All Categories

History

This section provides an overview for uv curable adhesives as well as their applications and principles. Also, please take a look at the list of 20 uv curable adhesive manufacturers and their company rankings. Here are the top-ranked uv curable adhesive companies as of July, 2025: 1.Parson Adhesives, Inc., 2.Perigee Direct, 3.Panacol-Elosol GmbH.

Table of Contents

UV curable adhesives are adhesives that cure by irradiation of ultraviolet light.

They are also called UV (ultraviolet) curable adhesives. Compared to general dry-curing adhesives, they are characterized by their excellent quick curing properties and small volume change during curing. In addition, since it does not require the application of heat, it is suitable for use with plastic materials with low heat resistance.

On the other hand, it is not suitable for use in intricate and complicated structures because it cures only the part irradiated by ultraviolet rays. Also, if many adhesives are used, they may not cure sufficiently.

Advantages of UV curable adhesives include instant curing, high bonding strength, transparency, weather resistance, heat resistance, and chemical resistance. They are also considered environmentally friendly because they do not contain solvents.

However, UV irradiation equipment is required for use. In addition, areas that UV light does not reach will not be cured.

Bonding printed circuit boards, fixing components, protecting wires, assembling liquid crystal displays, etc.

Bonding and reinforcing glass, assembling lenses and prisms, connecting optical fibers, etc.

Manufacturing headlights and taillights, fixing interior components, bonding emblems, etc.

Dental filling materials and cement, assembly and repair of medical equipment, etc.

Bonding and molding of synthetic resins and plastics, repair of molded products, etc.

Adhesion of metals, glass, and stones, repair of ornaments, etc.

UV curable adhesives contain ingredients such as monomers, oligomers, photoinitiators, and additives. When UV light is irradiated on UV curable adhesives, the photoinitiator absorbs the UV light and generates radicals, cations, or anions, depending on the type of photoinitiator.

Depending on the polymerization species generated by the initiator, radical polymerization, cationic polymerization, or anionic polymerization causes monomers and oligomers with small molecular weights to combine with each other to form polymers with large molecular weights, which is the curing mechanism.

The radical polymerization type has a fast curing speed and is widely used in general. Compared to the cationic and anionic polymerization types, it is easier to synthesize monomers and oligomers, making it possible to change the composition of the resin according to the required performance.

On the other hand, the cationic polymerization type and anionic polymerization type are characterized by small shrinkage during curing, and are effective in cases where the material cannot be shaped by pressurizing or where precision is required.

UV curable adhesives can be made with various characteristics depending on the type of monomer that makes up the adhesive. The monomers included in UV curable adhesives are listed below.

Examples of acrylic monomers used in UV curable adhesives include monofunctional acrylates and multifunctional acrylates, such as bifunctional and trifunctional.

Compared to bifunctional and trifunctional acrylates, monofunctional acrylates have fewer polymerization reaction sites, which reduces the cross-link density of the resin. This can be expected to reduce the viscosity of the resin and increase its polymerization reactivity.

It is used to adjust the properties of adhesives by mixing with other monomers or oligomers, rather than using alone.

They can create a two-dimensional crosslinked structure, which improves the strength of the adhesive. They can also increase solvent resistance and hardness. These acrylates have many reaction sites and cures in a short time, making them efficient in terms of workability.

However, if too much bifunctional or trifunctional acrylate is added, the overall polymerization rate may be poor because of the large number of reaction sites involved. In addition, the shrinkage of the adhesive during the polymerization reaction becomes larger, which may cause problems, such as poor adhesion to the base material or curvature of the base material.

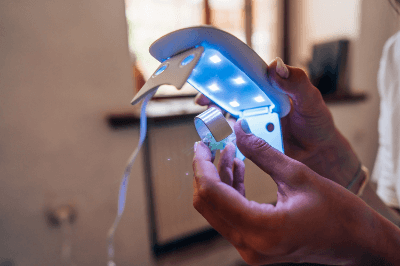

As with widely used heat-curing adhesives, apply an appropriate amount to the desired area. Next, using a UV light or other UV irradiation device, irradiate UV light to the area where the adhesive has been applied, and curing will begin immediately.

The curing reaction is completed in a short time, and the adhesive is bonded. As you can see, UV curable adhesives are very easy to use, so anyone can easily use them.

There are two main points to note when using UV curable adhesives: First, the irradiation intensity of the UV light used must be set appropriately. If the intensity is high, the curing reaction of the adhesive proceeds quickly, but if it is excessive, the curing reaction proceeds only on the surface of the adhesive and the interior may not cure sufficiently.

As a result, there is a possibility that the adhesive strength will become small. If the intensity is too small, the amount of radicals generated by irradiation is small and may react with oxygen in the air, resulting in inadequate curing.

Second, it is necessary for the UV light to reach the point where the adhesive is applied. Due to the characteristics of adhesives, most of the areas where they are applied are intricate or between items to be bonded. Therefore, the ultraviolet rays necessary for curing do not reach the adhesive, and curing may be insufficient. It is necessary to devise a way to ensure that the UV light is irradiated firmly to the area where the adhesive is applied.

*Including some distributors, etc.

Sort by Features

Sort by Area

Perigee Direct, established in 2006 in North Richland Hills, Texas, USA, is a manufacturer and supplier of specialty consumables tailored for the science and industrial sectors. The company offers a diverse range of optimal-quality products, including laboratory consumables, industrial adhesives, filtration solutions, plastic welding materials, and precision cleaning supplies. These products are used for superior quality, precision, and stability, ensuring consistent and accurate results in various applications. The offerings serve a broad array of industries, including research laboratories, pharmaceuticals, manufacturing, electronics, and aerospace. Some featured products include Loctite, Devcon, Royal Hardman, 3M, and Nordson.

Dymax Corporation was founded in 1980 and is headquartered in Torrington, Connecticut. The company develops and manufactures rapid and light-curable materials and light-curing systems for the medical, consumer electronics, wearables, aerospace, and automotive electronics industries. The company’s product segments include Light Curable Materials, Light-Curing Equipment, and Dispensing Equipment. Light Curable Materials include masking, gasketing, and activators. Light-Curing Equipment includes conveyor systems, flood-curing systems, and radiometers. Dispensing Equipment includes dispense valves, syringe dispensers, and material reservoirs. The company also offers application engineering, equipment, and system integration services.

Parson Adhesives, Inc. is a manufacturer of industrial and engineering adhesives, headquartered in Rochester, Michigan, and produces its products in Evansville, Indiana. The company’s products include anaerobic adhesives, composite and metal bonding adhesives, cyanoacrylate adhesives, UV-curable adhesives, etc. These products are ideal for Glass, Sign and Display, Plastic Products, Wood, and Pipe Sealants. It has over 2500 customers from the automotive, general assembly, electronics, etc, in 52 countries. The company is 100% US-based, with two joint ventures in India and China.

3M Company was founded in 1902 and is headquartered in St. Paul, Minnesota. 3M provides diversified technology services globally. 3M operates through four segments: Safety and Industrial, Transportation and Electronics, Health Care, and Consumer. The Safety and Industrial segment offerings include industrial abrasives, masking, and natural and color-coated mineral granules for shingles. The Transportation and Electronics segment offerings include ceramic solutions, light management films, and electronics assembly solutions. The Healthcare segment offerings include wound care, dentistry and orthodontia solutions, and filtration and purification systems. The Consumer segment offerings include consumer bandages, picture hanging, and stationery products.

ThreeBond International, Inc. is a manufacturer of industrial adhesives, sealants, and coating established in 1997 and headquartered in Cincinnati, OH. The adhesives include anaerobic adhesives, functional heat-resistant adhesive sheets, cyanoacrylate instant adhesives, acrylic structural adhesives, and instant adhesives. The sealants are liquid gaskets, silicone RTV sealants, and polymer sealants. The company also has degreasing agents and cleaners for industrial brakes & parts and offers pre-coated nuts and bolts. The ISO 9001 and 14001-certified company serves the automotive manufacturing, fuel cell, electronics, nail care, and medical industries.

Master Bond, Inc., founded in 1975 and has its headquarters in Hackensack, New Jersey, is a manufacturer specializing in adhesives, sealants, coatings, and potting compounds. Their offerings are used for bonding, sealing, encapsulating, and coating applications in which their products cater to industries such as aerospace, automotive, electronics, medical, and oil and gas providing durability, chemical resistance, thermal conductivity, and electrical insulation. Master Bond maintains stringent quality standards and is ISO 10993-5 certified, ensuring technologically advanced solutions for their customers' industrial needs.

Henkel Corporation is an American manufacturer specializing in sealants, adhesives, and coatings since its establishment as a subsidiary of German multinational company Henkel AG & Co. KGaA in 1974. Based in Rocky Hill, Connecticut, the company produces various oleochemicals, surfactants, and chemical intermediates used in the production of brand name industrial adhesives, skincare, and surface treatment products. Some of these include Technomelt, Purex, Bonderite, and Loctite. Henkel Corporation is divided into separate Adhesive Technologies, Beauty Care, and Laundry & Home Care business units. The company primarily supplies the product formulation needs of clients in the consumer goods and industrial sectors.

Permabond LLC, founded in 1978, is a manufacturer based in Pottstown, Pennsylvania, specializing in adhesive technologies. The company's portfolio includes anaerobic adhesives and sealants, and modified epoxy and modified silicone (MS) polymer adhesives. Additionally, the company offers single and two-part epoxy adhesives, structural acrylic adhesives, and ultraviolet (UV) light adhesives. These adhesive find application in various industries, serving the manufacturing of agricultural and construction machinery, electric vehicles (EVs), and lighting. Moreover, the company provides its adhesive technologies to sectors like aerospace, automotive, electronics, medical devices, and transportation. It also operates Blue Center Innovation Technologies, a laboratory for research and product development.

Tesa SE, established in 2001, is a developer and manufacturer of adhesive tapes and self-adhesive product solutions for various industries, commercial customers, and end consumers. The products include furniture, surface protection, security labeling, interior mounting, and mirror assembling are used for bonding products in the automotive, builiding, medical, printing, and appliances industries. Headquartered in Hamburg, Germany, the company operates in 100 countries and operates additional plants in Germany, Italy, China, and the USA, and is in the process of opening another in Vietnam.

Muromachi Chemicals Inc., founded in 1917 and headquartered in Fukuoka, Japan, is a manufacturer and supplier of pharmaceuticals, chemicals, and health foods. The company holds licenses for pharmaceutical manufacturing and sales, ensuring the quality and safety of pharmaceutical raw materials, including APIs, intermediates, and additives. Additionally, it provides services for intermediate and API development, as well as the synthesis of labeled compounds for pharmaceutical and agricultural applications. Furthermore, the company offers customized water treatment systems, covering both water purification and wastewater treatment, to meet the specific needs of its customers.

Denka Company Limited, founded in 1915, is a Japanese chemical manufacturer headquartered in Chuo City, Tokyo. The company offers a range of products made with the technology of fine ceramics and organic fine chemicals, such as adhesives, fluorescent materials, functional films, and heat dissipation materials. They also produce automotive parts, belts, hoses, electric wires and cables, and rubber gloves using chloroprene rubber. Additionally, Denka provides products made of polymer solutions, such as food packaging materials, building materials, and electric home appliances. In 2022, Denka launched the New Business Development to develop products and technologies in ICT and energy, healthcare, and sustainable living.

DIC, established in 1908 in Japan, is a manufacturer and supplier of printing inks, organic pigments, and PPS compounds. The company's product portfolio includes different printing inks, such as offset inks used for quality printing, gravure inks for packaging materials, and UV-curable inks for various applications. They also offer organic pigments used in automotive coatings, and PPS compounds, used in electronic and automotive components. DIC's products are used in industries like automotive, electronics, food, and housing. They provide quality products and services that meet societal needs while addressing local and global challenges.

Through its subsidiaries, Heraeus Group serves many industries around the world including green power generation, telecommunications, agriculture, aerospace, medical, jewelry, and environmental protection. Heraeus Group companies create products including fiber optics, ceramics, custom metals, surgical equipment, special purpose lamps, and photovoltaics.

Panacol-Elosol GmbH was established in 1978 and is headquartered in Steinbach, Hessen, Germany, as a manufacturer and provider of industrial and medical-grade adhesives. The company's product list comprises Vitralit, Elecolit, Structalit, Penloc structural glue from Panacol, and Cyanolit, among others. The adhesives have a wide range of applications, from bonding in electronics and smart cards to display bonding, optics, and medical-grade adhesives, while also functioning as liquid gaskets or UV mask materials. The company caters to various industries, including electronics, optoelectronics, medical, automotive, and luxury packaging.

Dexerials Corporation is a Japanese manufacturer and supplier of electronic materials and components for a wide range of industries, including automotive, consumer electronics, and telecommunications. Established in 2012 as a result of a merger between Sony Chemical & Information Device Corporation and Toshiba Ceramics Co., Ltd. The company offers products such as adhesives, coatings, films, tapes, and thermal management materials, among others. One of their primary products is the Dexerials thermal management material, which is a highly efficient solution for thermal management in electronic devices. It is designed to dissipate heat generated by electronic components.

DeepMaterial Co. Ltd., based in Shenzhen, China, is an ISO 9001 and ISO 14001-certified industrial adhesive manufacturer for semiconductor and electronic applications. Its products include conductive silver glue for chip bonding, UV moisture dual curing adhesive, and epoxy underfill adhesives, and it also provides customized adhesive services. It also offers thin-film electronic application materials and solutions such as protective films, semiconductor fillers, and packaging materials used by consumer electronics, communication terminals, and semiconductor companies. The company has passed the GB/T 29290 intellectual property management system and applies for over 50 invention and utility model patents each year.

Sekisui Chemical Co., Ltd., founded in 1947 is a manufacturer of plastics categorized into printed circuit boards, films, foams, powder aqueous, and sheets headquartered in Minato-ku, Tokyo, Japan. The company offers products used for adhesion & bonding, waterproofing & dustproofing, GAP Control, thermal management, and conductivity on various devices including electronic components, LEDs, camera modules, power devices, OLED & mini/μLED. Its products are used in smartphones & tablets, automotive electronics, home appliances, drones & industrial machineries, and wearables.

TORAY FINE CHEMICALS CO. LTD., founded in January 1932 and located in Chiba, Japan, is a manufacturer and supplier of fine chemical products. The company’s product line includes polysulfide polymer, medicine intermediates, rubber additives, and chemicals used for electronic materials. It also produces dimethyl sulphoxide, which cleans and releases agents. The company is ISO-certified, ensuring that its products meet the quality standards. It also has a subsidiary, Cangzhou Toray Fine Chemicals Co., Ltd., located in China.

TOAGOSEI CO., LTD, founded in Nagoya, Japan in 1944 is a manufacturer of commodity chemicals, adhesive materials and plastics. The company's product portfolio includes Acrylic acid used as a raw material in acrylic polymers, Synthetic hydrochloric acid, Sodium hypochlorite and Liquid chlorine, Their products find application in the disinfection of water, sewerage and pool, pulp bleaching, food industries, water and wastewater treatment, and ballast water purification. Their products are used in industries such as Food and Beverage , Pharmaceutical and Biotechnology, Chemical and Petrochemical, Environmental Testing and healthcare.

Ranking as of July 2025

Derivation Method| Rank | Company | Click Share |

|---|---|---|

| 1 | Parson Adhesives, Inc. |

11.9%

|

| 2 | Perigee Direct |

9.1%

|

| 3 | Panacol-Elosol GmbH |

6.7%

|

| 4 | DeepMaterial Co., Ltd. |

5.5%

|

| 5 | SEKISUI CHEMICAL CO., LTD. |

5.2%

|

| 6 | DYMAX |

5.2%

|

| 7 | Denka Company Limited |

5.2%

|

| 8 | Heraeus Holding GmbH |

5.2%

|

| 9 | Norland Products Inc. |

4.9%

|

| 10 | Master Bond, Inc. |

4.9%

|

Derivation Method

The ranking is calculated based on the click share within the uv curable adhesive page as of July 2025. Click share is defined as the total number of clicks for all companies during the period divided by the number of clicks for each company.Number of Employees

Newly Established Company

Company with a History

*Including some distributors, etc.

*Including some distributors, etc.

| Country | Number of Companies | Share (%) |

|---|---|---|

United States of America

United States of America

|

9 | 52.9% |

Japan

Japan

|

5 | 29.4% |

Germany

Germany

|

3 | 17.6% |

21 products found

21 products

Candil Design Co., Ltd.

240+ people viewing

Last viewed: 34 minutes ago

■Quickly repair cracks, cracks, and chips ・Because it is a solvent-free resin, there is no fading after filling. ・Ultraviolet curing type that dr...

Candil Design Co., Ltd.

220+ people viewing

Last viewed: 8 hours ago

■Quickly repair cracks, cracks, and chips ・Because it is a solvent-free resin, there is no fading after filling. ・Ultraviolet curing type that dr...

Denka Company Limited

280+ people viewing

Last viewed: 3 hours ago

Overview ■OP series This is an ene-thiol resin-based optical UV-curable adhesive created using our proprietary technology. It has excellent optical...

Fastener Industry Co., Ltd.

240+ people viewing

Last viewed: 4 hours ago

Loctite UV-curable adhesives, developed using Loctite's unique special resin synthesis technology and compounding technology cultivated through hig...

Fastener Industry Co., Ltd.

190+ people viewing

Last viewed: 4 hours ago

Loctite UV-curable adhesives, developed using Loctite's unique special resin synthesis technology and compounding technology cultivated through hig...

CEMEDINE Co.,Ltd

280+ people viewing

Last viewed: 4 hours ago

■Features ・Fast curing due to radical curing ・Flexible mechanical properties ・Excellent surface hardening properties ・Excellent adhesion to var...

Gengen Chemical Industry Co., Ltd.

230+ people viewing

Last viewed: 4 hours ago

■Features ・Because it is a solvent-free resin, there is no fading after filling. ・Ultraviolet curing type that dries very quickly ・Low voltage a...

Gengen Chemical Industry Co., Ltd.

230+ people viewing

Last viewed: 4 hours ago

■Features ・Because it is a solvent-free resin, there is no fading after filling. ・Ultraviolet curing type that dries very quickly ・Low voltage a...

Fine Sensing Co., Ltd.

270+ people viewing

Last viewed: 4 hours ago

■Features ・It does not cure until exposed to UV light, and cures quickly when exposed to UV light (faster than circulating adhesives) ・No heating...

Fine Sensing Co., Ltd.

290+ people viewing

Last viewed: 8 hours ago

■Features ・Highly flexible grades available ・No mixing required, can be cured in less than 30 seconds at room temperature ・A wide variety of cho...

Protech Engineering Co., Ltd.

190+ people viewing

Last viewed: 4 hours ago

■Summary In addition to selling screen mask manufacturing equipment, PROTEC also introduces "screen mask peripheral materials." These items have a ...

Würth Elektronik

250+ people viewing

Last viewed: 4 hours ago

■Features ・High output UV LED ・Low thermal resistance ・Standard soldering pad footprint ■UV-A ・UV curing ・Printing/Coating Adhesive ・Counter...

Nagase ChemteX Co., Ltd.

380+ people viewing

Last viewed: 1 hour ago

Our lineup includes high purity, clean room compatible, soft types with good heat shock resistance, and hard types with good heat resistance and du...

Reginas Kasei Co., Ltd.

190+ people viewing

Last viewed: 4 hours ago

This is an adhesive that instantly cures under ultraviolet light. Please use this when you are thinking of shortening the takt time. It is also pos...

CEMEDINE Co.,Ltd

250+ people viewing

Last viewed: 8 hours ago

■Features ・On-demand adhesive that starts curing with a UV trigger ・After UV irradiation, it hardens into a gel-like form and exhibits weak adhes...