All Categories

History

This section provides an overview for film thickness meters as well as their applications and principles. Also, please take a look at the list of 14 film thickness meter manufacturers and their company rankings. Here are the top-ranked film thickness meter companies as of January, 2026: 1.Semiconsoft, Inc., 2.Taijia Technology, 3.Automation Dr. Nix GmbH & Co. KG.

Table of Contents

Categories Related to Film Thickness Meters

1987~1991: Engaged in research on wire covering materials at Polymer Materials Laboratory.

1991~1997: Worked as a patent Engineer at Koike International Patent Office.

1997~2005 Worked as an intellectual property member at GE Yokogawa Medical System, currently working as a writer.

Linkedinhttps://www.linkedin.com/in/%E8%A3%95%E5%AD%90-%E9%88%B4%E6%9C%A8-92b21a234/

researchmap

https://researchmap.jp/0315rs2017

A film thickness meter is a device that measures the minute thickness of an object.

A film thickness meter is a device that measures the minute thickness of an object.

For example, it is used to examine thin films that are difficult to measure visually, such as the thickness of paint film or metal plating. There are several types of film thickness meters, and the measurement method is selected according to whether the object to be measured is light-transparent or not, and whether the measurement is done by contact or non-contact.

Film thickness meters are mainly used to measure the thickness of painted surfaces. Paint is applied to many everyday items such as home appliances, automobiles, etc., to maintain their durability as well as to maintain their aesthetics.

The thickness of the paint film must be appropriate and uniform. If the film thickness is not appropriate, i.e., if it is too thick, cracks may occur. If it is too thin, discoloration, loss of luster and deterioration of the substrate may occur. If the coating is not uniform, the durability may vary from place to place, making it impossible to maintain quality.

Therefore, a common method of quality control is to use film thickness meters to measure and control the thickness of the coated film on various items. There are various types of film thickness meters, and the appropriate device is used depending on the object to be measured. For example, when measuring the thickness of a transparent thin film, a spectral interferometer that uses a broadband light beam or an infrared film thickness meter that uses infrared light is used.

However, these methods cannot be used for metals because they do not allow light to pass through. When measuring metal plated thin films, electromagnetic film thickness meters that use changes in magnetic flux or eddy-current film thickness meters that use eddy-currents are suitable. In addition, non-contact film thickness meters, such as ultrasonic film thickness meters, are also used when it is difficult to make contact with the object to be measured.

Film thickness meters are available in a variety of measuring methods, and the appropriate device is used depending on the object to be measured. The following five methods are typical.

This is a film thickness meter that uses light interference. When light is incident on the object to be measured, light is reflected from the surface and the back of the thin film. These two reflected beams have a phase shift, and the shift is proportional to the thickness of the thin film. Waves are strengthened when they overlap in the same phase and weakened when they overlap in the opposite phase, making it possible to measure thickness by measuring the difference in interference.

This film thickness meter utilizes the absorption of infrared rays by the object to be measured. When an object is irradiated with infrared rays, certain wavelengths of infrared rays are absorbed depending on the material and thickness of the object to be measured. This property is used to measure the film thickness based on the spectrum obtained by spectroscopy of the transmitted or reflected light. If the relationship between the absorption rate of the material to be measured and the film thickness is measured in advance, the film thickness can be calculated.

This is a film thickness meter that utilizes changes in magnetic flux density. This measurement method is used when the object to be measured is formed on a metallic surface with magnetism, and utilizes the fact that the magnetic flux density changes when a magnet is brought close to the metal only or when a magnet is brought close to the object to be measured while it is on the metal. However, this method can only be used when the object to be measured is in contact with metal and the object is not metal.

The eddy-current film thickness meter uses the change in magnetic flux generated by a coil to measure the thickness of the object to be measured. When the coil is energized, magnetic flux is generated around the coil, and when the coil is brought close to the object to be measured, the magnetic flux changes according to the thickness of the object to be measured. The thickness of the object is measured by detecting this change in magnetic flux.

An ultrasonic film thickness meter is a film thickness meter that utilizes the reflection of ultrasonic waves. When ultrasonic waves are emitted from the surface of the object to be measured, they pass through the interior of the object to be measured and are reflected on the reverse side. The thickness can be measured from the time it takes for this reflection to occur.

For example, when measuring the thickness of a transparent thin film such as glass, a spectral interference film thickness meter using a broadband light beam or an infrared film thickness meter using infrared light is used. On the other hand, these film thickness meters cannot be used for thin films that do not transmit light, such as metals.

When measuring thin films of metal plating, electromagnetic film thickness meters that use changes in magnetic flux or eddy-current film thickness meters that use eddy-currents are used. In addition, non-contact film thickness meters, such as ultrasonic film thickness meters, are also used when it is difficult to make contact with the object to be measured.

Film thickness meters can be classified into three types: contact, non-contact, and cross-sectional observation.

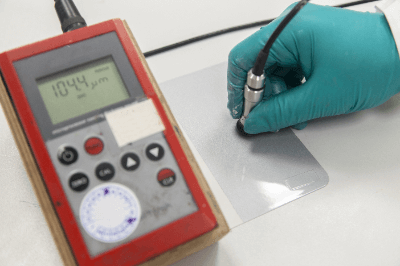

In contact-type film thickness meters, the sensor part is connected to the main body of the meter by a cable, and the sensor part is brought into contact with the object to measure the film thickness. Contact-type film thickness meters include the electromagnetic induction type, overcurrent type, ultrasonic type, and stylus type. The most orthodox type of film thickness meter can be purchased for several tens of thousands to 200,000 yen, depending on its performance.

Using a contact-type film thickness meter is simple; just place the sensor part against the substance to be measured, and a numerical value will be displayed. However, since the reaction speed varies depending on the substance, you may have to wait a few seconds for the sensor to react. Among contact-type film thickness meters, the electromagnetic induction type and the overcurrent type must be used depending on the substrate on which the measurement is to be made.

The electromagnetic induction type is used for magnetic materials such as iron and steel, while the overcurrent type is used for nonmagnetic materials such as aluminum and stainless steel. Dual types that measure with both methods are also available. The dual type can measure both magnetic and non-magnetic materials.

Non-contact film thickness meters emit light from the body of the meter and measure film thickness by detecting the interference of wavelengths of light reflected from the surface of the film and penetrating into the film as a spectrum. Basically, this form is used in places inaccessible to the human hand. Reflectance spectrophotometer, infrared spectrophotometer, capacitance spectrophotometer, and radiation spectrophotometer are available. Since a high-precision semiconductor device is used for the detection part, the price is higher than that of the contact type.

Cross-sectional film thickness meters are electron microscopes such as TEM and SEM. They are used to measure extremely small materials that cannot be measured with contact or non-contact methods. However, they are often used in research and technological development and are rarely employed in the field.

*Including some distributors, etc.

Sort by Features

Sort by Area

Fischer Technology, Inc., established in Windsor, CT in 1979 is a manufacturer of coating thickness and material testing instrumentation. Their product portfolio includes coating thickness gauges, material testing instruments such as hardness testers, adhesion testers, and gloss meters, adhesion testers, used for assessing the bond strength between coatings and substrates. The company serves markets including Electronics and Semiconductors, Marine and Offshore, Construction and Architecture and Quality Control. The company has a national distribution network and a customer support center.

Kett Electric Laboratory Co. Ltd., founded in 1946 with headquarters in Tokyo, Japan, is a manufacturer of precision measuring equipment and devices. The company's product line includes near-infrared grain testers, infrared moisture analyzers for wood, whiteness testers, water activity analyzers, and coating thickness electromagnetic probes. These products are used in laboratories and research facilities for the testing of materials and products, as well as in the field to measure the thickness of paint and undercoats. The company serves markets that include agriculture, pharmaceuticals, construction, and food processing.

Anton Paar, founded in 1933 and headquartered in Graz, Austria, is a manufacturer and supplier of analytical instruments Their product range includes density meters for measuring liquid and solid density, concentration meters for analyzing solution concentration, viscosity meters for assessing liquid viscosity, particle size analyzers for measuring particle size in liquids or solids, and chromatography systems for substance separation and identification in mixtures. Anton Paar's products cater to a wide range of industries, including food and beverage, pharmaceutical, and chemical, providing analytical solutions for diverse applications.

Hamamatsu Photonics K.K., established in 1953 and headquartered in Hamamatsu, Japan, is a manufacturer of sensors and emitters for both visible and invisible light. It stocks products like LEDs, lamps, and photodiodes used in several industries, including consumer electronics, dental imaging, and environmental monitoring. The sensor and light source components are also available as modules and units that can be incorporated into systems the company develops, like optical measurement systems or imaging systems. The ISO 9001-certified company stocks over 15,000 devices, units, and systems that ship to over 100 destinations worldwide, and it has ten research and production bases.

HUATEC Group, established in 2000, based in Beijing, China, is a reputable manufacturer and supplier of testing instruments. The company products portfolio includes a variety of metal and non-metal testing equipment, such as portable hardness tester, micro hardness tester, portable X-ray flaw detector, digital ultrasonic flaw detector, and ultrasonic thickness gauge, among others. Their employees include highly trained engineers for sales and services who offer satisfactory products and prompt services to home and abroad customers. The company has two sister factories located in the area of Beijing, Liaoning, Shandong, and Guangzhou.

Taiji Technology, established in 2002, based in Dalian, China, is a manufacturer and trader specialized in research, development and production of flow meters and level meters and other NDT testing equipment. The company’s products include ultrasonic flow meter, electromagnetic flow meter, vortex flow meter, ultrasonic level meter, rebar scanner, and thickness gauge, among others. Their products are used in various sectors ranging from field inspection, construction engineering, inspection, and testing. The company aims to provide after-sale service domestically and internationally.

Presto Group was founded in 1983 and is headquartered in Faridabad, Haryana, India. The ISO 9001:2015 certified company is a diversified manufacturer of paper, plastic, wiring, metallic, and other materials used in aerospace, automotive, computer component, plastics, and other industries. The company’s clients include Amazon, Coca-Cola, Pepsi, and Walmart. The company’s paper testing products include computerized box compression testers, stiffness testers, and others. The company also produces equipment for plastic manufacturing and molding, and painting, plating, and coating.

Automation Dr. Nix GmbH & Co. KG, established in 1968, is a German manufacturer based in Cologne. It specializes in crafting portable devices for measuring coating thickness on metal substrates, known for simplicity and high demand globally. The company meticulously produces the QNix series gauges in Germany, overseeing its complete development, production, and rigorous testing within its calibration laboratory. Each gauge comes with an accompanying test certificate, ensuring quality and durability. The company is geared towards continuous product improvement and providing great customer service.

Shenzhen Linshang Technology Co., Ltd., established in 2008 and headquartered in Shenzhen, China, is a manufacturer of measuring instruments. It specializes in five main categories of instruments, including solar film measurement, optical transmittance, ultraviolet measurement, gloss and coating thickness measurement, and thickness and hardness measurement. Some of its products include Solar Film Transmission Meters, Spectrum Transmission Meters, UV Energy Meters, Gloss meters, and Portable colorimeter. The company offers its products online, available through Aliexpress or Alibaba.

Elcometer Limited, established in 1947, has a global network of facilities and is a manufacturer in the UK and the USA of inspection equipment for the coatings, concrete, and NDT industries. The company's core portfolio of products covers four divisions: Blast, spray, coating inspections, and NDT equipment. Example products include industrial and commercial spray equipment used for protective coatings to meet OEM requirements, bodyshop spray equipment, and components used primarily to provide repair and customized work to the interior and body of passenger cars, trucks, vans, and trailers by their clients, including commercial, industrial, and OEMs.

SANKO ELECTRONIC LABORATORY CO.,LTD, established on August 1, 1963, and based in Kawasaki, Kanagawa, is a manufacturer and supplier of gauges and testing instruments. The company's product range includes Coating Thickness Meters, Moisture Meters, Pinhole Detectors, Needle Detectors, and Iron Piece Detectors. These instruments are used for measurements in various processes to ensure product quality. Industries such as manufacturing, electronics, construction, and safety use these products. In addition to manufacturing, the company offers services like customer support, product development, after-sales support, and client-specific solutions.

Caltech Instruments Pvt Ltd, established in 1998, is a manufacturer and supplier specializing in inspection equipment for coatings, corrosion, cathodic protection, and welding inspection equipment. The company consistently delivers quality products, coupled with superb customer experiences, at competitive prices in India, aligning with international standards such as ASTM, ISO, NACE, SSPC, DIN, BIS, and more. Along with its product range, the company also identifies and represents world-class manufacturers, expanding its supply capabilities and extending its reach globally, serving clients across various countries. It operates all its operations from its head office in Mumbai, India.

Semiconsoft, Inc., established in 2001, operates as a supplier of thin-film analysis software and services for semiconductor research and production, headquartered in Southborough, Massachusetts The company's journey is to offer solutions in the field of semiconductor Research and Development. With an eye on thin-film analysis, Semiconsoft has developed TFCompanion software, introduced in 2002. The company's devotion to the semiconductor industry is evident through its specialized software and services tailored to the needs of researchers and manufacturers, contributing to advancements in semiconductor technology.

Evident Corporation is a scientific research and development company in Shinjuku, Tokyo that was established in 2008. Formerly known as Olympus Scientific Solutions, the company specializes in developing cutting-edge technology and products for various industries, including aerospace, automotive, electronics, energy, and medical research. Evident Corporation has proliferated and expanded its product offerings and services to meet the needs of its customers. Their product offerings include non-destructive testing (NDT) solutions such as thickness gauges and automated inspection systems, XRF analyzers like handheld XRF analyzers, industrial microscopes, and video scopes and borescopes.

Ranking as of January 2026

Derivation Method| Rank | Company | Click Share |

|---|---|---|

| 1 | Semiconsoft, Inc. |

13.5%

|

| 2 | Automation Dr. Nix GmbH & Co. KG |

12.5%

|

| 3 | Elcometer Limited |

12.5%

|

| 4 | Fischer Technology, Inc. |

9.4%

|

| 5 | Taijia Technology |

8.3%

|

| 6 | Anton Paar GmbH |

7.3%

|

| 7 | Caltech Engineering Services, |

6.3%

|

| 8 | HUATEC Group |

6.3%

|

| 9 | Presto |

5.2%

|

| 10 | Evident |

5.2%

|

Derivation Method

The ranking is calculated based on the click share within the film thickness meter page as of January 2026. Click share is defined as the total number of clicks for all companies during the period divided by the number of clicks for each company.Number of Employees

Newly Established Company

Company with a History

*Including some distributors, etc.

*Including some distributors, etc.

| Country | Number of Companies | Share (%) |

|---|---|---|

Japan

Japan

|

4 | 36.4% |

China

China

|

2 | 18.2% |

India

India

|

2 | 18.2% |

United States of America

United States of America

|

1 | 9.1% |

Austria

Austria

|

1 | 9.1% |

Germany

Germany

|

1 | 9.1% |

165 products found - Page 4

165 products - Page 4

Hoshin Electronics Co., Ltd.

160+ people viewing

Last viewed: 16 hours ago

Transparent thin films such as silicon wafers are measured with high precision using light interference. ■Contents ・1 measuring head ・1 measurem...

Autex Co., Ltd.

230+ people viewing

Last viewed: 1 day ago

■Portable film thickness meter: simple, highly accurate, and affordable ・Simultaneous measurement of multilayer film thickness is also possible: T...

FTS Co., Ltd.

320+ people viewing

Last viewed: 1 day ago

The measurement principle is similar to thermal reflection, in which light is directed onto the object and the travel time of the heat is converted...

FTS Co., Ltd.

290+ people viewing

Last viewed: 13 hours ago

The measurement principle is similar to thermal reflection, in which light is directed onto the object and the travel time of the heat is converted...

MINO INTERNATIONAL LTD.

190+ people viewing

Last viewed: 3 hours ago

■Ideal for emulsion film thickness control The thickness of the emulsion film can be measured with high precision for more advanced printing.