19 Button Head Socket Cap Screw Manufacturers in 2024

This section provides an overview for button head socket cap screws as well as their applications and principles. Also, please take a look at the list of 19 button head socket cap screw manufacturers and their company rankings. Here are the top-ranked button head socket cap screw companies as of April, 2024: 1.ZAGO, 2.Dongguan Zhengchen Hardware Co., Ltd., 3.G-Fast Distribution Inc.

Table of Contents

1985-2014: Worked for Alstom Corporation, ABB Corporation, and Gadelius Corporation, designing Jungstrom air preheaters and mechanical design of diamond soot blowers. (ABB Corporation: https://new.abb.com/jp)

2014-2021: Worked as an engineering and project manager at Alvos Inc.

https://www.linkedin.com/in/yoichi-hiroki-92192394/

What Is a Button Head Socket Cap Screw?

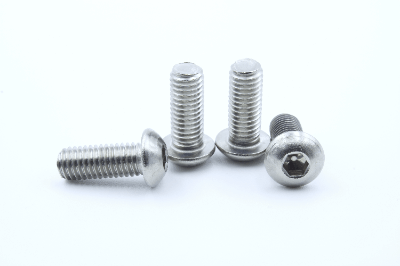

Button Head Socket Cap Screws are bolts with a rounded hemispherical bolt head that resembles a button when viewed from the side.

Button Head Socket Cap Screws are bolts with a rounded hemispherical bolt head that resembles a button when viewed from the side.

The end face of the bolt head is cut horizontally and a hexagonal hole is drilled. To tighten, a hexagonal wrench is used to insert the bolt into the hexagonal hole on the top surface of the head.

As general terms, button bolts and button caps are also synonymous. The shape of button head socket cap screws is the same as that of button cap screws if the nominal diameter of the screw is the same, but button head socket cap screws have a larger nominal diameter than button cap screws.

The standards for button head socket cap screws is the ANSI/ASME B 18.3 Hexagon Socket Button Head Cap Screws.

Uses of Hexagon Head Socket Cap Screws

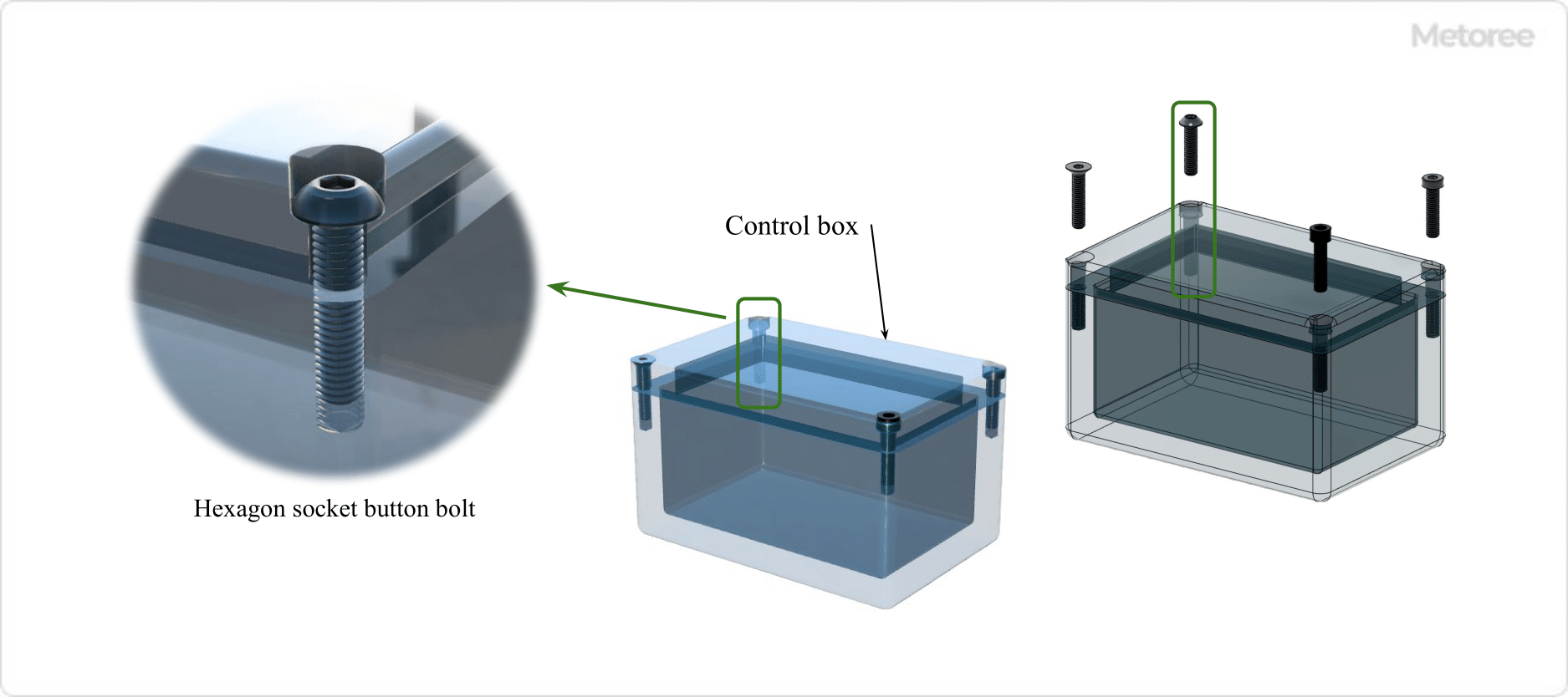

Figure 1. Example of button head socket cap screws use

Hexagon Head Socket Cap Screws are primarily used to mount and secure components on small machines and equipment where space is limited for installation.

On the mating side where the button head socket cap screws is to be installed, a counterbored hole is drilled slightly larger than the outside diameter of the bolt head and slightly deeper than the height of the head.

This allows the bolt head to be installed without protruding completely. Interference between the bolt head and other parts is avoided, resulting in a clean and neat appearance. In some cases, counterbored holes are not installed and used in the same way as hexagonal bolts.

Compared to hexagonal bolts, the bolt head is smooth and does not catch, so it is safer and less likely to be scratched even if touched by a person. Counterbored holes are drilled in the mounting area to hide the bolt head.

Principle of Button Head Socket Cap Screw

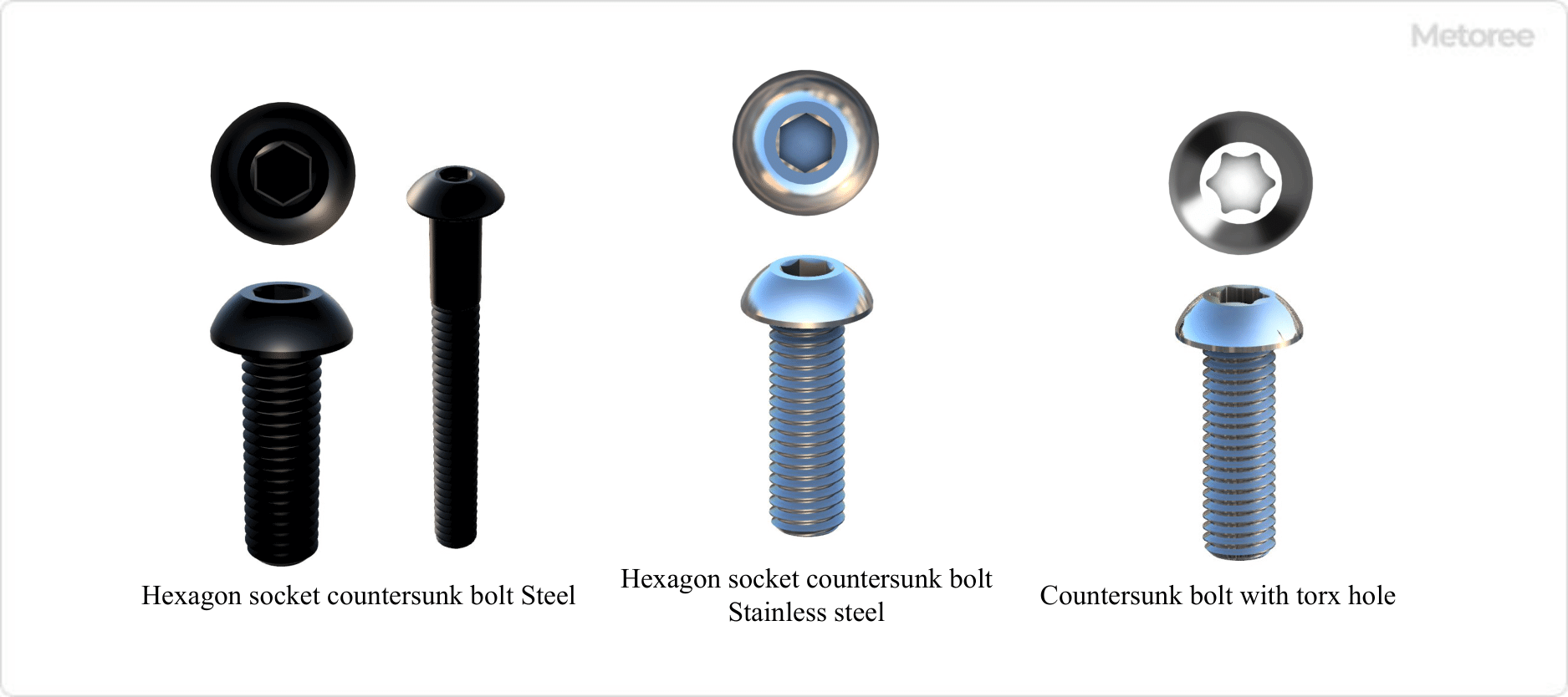

Figure 2. Hexagon socket button bolt

Button Head Socket Cap Screws are fastened with a screw (in this case, "screw" refers only to the screw shape), the same as an ordinary hexagonal bolt. Button Head Socket Cap Screws are often used for fastening by screwing directly onto a tapped female thread without using a nut.

Instead of inserting a wrench into the bolt head like a hexagonal bolt, a hexagonal wrench with a hexagonal cross section is inserted into the hexagonal hole and tightened. Therefore, it is necessary to secure a space between bolt heads and other parts.

However, since the tightening tool for the button head socket cap screw is a hexagonal wrench, no space is needed outside the bolt head, and the button head socket cap screw can be placed in close proximity to it. As a result, designs can be made with smaller dimensions and compact parts and devices can be realized.

The length of the button head socket cap screw is indicated by the length of the shaft part including the threaded part, excluding the height of the bolt head, in the same way as the length of ordinary bolts such as hexagonal bolts.

Other Information on Button Head Socket Cap Screws

1. Proper Use of Button Head Socket Cap Screws

The basic proper use of hexagon socket button head cap screws is as follows:

- Tightening force must be within the allowable range so that the threaded hole between the button head socket cap screw and the object to be fastened will not be broken.

- The repetitive force (due to vibration, etc.) applied to the threaded hole between the button head socket cap screw and the object to be fastened must be within the allowable range.

3. Looseness Prevention of Button Head Socket Cap Screw

To prevent loosening of button head socket cap screws, use an adhesive to prevent loosening, or use bolts that have been treated to prevent loosening.

4. Tightening Tools for Hexagon Head Socket Cap Screws

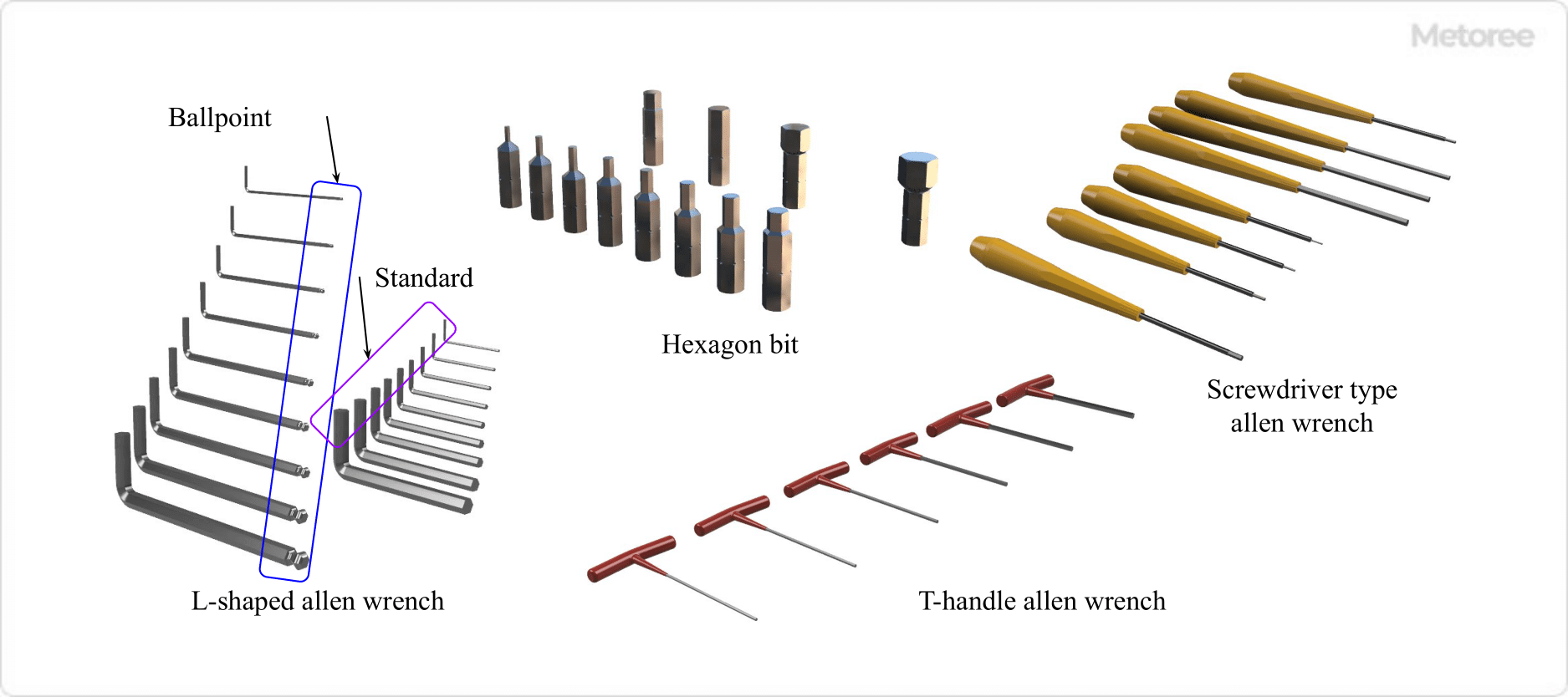

Figure 3. Types and shapes of button bolt tightening tools with hex holes

To tighten the button head socket cap screw, use a hexagonal wrench or other tightening tool appropriate for the size of the bolt. Compared to wrenches and monkey wrenches, hexagonal wrenches have the advantage of being able to apply a strong tightening force with less force and requiring less work space around the bolt when tightening.

Hexagonal wrenches are available in millimeter and inch sizes, and care must be taken when selecting a hexagonal wrench. Types of tightening tools include L-shaped hexagonal wrenches (hexagonal bar wrenches), T-shaped handle hexagonal wrenches, screwdriver-shaped hexagonal wrenches, and hexagonal bits.

The hexagonal wrenches and hexagonal bits have either a flat or ball point tip shape on the insertion side of the button head socket cap screw.

The shape of the ball point tip is R-processed at the corner so that the hexagonal wrench can be tightened even when the hexagonal wrench is at an angle.

List of 19 Button Head Socket Cap Screw Manufacturers

*Including some distributors, etc.

Sort by Features

- Default

- Company Size: largest first

- Year Founded: oldest first

- Year Founded: earliest first

Sort by Area

- United States of America

- China

- Germany

-

-

-

Arlington Fastener Company

Button Head Socket Cap Screws

Manufacturer Overview

Arlington Fastener Company was founded in 1969 and is located in Barrington, Illinois near Chicago. The company is a supplier of quality fasteners and through its subsidiary Tuttle Manufacturing, is also a manufacturer of custom fasteners. The company’s offerings include machine screws, sheet metal screws, threaded rods, and thread-forming screws. The company offers over 40,000 unique items in stock including domestic and import fasteners, standard and special. Designs not held in stock can generally be custom manufactured.

-

-

-

-

-

Fastening Products Company, Inc.

Button Head Socket Cap Screws

Manufacturer Overview

Fastening Products Company, Inc. was established in 1971 and is located in Delaware County, Pennsylvania. The veteran-owned and ISO 9001:2015 certified company serves industries including military OEM, petrochemical, power generation, and mass transit as a manufacturer of many types of military and commercial fasteners. The company’s product lines of fasteners include screws, bolts, nuts, washers, pins, and others. The company customizes products to fit customer specifications and supply them within scheduled delivery dates.

-

-

-

-

-

Product Components Corporation

Button Head Socket Cap Screws

Manufacturer Overview

Product Components Corp was founded by Joseph Saks in 1962 and operates out of Martinez, California. Product Components is a supplier of all types of plastic fasteners. Product Components provides custom molded, stamped, and machine stamped fasteners including screws, nuts bolts, knobs, washers, spacers, stand-offs, balls, and rivets among others. Product Components combines a full plastic fastener line including screws and bolts with engineered machined or molded component services for industrial applications for industries such as electronic, automotive, medical, aircraft, and food. Additional products include panel fasteners, spacers, standoffs, dowels, and other components for panel hardware.

-

-

-

-

-

American Fastener Technologies Corporation

BUTTON SOCKET CAP SCREWS

Company Overview

American Fastener Technologies Corporation (AFTC) is a manufacturer of precision-made industrial fasteners based in Gibsonia, Pennsylvania. Established in 1983, the company’s product portfolio includes masonry anchors, self-drilling screws, structural fasteners, and threaded rods. These primarily supply the military and defense, transportation, energy, and construction industries. The company stocks various materials and alloys tested to meet SAE, ASTM, and ISO standards. These are used in conjunction with AFTC services offered to clients including fabrication, testing, coating, and packaging of custom fasteners.

-

-

-

-

-

KD Fasteners, Inc.

BUTTON SOCKET CAP SCREWS

Company Overview

KD Fasteners, Inc. was founded in 1987 and headquartered in Addison, Illinois. The company is a fastener manufacturer and distributor, specializing in custom fasteners from such materials as steel, brass, silicon bronze, and other non-ferrous metals, supplying over 100,000 different fastener components. The company has 3 product segments: standard fasteners, standard metric fasteners, and custom fasteners. Custom fastener varieties include studs, washers, machine screws, flange bolts, and many other varieties. The company also offers many plating varieties including zinc, black oxide, waxing, and Magni 565 and 560.

-

-

-

-

-

National Bolt & Nut Corp.

Button Head Hex Socket Cap Screws

Company Overview

National Bolt & Nut Corporation is based in Schaumburg, Illinois. National Bolt & Nut is a distributor of bolts, nuts, and related tools, serving the heavy equipment & construction, mining, transportation, automotive, and alternative energy industries. National Bolt & Nut is ISO 9001 certified. National Bolt & Nut product listings include standard and custom nuts, spacers, and washers with assorted head styles. Other offerings include a variety of screws, pins, and sprockets.

-

-

-

-

-

Rainbow Nut and Bolt, Inc.

Button Head Socket Cap Screws

Company Overview

Rainbow Nut and Bolt, Inc. was founded in August 1978 in Santa Ana, California. The company is a distributor of various fastening products including special finishing coating and reworking services. The company sells a complete line of fasteners including nuts, bolts, socket products, anchor products, and screws. The 16 materials available for refinishing include blue zinc, black oxide, and nickel. Reworking services including special cut to length, re-threading, re-tapping, drilling, and bending.

-

-

-

-

-

Coburn-Myers Fastening Systems, Inc.

Button Head Socket Cap Screws

Company Overview

Coburn-Myers Fastening Systems Incorporated was founded in Trainer, Pennsylvania in 1981. Coburn-Myers manufactures and distributes industrial fasteners and related products. Coburn-Myers focuses both on standard bolts as well as custom designs featuring hundreds of combinations of materials, head styles, heat treatment, secondary operations, and finishes. Types available include hex bolts, heat cap screws, 12-point bolds, and stocked cap screws. Primary product also include buts, fasteners, studs, hand tools, anchors, washers, and other standard products.

-

-

-

-

-

Cold Headers, Inc.

Button Head Socket Cap Screws

Company Overview

Cold Headers, Inc is a manufacturer and distributor of Socket Screws and their related products since 1962. The company is located in Chicago, United States. Cold Headers' range of products includes shoulder screws, dowel pins, hex keys, and various alloy steel fasteners. The company offers all screws and fasteners in standard and custom sizes and comes in nylon, brass, and bronze materials. Socket screws are also available with spline drives.

-

-

-

-

-

Bayou City Bolt & Supply Co., Inc.

Button Head Socket Cap Screws

Company Overview

Bayou City Bolt & Supply Company, Inc. is a provider of industrial-type fasteners to various businesses, consumers, and industries around Houston Texas. These industries include energy production, construction, manufacturing & industrial, and the public sector. Bayou City Bolt offers fasteners in a variety of materials including low-carbon steel and aluminum, various coatings, such as zinc or Teflon coating, and special-order materials such as alloy 30 or bronze. In addition to fasteners, Bayou City Bolt also sells studs, drill bits, and other tools and accessories.

-

-

-

-

-

JT Industries, Inc.

Button Head Socket Cap Screws

Company Overview

JT Industries based in Bartlett, Illinois is a distributor of a wide variety of assembly components used in manufacturing applications. Some of the company’s manufacturers include Hellermann Tyton, Indusco, Micro Plastics, and Rotor Clips. The company’s product listings include cable ties, clips, fittings & wire ropes, labels, and socket head cap screws. Each product is available in multiple sizes, colors, and strength configurations. Orders can be made by contacting the company directly or making a request for a quote.

-

-

-

-

-

Metalloy

Button Head Socket Cap Screws

Company Overview

Metalloy was founded in 1969 and is based in St. Charles, Illinois. Metalloy is a distributor of industrial and construction supplies. Metalloy offers tube & pipe products, PVF, die sets & plates, die & mold tooling, general tooling, steel storage, and SK hand tools. Tube & tube products include mechanical tubing, stainless steel tubing, and piping. PVF includes piping, fittings, flanges, valves, studded outlets, and machined rings. Die sets & plates include parallels, risers, and steel tools. Die & mold tooling include die punches, die buttons, drill busings, and mold components.

-

-

-

-

-

Paramount Fasteners Inc.

Button Head Socket Cap Screws

Company Overview

Paramount Fasteners was founded in 1988 and is based in Santa Fe Springs, California. Paramount Fasteners supplies both common and rare industry standard nuts, bolts, screws, and other fastener products. Materials that Paramount Fasteners uses include B16, B8, B8M, B16, B7, 16-4, 17-7, Inconel, Hasteloy, and Monel and provided in 300 series stainless steel, 316 stainless steel, brass, bronze, carbon steel, nylon, and plastic. Paramount Fasters also distributes parts that have painted heads, hot dip galvanized, zinc plated, cad plated, black oxided, chrome plated, and flour coated.

-

-

-

-

Manufacturer Overview

VAG GmbH, founded in 1872 with headquarters in Germany, is a manufacturer of valves for infrastructure projects. The company's products include butterfly valves, house connection valves, gate valves, control valves with own-medium control for the regulation of pressure and flow rates in service areas, and electric check pump control valves. The company serves infrastructure projects such as water treatment and distribution, wastewater management, dams, and power stations. Services offered include commissioning, training, maintenance, on-site service, and the supply of original spare parts.

-

-

-

-

-

Dongguan Zhengchen Hardware Co., Ltd.

Ultra Low-Profile Hex Socket Cap Screw CBSTSR M2-M6

Manufacturer Overview

Dongguan Zhengchen Hardware Co., Ltd., situated in Dongguan City, China, is a manufacturer of a large array of engineering parts, tools, and equipment. The company makes ball plungers, spring plungers, ball rollers, special fasteners, and nylon tip set screws. It also manufactures adjusting screws, ball clamping screws, ball lock pins, shaft collars, and hinges. Its ball plungers, which consist of cylindrical bodies with threaded ends, are used to secure two or more pieces of material together.

-

-

-

-

-

-

Manufacturer Overview

ZAGO is a manufacturer of sealing fasteners established in 1993 and based in Newark, New Jersey, USA. The company primarily produces specialized fasteners designed to form a 360-degree seal for preventing fluids, gasses, or contaminants from leaking into or out of equipment. These include seal bolts or screws, switch boots that cover buttons or circuit breakers, and nuts. The company also offers custom product engineering, fabrication, and testing services for its clients with unique projects. It chiefly serves customers in the military, aerospace, and offshore renewable energy sectors.

-

-

-

-

Toolsavings, LLC

Button Head Socket Cap Screws

Company Overview

Toolsavings, LLC is based in Chicago, Illinois and is a supplier and distributor of industrial supplies for both individual and corporate customers. Toolsavings offers an extensive catalog spanning over 10 categories such as Cutting Tools, Toolholding, Air and Power Tools, Fasteners, and Measuring Instruments from brands such as 3M and Destaco. Cutting tools include drills, reamers, and saws. Toolholding includes boring heads, retention knobs, and sawholders. Air and Power Tools includes blow guns, grinders, and tire gages. Fasteners includes screws and pins. Measuring instruments includes calipers, microscopes, and squares.

-

-

-

-

-

G-Fast Distribution Inc

Button Head Socket Cap Screws

Company Overview

G-Fast has its roots back to 1989 and is based in Chicago, Illinois. G-Fast is a distributor and custom manufacturer of machine tools and equipment. Product offerings include bolts, screws, nuts, rivets, washers, pins, springs, wireforms, retaining rings, clamps, clips, pins, handles, electronic access tools, hinges, knobs, latches, panel fasteners, quick release pins, and wire management. Parts are available across several standards and materials. G-Fast’s services include custom specialized bolts, screws, and nuts, contract manufacturing, CNC machining, and cold heading.

-

-

Button Head Socket Cap Screw Manufacturer Ranking

*Including some distributors, etc.Ranking as of April 2024

Derivation Method| Rank | Company | Click Share |

|---|---|---|

| 1 | ZAGO |

25.0%

|

| 2 | Dongguan Zhengchen Hardware Co., Ltd. |

16.7%

|

| 3 | G-Fast Distribution Inc |

16.7%

|

| 4 | Toolsavings, LLC |

16.7%

|

| 5 | RAMPA TEC Inc. |

16.7%

|

| 6 | VAG |

8.3%

|

Derivation Method

The ranking is calculated based on the click share within the button head socket cap screw page as of April 2024. Click share is defined as the total number of clicks for all companies during the period divided by the number of clicks for each company.Number of Employees

- VAG: 150

Newly Established Company

- KD Fasteners, Inc.: 1987 (37 years ago)

- American Fastener Technologies Corporation: 1983 (41 years ago)

- Coburn-Myers Fastening Systems, Inc.: 1981 (43 years ago)

Company with a History

- RAMPA TEC Inc.: 1907 (117 years ago)

- Product Components Corporation: 1962 (62 years ago)

- Cold Headers, Inc.: 1962 (62 years ago)

Button Head Socket Cap Screw Manufacturers in United States

*Including some distributors, etc.

- Arlington Fastener Company

- Fastening Products Company, Inc.

- Product Components Corporation

- American Fastener Technologies Corporation

- KD Fasteners, Inc.

- National Bolt & Nut Corp.

- Rainbow Nut and Bolt, Inc.

- Coburn-Myers Fastening Systems, Inc.

- Cold Headers, Inc.

- Bayou City Bolt & Supply Co., Inc.

- JT Industries, Inc.

- Metalloy

- Paramount Fasteners Inc.

Global Distribution of Button Head Socket Cap Screw Manufacturers by Country

*Including some distributors, etc.

| Country | Number of Companies | Share (%) |

|---|---|---|

United States of America

United States of America

|

13 | 81.3% |

Germany

Germany

|

2 | 12.5% |

China

China

|

1 | 6.3% |