All Categories

History

This section provides an overview for steppers as well as their applications and principles. Also, please take a look at the list of 12 stepper manufacturers and their company rankings. Here are the top-ranked stepper companies as of February, 2026: 1.Anaheim Automation, Inc., 2.Lin Eng. Inc., 3.Changzhou Holry Electric Technology Co., Ltd..

Table of Contents

Categories Related to Steppers

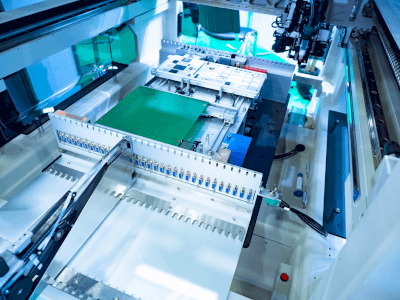

A stepper is a projection exposure system used in photolithography, the manufacturing process of semiconductors and liquid crystals.

As IC circuit patterns become finer and finer, it has become more difficult to create photomask patterns of actual size, and a stepper is an exposure system that uses the step-and-repeat method to expose mask patterns larger than the actual size in a reduced projection exposure. The step-and-repeat method means that when exposing semiconductor wafers or LCD substrates, the exposure area is divided into several sections, and once one section is exposed, the exposure is moved to the next section (step) and repeated (repeat).

A stepper is a type of exposure system that exposes the entire area to be exposed while stepping and repeating.

Steppers are used in the manufacture of semiconductors and liquid crystals, especially for exposure using masks in the photolithography process.

There are two types of stepper systems: the step-and-repeat system, which exposes wafers sequentially while stepping them because the area that can be transferred at one time is small; and the scanner system, which exposes wafers by scanning the reticle synchronously at a speed corresponding to the projection magnification. The latter is distinguished from steppers and is sometimes treated as a scanner.

Steppers uses a light source with a short wavelength to achieve high resolution in order to perform reduced projection exposures at high speed on large-diameter wafers and liquid crystals. The internal structure of steppers includes an exposure light source, projection lens, wafer stage, and wafer loader.

As the demand for large-scale integration of ICs increases, shorter wavelength exposure light sources are being used. In the 1990s, i-line light of 365nm was the principal light source. However, since then, shorter wavelengths such as Krf (wavelength: 248nm) and Arf (wavelength: 193nm) have been used.

A wafer stage is a stage that moves wafers at high speed in order to manufacture semiconductors such as ICs more quickly and with higher productivity. In addition to high-speed movement, high positioning accuracy is required for fine processing. The wafer loader is responsible for transporting wafers, such as removing wafers from the wafer stage and placing wafers on it.

Adhesion of foreign matter is a major enemy in IC manufacturing, and the sensitive wafers must be loaded and unloaded at high speed. Steppers are configured as shown above to perform sequential exposure while stepping wafers.

Due to the high demand for precision, steppers and scanner systems, these days are equipped with large-scale mechanisms, and the price per unit is increasing. Therefore, as the wiring process nodes become finer, it is not desirable to suddenly make major changes to light sources and equipment mechanisms. There is a tendency to try to master the use of these devices by improving them over several generations.

One of the technologies to achieve this is "immersion." Immersion refers to a method of increasing the exposure resolution of a light source by inserting a solution such as pure water between the resist on the wafer and the projection lens to shorten the wavelength of light compared to that in air. This is one of the technologies used in state-of-the-art photolithography processes.

Extreme ultraviolet lithography (EUV lithography) is the core of the next-generation exposure technology for the most advanced process nodes at a few nm, which can be exposed at a wavelength of 13.5nm, and is called extreme ultraviolet lithography. Although the world's leading semiconductor manufacturers are using this technology to compete in cutting-edge processes, as of 2022, only one company in the world has commercialized EUV lithography equipment.

*Including some distributors, etc.

Sort by Features

Sort by Area

Anaheim Automation is a manufacturer of motion control and automation products based in California since 1966. Their product list includes Stepper Motors and its Drivers, Controllers, Linear Actuators, and gearmotors that have applications in position control. There are also Brushless DC products, Servo motors, and systems, Integrated Circuits, AC Motors, and more that are necessary for equipment upgrades, process control, XY, and rotary tables, pump flow control, and material handling for industries that involve medical diagnostics, food, cosmetics, labeling, and robotics.

Lin Eng. Inc., established in 1987 and headquartered in Fremont, California, is a manufacturer, specializing in motion control solutions. Its product range encompasses stepper motors, including hybrid, PM, and integrated options, facilitating precise motion control. The company also offers a diverse selection of BLDC motors, from frameless to servo, ensuring smooth motion control. Additionally, provided too are motion control components such as drivers, controllers, encoders, and gearboxes, enabling the creation of customized motion control systems. The company keeps data with accordance to ISO9001:2015, AS9100D and many other standards, and its motors can be found in numerous FDA and FAA-approved applications.

Nanotec Electronic U.S. Inc., headquartered in the United States, has been an eminent manufacturer and supplier of motion control solutions for 30 years. The company specializes in developing superior motors, drives, and controllers that empower industries worldwide. Nanotec Electronic U.S. Inc. has forged a path of innovation in motion control technology. Their relentless pursuits revolve around delivering precision and efficiency to industries such as automation, robotics, and medical equipment manufacturing. Through steadfast devotion to cutting-edge solutions, they enable their clients to achieve enhanced performance and productivity.

DINGS' Motion USA, founded in 2008 in the United States, is a manufacturer and supplier of precision motion control products, focusing on linear and rotary positioning solutions. It offers a range of electromechanical solutions for various industries, including life sciences, medical, and laboratory applications. One of the company's unique offerings is the SERVOTRACK closed-loop stepper technology. The company has consistently provided precise linear motion solutions, with an emphasis on stepper linear actuators.

HOLRY MOTOR, founded in 2010 in China, is a motor manufacturer company. The company specializes in the design and production of brushless DC motors (BLDC), also known as Yongcheng synchronous motors, offering a diverse product line that includes standard and customized solutions for its clients. The company's brushless motors, such as servo motors, can automatically adjust the output power to adapt to load changes, which makes them suitable for various industrial applications.

MOON’s is headquartered in Shanghai, China. MOON’s is a manufacturer or motion control products. Among these products are stepper drives and motors, brushed and brushless DC motors, servo drives and motors, integrated motors, BLDC drives, lighting drivers and control products, and condition monitoring products. MOON’s has achieved ISO 14001 and ISO 9001 certification.

Oriental Motor USA Corp., established in 1978 and based in Torrance, California, is a manufacturer of motors and control systems and is ISO 9001 and ISO 14001 certified. The company stocks over 50,000 products that it sells worldwide, including actuators, motors, and controller products used in several industries like the medical, semiconductor, and factory automation industries. In 1983, the company developed brushless DC fans, and it later developed watertight, dust-resistant motors in 1990. In 1991, it came up with motorized linear slides and motorized cylinders.

Founded in New York in 1916, Kollmorgen designs and manufactures motion system, drives, motors, actuators, gear heads, automated guided vehicle (AVG) systems, and accessories across a number of implementations and industries. These include aerospace, AGV, food&beverage, machine tools, metal forming, medical automation and imaging, energy, packaging, pharmaceutical, postal sorting, printing, robotics, smart warehouses, and tire and rubber production. Kollmorgen assists customers both in custom designs and in allowing customers to design their own devices based on individual needs.

Ranking as of February 2026

Derivation Method| Rank | Company | Click Share |

|---|---|---|

| 1 | Anaheim Automation, Inc. |

39.1%

|

| 2 | Lin Eng. Inc. |

10.4%

|

| 3 | Changzhou Holry Electric Technology Co., Ltd. |

9.6%

|

| 4 | Nanotec Electronic U.S. Inc. |

8.7%

|

| 5 | Shanghai MOONS' Electric Co., Ltd. |

6.1%

|

| 6 | DINGS' MOTION USA |

5.2%

|

| 7 | Canon Electronics Inc. |

5.2%

|

| 8 | Kollmorgen Corporation |

5.2%

|

| 9 | ScaldoPack nv |

3.5%

|

| 10 | Tsubosaka Electric Co., Ltd. |

2.6%

|

Derivation Method

The ranking is calculated based on the click share within the stepper page as of February 2026. Click share is defined as the total number of clicks for all companies during the period divided by the number of clicks for each company.Number of Employees

Newly Established Company

Company with a History

*Including some distributors, etc.

*Including some distributors, etc.

| Country | Number of Companies | Share (%) |

|---|---|---|

United States of America

United States of America

|

4 | 50.0% |

China

China

|

2 | 25.0% |

Japan

Japan

|

2 | 25.0% |

30 products found

30 products

IPG Photonics Corporation

620+ people viewing

Last viewed: 1 hour ago

IPG's C-guns, pickers and handheld system steppers are used in combination with clamps and laser welding tools (up to 4kW) to replace resistance sp...

Izumiya Machinery Co., Ltd.

650+ people viewing

Last viewed: 5 hours ago

PCB (print circuit board) manufacturing exposure (with baking) device in a clean room. In the nanotechnology era, clean rooms require more precise,...

IPG Photonics Corporation

360+ people viewing

Last viewed: 1 hour ago

IPG's C-guns, pickers and handheld system steppers are used in combination with clamps and laser welding tools (up to 4kW) to replace resistance sp...

2 models listed

Union Optical Co., Ltd.

600+ people viewing

Last viewed: 51 minutes ago

■Summary This product is a space-saving mask aligner that is easy to handle, has high performance, and is low-priced, making it ideal for use in un...

Tsubosaka Electric Co., Ltd.

550+ people viewing

Last viewed: 50 minutes ago

■Features ・Simple exposure and printing equipment for photolithography process ・Tabletop type/integrated type saves space ・Equipped with color L...

Kyodo International, Inc.

590+ people viewing

Last viewed: 1 hour ago

The PhableR100 is a special device that uses the Talbot effect to expose periodic structures at a fine, single-shot exposure with a half pitch of 1...

IPG Photonics Corporation

670+ people viewing

Last viewed: 1 hour ago

IPG's C-guns, pickers and handheld system steppers are used in combination with clamps and laser welding tools (up to 4kW) to replace resistance sp...

Tsubosaka Electric Co., Ltd.

550+ people viewing

Last viewed: 51 minutes ago

■Features ・Exposure and printing equipment that guarantees parallelism ・Equipped with a 2kW ultra-high pressure mercury lamp ・Controlled by dedi...

Sanmei Co., Ltd.

400+ people viewing

Last viewed: 1 hour ago

■Three types of nanoimprint devices ・Small mold. nanoimprint stepper ・Batch full-scale transfer. All at once using a large mold ・Flat roll type....

IPG Photonics Corporation

410+ people viewing

Last viewed: 11 minutes ago

IPG's C-guns, pickers and handheld system steppers are used in combination with clamps and laser welding tools (up to 4kW) to replace resistance sp...

2 models listed

IPG Photonics Corporation

620+ people viewing

Last viewed: 5 minutes ago

IPG's C-guns, pickers and handheld system steppers are used in combination with clamps and laser welding tools (up to 4kW) to replace resistance sp...

Kyodo International, Inc.

550+ people viewing

Last viewed: 51 minutes ago

The Model 2000 is a fully automatic type device that can perform flood exposure or edge bead exposure. Shadow mask technology facilitates manufactu...

Kyodo International, Inc.

500+ people viewing

Last viewed: 1 hour ago

■PhableR 100 achieves high resolution below 300nm pitch ・PhableR 100 is a system based on EULITHA's proprietary exposure technology PHABLE (abbrev...

Sanmei Co., Ltd.

350+ people viewing

Last viewed: 51 minutes ago

High positional accuracy patterning on both top and bottom sides

Kyodo International, Inc.

510+ people viewing

Last viewed: 51 minutes ago

Model 6020 is a mask alignment exposure system suitable for large formats. Meets processing demands for flat panel displays and other large substra...

Kyodo International, Inc.

470+ people viewing

Last viewed: 51 minutes ago

The Model 6000 is a mask aligner system that is fully automatic, fully computer controlled, and features optical backside contact exposure. Through...

Kyodo International, Inc.

450+ people viewing

Last viewed: 51 minutes ago

The Model 800E semi-automatic double-sided mask aligner is a system in a hard package that combines optical double-sided alignment functionality. I...

Kyodo International, Inc.

410+ people viewing

Last viewed: 51 minutes ago

The Model 200 Mask Aligner is a tabletop device that is an affordable and simple system suitable for R&D and universities. ■Mask aligner A mask al...

Kyodo International, Inc.

350+ people viewing

Last viewed: 5 hours ago

A bench-top type R&D mask aligner suitable for medium-sized substrates up to 12”. ■Mask aligner A mask aligner is a device that uses ultraviolet l...

Ryokosha Co., Ltd.

500+ people viewing

Last viewed: 5 hours ago

■Features ・Manual exposure device ideal for other product types, small lot production, experiments, and research. (Effective exposure range φ6 inc...

Ryokosha Co., Ltd.

440+ people viewing

Last viewed: 5 hours ago

■Features ・All functions are compactly integrated ・Achieved 20% increase in takt time compared to our standard machine ・Two types of alignment m...

Sanmei Co., Ltd.

370+ people viewing

Last viewed: 50 minutes ago

Fully automatic exposure equipment for mass production process ■Features ・High versatility (compatible with 〇-type and □-type samples) ・Highly ...

Ryokosha Co., Ltd.

340+ people viewing

Last viewed: 50 minutes ago

■Summary We have exposure machines from various companies that can meet your needs.