70 Aluminum Casting Manufacturers in 2024

This section provides an overview for aluminum castings as well as their applications and principles. Also, please take a look at the list of 70 aluminum casting manufacturers and their company rankings. Here are the top-ranked aluminum casting companies as of April, 2024: 1.Thompson Aluminum Casting Company, 2.Chicago White Metal Casting, Inc., 3.PHB Inc.

Table of Contents

What Is Aluminum Casting?

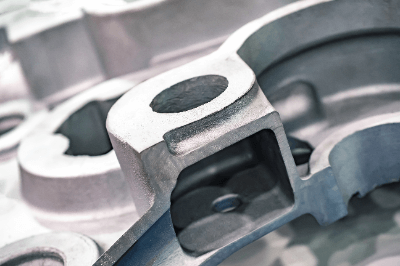

Aluminum Casting is a product made by processing aluminum alloy with a method called casting.

Aluminum Casting is a product made by processing aluminum alloy with a method called casting.

Casting refers to the process of heating an aluminum alloy at a temperature higher than its melting point, melting it, pouring it into a mold made in the desired shape, and cooling it to make a product. There are two main types of molds: sand casting and metal mold casting.

The advantages of the sand mold casting method are low cost, support for large shapes, and small-lot production. The advantages of the metal mold casting method are mass production and high dimensional accuracy. The mold casting method also includes the gravity method and die casting method.

Uses of Aluminum Casting

Aluminum Casting is often used in automobiles because of its light weight, excellent workability, electrical and thermal conductivity, recyclability, and corrosion resistance.

Parts in actual use include the following:

- Engine parts (cylinder blocks, cylinder heads, etc.)

- Body parts

- Suspension parts, etc.

Reducing the weight of automobiles leads to improved fuel efficiency and operability. In addition, the thermal conductivity is utilized to reduce cooling of parts that generate heat.

Principle of Aluminum Casting

Sand casting and Mold casting (gravity casting) are two different aluminum casting methods.

1. Sand Casting Method

- A wooden mold is used to create the shape of the product and the aluminum inlet into which the aluminum is poured.

- Sand mixed with an additive for hardening is filled into the mold.

- The sand mold is completed by removing the wooden mold (product shape and hot water outlet) from the sand mold.

- The upper and lower sand molds are made according to the above procedure.

- Align the completed sand molds top and bottom.

- Molten aluminum is poured from the hot water outlet into the top and bottom sand molds.

- After pouring, the mold is cooled and hardened.

- After hardening, the sand mold is broken and the aluminum casting is removed.

- After removing unnecessary parts and machining the surface, the casting is complete.

Mold Casting Method (Gravity Casting)

- A mold is made according to the shape of the product.

- Molten aluminum is poured into the mold by gravity*.

- After the molten aluminum is poured into the mold, it is cooled and hardened.

- After hardening, the mold is removed and the aluminum casting is taken out.

- After removing unnecessary parts and machining the surface, the product is complete.

*The method of injecting by pressure as well as gravity is called the die casting method.

Other Information on Aluminum Casting

1. Anodizing of Aluminum Casting

The surface of aluminum casting can be anodized to improve corrosion and wear resistance. Anodizing is also called anodic oxidation treatment. It is a treatment method in which aluminum is oxidized by passing an electric current through it in an electrolytic solution to produce a film that is thicker than the film produced by natural oxidation.

Aluminum casting contains a large amount of elements other than aluminum to increase its strength. Examples include silicon, copper, and magnesium. When anodizing aluminum casting, these elements may inhibit the formation of the coating. This is due to the segregation of elements other than aluminum in the casting, which changes the current-carrying conditions. To improve the situation, it is necessary to carefully remove dirt and undissolved fine particles from the casting surface, and to perform the treatment in a short time.

2. Defects in Aluminum Casting

Pinholes are one of the defects that occur in aluminum casting and are numerous fine needle-like bubbles. The size of the bubbles varies depending on the manufacturing conditions, but is about 0.1 mm. Pinholes occur when moisture in the air becomes hydrogen gas in the molten metal and is released outside the casting during the solidification process. They tend to occur in thick-walled parts of the product or parts that were difficult to cool.

Pinhole countermeasures include reducing contact between the molten aluminum alloy and air, and sufficiently drying raw materials and tools to prevent moisture contamination. It is also necessary to remove hydrogen gas from within the alloy as much as possible before solidification.

Defects other than pinholes include sinkholes, hot water borders, hot water wrinkles, seizures, and galling. These defects can be prevented mainly through maintenance such as temperature control of the mold and polishing of the mold.

List of 70 Aluminum Casting Manufacturers

*Including some distributors, etc.

Sort by Features

- Default

- Company Size: largest first

- Year Founded: oldest first

- Year Founded: earliest first

Sort by Area

- United States of America

- Canada

- China

- India

- Japan

- Netherlands

- United Kingdom

- Vietnam

-

-

-

AmTech OEM

Aluminum Die Castings

Manufacturer Overview

Amtech Manufacturing, Inc., established in 1995 with facilities in North America, is a contract manufacturer of gear parts and drive components. The company's products include gears, shafts, castings, forgings, and screw machine parts. Amtech Manufacturing, Inc. also offers flexplate Assemblies, flywheel Assemblies, screw machining, stamping, and fineblanking. The company also offers custom manufacturing, machining, engineering, and laser cutting services. Amtech Manufacturing, Inc. services original equipment manufacturers in the automotive, construction, marine, power sports, and robotics markets.

-

-

-

-

-

Chicago White Metal Casting, Inc.

Aluminum Die Castings

Manufacturer Overview

CHICAGO WHITE METAL CASTING Inc., established in 1937 in Chicago, USA is a manufacturer of die-castings using aluminum, magnesium, and zinc. The company produces castings that require minimal or no additional processing, offering design capabilities, machining, finishing, and turnkey operations. Some of its products are electric and electronic die-castings made from magnesium and zinc under pressure, such as mesh and lattice-shaped casings, servo drives, commercial scales, PV panels, and more. All products must meet stringent criteria: must be robust and durable, lightweight for portability, waterproof, dust-resistant, and equipped with EMI protection.

-

-

-

-

-

Fort Recovery Industries, Inc.

Aluminum Die Castings

Manufacturer Overview

Fort Recovery Industries Inc., established in 1945, is a manufacturer of die castings based in Ohio, United States. The company manufactures ISO-CERTIFIED zinc and aluminum castings used in plumbing, appliance, automotive and furniture applications. Fort Recovery also has operations in China that feature powder coating, polishing, plating and in-house casting. It conducts its production process environment-friendly by minimizing waste generation. Also, the company supports the community through the Fort Recovery Community Foundation.

-

-

-

-

-

Soldy Manufacturing

Aluminum Die Castings

Manufacturer Overview

Soldy Manufacturing, founded in 1982 in the USA, is a manufacturer specializing in zinc alloy and aluminum alloy die casting, serving a wide range of industries. Company employs a technologically advanced process monitoring system for consistent quality control and offers custom heat treatment options while delivering prime, cost-effective solutions to cater diverse industries; such as automotive, medical, telecommunications, and more. Whether it's zinc or aluminum die casting, Soldy ensures precision and efficiency, making it a dependable partner for manufacturing parts and components. It serves customers across the United States, Canada, Mexico, and Western Europe.

-

-

-

-

-

PHB Inc

Aluminum Die Castings

Manufacturer Overview

PHB Inc., established in 1984 with a history in the industry dating back as far as 1096 and headquarters in the USA, is a custom manufacturer and supplier of die cast tooling, parts, and supplies. The company's manufacturing capabilities include aluminum and zinc die casting, precision CNC machining, plastic and rubber molding, tool and die design, and production. It also provides final part finishing and product assembly. The company provides services, including engineering, product development, and prototyping. Other services include millipore testing, leak testing, impregnation, and cryogenic deflashing.

-

-

-

-

-

KenWalt Die Casting Company

Aluminum Die Castings

Manufacturer Overview

KenWalt Die Casting Company, established in 1968, is a manufacturer of die casting based in Los Angeles, United States. The company develops zinc and aluminum die castings for nuclear energy, water systems, electrical, automotive and aerospace applications. It uses automated production such as sprayers, automated ladlers and automated programmable controllers, to ensure the castings meet the proper standards. The company's castings come with a Kan-Ban inventory to help manage the stock.

-

-

-

-

-

Thompson Aluminum Casting Company

Aluminum Casting

Manufacturer Overview

Thompson Aluminum Casting Company, based in Cleveland, Ohio, is a manufacturer and supplier of metal castings, founded in 1946. They specialize in the production of aluminum castings and magnesium castings, utilizing sand and permanent mold methods. They produce engine components and various structural parts through the casting process. Their casting techniques are used for the creation of durable components, which are essential for the functioning and stability of engines and structures in the aerospace and defense industries. Thompson Aluminum Casting Company holds NADCAP accreditation, ISO 9001 certification, and AS 9001 certification, in compliance with industry standards in the aerospace sector.

-

-

-

-

-

Olson Aluminum Castings

ALUMINUM CASTING

Manufacturer Overview

Olson Aluminum Castings is a custom manufacturer of industrial grade pressure tight and leak-free castings established in 1975 and based in Rockford, Illinois. The company produces various castings made from A356, 319, 535, and 713 aluminum alloys for clients in the automotive, aerospace, defense, and industrial sectors. The company's extensive product lineup includes impellers for fluid propulsion and movement, heat sinks for electronic cooling equipment, manifolds for gas or liquid distribution, and gearboxes for power transmission. Olson Aluminum Castings also offers prototype casting design and engineering services to clients from its ISO 9001:2015 certified main facility.

-

-

-

-

-

Alumicast Inc.

Aluminum Castings

Manufacturer Overview

Alumicast, Inc., headquartered in Dallas, Georgia, is a manufacturer and supplier of aluminum castings and precision machined components. Their company specializes in producing aluminum castings for industries such as automotive, energy, electronics, and medical applications. The company is ISO 9001:2015 certified, which means that it has met rigorous standards for quality management. Their products are used for various applications, including automotive parts, electronic enclosures, and medical hardware, providing lightweight, durable, and intricate solutions for a range of industrial and commercial applications.

-

-

-

-

-

Wabash Castings LLC

Aluminum Castings

Manufacturer Overview

Wabash Castings LLC, established in 1978 and headquartered in Wabash, Indiana, is a supplier and manufacturer of aluminum sand castings. The company specializes in aluminum sand casting parts for agriculture, automotive, recreation, railroad, and off-highway industries. They employ the green sand casting process and offer capabilities such as computer-aided engineering, sand core manufacturing, robotics, 3D printing, and X-ray technology. They hold IATF 16949: 2016 and the Environmental Management System ISO 14001: 2015 certifications.

-

-

-

-

-

Supreme Castings & Pattern Co., Inc.

Aluminum Castings

Manufacturer Overview

Established in 1971, based in Anaheim, CA, Supreme Castings & Pattern Co., Inc. manufactures precision aluminum castings and plaster mold castings with Military and aerospace applications. They supply castings to several commercial electronics and medical equipment manufacturers and they serve products to the companies like Honeywell, Northrop-Grumman, G.E. Aviation, and, L3-Communications. The company provides plaster mold castings and Rapid prototyping services for the Military sector and they offer aluminum castings that have applications in aerospace, electronics, commercial, and, medical industries.

-

-

-

-

-

Mystic Valley Foundry, Inc.

Aluminum Castings

Manufacturer Overview

Mystic Valley Foundry, Inc., founded in Somerville, MA, in 1936 is a manufacturer of aluminum and brass/bronze castings. The company's product portfolio includes aluminum components, Non-Ferrous Sand Casting, and Green Sand Casting. The company serves industries such as Oil and Gas, Aerospace and Defense, Automotive and Transportation, Construction, and Power Generation. The company also provides services such as Engineering and Product Design Assistance, Rapid Prototyping, customer support and national delivery.

-

-

-

-

-

Integrated Solutions Outsourced Manufacturing

Aluminum Castings

Manufacturer Overview

Integrated Solutions Outsourced Manufacturing is an overseas manufacturer of machine parts founded in 2002, with domestic operations based in Garden Grove, California, USA. The company works with various metals and plastics, providing manual and CNC turning and milling, custom die and mold casting forging, welding, and gear design and manufacturing services. Products they sell include material handling equipment such as conveyors, rollers, carts, and cranes, heat induction coils, rolls of rubber, steel, and, aluminum, Polyethylene Terephthalate and BOPP film, and custom plastic components.The company primarily caters to OEM and general manufacturing industries.

-

-

-

-

-

Amos Industries, Inc.

Aluminum Castings

Manufacturer Overview

Amos Industries, Inc., founded in 1999 and based in Aurora, Illinois, is a manufacturer and supplier of machine parts. It offers R&D, stamping, forgings, castings, metal injection molding, precision machining, surface treatment, product assembly, heat treatment, and more. The company provides services ranging from sample development and product optimization to an after-sale service as a e-stop-shop experience. It serves customers in the motive, agricultural, marine, sports & athletics, aerospace, healthcare and related industries.

-

-

-

-

-

Aero Metals, Inc.

Aluminum Castings

Manufacturer Overview

Aero Metals, Inc., established in 1961, is a LaPorte, Indiana-based manufacturer of metal parts. The company specializes in precision investment castings using various types of materials such as stainless steel, ductile iron, cobalt-based alloys, and aluminum. Aero Metals is a major investment casting supplier of Hydraulic fluid system components, Landing and braking components, and Cargo systems to aviation and aerospace customers. The company also manufactures parts for agricultural, industrial, and military equipment as well as medical devices.

-

-

-

-

-

Roto Dynamics Inc.

Aluminum Castings

Manufacturer Overview

Roto Dynamics Inc., founded in 2004 and headquartered in Orange, California, is a manufacturer of rotationally molded plastic products. They offer a range of products and services, including design and development, mold making, rotational molding, and assembly and finishing. The company is ISO 9001:2015 certified and is a member of the Rotational Molding Association. The company has the ability to mold complex rotomolded parts using various plastic resins, colors, textures, threaded inserts, as well as foam fill and molded-in graphics. They cater to diverse industries such as agriculture, chemical, construction, marine, and medical.

-

-

-

-

-

Wisconsin Aluminum Foundry Co

Aluminum Castings

Manufacturer Overview

Wisconsin Aluminum Foundry, founded in 1909 and headquartered in Manitowoc, Wisconsin, is a manufacturer of aluminum castings. They specialize in aluminum and copper-based alloy castings through machining, heat treating, inspection, tooling, as well as pattern making, and prototyping. The company is ISO 9001:2015 certified, ITAR registered, and NADCAP accredited. They have also received several awards, such as Wisconsin Manufacturer of the Year in 2015 and Award of Excellence from the American Foundry Society in 2017.

-

-

-

-

-

Franklin Bronze Plaques

Aluminum Castings

Manufacturer Overview

Franklin Bronze Plaques is a manufacturer of custom bronze plaques and awards that is headquartered in Franklin, Tennessee, and has been in operation since 1878. The company offers a wide range of bronze plaques, including awards, recognition plaques, and custom plaques. It uses the no-bake molding system that produces sand castings in brass, bronze, aluminum, stainless steel, and nickel-based alloys. Franklin Bronze Plaques offers other multiple finishes, including gold and silver and some of its popular products include completed projects, custom shapes, memorial plaques, embossed background relief and aluminum plaques. The company's customers include businesses, organizations, and individuals.

-

-

-

-

-

Engineered Precision Casting Co., Inc. (EPCO)

Aluminum Castings

Manufacturer Overview

The Engineered Precision Casting Co., Inc. (EPCO), founded in 1946, is a manufacturer company of casting materials headquartered in Middletown, New Jersey, United States. The company offer various types of casting materials, such as stainless steel casting, carbon steel casting, nickel-base alloys, cobalt-base alloys, and copper-base alloys. The company's products have been used in various line of industries including aircraft and aerospace, military and defense, oil and gas, medical equipments, and power generation industry. The company has been certified in quality certifications, including ISO 9001, AS9100, AS9102, and AC7110.

-

-

-

-

-

Bremer Manufacturing Co., Inc.

Aluminum Castings

Manufacturer Overview

Bremer Manufacturing Co., Inc., is a manufacturer of aluminum sand castings, established in 1922, and located in Bedford, Massachusetts. They specialize in complex, highly-cored aluminum sand castings ranging from a few ounces to 125 pounds. The company offers maintenance and repair services, and have undertaken diverse projects, including refurbishing submarine components and custom firetruck frame. Bremer Manufacturing Co. holds ISO 9001 certification and is an approved tier 1 and 2 supplier to diesel and internal combustion engine manufacturers and metalworking companies in North America and overseas.

-

-

-

-

-

The Federal Group USA

Aluminum Castings

Manufacturer Overview

Federal Group USA, founded in 1980, is a manufacturer of custom metal components for various industries, headquartered in Fernand, Michigan, USA. From fasteners to metal stamping and CNC machining, they provide a comprehensive range of engineering and manufacturing services. They are a Thomas Verified Supplier, Quality Systems Basics and ISO 9001:2015 certified company. The company’s capabilities include cold heading, metal fabrication, additive manufacturing, and precision CNC machining. Their product applications cater to diverse industries, from automotive and aerospace to medical and consumer goods.

-

-

-

-

-

G&W Foundry Corp.

Aluminum Castings

Manufacturer Overview

G&W Foundry Corp. was founded in 1932 in Millbury, Massachusetts, USA, as a manufacturer of metal products. The company specializes in custom castings, forgings, and stampings, including sand, iron, and machined components, offering precision CNC machining, metal fabrication, and injection molding. It also offers sourcing, design, and inventory management. These offerings are essential in manufacturing processes for creating critical components, including plastic components, ensuring precise part fabrication, streamlining manufacturing processes, and enhancing component durability and performance. The company caters to a diverse range of industries, including automotive, marine, agricultural, rail parts, construction, earthmoving, highway, and HVAC sectors.

-

-

-

-

-

MFI Global Manufacturing, Inc.

Aluminum Castings

Manufacturer Overview

MFI Global Manufacturing, Inc., established in 1985, and located in Newport Beach, California, is a custom manufacturer of metal and plastic parts. Its capabilities includes, stampings, forgings, castings, fasteners, machining, as well as injection molding, assembly & packaging, and warehousing in which these cater in industries such as agriculture, military, mining, and automotive. Utilized materials includes stainless steel, aluminum, ceramic, titanium, plastic, and more. The company is also ISO/TS16949 and ISO9001 certified for its management and products.

-

-

-

-

-

Source International

Aluminum Castings

Manufacturer Overview

Source International is an American-owned industrial supplier established in 1988, headquartered in Louisville, Kentucky and with offices in Xiamen, China and Ho Chi Minh, Vietnam. The company provides its customers with access to its multinational network of factories for them to source their requested items. The company’s factory network has manufacturing capabilities of plastic injection molding, CNC machining, metal forging, and product assembly, among others. They do not directly market any products of their own, offering OEM services and their custom tooling fabrication and mold making to customer specifications as their core business model.

-

-

-

-

-

Marlborough Foundry, Inc.

Aluminum Castings

Manufacturer Overview

Marlborough Foundry, Inc., established in 1953 and headquartered in Marlborough, Massachusetts, is an aluminum castings manufacturer. The company offers a wide product range, serving various industries, including the military sector with castings for personal armor, sonar, and radar transducer heads. They have also produced aluminum castings for the medical industry, ranging from small parts like knuckles on dentist chair lights to large CAT scan tables. They specialize in providing medium-sized aluminum castings through sand and permanent mold methods, weighing from 15 to 100 pounds. Their quality control system adheres to MIL-I-45208A standards.

-

-

-

-

-

Barron Industries

Aluminum Castings

Manufacturer Overview

Barron Industries, established in 1923 and headquartered in Oxford, Michigan, is a manufacturer and supplier of precision investment castings. They specialize in providing precision investment castings and prototype castings using ferrous and non-ferrous metals, including lightweight aluminum, high-strength stainless steel, nickel, and cobalt-based alloys. They offer a comprehensive range of services such as machining, assembly, finishing, and engineering support, catering to industries including aerospace, defense, automotive, medical, and industrial. The company holds AS9100 and ISO9001 certifications, ensuring adherance to industry standards and processes.

-

-

-

-

-

Woodward Industries, Inc.

Aluminum Castings

Manufacturer Overview

Woodward Industries, Inc., established in 1953 and headquartered in Saint Paul, Minnesota, is a custom manufacturer of engineered products. The company offers foundry tooling, molds, prototypes, aluminum castings, and assemblies for a range of industries such as medical, sports kayaking, and military. Some of its products include V-Process Cope and Drag Patterns, urethane Battery Molds for the medical industry, aluminum blow molds for sport kayaking, and foam model parts for the military.

-

-

-

-

-

Cast Aluminum Solutions, LLC

Aluminum Castings

Manufacturer Overview

Cast Aluminum Solutions, LLC, is a custom manufacturer of custom and standard heat exchangers, thermal components, and circulation heaters for microelectronics, global aerospace, food service, medical, and industrial fluid markets. The company in Batavia, Illinois 60510, USA, offers comprehensive Design & engineering, new product development& prototype, and full-service manufacturing& production services. The company is ISO 9001: 2015 certified and a winner of Manufacturer of the Year (Illinois Manufacturing Alliance), Inc. 5000, and the ML100 Manufacturing Leadership Award. The company uses the Solidworks 3-D computer-aided design (CAD) application design software and Finite Element Analysis to create thermal and structural models.

-

-

-

-

-

MCMILLANCO, LLC

Aluminum Castings

Manufacturer Overview

MCMILLANCO, LLC is a manufacturer that provides custom component manufacturing solutions, based in West Liberty, Ohio. The services provided by MCMILLANCO, LLC are primarily focused on manufacturing processes. They offer services such as aluminum sand casting foundry, machining, metal stamping, injection molding, and vapor deposition coating. These services are utilized in the manufacturing industry to produce components, parts, and finished products such as in medical device manufacturing, steel fabrication, natural gas, defense, and film production.

-

-

-

-

-

RCM Industries, Inc.

Aluminum Die Castings

Company Overview

RCM Industries, Inc. is a manufacturer and supplier of aluminum die casting products and was founded in 1951 as RCM Industries and is based in Franklin Park, Illinois, United States. The company's range of offerings encompasses die castings, finishing, machining, and assembly services, among other services. The company's die casting goods and accessories exhibit innovation, efficiency, precision, and user-friendliness. These products have been specifically engineered to cater to a diverse array of requirements across several sectors, including but not limited to the automotive, medical, industrial, and consumer electronics industries.

-

-

-

-

-

Precise Cast Prototypes & Engineering, Inc.

Aluminum Sand Casting

Company Overview

Precise Cast Prototypes & Engineering, Inc., established in 2004 and based in Commerce City, Colorado, USA, is a manufacturer and supplier of metal castings and machined parts. The company's product range includes aluminum castings, magnesium castings, zinc castings, CNC machining, and rapid prototype machining. These products play a role in the creation of durable components for various applications. The company primarily serves the aerospace & defense, automotive, electronics, medical devices, and industrial equipment industries. Its services consist of prototype creation, rapid machining, engineering design assistance, and rapid prototype machining.

-

-

-

-

-

Leitelt Brothers, Inc.

Aluminum Sand Casting

Company Overview

Leitelt Brothers, Inc. established in 1908 and based in Chicago, IL, USA, is a seasoned manufacturer and supplier of metal sand castings. The company's product range includes aluminum sand castings, brass sand castings, bronze sand castings, non-ferrous castings, and specialty alloys upon request. These components are used in various applications and have been crafted with precision and expertise. It serves industries such as mining, marine, rolling mill, and architectural sectors. The company also provides services like green sand molding, air set molding, in-house machining, and weldment conversion.

-

-

-

-

-

-

-

-

-

Aluminum Alloys, Inc.

Aluminum Castings

Distributor Overview

Aluminum Alloys, Inc., established in 1953, based in Sinking Springs, Pennsylvania, is a distributor of fabrication, casting, molding and machining working with aluminum material. The company offers services in turning, milling, drilling, CNC, NC and conventional machining. The company also provides and produces parts using single pour, automatic or roto-lift molding processes. Secondary services offered include finishing services for castings, used for large and complex castings. The company serves power generation, military, food processing, automotive, electrical and medical industries.

-

-

-

-

-

Control Plastics Inc.

Aluminum Castings

Distributor Overview

Control Plastics Inc. is a supplier of plastic and metal components, operating in the USA since 1978. Their devotion to excellence and precision has solidified their position as a partner for industries spanning aerospace, electronics, and consumer goods. Offering diverse services, including design, prototyping, and manufacturing, Control Plastics Inc. delivers tailored solutions to meet clients' unique needs. Boasting a proven track record of delivering products on time, Control Plastics Inc. excels in fostering strong client relationships and utilizing advanced manufacturing technologies.

-

-

-

-

-

Alumistar, Inc.

Aluminum Castings

Distributor Overview

Alumistar Inc., established in 2003, is based in California, United States, and is a distributor specializing in the Mining & Metals sector. This aluminum foundry is maintained and run by individuals residing within the local community. The company provides its customers with superior sand-cast aluminum components for their products, leveraging the expertise and knowledge of its skilled staff in the foundry. The casting process involves the production of each component using aluminum ingots, which are tailored to meet the specifications provided by the customer.

-

-

-

-

-

ForceBeyond, Inc.

Aluminum Castings

Distributor Overview

ForceBeyond, Inc., is a supplier of fabricated products such as castings, hot and cold forgings, fitting & fasteners, and cast iron parts since 2006. The castings are from metals such as aluminum & zinc, carbon & alloy, stainless steel, and titanium; high-pressure valves and steam y-strainers are available. The products are used in automotive & transportation, mining energy & power utility, medical, HVAC & Flow control, and commercial industries. Services such as supply chain management, sub-assembly, custom packaging, and global sourcing are offered in the New Castle, Delaware-based company which is ISO 9001:2015 certified.

-

-

-

-

-

Sunrise

Aluminum Die Castings

Manufacturer Overview

Sunrise Metal Technology Co., Ltd., founded in 2013, is a Chinese manufacturer based in Kunshan, Jiangsu, specializing in die casting solutions. The company provides a range of services centered around aluminum die casting manufacturing and computer numerical control (CNC) machining, specifically for aluminum materials. This includes CNC milling, drilling, tapping, and boring processes. It also offers rapid prototyping services utilizing both additive and subtractive manufacturing techniques. Optional surface finishing services are available for both the die casting and machining processes. The company serves various industries with its die casting and machining capabilities, notably catering to the automotive, marine, medical, and telecommunications sectors.

-

-

-

-

-

Enchuang Precision Hardware Technology Co., Ltd.

Aluminum Die Castings

Manufacturer Overview

Enchuang Precision Hardware Technology Co. Ltd, established in 2010, is a manufacturer of industrial machinery based in Dongguan, China. The company specializes in hardware, such as zinc die casting, connector shells, and connector housing used in manufacturing industries. It offers processing services such as surface treatment, aluminum, zinc alloy and magnesium die-castings. Its main partners include Amphenol, BYD, JONHON, IMS and TTI. The company’s products are IATF-CERTIFIED and are exported to the United States, UK, France, Germany and Italy.

-

-

-

-

-

HX metal casting Co., Ltd.

Aluminum Alloy Casting

Manufacturer Overview

HX metal casting Co., Ltd., established in 2003 and based in Shantou, China, is a manufacturer of industrial metal casting products. The company specializes in low carbon steel casting, stainless steel and alloy steel casting, aluminium castings and brass castings. Starting with a machining workshop with lathe and milling machines, it has expanded its business to OEM industries. With a casting foundry equipped with two production lines of lost wax casting, it provides casting solutions in tracery, craft, mechanical parts, auto parts and tools. The company offers custom steel manufacturing and OEM metal fabrication services according to design drawings or original samples.

-

-

-

-

-

Asanuma Giken Co.,Ltd.

SEMISOLID ALUMINUM CASTING

Manufacturer Overview

Asanuma Giken Co., Ltd., located in Shizuoka, Japan, is a prototype manufacturer specializing in supporting the development of next-generation vehicles and advanced products. The company excels in prototype production for transportation equipment, demonstrating expertise in precision aluminum sand mold casting and machining. As part of its offerings, it's also involved in the production and sale of daily check tools for Coordinate Measuring Machines (CMM) and provides commissioned measurement services. Furthermore, the company undertakes gauge block calibration, ensuring the accuracy and reliability of measurement instruments.

-

-

-

-

-

SINTOKOGIO, LTD.

Aluminum casting

Manufacturer Overview

Sintokogio, Ltd., headquartered in Nagoya City, Japan, and established in 1934, is a versatile manufacturer of industrial equipment and machinery. They specialize in manufacturing equipment and machinery for foundries, including molding machines, sand mixers, and casting robots. Additionally, Sintokogio caters to the surface treatment industry by providing shot blasting machines, painting systems, and coating equipment. They also offer environmental solutions, such as dust collectors, exhaust gas treatment systems, and waste treatment equipment, ensuring efficient operations of the industries. Sintokogio, Ltd. operates multiple manufacturing facilities across various locations in Japan, including Toyokawa, Ichinomiya, and Osaki.

-

-

-

-

-

F.C.C. Co.,Ltd.

Lightweight, compact, high-precision aluminum die casting

Manufacturer Overview

F.C.C. Co., Ltd., originally established as Fuji Lite Industries Co., Ltd. in 1939 and headquartered in Sato-cho, Hamamatsu City, Shizuoka Prefecture, Japan, is a manufacturer of clutches and facings. Its product line includes motorcycle clutches, automobile clutches, and general-purpose clutches, serving various applications in the automotive and lawn care sectors. These are integral to the operation of motorcycles, automobiles, and various machinery, enabling the controlled transfer of power and facilitating the functionality of these vehicles and equipment. The company holds certifications such as ISO 9001, ISO 14001, TS 16949, and QS9000, reflecting its adherence to quality standards.

-

-

-

-

-

Bonnell Aluminum

ALUMINUM CASTING PROCESS

Manufacturer Overview

Bonnell Aluminum, established in 1950 and headquartered in Georgia, United Stated, is a manufacturer in the aluminum extrusion industry. The company specializes in providing custom aluminum extrusions, fabrication, and finishing services to a diverse range of industries. Its products are utilized across various sectors for applications such as architectural building systems, automotive components, and consumer electronics. The company supports industries by delivering tailored aluminum products for a wide array of applications.

-

-

-

-

-

Dynacast, a Form Technologies Company

ALUMINUM DIE CASTING METALS

Manufacturer Overview

Dynacast, a Form Technologies Company, founded in Charlotte, NC in 1936 is a manufacturer of precision components using proprietary die-casting technology and tooling techniques. The company's product portfolio includes die casting materials, Optical Components, Machined Parts, Custom Fasteners and intricate components for electronic devices, circuit boards, and telecommunications equipment. Their products are used in markets such as Automotive and Transportation, Telecommunications, Industrial Automation, Healthcare and Medical Devices and Aerospace and Defense.

-

-

-

-

-

Modern Aluminum Castings Co., Inc.

Aluminum Castings

Manufacturer Overview

Modern Aluminum Castings Co., Inc., established in 1919, is a pattern maker and manufacturer of aluminum castings for OEMs worldwide based in Terre Haute, Indiana. The company is a one-stop source for Castings and Component Parts including Aluminum Sand Castings, Aluminum Permanent Mold Castings, Iron Castings as well as Investment Castings. Modern Aluminum Castings also offers design assistance for wood and metal patterns, including Close Tolerance Aluminum Castings. The company serves a wide range of industries including Automotive, Medical Devices, and Industrial machinery.

-

-

-

-

-

Impro Industries USA, Inc.

Aluminum Castings

Manufacturer Overview

Imperial Carbide, Inc., founded in 1966, and located in Meadville, Pennsylvania, is a custom manufacturer of precision tool and die components. Its capabilities include precision CNC turning & drilling, milling, threading, broaching, and wire or sinker electrical discharge machining (EDM), which are caters to industries such as aerospace, packaging, automotive, medical, electronics. Its capabilities are utilized to fabricate intricate and precise components for various industries, ensuring accurate dimensions and specifications.

-

-

-

-

-

PMIeng

Aluminum Castings

Manufacturer Overview

Progressive Manufacturing Ideas Eng (PMI Eng) is an American ISO 9001:2015, ITAR registered contract manufacturer specializing in metal components engineering processes since its establishment in Grapevine, Texas in 1976. The company’s capabilities include cold forming, sand casting, laser cutting, machining, and 3D printing. They also offer shaping and forming services such as forging, stamping and punching. These are used in the production of high strength and low cost complex metal parts. PMI Eng chiefly serves clients in the defense and military, aerospace, and medical industries, including Raytheon, BAE Systems, and Stryker.

-

-

-

-

-

Nanjing Power-Est Industry&trade Co., Ltd.

Aluminum Die Castings

Company Overview

Nanjing Power-Est Industry & Trade Co.,established in 2015, is a manufacturer and supplier of industrial components based in Nanjing, China. The company's product portfolio includes iron, steel and brass castings, machining parts and plastic parts. The products are used in the automobile, agricultural, medical and electronics industries to create engine blocks, switchgear and circuit breakers. The company has two manufacturing sites, an in injection molding facility and an aluminum die-casting factory which are ISO 9001-certified.

-

-

-

-

Company Overview

Reliable Manufacturing Company (RMC) is a manufacturer and supplier of ferrous and non-ferrous metals founded in 1999 and headquartered in Shangdong, China. The company manufactures intricate precision near-net or net custom castings for metals like iron, steel, zinc, brass, and copper-based alloys. Its product portfolio includes investment, sand, shell mold, lost foam, and vacuum casting. RMC products are applied in various industries, including logistics equipment, automotive, agricultural, and construction machinery. The company offers a range of services, including metal foundry, outsourced heating, surface treatment as well as the supply of single prototype parts and complex designing.

-

-

-

-

-

ZheJiang Dongrun Casting Industry Co,.Ltd.

Aluminum Sand Casting

Company Overview

ZheJiang Dongrun Casting Industry Co Ltd, established in 1995 and based in Zhejiang Province, is a manufacturer and supplier of CNC machinery products. Its product portfolio includes sand casting, gravity die casting, aluminum sand casting, high pressure, and low-pressure die casting. The company’s products are used in multiple industries including automotive, medical, fuel, gas, electric, lighting, and furniture. They also offers design solutions, processing systems, and equipments with different specifications.

-

-

-

-

-

HIROSHIMA ALUMINUM INDUSTRY CO., LTD.

Die Casting Production

Company Overview

Hiroshima Aluminum Industry Co., Ltd., a manufacturer and distributor originally established as Tajima Kurazou Shoten in Yokokawa-cho, Hiroshima City in 1921, boasts a rich and enduring history. The company's expertise extends to offering comprehensive services, including the design, production, and sales of molds for a wide range of applications. The company is known for manufacturing and distributing cooking utensil products and crafting quality light alloy ingots suitable for various industrial applications. Equipped to handle all operations that complement its services, it ensures a holistic approach to meeting its customers' needs.

-

-

-

-

-

Reliance Foundry Co. Ltd.

Rims, Tins, and Airplanes: Aluminum and Aluminum Castings

Company Overview

Reliance Foundry Co. Ltd. is a manufacturer of superb custom and stock cast metal products. Established in 1925 and located in USA. The company is a long-recognized supplier of outdoor site furnishings, bike storage systems, hardscape products, and traffic management supplies. Reliance also draws on its long history to provide excellence in the manufacture of steel wheels as well as superior custom casting services. Reliance Foundry has built upon a long tradition of metal casting expertise to become an award-winning supplier for high-profile and everyday needs across North America.

-

-

-

-

-

Gensun Precision Machining Co., Ltd

Aluminum Castings

Company Overview

Gensun Precision Machining Co., Ltd, established in 2006 and headquartered in Dongguan, China, is a manufacturer, distributor, and supplier of custom precision machined parts. Their custom machined products cater to industries such as aerospace, medical devices, electronics, telecommunications, and consumer products. Gensun holds ISO 9001:2015 and ISO 14001:2015 certifications, highlighting their adherence to quality. The company helps technical developments and industrial applications by providing the precision components that are crucial for assuring dependability, and efficiency.

-

-

-

-

-

American Aluminum Extrusions

Aluminum Die Castings

Company Overview

American Aluminum Extrusions, established in 2001 and based in Roscoe, Illinois, USA, is a manufacturer and supplier of aluminum extrusions and fabrications. The company’s product lineup includes quality aluminum extrusions and fabrications, pivotal for the Transportation, Distribution, Building and Construction, and Electrical industries. The company's services include the provision of standard, individualized customer service, design, and tolerance specifications, ensuring that clients obtain great quality and tailored aluminum solutions meant for various needs.

-

-

-

-

-

LE SUEUR INCORPORATED

Aluminum Die Castings

Company Overview

Le Seur Incorporated, established in 1946, is a manufacturer and supplier of aluminum castings based in Minnesota, United States. The company uses production methods like permanent mold, die casting, plastic injection molding, sand casting and precision machining. The castings are ISO-CERTIFIED and go through casting X-ray and metallurgical labs for testing to meet quality standards. These products are used in medical, agricultural, military, recreational and transportation applications by 130 customers worldwide.

-

-

-

-

-

Pace Industries, Inc.

Aluminum Die Castings

Company Overview

Pace Industries, Inc. established in 1970 and headquartered in Novi, Michigan, USA, is a manufacturer and supplier of die-cast products. The company's product range includes aluminum die casting, machining, magnesium die casting, zinc die casting, and tool and die. These products are essential for various applications like thin wall, test/validation, assembly, and prototyping. Serving industries such as appliance, aerospace and defense, automotive, and lighting and electrical, it ensures the delivery of quality solutions. Its integrated services further include production capabilities, product development, and materials expertise.

-

-

-

-

-

Le Claire Manufacturing Co.

Aluminum Sand Casting

Company Overview

Le Claire Manufacturing Co., established in 1966 and based in Bettendorf, Iowa, USA, is a manufacturer and supplier of aluminum castings. The company's product range includes sand castings, permanent mold castings, CNC machining, molds, and patterns. These products are for customers requiring an end-to-end service. It serves industries such as agriculture, recreational vehicles, heavy trucks, and marine. The company also offers engineering expertise, upfront design assistance, on-time delivery, and customer service.

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

Kedar Enterprises

Aluminum Sand Casting

-

-

-

-

-

Cast Metals Technology

Aluminum Sand Casting

-

-

-

-

-

Superior Bronze Corporation

Aluminum Castings

Company Overview

Founded in 1917, with its headquarter in Erie, Pennsylvania, Superior Bronze Corporation manufactures sand castings in brass, bronze, monel, stainless steel, aluminum, and other special alloys. Their products have been used in general industrial, commercial, and military settings. The company offers core-making that ranges from a single core of simple design to multiple complex-core inserts that have many commercial applications. They also provide melting, molding, and machining services including milling, drilling, turning, and tapping that are needed in the construction industry.

-

-

-

-

Distributor Overview

VPIC Group, established in 1994 and headquartered in Dong Nai, Vietnam, is a supplier that offers a range of manufacturing services. The company offers a range of manufacturing services such as aluminum die casting, hot forging, tooling, CNC and assembly, and more. It also provides secondary manufacturing processes such as bicycle frame manufacturing and investment casting. Its services can help businesses achieve their desired product specifications and quality standards. The company has received ISO 9001, ISO TS/16949, and ISO 14001 certifications. It serves various industries such as power sports, automotive, agriculture, construction, healthcare, and more.

-

-

-

-

-

QINGDAO BRILLIANT MACHINERY

Aluminum Die Castings

Distributor Overview

Qingdao Brilliant Machinery is a supplier of extrusion products and aluminum/magnesium casting components based in Qingdao, China. The company's supply portfolio includes aluminum and magnesium alloys used in communication electronics, rail transit and automobile industries. The products are tested using technologies like electronic Brinell hardness tester, X-ray detection, salt spray tester and metallurgical microscope. The company supplies its products to Alstom, CAF, Bombardier, BMW and Harley-Davidson. It also has ISO and BV accreditations of standard assurance.

-

-

Aluminum Casting Manufacturer Ranking

*Including some distributors, etc.Ranking as of April 2024

Derivation Method| Rank | Company | Click Share |

|---|---|---|

| 1 | Thompson Aluminum Casting Company |

3.5%

|

| 2 | Chicago White Metal Casting, Inc. |

3.5%

|

| 3 | PHB Inc |

3.5%

|

| 4 | Alumicast Inc. |

3.5%

|

| 5 | Olson Aluminum Castings |

3.1%

|

| 6 | AmTech OEM |

3.1%

|

| 7 | Mystic Valley Foundry, Inc. |

3.1%

|

| 8 | Asanuma Giken Co.,Ltd. |

2.6%

|

| 9 | Soldy Manufacturing |

2.6%

|

| 10 | Control Plastics Inc. |

2.6%

|

Derivation Method

The ranking is calculated based on the click share within the aluminum casting page as of April 2024. Click share is defined as the total number of clicks for all companies during the period divided by the number of clicks for each company.Number of Employees

- F.C.C. Co.,Ltd.: 8,053

- HIROSHIMA ALUMINUM INDUSTRY CO., LTD.: 5,712

- SINTOKOGIO, LTD.: 1,772

Newly Established Company

- Nanjing Power-Est Industry&trade Co., Ltd.: 2015 (9 years ago)

- Sunrise: 2011 (13 years ago)

- Enchuang Precision Hardware Technology Co., Ltd.: 2010 (14 years ago)

Company with a History

- Wisconsin Aluminum Foundry Co: 1909 (115 years ago)

- HIROSHIMA ALUMINUM INDUSTRY CO., LTD.: 1921 (103 years ago)

- G&W Foundry Corp.: 1932 (92 years ago)

Aluminum Casting Manufacturers in United States

*Including some distributors, etc.

- AmTech OEM

- Chicago White Metal Casting, Inc.

- Fort Recovery Industries, Inc.

- Soldy Manufacturing

- PHB Inc

- KenWalt Die Casting Company

- Thompson Aluminum Casting Company

- Olson Aluminum Castings

- Alumicast Inc.

- Wabash Castings LLC

- Supreme Castings & Pattern Co., Inc.

- Mystic Valley Foundry, Inc.

- Integrated Solutions Outsourced Manufacturing

- Amos Industries, Inc.

- Aero Metals, Inc.

- Roto Dynamics Inc.

- Wisconsin Aluminum Foundry Co

- Franklin Bronze Plaques

- Engineered Precision Casting Co., Inc. (EPCO)

- Bremer Manufacturing Co., Inc.

- The Federal Group USA

- G&W Foundry Corp.

- MFI Global Manufacturing, Inc.

- Source International

- Marlborough Foundry, Inc.

- Barron Industries

- Woodward Industries, Inc.

- Cast Aluminum Solutions, LLC

- MCMILLANCO, LLC

- RCM Industries, Inc.

- Precise Cast Prototypes & Engineering, Inc.

- Leitelt Brothers, Inc.

- Cast Rite Metal Company

- Aluminum Castings Company LLC

- Aluminum Alloys, Inc.

- Control Plastics Inc.

- Alumistar, Inc.

- ForceBeyond, Inc.

Global Distribution of Aluminum Casting Manufacturers by Country

*Including some distributors, etc.

| Country | Number of Companies | Share (%) |

|---|---|---|

United States of America

United States of America

|

38 | 65.5% |

China

China

|

11 | 19.0% |

Japan

Japan

|

4 | 6.9% |

Canada

Canada

|

1 | 1.7% |

United Kingdom

United Kingdom

|

1 | 1.7% |

India

India

|

1 | 1.7% |

Netherlands

Netherlands

|

1 | 1.7% |

Vietnam

Vietnam

|

1 | 1.7% |