All Categories

History

This section provides an overview for perforated metals as well as their applications and principles. Also, please take a look at the list of 20 perforated metal manufacturers and their company rankings. Here are the top-ranked perforated metal companies as of July, 2025: 1.MarCo Speciality Steel, Inc., 2.T/J Fabricators, Inc., 3.Moz Designs Inc..

Table of Contents

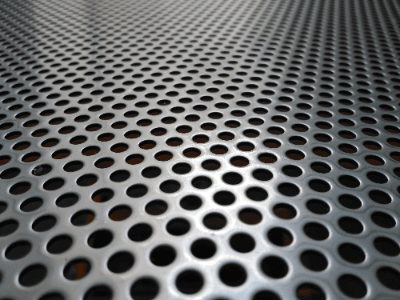

Perforated Metal is a metal sheet in which holes are punched in steel sheet (stainless steel sheet, aluminum-plated steel sheet, etc.) using a punching die.

Perforated Metal is a metal sheet in which holes are punched in steel sheet (stainless steel sheet, aluminum-plated steel sheet, etc.) using a punching die.

Perforating is a method of drilling holes in plate materials. Perforated Metal is punched with holes arranged in a regular pattern, and the use of a special die reduces the processing time.

Perforated Metal is used for safety shields to prevent people from touching it, as well as for objects and lighting that require design.

Perforated Metal can be used not only in its sheet form, but also in a wider range of applications through various processing.

Examples of applications are as follows:

Exhaust mufflers, air filters, oil filters, radiator covers, front grilles (the front grille of automobiles), etc.

Building exteriors, building interiors (elevators, stair railings, sunroom roofs, etc.), ceiling materials, exhaust tops

Strainers, vents, stairs, and fences used in power plants and oil, gas, and chemical refineries

Centrifuges, etc. used in food, chemical, pharmaceutical development, etc.

Speakers, electronic storage boxes, air conditioner filters, light fixture covers

Chairs, table legs, chair backs, bed frames.

Houses and appliances, kitchen and bathroom drains, microwave oven doors (to prevent leakage of radio waves), dishwasher drains

Filters for water supply and drainage pipes, metal shelves of vending machines, aircraft engine covers, soundproofing materials, air and water filtration materials, etc.

Perforated Metal is widely used in a variety of applications, mainly for products that require metal plates with numerous regular holes.

In addition, although round holes are the most common type of holes punched in plates, it is also possible to process square holes and long round holes. For this reason, Perforated Metal is used not only for utilitarian purposes but also for decorative items. For example, Perforated Metal can be formed into cylindrical shapes, or Perforated Metal can be bent and assembled into box shapes.

Perforated Metal is processed by using a punch (convex) and a die (concave), which are used to punch numerous holes in a sheet of metal. Perforated Metal processing is capable of producing a large number of holes with a more regular distribution on a metal plate in a shorter time than other processing methods.

Perforated Metal is generally manufactured using a press machine called a turret punch press, which can now be programmed and automatically controlled to process the metal sheet.

Perforated Metal has the following properties:

Since the metal sheet is perforated, the weight can be reduced while maintaining the required strength of the metal sheet. In addition, since the holes are evenly arranged, stress distribution is uniform and stress concentration is less likely to occur. Perforated Metal used in the construction and automotive industries is strong and rigid.

Perforated Metal is used in construction, exhaust systems, sound control, etc., because its numerous holes allow wind and air to pass freely through the holes in Perforated Metal. High air permeability reduces increases in humidity and the formation of mold.

Perforated Metal has a perforated metal sheet structure, making it lighter than metal sheets of the same external size and of the same material. In the construction and automotive industries, Perforated Metal can be used to reduce the weight of structures and vehicles. Its light weight and ease of handling can reduce construction costs.

Perforated Metal is durable and can withstand outdoor environments because it is made of metal. Air, water, and snow can pass through the holes in Perforated Metal, so the metal sheet is not damaged by accumulated snow and water. This makes it suitable for use in buildings and outdoor facilities.

Various hole patterns and shapes allow various designs to be expressed on buildings and furniture. A wide variety of patterns can be created by devising hole size, hole arrangement, hole shape, etc.

Perforated Metal has high thermal conductivity because it is made of metal, and is used in heat exchangers and heating equipment. Because of its high thermal conductivity, it can also be used as a heat sink.

Perforated Metal is generally available with round holes, but can also be processed with square or long round holes. Therefore, it is used not only for utility items but also for decorative items.

Perforated Metal is manufactured using a punch (convex) and a die (concave), which are used to punch numerous holes in a sheet of metal. The press machine used to manufacture Perforated Metal is generally a turret punch press, which can now be programmed and automatically controlled to process the metal sheet.

A turret punch press is a press machine that drills holes in a metal plate by fixing differently shaped dies to a circular die holder called a turret and using NC control.

NC control is a type of numerical control, a technology that uses computers to control the movements of machines and robots. NC stands for Numerical Control and means a method of moving a machine based on numerical instructions.

*Including some distributors, etc.

Sort by Features

Sort by Area

Marco Specialty Steel, Inc. established in 1992 is a main supplier of specialty metals such as stainless steel, nickel alloys, and titanium. The company is headquartered in Houston, Texas. The company provides the industry's turn-around times for custom manufacturing of woven or welded wire cloth, punched perforated metal, expanded metal, bar grating, and fiberglass grating. They maintain a broad and diverse inventory that is tailored to meet the demanding daily requirements of their customer base. Additionally, the organization provides custom manufacturing and fabrication services for all their products.

Alabama Metal Industries Corporation (AMICO Global), established in 1939 with headquarters in the USA, is a global manufacturer of steel and FRB (fiberglass-reinforced plastic) fabrications and architectural solutions. The company's product portfolio includes industrial flooring, perforated metals, one-piece fiber-reinforced plastic grating, and perimeter security fencing. Examples of its extensive product line include high-security modular fencing, exterior ventilated wall systems, and STAY-FORM concrete forming systems. These products, materials, and systems are used across various industries for interior and exterior architecture, including the construction of buildings, processing plants, and oil rigs, as well as for site security.

Moz Designs, Inc., established in 1989 with headquarters in the USA, is a manufacturer of turnkey architectural metal products for interior and exterior design. The company's product line includes metal sheets, columns, ceilings, walls, and room dividers in various colors, textures, and grains. These products are used in hospitality, workplace, transportation, and retail markets, including large-scale exterior installations. The company was acquired by Armstrong World Industries in 2020 and operates independently of its parent company. Its clients include Amazon, Google, Marriott, Hilton, Journey’s, and Netflix.

Mc Nicols Co, founded in the year 1952, and based in California, USA, is known as a manufacturer and supplier of metals and flooring products. Their product portfolio includes perforated and expanded metal, wire mesh, bar and fiberglass grating, designer metals, deck and flooring products. The company also offers fabrication, custom, and designer services with packaging and logistics. The products are used in various industries including distribution, construction, fabrication, manufacturing, agriculture, and energy.

Established in 1962, Metalex, Powered by UPG, is a well-established US-based manufacturer and supplier specializing in expanded metal and perforated metal products. The company offers an extensive range of products, including expanded metal, perforated metal, and safety grating, with applications in architecture, automotive, and industrial manufacturing. What sets Metalex apart is its capacity to deliver customized solutions to meet diverse customer requirements. Examples include their provision of expanded metal meshes for architectural facades and perforated metal sheets used in acoustic panel manufacturing, showcasing their devotion to addressing specific client needs.

T/J Fabricators, Inc., established in 1967 and headquartered in Addison, Illinois, is a manufacturer specializing in precision sheet metal fabrications. The company has been delivering sheet metal services across Illinois, Indiana, and the United States. Its product offerings encompass an array of services, including precision laser cutting that grants intricate shapes, patterns, and logos on steel, aluminum, and stainless steel. The company's capabilities extend to metal fabrication, welding, in-house engineering, and complex forming, producing cabinets, enclosures, structures, and more.

Mega Steel & Tube, established in 1970, based in Gardena, California, is a manufacturer of standard and custom carbon steel products. The company’s product portfolio includes tubes, pipes, bars, perforated and expanded metal, and sheets, among others. The products are distributed in the Western U.S. and Mexico border cities. The services provided include sawing, cutting, forming, slitting and milling. The company has a large inventory on the floor with modern equipment and 10 overhead cranes with a remote control system to cover the storage warehouse and the manufacturing lines.

Accurate Perforating Co., established in 1948, and headquartered in Chicago, Illinois, is a manufacturer of perforated metal sheets and custom perforated products. Their product offerings find applications in various industries, such as architecture, interior design, HVAC, acoustics, filtration, and more. The perforated metal sheets are utilized for decorative purposes, ventilation, screening, and sun shading. Accurate Perforating Co. ensures quality and precision in their products and adheres in providing excellent customer service.

Creative Building Supply (CBS) is a manufacturer specializing in sheet metal fabrication, perforated and corrugated metal for residential, commercial, and architectural industries. The company is based in Lakewood, New Jersey, and was founded by Jim Vihonsky. Their line of products include Corrugated Metal Panels, Metal Roofing, Metal Siding, and Light Gauge Metal Roofing. The company also offers custom fabrication, from trim work and custom-formed metal flashings to massive corrugated steel panels for roofing and siding projects.

FedTech was founded in 1996 and is headquartered in Mounds View, Minnesota. The ISO 9001:2015 certified company is a manufacturer and value-added service provider of machining services for several industries including automotive, aerospace, medical, and manufacturing industries. The company’s vertically integrated machining services include laser and waterjet cutting, CNC machining, metal fabrication, and finishing services. Services include assembly and sub-assembly, heat treating, liquid and powder painting, packaging & kitting, and custom material procurement.

Johnson Bros. Metal Forming Company was founded in 1947 in Chicago, Illinois as a manufacturer of roll-forming machines. Today the company is based in Berkeley, Illinois, and has a much-expanded product line serving industries such as agriculture, communications, glass, sports products, and woodworking. The company’s roll-forming capabilities include compatibility with materials such as brass, aluminum, titanium, and other metals. The company is capable of manufacturing products as varied as framing, hats, wireways, tubing, and cable trays.

Custom Filtration Inc. is a Corcoran, Minnesota-based manufacturer of custom filters primarily made from wire cloth using stainless steel, bronze, Monel, and other metals. The company’s products are used across almost all industries from agriculture and automotive to metalworking to textiles and utilities. Among the company’s wired cloth products, the company designs and manufactures custom-molded PVC, slit and stamped 304 stainless steel blanks, and custom cylindrical steel and copper screens using various weave types such as plain, plain Dutch, twilled, and twilled Dutch weaves.

Aluminum Distributing, Inc. (ADI Metal) was established in 1958 in Fort Lauderdale, Florida where it is still headquartered today. ADI Metal is a distributor of metal and metallic materials for both private and public industrial and maritime industries both in the United States and abroad. ADI Metal is ISO 9001:2015 certified. ADI Metal’s product segments are split into aluminum alloy products, stainless steel products, and other ferrous and non-ferrous metals. These metals include armor plating, brass, bronze, carbon steel, copper, cupronickel, and titanium.

Okutani Ltd., founded in 1895 and headquartered in Itasca, Illinois, is a manufacturer in the mesh and metal industry. The company delivers various products, including wire mesh, expanded metal, and various filtration solutions, serving multiple industries across the globe. It specializes in woven wire cloth, perforated metal, and expanded metal products. These materials are pivotal in numerous industries, providing essential manufacturing and environmental sustainability components. The company’s woven wire cloth and perforated metal sheets showcase its steadfastness to excellence, meeting market demands with advanced technology and expertise.

Direct Metals LLC, founded in the year 1996, and based in Georgia, USA, is a manufacturer and supplier of industrial metal and fiberglass products. Their product portfolio includes wire mesh, architectural metal, perforated and expanded metal, bar and safety grating, and fiberglass grating. The company also offers fabrication services, and custom metal and fiberglass inventories. The company is ISO-certified and manufactures according to NAAM standards. The products are used in architectural industries.

Grating Pacific, founded in 1971 and headquartered in Los Alamitos, California, USA, is a distinguished manufacturer and supplier specializing in metal grating and related products. The company's primary effort lies in producing an extensive range of gratings, including steel, aluminum, and fiberglass varieties, essential for industrial flooring, safety applications, and architectural projects. As a key player in the grating manufacturing, Grating Pacific's offerings find applications in diverse sectors such as construction, transportation, and infrastructure. With a promise to durability and innovation, the company backs to safe and functional environments, solidifying its status as an important provider of grating solutions.

Conard Corp., established in 1965, is an AS9100 and ISO 9001-certified precision photochemical manufacturer located in Glastonbury, Connecticut. The company produces photoetched parts in various metal alloys, such as steel, copper, aluminum, and molybdenum. Additionally, the company provides prototyping, engineering, and design services for custom parts. They serve several industries, including the medical, aerospace, and energy industries. Their products are applied in various residential and commercial products, which include sensor and measurement equipment, transistors, wifi devices, and solar panels.

Fleischer Tube Distributors Corp., established in Bay Shore, NY, in 1973 is a distributor of steel, stainless, aluminum, alloys and red metals. Their product portfolio includes various shapes and sizes of Steel Products used for construction, manufacturing, and fabrication applications, Stainless Steel Products used in industries including food processing and architecture and specialty alloys, such as nickel alloys and titanium, used in industries like chemical processing, and power generation.

Power Engineering Co., Inc., headquartered in Hailey, Idaho, has been an engineering and environmental consulting firm, serving as a service supplier of integrated, multidiscipline solutions since 1976. Its extensive array of consulting services encompasses power plant design, transmission, distribution solutions, renewable energy project development, and environmental compliance. Additionally, the company offers industrial project support, civil engineering services, safety assessment, and educational training. Power Engineering holds the distinction of being the largest Power Delivery detail designer in the U.S., with locations spanning over 45 offices across North America.

Ranking as of July 2025

Derivation Method| Rank | Company | Click Share |

|---|---|---|

| 1 | MarCo Speciality Steel, Inc. |

8.2%

|

| 2 | T/J Fabricators, Inc. |

8.0%

|

| 3 | Moz Designs Inc. |

7.8%

|

| 4 | Accurate Perforating Co. |

6.6%

|

| 5 | AMICO Global Ltd |

6.2%

|

| 6 | Metalex, Powered by UPG |

6.2%

|

| 7 | Creative Building Supply |

5.9%

|

| 8 | Johnson Bros. Roll Forming Co. |

5.3%

|

| 9 | Mega Steel & Tube |

5.0%

|

| 10 | Fedtech, Inc. |

5.0%

|

Derivation Method

The ranking is calculated based on the click share within the perforated metal page as of July 2025. Click share is defined as the total number of clicks for all companies during the period divided by the number of clicks for each company.Number of Employees

Newly Established Company

Company with a History

*Including some distributors, etc.

*Including some distributors, etc.

| Country | Number of Companies | Share (%) |

|---|---|---|

United States of America

United States of America

|

13 | 92.9% |

Japan

Japan

|

1 | 7.1% |

55 products found

55 products

Kyoei Uchi

750+ people viewing

Last viewed: 21 hours ago

■ Overview -The punching metal is a material made in a metal plate punching (punched) with a mold. ・ It is used for buildings and residential devi...

5 models listed

Metaltech Co., Ltd.

170+ people viewing

Last viewed: 7 hours ago

Perforated metal is a metal plate made of iron, stainless steel, aluminum, etc., with holes, such as round, square, or long holes, drilled into it....

Kyoei Uchi

430+ people viewing

Last viewed: 8 hours ago

■ Overview -The punching metal is a material made in a metal plate punching (punched) with a mold. ・ It is used for buildings and residential devi...

Metaltech Co., Ltd.

150+ people viewing

Last viewed: 3 hours ago

Perforated metal is a metal plate made of iron, stainless steel, aluminum, etc., with holes, such as round, square, or long holes, drilled into it....

Kyoei Uchi

380+ people viewing

Last viewed: 12 hours ago

■ Overview -The punching metal is a material made in a metal plate punching (punched) with a mold. ・ It is used for buildings and residential devi...

Metaltech Co., Ltd.

140+ people viewing

Last viewed: 11 hours ago

Perforated metal is a metal plate made of iron, stainless steel, aluminum, etc., with holes, such as round, square, or long holes, drilled into it....

Kyoei Uchi

530+ people viewing

Last viewed: 2 hours ago

■ Overview -The punching metal is a material made in a metal plate punching (punched) with a mold. ・ It is used for buildings and residential devi...

Metaltech Co., Ltd.

160+ people viewing

Last viewed: 12 hours ago

Perforated metal is a metal plate made of iron, stainless steel, aluminum, etc., with holes, such as round, square, or long holes, drilled into it....

Metaltech Co., Ltd.

150+ people viewing

Perforated metal is a metal plate made of iron, stainless steel, aluminum, etc., with holes, such as round, square, or long holes, drilled into it....

NC Sangyo Co., Ltd.

180+ people viewing

Last viewed: 7 hours ago

■Applications Speaker mesh, filter, design hole, barrel plate ■Features We can provide perforated sheets for all kinds of materials, processed res...

Metaltech Co., Ltd.

160+ people viewing

Last viewed: 6 hours ago

Perforated metal is a metal plate made of iron, stainless steel, aluminum, etc., with holes, such as round, square, or long holes, drilled into it....

Amisen Co., Ltd.

210+ people viewing

Last viewed: 4 hours ago

■A product with holes punched in a fixed array on a metal plate. This is a product with holes drilled in a fixed array on a metal plate, and can be...

4 models listed

Yagyu Shokai Co., Ltd.

180+ people viewing

Last viewed: 1 day ago

■Features ・Magnesium alloy exhibits a stable shielding effect of 90 to 100 dB in the 30 to 200 MHz band. *As this is a cutting material, there may...

Yagyu Shokai Co., Ltd.

180+ people viewing

Last viewed: 5 hours ago

Nikkal Shoko Co., Ltd.

210+ people viewing

Last viewed: 3 hours ago

Punched wire mesh is made by forming many holes at a fixed pitch over a wide area using a special press machine on steel plates, etc. ■Application...

Nikkal Shoko Co., Ltd.

250+ people viewing

Punched wire mesh is made by forming many holes at a fixed pitch over a wide area using a special press machine on steel plates, etc. ■Application...

Nikkal Shoko Co., Ltd.

200+ people viewing

Punched wire mesh is made by forming many holes at a fixed pitch over a wide area using a special press machine on steel plates, etc. ■Application...

Nikkal Shoko Co., Ltd.

280+ people viewing

Last viewed: 1 day ago

Punched wire mesh is made by forming many holes at a fixed pitch over a wide area using a special press machine on steel plates, etc. ■Application...

Nikkal Shoko Co., Ltd.

190+ people viewing

Punched wire mesh is made by forming many holes at a fixed pitch over a wide area using a special press machine on steel plates, etc. ■Application...

Metaltech Co., Ltd.

200+ people viewing

Last viewed: 3 hours ago

■About perforated folded plates Perforated folded plates, which are made of perforated metal that gently transmits light and wind and are made stro...

Inada Wire Mesh Co., Ltd.

130+ people viewing

Punched wire mesh (punched metal) was created by punching holes in a steel plate, which is stronger than wire mesh, for the purpose of sieving crus...

Inada Wire Mesh Co., Ltd.

120+ people viewing

Last viewed: 3 hours ago

■Punched steel wire mesh (punching metal) Although it depends on the purpose and frequency of use, punched wire mesh is generally a board with hole...

Inada Wire Mesh Co., Ltd.

110+ people viewing

■Stainless steel punched wire mesh (punching metal) Although it depends on the purpose and frequency of use, punched wire mesh is generally a board...

Inada Wire Mesh Co., Ltd.

120+ people viewing

Last viewed: 1 day ago

■Aluminum punched wire mesh (punching metal) Although it depends on the purpose and frequency of use, punched wire mesh is generally a board with h...

Hokkaido Screen Manufacturing Co., Ltd.

100+ people viewing

Last viewed: 1 day ago

This is a long hole shape. It is possible to manufacture by combining materials, plate size, plate thickness, hole diameter, opening ratio, etc. ■...

Fuji Shokai Co., Ltd.

110+ people viewing

Last viewed: 1 day ago

Punched metal is an aluminum plate with holes drilled using a punching press mold. Due to the excellent workability unique to aluminum, it can be u...

Hokkaido Screen Manufacturing Co., Ltd.

90+ people viewing

Last viewed: 16 hours ago

It has a round hole shape. It is possible to manufacture by combining materials, plate size, plate thickness, hole diameter, opening ratio, etc. ■...