All Categories

History

This section provides an overview for bearing nuts as well as their applications and principles. Also, please take a look at the list of 13 bearing nut manufacturers and their company rankings. Here are the top-ranked bearing nut companies as of February, 2026: 1.A.Nairsons Industries (India)., 2.CHIN SING PRECISION INDUSTRY CO., LTD., 3.HARDLOCK.

Table of Contents

Categories Related to Bearing Nuts

1985-2014: Worked for Alstom Corporation, ABB Corporation, and Gadelius Corporation, designing Jungstrom air preheaters and mechanical design of diamond soot blowers. (ABB Corporation: https://new.abb.com/jp)

2014-2021: Worked as an engineering and project manager at Alvos Inc.

https://www.linkedin.com/in/yoichi-hiroki-92192394/

A bearing nut is a component used to fasten a bearing.

The lock nut is also used as a synonym. There are several ways to fasten a bearing, and fastening with a bearing nut is one of them. A bearing nut is mainly used to tighten and secure the inner ring of a bearing.

Bearing nuts are used for fastening bearings. This is mainly the case when bearings are used at the shaft end.

Especially when bearings are fastened to shafts with removal sleeves, different size bearing nuts are used for tightening and removal. When used as a shaft support component on rotating machinery where the shaft rotation direction is clockwise, left-hand threaded bearing nuts are often used because the nut threads easily loosen in the same direction as the rotation direction.

When using bearing nuts to fasten a bearing,

The following methods are available for fastening bearings using bearing nuts.

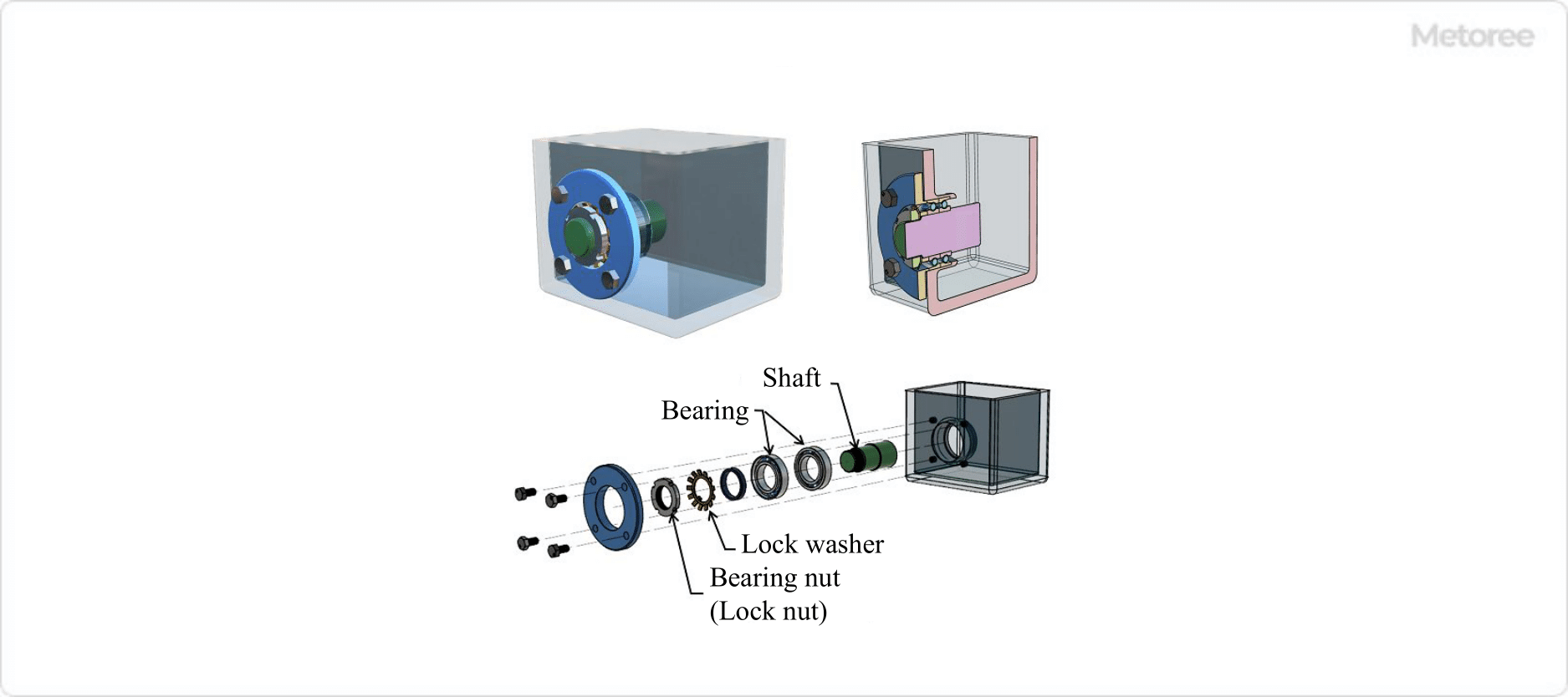

Figure 1. Principle of bearing nut

Bearing nuts are used as an example when fastening a bearing with a cylindrical bore in the inner ring to a shaft. The bearing nuts are screwed onto the male thread machined on the shaft end and used to press the inner ring to fix it in place.

Lock washers are sometimes used to prevent the bearing nuts from loosening. The lock washer has a flange on both the inner and outer diameters. The inner diameter side engages with the shaft groove and the outer diameter side engages with the bearing nuts groove, restraining and securing the bearing nuts in the direction of rotation.

Figure 2. Example of bearing nut use (1)

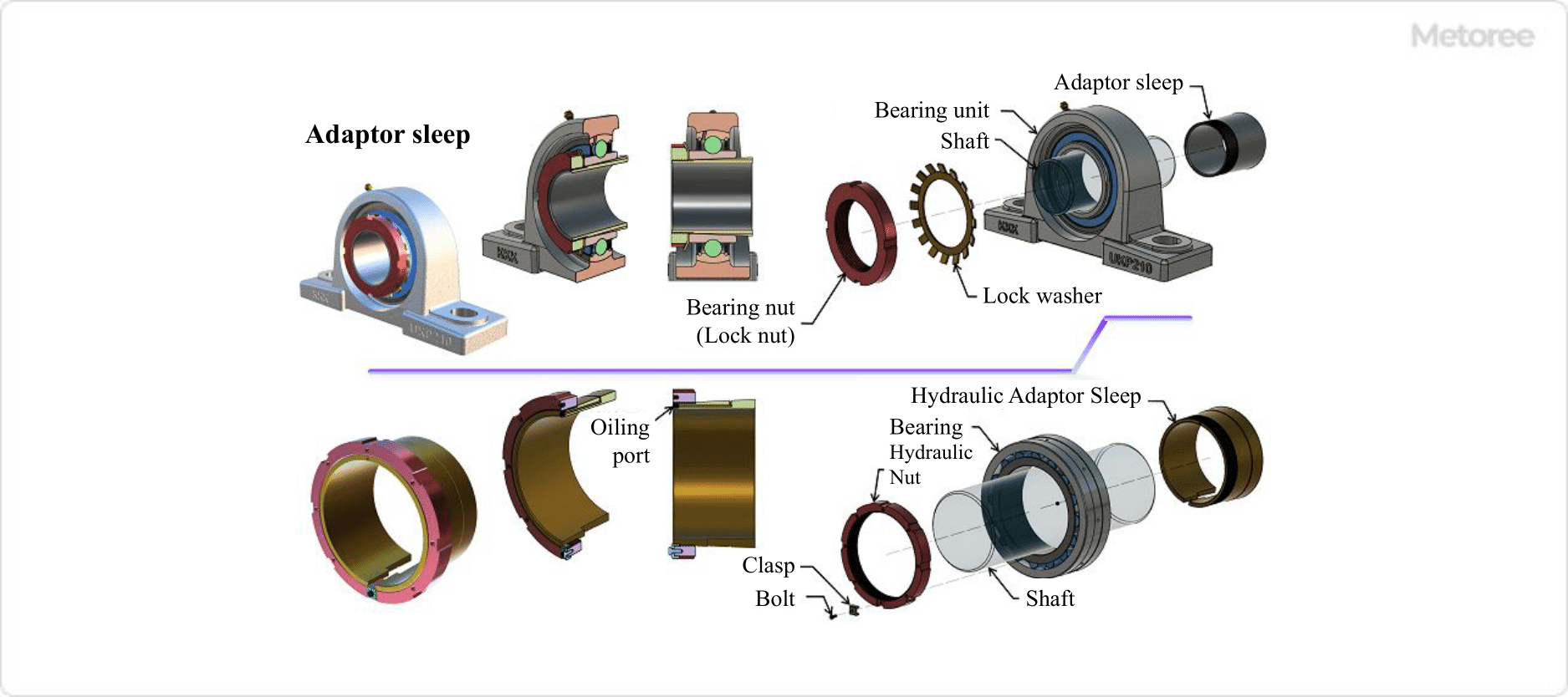

Figure 3. Example of bearing nut use (2)

As an example of fastening a bearing with a tapered inner ring bore to a shaft, an "adapter sleeve" or "removal sleeve" and bearing nuts are used. When using an adapter sleeve and bearing nuts, fit the adapter sleeve onto the shaft and screw the bearing nuts onto the male thread of the adapter sleeve, so that the adapter ring is pushed in, and the fit between the inner ring and adapter ring becomes stronger, and the inner ring is fastened to the shaft. The inner ring is then fastened to the shaft.

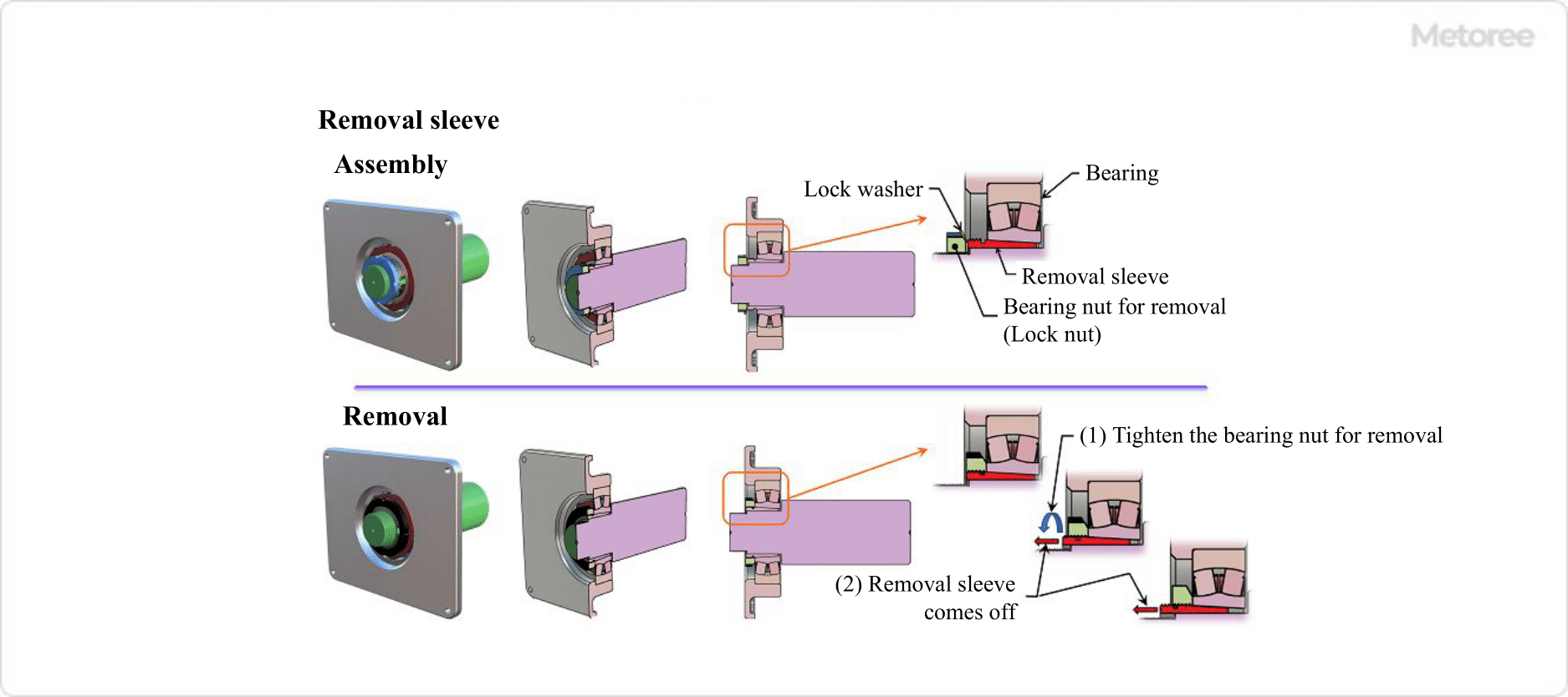

When using the removal sleeve and bearing nuts, insert the removal sleeve onto the shaft and screw the bearing nuts onto the male thread of the removal sleeve, which pushes in the removal sleeve to strengthen the fit between the inner ring and the removal sleeve and fasten the inner ring to the shaft. The inner ring is fastened to the shaft.

Note that when the removal sleeve is used, the bearing nuts are also used to remove the bearing. By screwing the bearing nuts onto the male thread at the shaft end, the removal sleeve is pulled out to loosen the fit between the inner ring and the removal sleeve, and the inner ring and shaft are released.

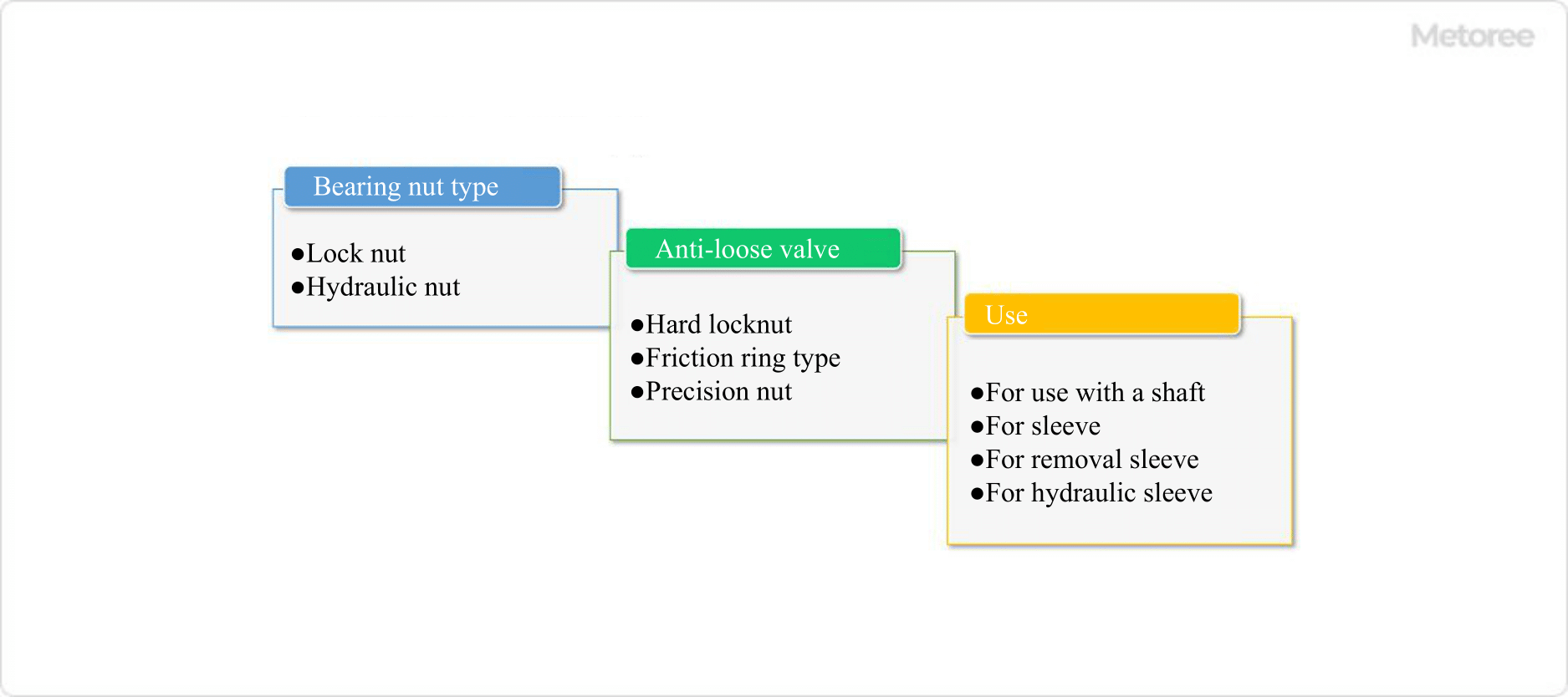

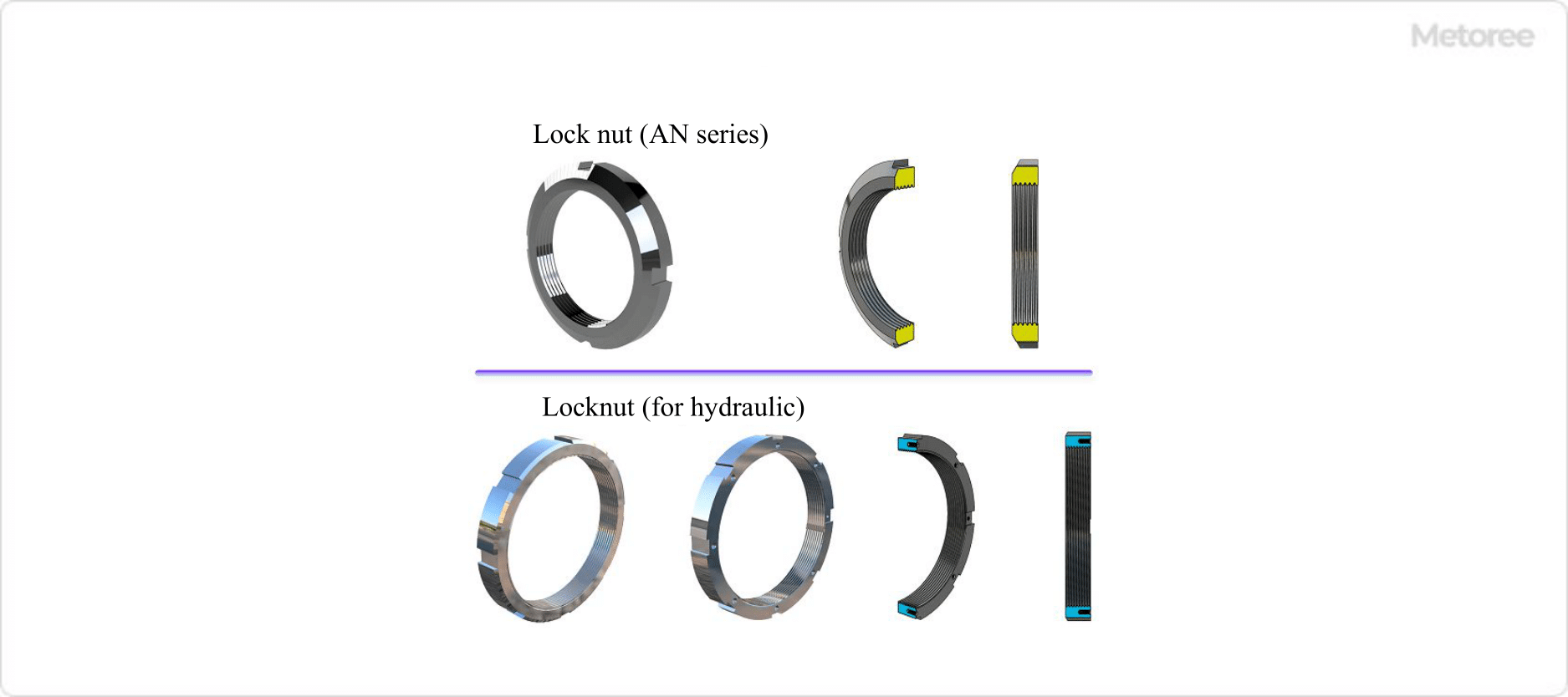

Figure 4. Types of bearing nuts (1)

The types of bearing nuts can be classified as shown in the above figure according to type, type of loosening prevention, and application.

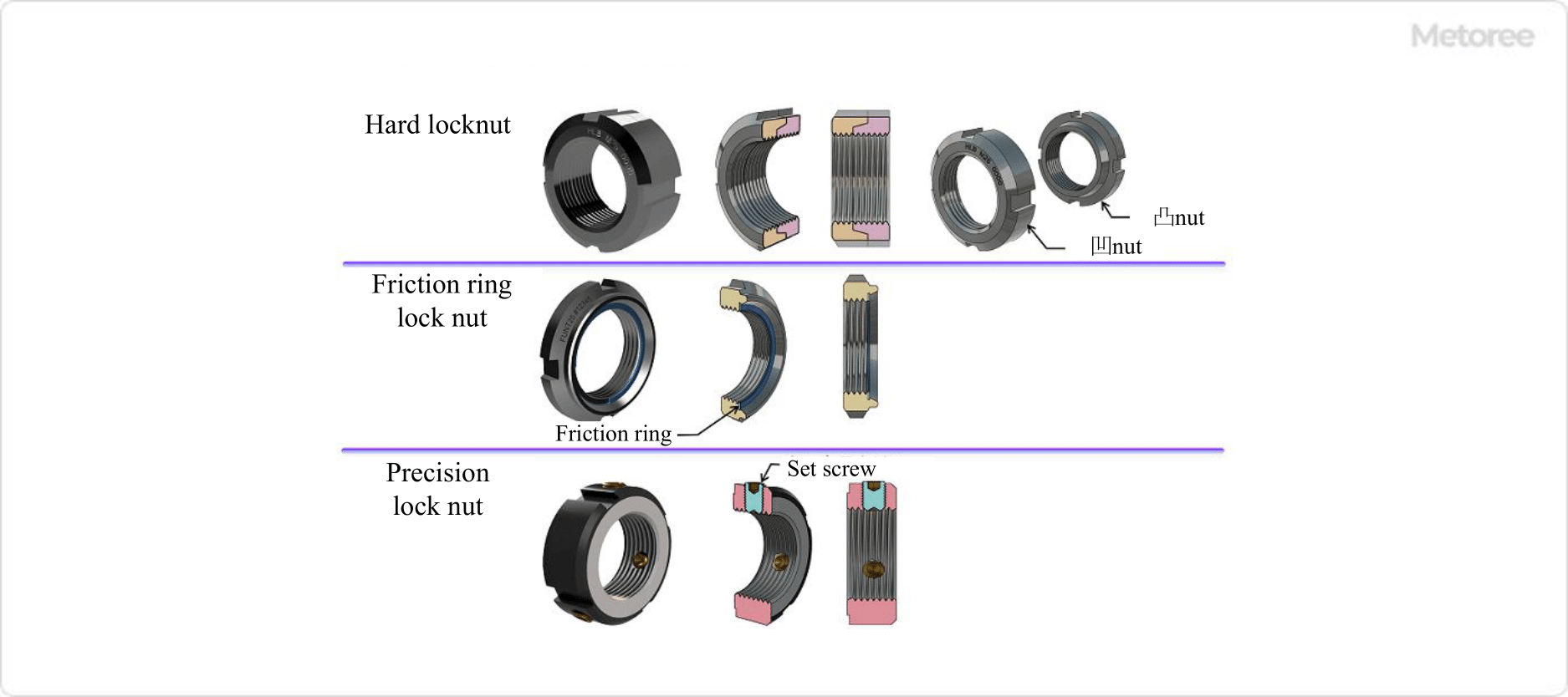

Figure 5. Types of bearing nuts (2)

Figure 6. Types of bearing nuts (3)

The chamfered side of the bearing nuts is the bearing side. The lock washer is installed along this chamfered side. The model number of the bearing nuts, such as AN10, is stamped on the non-chamfered side of the bearing nuts, making it easy to see when removing the nut.

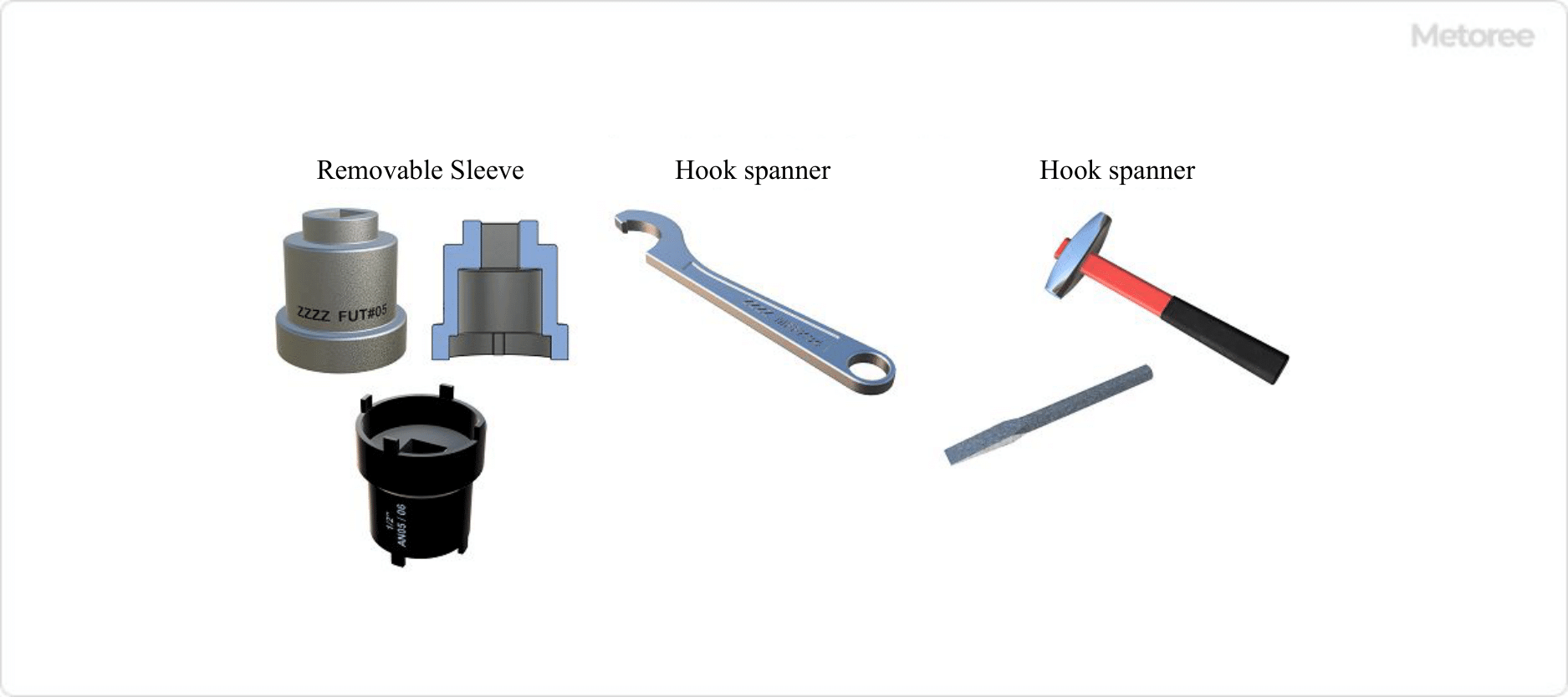

Figure 7. Tool for bearing nut

Loosening of the bearing nuts due to vibration while the equipment is in operation may cause abnormal noise or damage to parts including bearings. Therefore, it is important to tighten the bearing nuts with appropriate tools. The following types of tools are available for tightening bearing nuts:

Sockets for bearing nuts (locknut sockets)

Sockets for wrenches to tighten bearing nuts. The size is selected to fit the outer diameter of the bearing nuts and is attached to a standard socket wrench.

Hook spanner

This is a wrench-type tool for tightening bearing nuts. The convex part of the hook is hooked onto the concave part of the bearing nuts and rotated using the principle of leverage to tighten the nut. Use a hook spanner of the appropriate size for the outside diameter of the bearing nuts. This wrench can be used effectively in places where bearing nuts wrench cannot fit.

Hammer

Hammers are used for tightening and retightening the bearing nuts. Place the flat hammer in the recess of the bearing nuts and tap it in with the hammer. This is one of the methods to prevent loosening. This method is used when a wrench or similar tool is not strong enough. As a precaution, impact is applied to the recess of the bearing nuts so that it does not come off and damage other parts of the bearing nut. Also, be careful not to hit it too hard, as it will crush the recess of the bearing nuts.

*Including some distributors, etc.

Sort by Features

Sort by Area

Schaeffler Group USA Inc. (SGUS) is an American manufacturer and supplier of automotive products and solutions established in 1946 as the North American subsidiary of the Shaeffler Group, which operates globally. Based in Fort Mill, South Carolina, the company manufactures standard engine, transmission and chassis products such as torsion dampers, valve train systems, and camshaft phasing units. They also produce aftermarket repair solutions like clutch and release systems, as well as various industrial bearings and linear motion systems. SGUS primarily supplies the automotive sector, as well as the industrial operations of various industries including rail, green energy, and aerospace.

PCC Fasteners is a global designer and manufacturer of aerospace fasteners and precision-engineered components established in 1953 and is located in California, USA. The company offers airframe bolts, screws, pins, and lock bolts, as well as specialty fasteners like blind rivets, panel fasteners, and preload-indicating washers. It also supplies various engineered components, such as latches, struts, fluid fittings, and rods, for use in fluid conveyance systems, actuation and control assemblies, and aircraft structures. The company is a division of Precision Castparts Corp, and it caters to aerospace, energy, marine, missiles and space, and automotive industries.

A.Nairsons Industries (India) was founded in 1968 and headquartered in Sanehwal, Ludhiana, as a lock nut, adapter sleeves, and withdrawal sleeve manufacturer. The company is involved in the production, distribution, and exportation of various products, including adapter sleeves, withdrawal sleeves, lock washers, lock nuts, pillow block bearings, hook spanners, lock clips, ms bearings, plummer blocks bearings, wheel hubs, and other related items. These products were created by skilled specialists utilizing quality raw materials and advanced technologies.

Viha Steel & Forging, established in 2010 based in Mumbai, Maharashtra, is an Indian manufacturer of flanges. The company’s offerings encompass various types of flanges, including companion, lap joint, and orifice flanges. The company also produces slip-on, socket weld, and threaded flanges. Nipo flanges, a combination of welding neck flanges and Nipolet fittings, as well as flanges that meet the American Petroleum Institute (API) standards, such as API and API 6A flanges, are also available. These flanges are manufactured from various materials, including carbon steel, stainless steel, and titanium, and find applications in industries like oil and gas, petrochemicals, and shipbuilding.

Pavan Enterprise, established in 1988, operates as a manufacturer, wholesaler, and retailer of a diverse assortment of products, including adapter sleeves, lock nuts, lock washers, and hook spanners, and is headquartered in Vijayawada, Andhra Pradesh. As a result of their customer-centric strategies, highly competent workforce, and efficient management practices, they have achieved a commendable standing in the market. Pavan Enterprise is devoted to excellence by continuously improving its products, processes, and systems.

Chin Hsing Precision Industry Co., Ltd, established in 1990 and located in Minxiong, Taiwan, is a manufacturer of bearing adapter sleeves, hydraulic adapter sleeves, and the like. The company crafts adapter sleeves and hydraulic adapter sleeves, withdrawal and hydraulic withdrawal sleeves, and lock nuts and prevailing torque bearing nuts with metal inserts. It also produces lock washers, brass self-lubricating bushings and ceramic ball bearings, and linear guides and ball screws. Its adapter sleeves have good self-locking properties and are also used in heavy-duty transmission or shock vibration applications.

CHIN SING PRECISION INDUSTRY CO., LTD. is a Taiwanese manufacturer of precision metal stampings and machining parts. The company was founded in 1990 and is headquartered in Taipei. Chin Sing's main activity is the design, development, and manufacturing of precision metal stampings and machining parts including bearing adapter sleeves, hydraulic adapter sleeves, withdrawal sleeves, hydraulic withdrawal sleeves, and GUK self-lock nuts, among others. The company also offers a wide range of services, such as prototyping, testing, and assembly. Chin Sing's products are used by many customers, including the automotive, electronics, and medical industries.

Ravi Engineering Company is a manufacturer and supplier of industrial components established in 2001 and located in Gujarat, India. The company’s product offerings include an extensive range of bearing sleeves, internal circlip, dowel pins, rubber oil seals, and disc washers. It also offers stainless steel machine keys, cotter pins, brass grease nipples, and various industrial components. It has a 4,000-square-foot facility with drilling machines, pneumatic machines, punching equipment, and bend grinders to design and fabricate components for agricultural machinery, tractors, and industrial processing.

HARDLOCK is a manufacturer and distributor of loosening prevention measures headquartered Higashi-Osaka, Osaka Prefecture which was established in 1974. The company has a product catalog including HLN Hardlock Nut, HLB Hardlock Bearing Nut, and HLS Hardlock Set Screw. The company sells fastening bolt nuts that utilize Japanese wedging principles. The product catalog of the company features a self-locking design, torque and axial force control, and a reusable feature. The company caters to diverse applications ranging from industrial machinery, transmission towers, railroad facilities, architecture, and civil engineering.

Ranking as of February 2026

Derivation Method| Rank | Company | Click Share |

|---|---|---|

| 1 | A.Nairsons Industries (India). |

16.7%

|

| 2 | CHIN SING PRECISION INDUSTRY CO., LTD. |

11.1%

|

| 3 | HARDLOCK |

11.1%

|

| 4 | New United Engineering Works |

8.3%

|

| 5 | Handan Qijing Fastener Manufacture Co., Ltd. |

8.3%

|

| 6 | Schaeffler Group USA Inc. |

8.3%

|

| 7 | Ravi Engineering Company |

5.6%

|

| 8 | PCC Fasteners |

5.6%

|

| 9 | Pavan Enterprise. |

5.6%

|

| 10 | Viha Steel & Forging |

5.6%

|

Derivation Method

The ranking is calculated based on the click share within the bearing nut page as of February 2026. Click share is defined as the total number of clicks for all companies during the period divided by the number of clicks for each company.Number of Employees

Newly Established Company

Company with a History

*Including some distributors, etc.

*Including some distributors, etc.

| Country | Number of Companies | Share (%) |

|---|---|---|

India

India

|

5 | 38.5% |

Japan

Japan

|

3 | 23.1% |

United States of America

United States of America

|

2 | 15.4% |

Taiwan

Taiwan

|

2 | 15.4% |

China

China

|

1 | 7.7% |

234 products found

234 products

Reco Support Co., Ltd.

360+ people viewing

Last viewed: 15 hours ago

■Dulimai Tech's precision lock nuts This is a precision lock nut that can be used not only as a general nut, but also in places with strict accurac...

Hard Rock Industries Co., Ltd.

490+ people viewing

Last viewed: 6 hours ago

HLB-R is an improved type of HLB and uses the same wedge-based integrated structure technology. Even if high loads are applied repeatedly, the init...

Fuji Precision Co., Ltd.

470+ people viewing

Last viewed: 16 hours ago

■Features ・Reusable ・Fine adjustment is possible at any position, and torque management is also easy. ・No need for toothed washer or shaft keywa...

10 models listed

Reco Support Co., Ltd.

320+ people viewing

Last viewed: 15 hours ago

■Dulimai Tech's precision lock nuts This is a precision lock nut that can be used not only as a general nut, but also in places with strict accurac...

Hard Rock Industries Co., Ltd.

510+ people viewing

Last viewed: 15 hours ago

There is no need to bend the troublesome tongued washer into a lock nut. A hexagonal single type that can maintain the bearing's initial rigidity a...

Global Parts Co., Ltd.

260+ people viewing

Last viewed: 9 hours ago

The M-YSF lock nut is designed to tighten the shaft from three locations diagonally (30 degrees) to the thread. This superior tightening method pro...

10 models listed

Hard Rock Industries Co., Ltd.

390+ people viewing

Last viewed: 16 hours ago

The HLB uses the same wedge-integrated structure technology as the Hardlock Nut, so it can maintain the initial preload for a long period of time n...

Hard Rock Industries Co., Ltd.

490+ people viewing

Last viewed: 16 hours ago

The HLB uses the same wedge-integrated structure technology as the Hardlock Nut, so it can maintain the initial preload for a long period of time n...

Reco Support Co., Ltd.

370+ people viewing

Last viewed: 14 hours ago

■Dulimai Tech's precision lock nuts This is a precision lock nut that can be used not only as a general nut, but also in places with strict accurac...

Osaka Forming Co., Ltd.

450+ people viewing

Last viewed: 16 hours ago

■Safe and reliable anti-loosening effect The [E-LOCK series] is available in a wide variety of sizes, shapes, and functions to meet the various nee...

Nikki Co., Ltd.

510+ people viewing

Last viewed: 1 hour ago

■What is AN nut (bearing nut)? A nut is one of the fastening parts used for assembling machines. It has an opening called a female thread (female t...

Global Parts Co., Ltd.

230+ people viewing

Last viewed: 16 hours ago

The M-YSR lock nut tightens the shaft from three points in the radial direction. The thickness (h) of this lock nut is thinner than other types, so...

10 models listed

Fuji Precision Co., Ltd.

420+ people viewing

■Features ・Reusability Reusable ・Easy tightening: Fine adjustment is possible at any position, and torque management is also easy. ・Labor saving...

Reco Support Co., Ltd.

340+ people viewing

Last viewed: 6 hours ago

■Dulimai Tech's precision lock nuts This is a precision lock nut that can be used not only as a general nut, but also in places with strict accurac...

Reco Support Co., Ltd.

360+ people viewing

Last viewed: 15 hours ago

■Dulimai Tech's precision lock nuts This is a precision lock nut that can be used not only as a general nut, but also in places with strict accurac...

Global Parts Co., Ltd.

230+ people viewing

Last viewed: 16 hours ago

The SYSF lock nut is designed to tighten the shaft from three locations diagonally (30 degrees) to the thread. This superior tightening method prov...

10 models listed

Global Parts Co., Ltd.

200+ people viewing

Last viewed: 16 hours ago

M-YSA lock nuts are designed to tighten the shaft from three points in the axial direction, making them suitable for environments that require spec...

10 models listed

Global Parts Co., Ltd.

230+ people viewing

Last viewed: 16 hours ago

The SYSR lock nut is designed to tighten the shaft from three points in the radial direction. The thickness (h) of this lock nut is thinner than ot...

10 models listed

Global Parts Co., Ltd.

200+ people viewing

Last viewed: 16 hours ago

YSK lock nuts utilize the elastic deformation of the lock nut body to tighten the shaft. This tightening method provides more than three times the ...

10 models listed

Reco Support Co., Ltd.

340+ people viewing

Last viewed: 8 hours ago

■Dulimai Tech's precision lock nuts This is a precision lock nut that can be used not only as a general nut, but also in places with strict accurac...

Global Parts Co., Ltd.

260+ people viewing

Last viewed: 9 hours ago

SYSA lock nuts are designed to tighten the shaft from three points in the axial direction, making them suitable for environments that require speci...

10 models listed

Reco Support Co., Ltd.

370+ people viewing

Last viewed: 15 hours ago

■Dulimai Tech's precision lock nuts This is a precision lock nut that can be used not only as a general nut, but also in places with strict accurac...

Global Parts Co., Ltd.

220+ people viewing

Last viewed: 16 hours ago

YSF lock nuts are designed to tighten the shaft from three locations diagonally (30 degrees) to the thread. This superior tightening method provide...

10 models listed

Global Parts Co., Ltd.

330+ people viewing

Last viewed: 16 hours ago

YSR lock nuts are designed to tighten the shaft from three points in the radial direction. This lock nut is thinner than other types, so it can be ...

10 models listed

Nikki Co., Ltd.

230+ people viewing

Last viewed: 14 hours ago

■Features By using a special stainless steel set screw, it is now possible to tighten the set screw with high torque. By finishing the effective th...

6 models listed

Nikki Co., Ltd.

280+ people viewing

Last viewed: 16 hours ago

■Features For ball screw support bearings, the screw shaft and bearing can be fixed easily and accurately. *Other product numbers are available.

10 models listed

Reco Support Co., Ltd.

350+ people viewing

Last viewed: 15 hours ago

■Dulimai Tech's precision lock nuts This is a precision lock nut that can be used not only as a general nut, but also in places with strict accurac...

Global Parts Co., Ltd.

230+ people viewing

Last viewed: 4 hours ago

YSA lock nuts are designed to tighten the shaft from three points in the axial direction, making them suitable for environments that require specia...

10 models listed

Nikki Co., Ltd.

160+ people viewing

■Features By making a slit in the nut itself and tightening the cap bolt with an even torque, the threaded part of the shaft and the threaded part ...

10 models listed

Reco Support Co., Ltd.

330+ people viewing

Last viewed: 7 hours ago

■Dulimai Tech's precision lock nuts This is a precision lock nut that can be used not only as a general nut, but also in places with strict accurac...