All Categories

History

This section provides an overview for flux as well as their applications and principles. Also, please take a look at the list of 18 flux manufacturers and their company rankings. Here are the top-ranked flux companies as of March, 2026: 1.Continental Blower, LLC, 2.ISHIKAWA METAL Co.,Ltd., 3.Nordson Corporation.

Table of Contents

Categories Related to Flux

Flux is a soldering agent made mainly from resin.

Flux is an organic substance found in trees, most famously pine resin, which is a sticky liquid. The flux is made by mixing the resin with an activator.

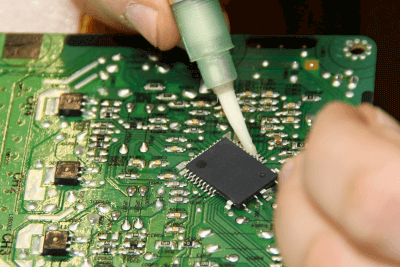

When electronic components are mounted on a circuit board, a soldering iron is used to melt a long, thin piece of metal called solder to form a joint.

Flux is mixed with this solder.

If the flux is not used, not only will the product not be completed, but it will also result in a large number of defective products, which could lead to an accident.

The main use of flux is for bonding electronic components.

If you look at an electronic circuit board, you will see many rounded pieces of silver metal. This metal is solidified from the solder that has been melted by heat, and flux is added to the solder to keep it from oxidizing and forming.

There are also fluxes for joining metals, which are mixed with solder when metals are soldered together.

There is also flux for stainless steel. Stainless steel forms a passive film on its surface. A flux is used to remove this passive film.

The number one feature of flux is that it allows the solder to form on the electronic board without degrading its quality.

When solder is melted, the work area is often at room temperature, and the melted solder is highly heated. This causes the metal surface of the melted solder to oxidize, resulting in defective electronic substrates.

The role of flux is to inhibit the oxidation of solder, and a film of flux is formed to cover the metal surface.

In addition, the solder itself has high surface tension and quickly becomes spherical when melted in the normal way. To prevent this from happening, flux is added to lower the surface tension of the solder.

On the other hand, the disadvantage of flux is that it remains attached to the solidified metal and remains on the electronic board.

Since flux is intended to condition the basic solder, it is unnecessary once the solder has solidified successfully.

However, if flux remains, the PCB will be defective, and the PCB will need to purchase a special cleaning agent to remove it, or consider the use of a large cleaning machine.

*Including some distributors, etc.

Sort by Features

Sort by Area

Nordson Corporation, established in 1954 and headquartered in Westlake, Ohio, USA, is a global manufacturer and marketer of differentiated products for precision dispensing and processing. They cater to diverse end markets, including packaging, electronics, medical, energy, and transportation. With over 6,800 employees across more than 35 countries, Nordson offers solutions for bonding, adhesive dispensing, fluid management, test and inspection, and UV curing. Their product line includes dispense tips, syringe barrels, dispensers, srapy valves, fluids, and syringe systems among others. Comprised of eight divisions, they are ISO 9001:2015 certified and provide systems, precision technology, and after market parts.

Senju Metal Industry Co., Ltd. (SMIC) is a manufacturer of soldering systems, factory automation (FA) equipment, and slide bearings based in Adachi-ku, Tokyo. The company was founded in 1938 and produces various soldering solutions and materials for applications in aerospace, electronics, automotive and medical technology. The company's specialized product lineup includes wave, laser, reflow, and micro soldering systems, as well as FA equipment like pureloy wires and spray fluxes. SMIC's client corporations include Intel, Philips, and NASA.

KOKI Company Limited, established in 1952, is a Japan-based manufacturer of soldering materials for the electronic and electrical industries, located in Adachi, Tokyo. Their products include solder paste, wave soldering flux, tack flux, flux-cored solder wire, and heat-curable SMT adhesive for power semiconductor devices. These products enable efficient soldering processes, ensuring secure connections between components and PCBs. KOKI Company Limited has been awarded Green Accreditation by Mitsubishi Electric Group, receiving a Rank A certification based on their Green Accreditation standards. They have also been awarded the Technology Development Award by Fujitsu Ten for their contribution to developing functional solder paste.

Indium Corporation, established in 1996, is an ISO 9001:2015 certified manufacturer and supplier of advanced electronics assembly materials solutions. The company provides solder and thermal management products for over 3,000,000 electric vehicles. Their products are used in essential markets such as medical equipment, fire suppression, transportation, automotive, defense, and emergency communication devices. They have facilities across the Americas, Asia/Pacific, China, and Europe, with multiple licenses and certifications in each. Their wide range of products includes solder paste, thermal interface materials, fluxes, die-attach materials, and more.

ESAB, founded in 1904 and headquartered in Maryland, United States, is a manufacturer of welding as well as cutting equipment and consumables. It manufactures accessories and consumables, arc welding equipment, cutting automation, filler metals, and gas equipment. Moreover, it offers manual plasma cutting, PPE/Safety, robotics, torches, and welding automation. For arc welding, Fabricator EM 400i, for instance, is ideal for heavy industries due to the use of solid and flux-cored wires together with fabricator feed. ESAB has earned ISO 9001, ISO 14001, and the Occupational Health and Safety Advisory Services 18001 certifications.

Detroit Torch & Mfg. Co. is a manufacturer of cutting torch and welding systems established in 2014 and based in Rochester Hills, Michigan, USA. The company specializes in torches, components, and related accessories used for cutting or welding various metals. Its product line includes complete torch kits, gas flow regulators, and DHC2000 torches for cutting or welding operations. The company also offers additional repair and warranty services for its torches and torch parts. Its products are mainly used in jewelry making, automotive repair or restoration, and metal fabrication processes.

Caig Laboratories, Inc., established in 1956 and headquartered in Poway, California, is a manufacturer specializing in electronic chemicals. Its product range encompasses cleaners, lubricants, enhancers, as well as preservatives, and accessories tailored for electronic, electrical, and mechanical applications. These cleaners are designed to effectively clean electronic components, while its lubricants reduce friction between moving parts in electronic devices. The company also offers cleaning brushes, pen tips, and straws to complement its chemical products.

Kurz Ersa has been a manufacturer of machines since 1779 and is based in Kreuzwertheim, Germany. The company operates across diversified business areas, encompassing Electronics Production Equipment, Casting Solutions, Particle Foam Processing, Automation, and Additive Manufacturing. In the realm of Electronics Production Equipment, they offer soldering machines and tools, the Casting Solutions division specializes in light metal casting techniques, and the Particle Foam Processing provides solutions for molded parts. Automation is another domain in which they provide technological solutions. Their expertise in Additive Manufacturing allows delivering of metal 3D printing solutions.

We, Ishikawa Metal was founded in 1935 and since from the start we eagerly set our mind to produce solder products. In our history, so many unique products were developed and have been approved by many customers. Our developing concept is inquiry-based development to fulfill each customer’s requirement.

Techsil Ltd., founded in 1989 and headquartered in Bidford-on-Avon, United Kingdom, is a distributor of industrial adhesives, sealants, tapes, and UV curing equipment, and operates as a division of Diploma PLC. The company offers a comprehensive range of products from various renowned brands, including ThreeBond, Power Adhesives, and BJB Enterprises. As an ISO 9001-certified entity, it provides additional services such as contract gasketing, repacking, and tape conversion. With an extensive inventory of over 2000 products, Techsil Ltd. collaborates with engineers to streamline production processes across diverse industries, including energy, aerospace, and electronics.

Ranking as of March 2026

Derivation Method| Rank | Company | Click Share |

|---|---|---|

| 1 | Continental Blower, LLC |

14.3%

|

| 2 | ISHIKAWA METAL Co.,Ltd. |

11.3%

|

| 3 | Nordson Corporation |

8.7%

|

| 4 | SUPERIOR FLUX & MFG. CO. |

6.5%

|

| 5 | International Chemicals And Metals. |

5.6%

|

| 6 | Aufhauser Corporation |

5.6%

|

| 7 | ESAB |

5.6%

|

| 8 | SENJU METAL INDUSTRY CO., LTD. |

5.6%

|

| 9 | Detroit Torch & Mfg. Co. |

5.2%

|

| 10 | Kurtz Ersa |

5.2%

|

Derivation Method

The ranking is calculated based on the click share within the flux page as of March 2026. Click share is defined as the total number of clicks for all companies during the period divided by the number of clicks for each company.Number of Employees

Newly Established Company

Company with a History

*Including some distributors, etc.

*Including some distributors, etc.

| Country | Number of Companies | Share (%) |

|---|---|---|

United States of America

United States of America

|

4 | 44.4% |

Japan

Japan

|

3 | 33.3% |

India

India

|

2 | 22.2% |

64 products found

64 products

Toyo Souzai Co., Ltd.

440+ people viewing

Last viewed: 1 day ago

■How to use ・Before brazing, apply this agent sufficiently to the area to be heated using a brush. ・After work, residue will remain on the metal ...

Ijima Precious Metals Refining Co., Ltd.

420+ people viewing

Last viewed: 1 day ago

There is a ``paste type'' that can be used immediately, and a ``powder type'' that allows you to melt and use only the amount you need when you nee...

Metal Welding Materials Co., Ltd.

400+ people viewing

Last viewed: 1 day ago

Flux is an essential product for atmospheric brazing. Removes the oxide film on the base material to protect the surface and improve wettability. ...

11 models listed

Denka Company Limited

500+ people viewing

Last viewed: 1 day ago

■Summary This is a sintered type synthetic flux that exhibits highly efficient desulfurization and deoxidation ability, applying the steel additive...

Matsuo Handa Co., Ltd.

470+ people viewing

Last viewed: 1 day ago

Reduces solder balls and enables stable printing. Contributes to reducing waste solder paste. ■ Significantly reduces solder balls By suppressing ...

Aoki Metal Co., Ltd.

450+ people viewing

Last viewed: 1 day ago

A paste-like soldering solvent. Although it does not contain zinc chloride, it can be used for soldering as strong as zinc chloride. This product ...

Metal Welding Materials Co., Ltd.

340+ people viewing

Aluminum brazing is possible with the cesium-containing flux kneaded into the wire. (Standard product dimensions 1.6φ to 3.0φ) ■Applications/Featu...

Toyo Souzai Co., Ltd.

220+ people viewing

Last viewed: 7 hours ago

We would like to introduce aluminum solder flux.

6 models listed

K-World Ltd.

470+ people viewing

Last viewed: 1 day ago

■Features ・Ideal for chip parts and fine pitch soldering. - Easy to replace flexible brush tip. ・1 set of 5 pieces

Metal Welding Materials Co., Ltd.

510+ people viewing

Last viewed: 1 day ago

Silver soldering is possible with the flux coated on the silver soldering rod. (Core wire 1.5φ×500L [2.55φ×500L including flux coating]) ■Applicat...

K-World Ltd.

240+ people viewing

Last viewed: 3 hours ago

Ideal for flat IC soldering, connector retrofitting, alcohol cleaning, etc. 1 set of 5 pieces

2 models listed

Metal Welding Materials Co., Ltd.

360+ people viewing

Last viewed: 12 hours ago

Silver brazing is possible with the flux filled in the wire. (Standard product dimensions 0.6φ to 2.0φ) ■Applications/Features ・No need to apply ...

P-One Shop

420+ people viewing

■Applications Water piping, refrigerant refrigeration piping, air conditioning equipment, electrical equipment, construction materials, etc. ■Main...

P-One Shop

460+ people viewing

■Main ingredient Zinc chloride, ammonium chloride, hydrogen bromide metal salts, etc. ■Characteristics ・Specific gravity 1.32, active temperature...