13 Cemented Carbide Manufacturers in 2024

This section provides an overview for cemented carbide as well as their applications and principles. Also, please take a look at the list of 13 cemented carbide manufacturers and their company rankings. Here are the top-ranked cemented carbide companies as of April, 2024: 1.Yillik Precision Carbides, Division of PSM Industries, Inc., 2.Castlebar Corporation, 3.Dura-Metal Products Corporation.

Table of Contents

1987~1991: Engaged in research on wire covering materials at Polymer Materials Laboratory.

1991~1997: Worked as a patent Engineer at Koike International Patent Office.

1997~2005 Worked as an intellectual property member at GE Yokogawa Medical System, currently working as a writer.

Linkedinhttps://www.linkedin.com/in/%E8%A3%95%E5%AD%90-%E9%88%B4%E6%9C%A8-92b21a234/

researchmap

https://researchmap.jp/0315rs2017

What Is Cemented Carbide?

Cemented carbide is a generic term for composite alloys made by adding iron-based metals to metals in groups 4-6 of the periodic table.

In particular, WC-Co alloys, in which cobalt is bonded to tungsten carbide, are commonly used. They are extremely hard and can maintain their room temperature hardness even at high temperatures. They are also strong and resistant to external forces, such as bending.

Uses of Cemented Carbide

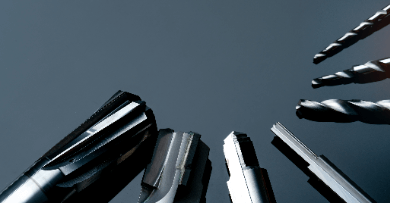

Cemented carbides are used in fields where wear resistance is required. Specifically, they are used in cutting and polishing tools for glass, plastic, and metal processing. They are also suitable for applications such as drills for drilling holes in rock and concrete, nozzles for industrial products, pipes for electrodes, pins for dot printers, and punch pins.

Cemented carbide is second only to diamond in hardness and maintains its hardness even at high temperatures. It is also characterized by its high strength and resistance to bending under load. They are used in fields where these characteristics can be utilized.

Principle of Cemented Carbide

Cemented carbides are composite alloys made by bonding (sintering) metal oxides of metals belonging to groups 4 to 6 of the periodic table with iron-based metals, as described above.

The following nine metals belonging to groups 4-6 of the periodic table are listed.

- W (Tungsten)

- Cr (Chromium)

- Mo (Molybdenum)

- Ti (Titanium)

- Zr (Zirconium)

- Hf (Hafnium)

- V (Vanadium)

- Nb (Niobium)

- Ta (Tantalum)

Typical ferrous metals are as follows:

- Fe (Iron)

- Co (Cobalt)

- Ni (Nickel)

Among these, WC-Co alloys made by adding cobalt as a binder to tungsten carbide are the most representative.

Cemented Carbide Manufacturing Methods

Cemented carbides are manufactured by a special method called powder metallurgy. This is because the melting point of tungsten carbide, the main material used in cemented carbide, is as high as 2,900℃, making it difficult to melt it like iron.

Powder metallurgy is a manufacturing method in which metal powder is pressed and then hardened. Cemented carbide is manufactured by mixing tungsten carbide metal powder with cobalt or other metal powder as a binder, pressing and hardening the mixture, and then sintering it at a high temperature of 1,300 to 1,500℃.

Various composite alloys can be produced by changing the composition of the metal powder to suit the application. At present, in addition to the "WC-Co series," there are many other types developed, including the "WC-TiC-Co series," "WC-TaC-Co series," and "WC-TiC-TaC-Co series.

Cemented Carbide Machining Methods

Cemented carbides are so hard that they cannot be machined by ordinary methods. Therefore, it is machined either by using diamonds, which are harder than cemented carbide, or by using pulsed electric discharge from a pulsed power source.

1. Machining Using Diamond

Diamond is very expensive, so diamond abrasives are used on a wheel for cutting and polishing. The disadvantage is that the diamond portion to be cut is small, so the cutting is done gradually and the process takes a long time. For this reason, tools with a diamond coating on the cutting tool itself have recently been developed.

2. Electric Discharge Machining

Electrical discharge machining includes wire machining and profile drilling. In wire processing, wires are stretched above and below the material, and the material is cut by an electric discharge from the wires. Shape drilling refers to a method in which the material is placed in a liquid and the electrode is brought close to the material while discharging electricity to melt the metal.

Other Information on Cemented Carbide

Cemented Carbide Standards

Cemented carbide is described as HW-P20, which is a cross between a classification by cutting tool material (HW part) and a classification by work material (P20 part).

This indicates what kind of material and what kind of workpiece can be machined. Cemented carbides mainly composed of tungsten carbides are classified into HW and HF according to the particle size, with HW being those with an average particle size of 1 μm or larger and HF being those with an average particle size of less than 1 μm.

HT and HC are also listed as cemented carbides in the standard. HT refers to cermet, which is mainly made of titanium, tantalum, and niobium carbides and nitrides with a low content of tungsten carbide. HC is a symbol for coated cemented carbide, nitride, oxide, or diamond coated on one or more layers on the surface of cemented carbide.

List of 13 Cemented Carbide Manufacturers

*Including some distributors, etc.

Sort by Features

- Default

- Company Size: largest first

- Year Founded: oldest first

- Year Founded: earliest first

Sort by Area

- United States of America

- China

- Japan

-

-

-

Yillik Precision Carbides, Division of PSM Industries, Inc.

Tungsten Carbide Parts & Components

Manufacturer Overview

Yillik Precision Carbides (YPC) is an American custom manufacturer of tungsten carbide alloy products and parts that was established in 1956 as a division of PSM Industries, Inc. Based in Ontario, California, the company produces carbide seal ring nozzles, bushings, guides, rollers, and sizing dies, among other industrial components fabricated to customer specifications. It also offers inventory, supply chain management, and lean manufacturing services to customers. YPC chiefly serves clients in the automotive, transportation, defense, aerospace, and energy production sectors.

-

-

-

-

-

Total Engineered Products, Inc.

Custom Carbide

Manufacturer Overview

Total Engineered Products, Inc. (TEP) is an American custom manufacturer of carbide and ceramic wear parts established in 2002 and based in Addison, Illinois. The company specializes in producing various carbide or ceramic products including slitters, knives, needles, dies, and valve assemblies. These are commonly used in the steel- and metalworking, power generation, automotive, and aerospace sectors. TEP also offers engineering, design, and material selection assistance to customers requiring additional support.

-

-

-

-

-

General Carbide Corporation

Cemented Carbide

Manufacturer Overview

General Carbide Corporation, established in 1968, is a vertically integrated manufacturer of finished tooling and wear parts based in Greensburg, PA. As an ISO 9001:2015-certified company, they employ more than 250 highly-skilled professionals and have four facilities. With Mona Pappafava-Ray as CEO since 2002, they have achieved the Outstanding CEOs & Top Executives, Business Women First Award, Torch Award, and EY Entrepreneur Of The Year 2019 Award. The company offers a wide range of tungsten carbide and steel tooling products for over two dozen market segments, including automotive, oil and gas, and stamping, among others.

-

-

-

-

-

California Nanotechnologies

Cemented Carbide

Manufacturer Overview

California Nanotechnologies, founded in Cerritos, California, in 2005 is a manufacturer of Spark Plasma Sintering (SPS) and Cryogenic Milling. The company's product portfolio includes SPS systems to utilize pulsed direct current to achieve rapid, high-density sintering of advanced materials, such as ceramics, metals, and composites and cryogenic milling machines used for ultra-low temperatures to process and mill a wide range of materials, including polymers and elastomers. The company serves markets including Medical and Healthcare, Aerospace and Defense, Consumer Goods, Industrial Manufacturing and Construction and Building.

-

-

-

-

-

Castlebar Corporation

Cemented Carbide

Company Overview

Castlebar Corporation is an American manufacturer and distributor of specialized tooling products that was established in Canton, Ohio in 1997. The company primarily produces cemented tungsten carbide tooling products, such as tungsten carbide blanks, unground and coolant tungsten carbide rods, grade C2 tungsten carbide blanks, and carbide inserts for mining, grinding or milling. Castlebar Corporation products are commonly used by military contractors and recycling companies, as well as in metalworking, manufacturing plants, and road maintenance operations.

-

-

-

-

-

Innovative Carbide, LLC

Tungsten Carbide

Company Overview

Innovative Carbide is a manufacturer of tungsten carbide wear components headquartered in Pennsylvania, USA. Founded in 1988, the company manufactures a comprehensive range of products, including wear plates, carbide dies and tooling, concrete roof tile tooling, oil and gas components, and more. The company's products are engineered to exhibit hardness, wear resistance, and durability, making it suitable for demanding industrial environments across various sectors, including ammunition and defense, concrete roof tile industry, container industry, oil & gas, and metal forming dies & tools.

-

-

-

-

-

Nippon Tungsten Co., Ltd.

CEMENTED CARBIDE

Manufacturer Overview

Nippon Tungsten Co., Ltd., founded on April 1, 1931, and headquartered in Fukuoka, Japan, is a manufacturer of machine parts and electrical components. Its diverse product line caters to various industries, featuring tungsten and molybdenum products for electrical contacts, cemented carbide, and ceramics. It also produces resistance welding electrodes primarily used in automotive welding, fine ceramics for electronic devices and wear-resistant tools, and magnetic head substrates for hard disk drive manufacturing.

-

-

-

-

-

Sumitomo Electric Industries, Ltd

Cemented Carbide

Manufacturer Overview

Sumitomo Electric Hardmetal Corp., established in April 2003, is a leading manufacturer and supplier of cutting tools and laser optics. Based in Itami, Hyogo, Japan, the company offers a diverse range of products, including cemented carbide, CBN, and sintered diamond cutting tools under brands like IGETALLOY and SUMIBORON. Sumitomo Electric Hardmetal Corp. serves various industries by providing cutting-edge solutions for precision machining and laser processing. As a subsidiary of Sumitomo Electric Industries, Ltd., the company upholds its rposition for innovation, reliability, and customer satisfaction.

-

-

-

-

-

A.L.M.T. Corp.

Cemented carbides

Manufacturer Overview

A.L.M.T. Corp., founded in Japan in 1939, is a manufacturer of heat spreaders, tungsten/molybdenum powder and machined products. The company's product portfolio includes diamond cutting tools, CBN cutting, grinding tools, metallic materials that are used for electrodes in various electronics and heat-resistant parts for high temperature furnaces and drawing dies. The company serves industries such as oil and gas, aerospace and defense, automotive and transportation, construction, and power generation. The company also provides services including national distribution, product selection, installation, preventative maintenance, troubleshooting, repair and customer service.

-

-

-

-

-

Zigong Xingyu Cemented Carbide Dies&Tools Co.,Ltd.

tungsten carbide

Manufacturer Overview

Zigong Xingyu Cemented Carbide Dies & Tools Co., Ltd. is a manufacturer and supplier of tungsten carbide and related components based in Sichuan, China. Founded in 1999, the company primarily manufactures cemented carbide dies and tools. Cemented carbide, or tungsten carbide, is a complex and wear-resistant material used in various industrial applications, including metalworking, manufacturing, mining and construction, and automotive. The company's product portfolio includes tungsten carbide customized parts, rods and plates, cutting tools, mold and dies, and mining tools. The company cooperates with numerous companies and institutions worldwide.

-

-

-

-

-

Changsha Heijingang Industrial Co., Ltd.

Mining Cemented Carbide

Manufacturer Overview

Changsha Heijingang Industrial Co., Ltd., established in 1999, is a manufacturer of rock drilling tools and pneumatic tools headquartered in Changsha, China. The company offers a wide range of rock drilling tools and pneumatic tools designed to meet the various needs of drilling and mining operations. Its product lineup includes rock drilling bits, DTH (Down-The-Hole) hammers, drill pipes, and various pneumatic tools. The company primarily serves mining companies and drilling contractors with clients worldwide, including the USA, Russia, Canada, Australia, and South Africa.

-

-

-

-

-

Southwest Tool Services, Inc.

custom shape carbides & cemented carbides

Manufacturer Overview

Southwest Tool Services, Inc. (STS) is an American manufacturer of industrial tooling and related products that was established in Phoenix, Arizona in 1980. The company’s extensive product portfolio includes various carbide tools, cutting tools, measuring tools, hand tools, and power tools. It also offers various abrasives as well as safety equipment, such as gloves, goggles, and masks. STS products are used by clients in the construction, energy production, transportation, and infrastructure sectors.

-

-

-

-

-

Dura-Metal Products Corporation

Cemented Carbide

Manufacturer Overview

Dura-Metal Products Corporation, established in 1971, is a manufacturer of precision machined components located in Pennsylvania, USA. The company manufactures precision machined components using various materials, including hardened tools and high-speed steels, ferroalloys, cemented carbides, and advanced technical ceramics. These components are crucial in industries that demand quality and durable tooling solutions. The company employs various manufacturing processes to create its precision components. The company serves various industries, including Aerospace and Defense, Automotive, Container, Electronics, and more.

-

-

Cemented Carbide Manufacturer Ranking

*Including some distributors, etc.Ranking as of April 2024

Derivation Method| Rank | Company | Click Share |

|---|---|---|

| 1 | Yillik Precision Carbides, Division of PSM Industries, Inc. |

15.4%

|

| 2 | Castlebar Corporation |

12.8%

|

| 3 | Dura-Metal Products Corporation |

12.8%

|

| 4 | Southwest Tool Services, Inc. |

10.3%

|

| 5 | Innovative Carbide, LLC |

10.3%

|

| 6 | Total Engineered Products, Inc. |

7.7%

|

| 7 | California Nanotechnologies |

7.7%

|

| 8 | Nippon Tungsten Co., Ltd. |

7.7%

|

| 9 | A.L.M.T. Corp. |

7.7%

|

| 10 | Sumitomo Electric Industries, Ltd |

5.1%

|

Derivation Method

The ranking is calculated based on the click share within the cemented carbide page as of April 2024. Click share is defined as the total number of clicks for all companies during the period divided by the number of clicks for each company.Number of Employees

- A.L.M.T. Corp.: 1,291

- Sumitomo Electric Industries, Ltd: 578

- Nippon Tungsten Co., Ltd.: 434

Newly Established Company

- Sumitomo Electric Industries, Ltd: 2003 (21 years ago)

- Zigong Xingyu Cemented Carbide Dies&Tools Co.,Ltd.: 1999 (25 years ago)

- Changsha Heijingang Industrial Co., Ltd.: 1999 (25 years ago)

Company with a History

- Nippon Tungsten Co., Ltd.: 1931 (93 years ago)

- General Carbide Corporation: 1968 (56 years ago)

- Southwest Tool Services, Inc.: 1980 (44 years ago)

Cemented Carbide Manufacturers in United States

*Including some distributors, etc.

- Yillik Precision Carbides, Division of PSM Industries, Inc.

- Total Engineered Products, Inc.

- General Carbide Corporation

- California Nanotechnologies

- Castlebar Corporation

- Innovative Carbide, LLC

Global Distribution of Cemented Carbide Manufacturers by Country

*Including some distributors, etc.

| Country | Number of Companies | Share (%) |

|---|---|---|

United States of America

United States of America

|

6 | 54.5% |

Japan

Japan

|

3 | 27.3% |

China

China

|

2 | 18.2% |