufacturer and supplier of analytical instruments Their product range includes density meters for measuring liquid and solid density, concentration meters for analyzing solution concentration, viscosity meters for assessing liquid viscosity, particle size analyzers for measuring particle size in liquids or solids, and chromatography systems for substance separation and identification in mixtures. Anton Paar's products cater to a wide range of industries, including food and beverage, pharmaceutical, and chemical, providing analytical solutions for diverse applications.

Rigaku Corporation is an ISO 9001-certified manufacturer and distributor of specialized analytical instruments that was founded in 1951 in Tokyo, Japan. The company produces various instruments that rely on x-ray technology for scientific and industrial analysis. Its products include x-ray diffraction (XRD) systems for analyzing powders or stress, x-ray topography systems for evaluating crystal quality, and x-ray reflectometry (XRR) systems for thin film thickness or density measurement operations. The company chiefly serves client manufacturers of semiconductors, biotechnology, and photovoltaics.

Proto Manufacturing Ltd. (PROTO) is a Canadian designer and manufacturer of x-ray diffraction (XRD) solutions established in 1967 and based in Windsor, Ontario. The company produces various XRD systems, including large-chamber, portable, modular and miniaturized models for material analysis, as well as x-ray sources for generating x-ray beams, detectors for capturing and processing, and software for in-depth analysis of XRD data used by clients in the mining, energy, defense, and aerospace industries.

Stresstech Bharat Pvt. Ltd., established in 1984 and based in Finland, is an ISO/IEC 17025 accredited manufacturer and supplier of non-destructive and destructive testing solutions. The company's product range includes xstress diffractometers, bark hausen noise equipment, prism 3, and x-ray diffraction equipment. These products are used for residual stress measurement, heat treatment verification, retained austenite measurement, and grinding burn detection. It primarily serves industries such as manufacturing, research institutes, universities, and material research. The company also provides measurement services, on-site customer support, data-driven quality control assessment, and measurement data reporting.

Ranking as of July 2025

Derivation Method| Rank | Company | Click Share |

|---|---|---|

| 1 | Angstrom Advanced Inc. |

18.2%

|

| 2 | ALVORD SYSTEMS INC. |

15.1%

|

| 3 | Verichek Technical Services, Inc. |

12.3%

|

| 4 | Proto Manufacturing |

8.7%

|

| 5 | Stresstech Bharat Pvt. Ltd. |

7.5%

|

| 6 | Shimadzu Scientific Instruments |

6.9%

|

| 7 | Spectory |

6.4%

|

| 8 | Anton Paar GmbH |

6.2%

|

| 9 | Bruker Corporation |

5.7%

|

| 10 | Thermo Fisher Scientific Inc. |

5.2%

|

Derivation Method

The ranking is calculated based on the click share within the x-ray diffractometer page as of July 2025. Click share is defined as the total number of clicks for all companies during the period divided by the number of clicks for each company.Number of Employees

Newly Established Company

Company with a History

*Including some distributors, etc.

*Including some distributors, etc.

| Country | Number of Companies | Share (%) |

|---|---|---|

United States of America

United States of America

|

7 | 70.0% |

Austria

Austria

|

1 | 10.0% |

Japan

Japan

|

1 | 10.0% |

India

India

|

1 | 10.0% |

32 products found

32 products

Pulstech Industry

620+ people viewing

Last viewed: 10 hours ago

feature Small, lightweight, non -destruction, high -speed measurement is realized. Efficient measurements can be performed by detecting diffractin...

Pulstech Industry

480+ people viewing

Last viewed: 13 hours ago

feature It is a scanner that detects "unevenness of hardness" on the surface of the steel material due to the world's first contact and non -destru...

Spectory

1230+ people viewing

Last viewed: 2 hours ago

■ Desktop type / X -ray diffraction device (XRD) AERIS (XRD), a desktop type X -ray diffraction device (XRD), has achieved data quality and data ac...

Spectory

470+ people viewing

Last viewed: 4 hours ago

■ Desktop type / X -ray diffraction device (XRD) AERIS (XRD), a desktop type X -ray diffraction device (XRD), has achieved data quality and data ac...

Spectory

570+ people viewing

Last viewed: 23 hours ago

■ Desktop type / X -ray diffraction device (XRD) AERIS (XRD), a desktop type X -ray diffraction device (XRD), has achieved data quality and data ac...

Spectory

590+ people viewing

■ Desktop type / X -ray diffraction device (XRD) AERIS (XRD), a desktop type X -ray diffraction device (XRD), has achieved data quality and data ac...

Spectory

550+ people viewing

Last viewed: 8 hours ago

■ Desktop type / X -ray diffraction device (XRD) AERIS (XRD), a desktop type X -ray diffraction device (XRD), has achieved data quality and data ac...

Cosmo Trading Co., Ltd.

270+ people viewing

Last viewed: 4 hours ago

The D8 ADVANCE is based on the D8 diffractometer series platform and is fully designed for all X-ray powder diffraction and scattering applications...

Cosmo Trading Co., Ltd.

260+ people viewing

Last viewed: 10 hours ago

D8 ADVANCE Plus is the ultimate X-ray platform for versatile, multi-user labs. The system perfectly matches the needs of all sample types, includin...

Cosmo Trading Co., Ltd.

310+ people viewing

Last viewed: 1 hour ago

World's first benchtop XRD platform: Supports powder X-ray diffraction (reflection method/transmission method arrangement), thin film measurement (...

Cosmo Trading Co., Ltd.

430+ people viewing

■Excellent data quality and outstanding ease of use D2 PHASER achieves both data quality and measurement speed, which was previously considered imp...

Cosmo Trading Co., Ltd.

230+ people viewing

Last viewed: 6 hours ago

■Specialized for powder XRD applications D8 ENDEAVOR is an X-ray diffraction system that offers simple operation, excellent detection accuracy, hig...

Bruker Corporation

520+ people viewing

Last viewed: 8 hours ago

■XRD equipment for quality control of compound semiconductors The Bruker QC3/QC-Velox instrument is designed specifically as an industrial XRD inst...

Bruker Corporation

440+ people viewing

Last viewed: 3 hours ago

■Crystal defect visualization device/X-ray topography The Bruker JV QCTT instrument is a comprehensive solution that provides crystal defect inspec...

Bruker Corporation

410+ people viewing

■Fully automatic/multipurpose XRD device for thin film analysis The Bruker JV-DX instrument is the latest instrument that can fully automate all me...

Cosmo Trading Co., Ltd.

290+ people viewing

Last viewed: 9 hours ago

The most versatile and flexible XRD solution. It covers applications such as research, development, and quality control, regardless of academic or ...

Cosmo Trading Co., Ltd.

310+ people viewing

Last viewed: 9 hours ago

The most powerful and accurate XRD solution. It covers a wide range of applications such as research, development, and quality control in academic ...

Cosmo Trading Co., Ltd.

260+ people viewing

The D8 ADVANCE ECO is a fully featured eco model of the D8 ADVANCE that is the entry point to the D8 diffractometer series platform. Today, the res...

Spectory

540+ people viewing

Last viewed: 19 hours ago

Multi -purpose X -ray scattering platform Empyrean Nano Edition is an X -ray scattering device for hybrid laboratory. The feature is that various ...

Spectory

540+ people viewing

Last viewed: 1 day ago

The newly developed Multicore Optics, which is mounted on the multi -purpose X -ray diffraction device EMPYREAN, has made it possible to measure a ...

Spectory

510+ people viewing

The Empyrean Alpha-1 is composed of a unique symmetric GE monocular light spectroscope (Johansson type), and provides a complete CU or CO Kα1 exclu...

Spectory

510+ people viewing

Last viewed: 11 hours ago

■ Thin film single crystal analysis X -ray diffraction device MalverN Panalytical's thin film single crystal analysis X -ray diffraction device (MR...