All Categories

History

This section provides an overview for x-ray inspection system as well as their applications and principles. Also, please take a look at the list of 42 x-ray inspection system manufacturers and their company rankings. Here are the top-ranked x-ray inspection system companies as of July, 2025: 1.Autoclear LLC, 2.Rad Source Technologies, 3.RPMI Packaging, Inc..

Table of Contents

Categories Related to X-ray Inspection System

X-ray inspection equipment are devices that can accurately identify elements and hazardous substances in areas invisible to the eye without destroying the object.

X-ray inspection equipment are devices that can accurately identify elements and hazardous substances in areas invisible to the eye without destroying the object.

Based on the transmitted image obtained by irradiating X-rays to the inspected item, the invisible internal conditions are inspected and evaluated.

Since it can see through the inside of a product, which cannot be photographed by a visible light camera, this equipment is indispensable for maintaining high quality in manufacturing, including measures to prevent contamination by foreign matter and hazardous substances.

Today, X-ray inspection systems are used not only in the manufacturing and processing of medical, food, and electronic parts, but also in the construction and aviation industries.

Examples include X-ray imaging at hospitals and baggage checks at airports.

In the medical industry, they are used for endoscopes, CT scanner systems, digital ray systems, and in research fields such as animal research.

X-rays are a form of radiation consisting of photons that have high energy and propagate in flux, and "electromagnetic rays" with short wavelengths. X-rays are a type of radiation.

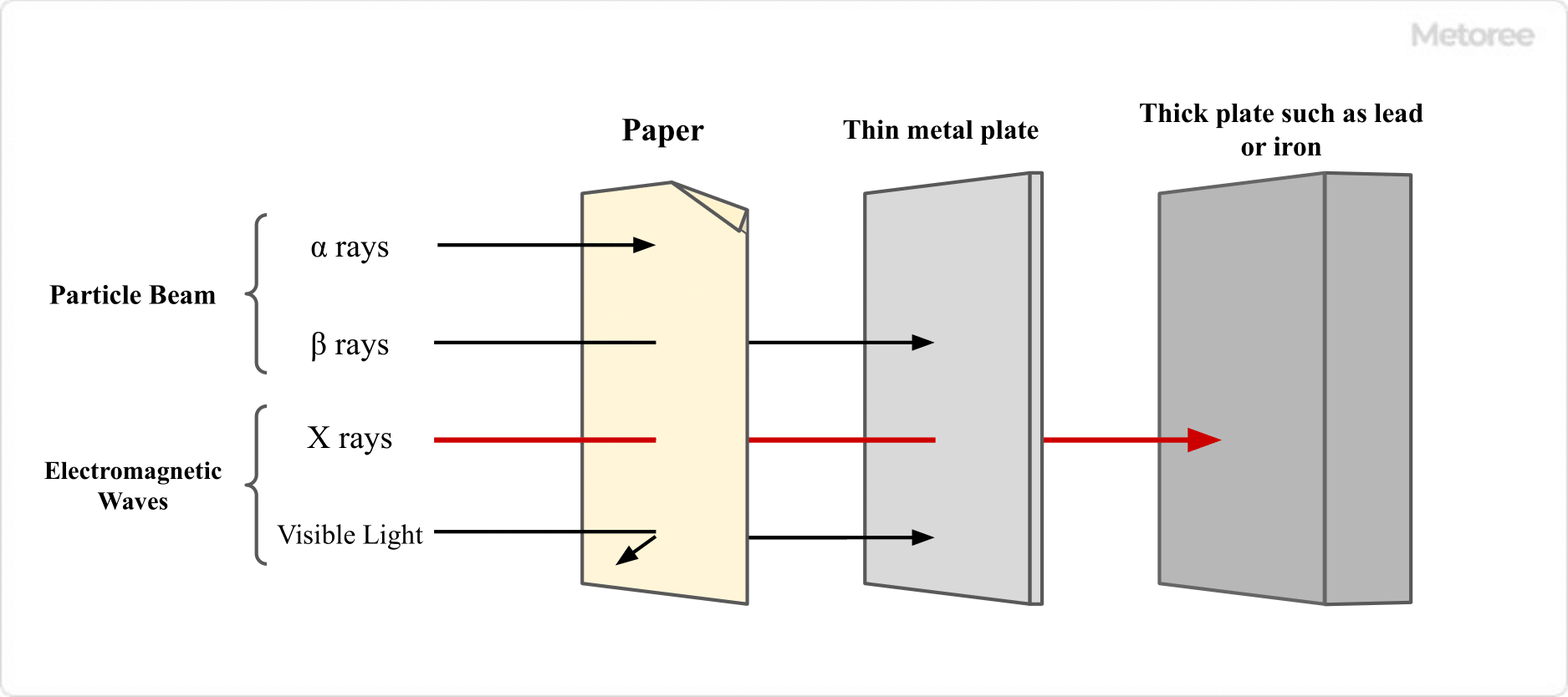

There are five types of ionizing radiation, including X-rays: alpha rays, beta rays, gamma rays, X-rays, and neutron rays.

Among these, X-rays, along with gamma rays, are electromagnetic waves with very short wavelengths, making them highly penetrating through matter by passing between atoms that make up matter.

However, they can be blocked by thick plates of lead or iron.

When X-rays collide with electrons orbiting the nucleus of a material, various interactions such as the photoelectric effect and inelastic scattering occur.

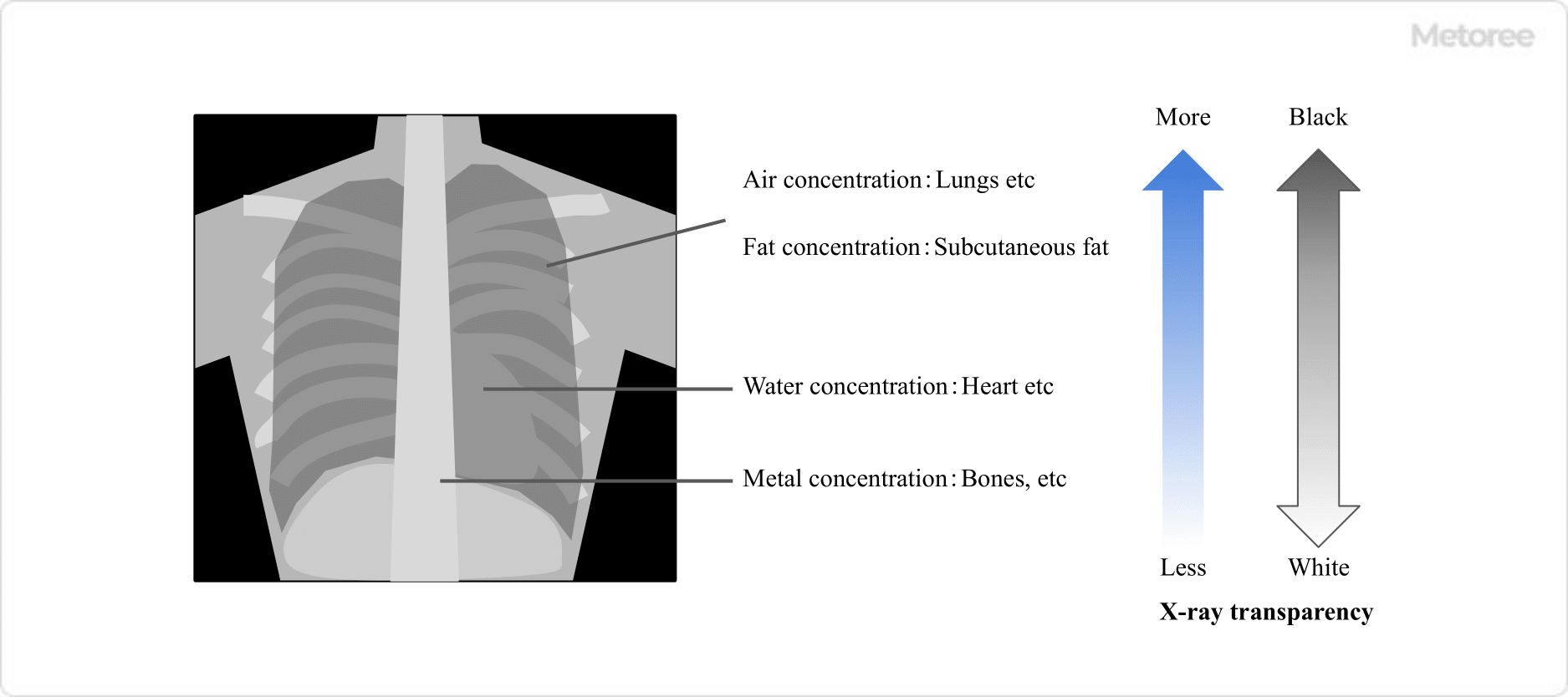

X-rays that do not undergo these phenomena penetrate the material and become transmitted X-rays, and the more transmission there is, the darker the image appears.

Conversely, areas that are attenuated appear bright and white. In fact, images taken using X-rays are black and white, where the shade is determined by the amount of transmitted X-rays.

In general, it is known that the intensity of transmitted X-rays is determined by factors such as the atomic number, density, and thickness of the object material.

X-rays, discovered by Roentgen in 1895, are electromagnetic waves with wavelengths of approximately 1 pm - 10 nm.

They are also a form of radiation, and are used in X-ray photography for medical examinations and nondestructive testing, as well as in the analysis of crystal structures using the diffraction phenomenon.

Most people's conception of X-ray inspection equipment is that it is a large-scale device that takes pictures of the entire body.

However, today, a wide variety of portable X-ray inspection systems are available, and they are mainly used for nondestructive testing at factories and construction sites.

Their features are often referred to as portable nondestructive testing equipment that can be easily used at any time and place.

It is a device that inspects all kinds of objects with X-ray images by combining a polarized X-ray and a high-precision digital detector.

Without destroying the object to be inspected, it is possible to check for cracks, fissures, corrosion, and other abnormalities, as well as the finish of welded parts.

X-ray inspection systems are highly mobile and ideal for completion and periodic inspections at factories and construction sites. However, since they are a source of ionizing radiation, they should be handled with care.

*Including some distributors, etc.

Sort by Features

Sort by Area

North Star Imaging Inc., founded in 1986 and based in Rogers, USA, is a manufacturer of industrial X-ray systems non-destructive testing (NDT) equipment. The company designs and manufactures 2D digital radiography & 3D computed tomography systems. These products are frequently used for failure analysis, Quality Control and internal measurements. This technology is used by many different markets including medical devices, electronics and aerospace. The company is ISO certified for its quality and environmental standards, and has ASNT & NAS 410 certified employees.

Moxtek, Inc. is an ISO 9001-certified manufacturer of advanced X-ray and nano-optical components founded in 1986 and based in Orem, Utah, USA. The company’s products are designed for imaging devices, display electronics, and analytical instrumentation. These include portable and benchtop x-ray instruments, high- and low-energy x-ray windows, and wire-grid polarizers for visible to near-infrared applications. The company’s products have applications in various industries such as transportation, energy storage manufacturing, and the security industry.

Fischer Technology, Inc., established in Windsor, CT in 1979 is a manufacturer of coating thickness and material testing instrumentation. Their product portfolio includes coating thickness gauges, material testing instruments such as hardness testers, adhesion testers, and gloss meters, adhesion testers, used for assessing the bond strength between coatings and substrates. The company serves markets including Electronics and Semiconductors, Marine and Offshore, Construction and Architecture and Quality Control. The company has a national distribution network and a customer support center.

Rad Source Technologies, established in 1997, is a manufacturer of radiation technology solutions. It's headquartered in Georgia, Unites States and it specializes in the development and manufacturing of advanced X-ray irradiators and non-nuclear irradiation systems. Its products catalog includes the RS 2000 Small Animal Irradiator, the blood irradiator, the Biological Irradiator, the 420 Cannabis Decontamination Systems, among others. Its cutting-edge products find applications in various industries, including medical research, pharmaceuticals, and food safety.

Skyray Instruments, founded in 1992 with its headquarters in Texas, USA, is a manufacturer of analytical and measuring instruments. The company specializes in the design and manufacture of products for spectroscopy, chromatography, and mass spectroscopy. It has ISO 9001 certification and offers modern spectrometers, chromatographs, and mass spectrometers. These equipment have advantages such as high sensitivity, precision, and efficacy in analyzing a variety of compounds. It provides services to a diverse range of businesses, including pharmaceuticals, environmental surveillance, food & drinks, and research organizations.

Bruker, founded in 1960 and based in Billerica, Massachusetts, is a manufacturer and distributor of scientific instruments and analytical and diagnostic solutions. The company's product range includes analyzers, microscopes, and imaging solutions, which have applications in fields such as life science research, cell biology, and microbiology. In 1969, the company developed the world's first FT-NMR spectrometer system, enabling broadband proton decoupling. In 1997, it further expanded its capabilities by acquiring the analytical X-ray division of Siemens AG. The company holds ISO 9001 and ISO 13485 certifications, and its products are available for sale worldwide.

RPMI Packaging, Incorporated was founded in 1966 and is headquartered in Lebanon, Ohio. The company is a sales agency representing packaging equipment manufacturers, specializing in selling packaging equipment and material handling systems on behalf of manufacturers and engineering companies from around the world to customers around the world. The company’s services include onsite training and consultancy for manufacturers to assist in installation, startup, maintenance, and machine usage efficiency to decrease costs and downtime. Machine types that the company sells include primary and secondary packaging, quality control machines, and material handling machines.

Hitachi High Tech was established in April 1947 and operates in 26 countries with products and services ranging from semiconductor manufacturing equipment and Medical and Biosystems to Analytical Systems and Manufacturing related equipment and solutions. A unique state-of-the-art technology company with two functions as a manufacturer and a trading company with the motto of "Tackling social issues," the Hitachi High-Tech Group aspires to be a company that pursues not only economic value, such as revenue and profit, but also provides social and environmental value by contributing to resolving social issues through its business activities, including products and services. They also provide one-stop services, such as evaluations and analysis at a global level.

Source-Ray is a leader in designing, developing, and manufacturing advanced x-ray systems within the USA. With two primary focus areas, our product line consists of standard and custom high-frequency x-ray generators in fully integrated or modular enclosures and complete medical & veterinary x-ray systems. We have a passion for innovation and a commitment to excellence. Within our 15,000 square foot ISO/MDSAP 13485 and FDA Registered facility, we take pride in ensuring our products are crafted to the highest quality standards. Our team continuously works to improve our systems and services to achieve this goal.

Autoclear LLC is a leading global provider of advanced security solutions, specializing in the design, manufacturing, and support of high-quality, professional security equipment. With over 80 years of industry expertise, Autoclear has established itself as a trusted name in the field. Our diverse range of products includes state-of-the-art X-ray scanners, metal detection systems, and advanced trace detection solutions for explosives and narcotics. We cater to a wide array of sectors, including private enterprises, schools, government facilities, militaries, customs agencies, agricultural and electronics inspection, public venues, and events. Autoclear is dedicated to non-invasive detection methods, prioritizing safety and efficiency. Our commitment to innovation and continuous improvement ensures that our clients receive the most reliable and cutting-edge security equipment available in the market.

Qualitest International Inc., founded in 1999, is a supplier of testing equipment such as hardness testers, material testing equipment, universal testing machines, and instruments for testing rubber, metals, paper, plastic, paint, and packaging materials used in the gold and jewelry, mining, oil and gas, surveying, and ultrasonic industries. The Lauderdale, Florida-based business offers technical support, calibration, and repair either directly or through the global QualiService authorized network. The company has an online store with international shipping.

Hitachi, Ltd was established in 2002 and headquartered in Chiyoda-ku, Tokyo is a manufacturer of industrial electrical equipment and system solutions. The company offers an extensive and diversified product portfolio including industrial drive systems, power electronics, energy-related equipment, power distribution systems, and various other industrial solutions. These products serve as integral components that drive advancements in industrial capabilities across diverse sectors by playing a pivotal role in promoting energy conservation and storage, automating robot systems in large factories, enabling smarter manufacturing through digital solutions, and facilitating efficient transportation within industrial facilities.

Rigaku Corporation is an ISO 9001-certified manufacturer and distributor of specialized analytical instruments that was founded in 1951 in Tokyo, Japan. The company produces various instruments that rely on x-ray technology for scientific and industrial analysis. Its products include x-ray diffraction (XRD) systems for analyzing powders or stress, x-ray topography systems for evaluating crystal quality, and x-ray reflectometry (XRR) systems for thin film thickness or density measurement operations. The company chiefly serves client manufacturers of semiconductors, biotechnology, and photovoltaics.

System Square Inc., established in 1989 and heaquartered in Nagaoka, Japan, is a designer and manufacturer of detection technologies, specializing foreign body detection systems used for various applications in the food, pharmaceuticals, cosmetics, and industrial products. The company offers various systems, including metal detectors, X-ray inspection systems, and seal inspection systems, capable of non-contact and non-destructive inspections and together with sorters, eliminate defective products. These systems are also capable of performing shape inspections for cracks and chippings, weight inspection, and quantity measurement. System Square Inc. has locations across the world, including China, Indonesia, Brazil, and Spain.

Shenzhen Zhuomao Technology Co. Ltd. (SEAMARK), established in 2005 in Shenzhen, China, is a developer and manufacturer of electrical assembly equipment, industrial machines, and systems. The company's original product offering was limited to intelligent soldering equipment and intelligent inspection devices. Since 2020, it has expanded its product line with a range of BGA rework stations, industry X-ray inspection systems, and X-Ray SMD component counting equipment. It also provides custom solutions for both soldering applications and product inspection and identification systems.

Rexfab, established in Sherbrooke, Québec, in 1990, is a manufacturer of automated bakery equipment. The company's product range includes Conveyor Systems, Inline Vacuum Depanneur, Pan Cleaning, Food Safety Equipment and Slicing & Bagging. Their products are used in industries such as Commercial Bakeries and Pastry Shops, Industrial Food Production Facilities, Hotels, Restaurants, and Catering Services. The company also provides services including national distribution, product selection, installation, preventative maintenance, troubleshooting, repair and customer service.

CASSEL Inspection, headquartered in Dransfeld, Germany, has been a manufacturer of metal detectors and X-ray inspection systems since 1994. The company offers inspection equipment that can provide protection at any stage of production, from incoming raw materials to finished stock. Its product range encompasses metal detectors, X-ray inspection systems, checkweighers, needle detectors, and conveyor systems. The company also extends services such as installation, calibration, training, and maintenance for its products.

NOVO DR Ltd. (NVDR) is a developer and manufacturer of pharmaceuticals for skin health and wound dressing founded in 1966 and based in Petah Tikva, Israel. The company produces various branded items such as NOVOSORB, a biodegradable antimicrobial solution using slow-release iodine; NOVOFLEX, which adheres to ulcers or burns; NOVOGEL, a hydrogel for dry or necrotic wounds, and NOVOSPRAY, which creates a thin layer of hydrogel on superficial wounds like abrasions or skin tears. NVDR also provides clinical education, training, consultation, and R&D services to its clients, which include the McKesson Corporation, Teva Pharmaceutical Industries and the Perrigo Company.

Matsusada Precision Inc is located in Shiga, Japan, and was established in 1978, known as the developer, manufacturer, and global supplier of power supply products and imaging products. The power supply products include high voltage amplifiers, AC, DC, and regenerative DC power supplies as well as optical sensors, which have their use in research centers, aerospace, analytical instruments, electronics, and almost all industries that use power to operate. The imaging products are associated with businesses that use X-ray inspection as a service such as life sciences and electronics Environmental improvement equipment is also supplied, but only in Japan.

Mettler Toledo was incorporated in 1945 in Toledo, Ohio, and is today headquartered in Greifensee, Switzerland. Mettler Toledo is a manufacturer of various analytical instruments for use in laboratories, industrial and manufacturing, and food retailing applications to customers globally. Mettler Toledo offers many products across product lines for uses such as product inspection, process analytics, jewelry scales, moisture analyzers, and software for laboratory weighing. Mettler Toledo also offers numerous accessories such as density kits, hands-free accessories, weighing tables, and weight accessories.

Anritsu Corporation, established in 1931 and based in Atsugi, Japan, is a manufacturer of electronic measuring instruments, quality assurance systems, and Information and Telecommunication equipment and devices. Its test and measurement products include power meters, power sensors, and conformance test systems, while X-ray inspection systems, metal detectors, and checkweighers ensure food safety and security. Other products like instrumentation-grade adapters and optical sensing equipment are used in IT. The company’s stock was listed in the 2nd section of the Tokyo Stock Exchange in 1961, and in 1968, it was listed in the 1st section.

Toshiba IT and Control Systems Corporation, established in 1983, and based in Tokyo, Japan is a manufacturer and supplier of power electronics and inspection systems. The product portfolio includes power electronics, mechatronics, X-ray non-destructive inspection systems, control engineered systems, development design creation. The company also offers maintenance services and sales for industrial as well as public use. The products are used in many industries with various applications which include electronics, sensors, resins, chip-mounted boards, batteries, and other devices.

Building on decades of experience and an unfailing passion for technology, Comet Yxlon is a globally leading company for industrial X-ray and CT system solutions with integrated services for industrial environments – from R&D labs to production settings. Comet Yxlon supplies tailored service solutions for a wide range of production environments through offline applications, at-line scenarios, or in-line implementation, and their diverse field of quality assurance and quality control. With inspection systems that help manufacturers and developers control product quality, their specialized systems are used in the most diverse areas such as aerospace, automotive, electronics, science & research, and many more.

Antares Vision S.p.A., established in 2007 and headquartered in Alseno, Italy, is a manufacturer of inspection and tracking solutions. The company, including its subsidiary FT System, offers inspection and tracking solutions for the beverage, cosmetics, and pharmaceutical industries. It specializes in container inspection, leak detection, and fill-level inspection. Its track-and-trace solutions enable end-to-end visibility in the supply chain. Its digital factory platform facilitates data-driven decision-making and enhances productivity in manufacturing plants. In 2014, the company represented Italy at the European Business Awards, winning the National Champion title in the technological innovation category.

GOEPEL electronic, established in 1991 in Jena, Germany, operates as a manufacturer and supplier of test and inspection solutions for electronic and mechanical components. Its offerings encompass boundary scan test systems, automotive test systems, embedded JTAG solutions, optical inspection systems, and X-ray inspection systems. These tools are pivotal in fault detection, diagnosing issues, verifying functionality, and upholding quality standards across applications like printed circuit boards, automotive electronics, industrial automation, and aerospace. The company has been certified according to DIN EN ISO 9001 by TÜV Rheinland since 1996.

Sesotec, founded in Germany in 1976, is a manufacturer of physical contamination detection and sorting systems for the food, plastics, and recycling industries. The company offers a range of products, including metal detectors, X-ray scanners, sorting systems, x-ray inspection systems, and recycling sorting systems with conveyor belts, as well as providing various services, such as technical support, training, and consulting, for clients like food and beverage manufacturers, plastic recyclers, and pharmaceutical packaging manufacturers.

Gilardoni S.p.A., a Socio Unico, was established in 1947 and is headquartered in Mandello del Lario, Italy as a manufacturer and designer of X-ray and ultrasound equipment. The company offers various products, including portable X-ray machines, explosive trace detectors, anti-explosive containers, ultrasound devices, shearography equipment, and radtag systems. These equipment have applications in various fields, such as the manufacturing of X-ray irradiators for preventing TA-GvHD, a fatal disease associated with blood transfusion, as well as the detection of weapons and drugs contained in hand luggage. The company also produces millimeter-wave machines for scanning people and detecting traces of solid explosives.

Omron Corporation, started in 1933 and headquartered in Kyoto, Japan, is a manufacturer of automation components, equipment, and systems, and it developed the first contactless proximity switch in 1960. It has four domains, including industrial automation, electronic components, healthcare, and social systems, and it provides products and services in around 120 countries and regions. Some of its products include microsensing devices, access control systems, industrial robots, surveillance cameras, and blood pressure monitors. In 1971, it developed the first online cash machine, and in 1972, it established Japan’s first welfare factory.

Teledyne ICM, founded in 1993 and based in Andrimont, Belgium, is a manufacturer and distributor of portable radiography solutions. The company provides a diverse product catalog, including detectors, standalone systems, portable X-ray systems, generators, and security products, among others. These radiography solutions find applications such as using detectors for security inspections to analyze suspicious objects, employing non-destructive testing for the radiography of welds or cracks, as well as detecting corrosion under insulation.

Minebea Intec GmbH is a manufacturer and supplier of industrial weighing technology products that was established in Hamburg, Germany in 1866 before being acquired by Japan’s MinebeaMitsumi Group in 2015. The company’s product lineup includes checkweighers for inspection or quality control applications, industrial load cells for standard weighing applications using mechanical force, and OCR print control systems. It also offers its customers product calibration, maintenance, and repair services. The company’s products are used mainly by clients in the transportation, logistics, and ports sectors.

Ma Stoken Solution, established in 1998 and based in Tokyo, Japan, is a manufacturer and supplier of automatic identification systems. The company's product portfolio includes handheld barcode scanners, barcode verification machines, RFID printers, image processing systems, and other related systems. These products are used in various industries, including pharmaceuticals, transport, construction, distribution, retail, and more. The company holds the ISO 9001:2000 Quality Management System and ISO 14001 Environmental Management System certifications, and also provides services such as design, operation, sale, and maintenance.

Evident Corporation is a scientific research and development company in Shinjuku, Tokyo that was established in 2008. Formerly known as Olympus Scientific Solutions, the company specializes in developing cutting-edge technology and products for various industries, including aerospace, automotive, electronics, energy, and medical research. Evident Corporation has proliferated and expanded its product offerings and services to meet the needs of its customers. Their product offerings include non-destructive testing (NDT) solutions such as thickness gauges and automated inspection systems, XRF analyzers like handheld XRF analyzers, industrial microscopes, and video scopes and borescopes.

OMRON Industrial Automation is the UK branch of OMRON, originally founded in Japan in 1933. OMRON Industrial Automation serves food and beverage industry, panel board design, automotive manufacturing industries among others. OMRON Industrial Automation products categories include automation systems such as industrial PCs and human machine interfaces (HMI), safety such as safety switches and safety logic control systems, switching components such as solid state relays, motion & drives such as motion controllers, sensing such as photoelectric sensors, software, robotics, quality control & inspection systems, as well as control components including power supplies and digital panel indicators.

Ranking as of July 2025

Derivation Method| Rank | Company | Click Share |

|---|---|---|

| 1 | Autoclear LLC |

5.5%

|

| 2 | Rad Source Technologies |

4.9%

|

| 3 | RPMI Packaging, Inc. |

4.9%

|

| 4 | Rexfab |

4.4%

|

| 5 | Fischer Technology, Inc. |

4.3%

|

| 6 | Mettler-Toledo |

4.3%

|

| 7 | Moxtek, Inc. |

3.9%

|

| 8 | North Star Imaging Inc. |

3.7%

|

| 9 | Skyray Instruments |

3.7%

|

| 10 | CASSEL Inspection US |

3.7%

|

Derivation Method

The ranking is calculated based on the click share within the x-ray inspection system page as of July 2025. Click share is defined as the total number of clicks for all companies during the period divided by the number of clicks for each company.Number of Employees

Newly Established Company

Company with a History

*Including some distributors, etc.

*Including some distributors, etc.

| Country | Number of Companies | Share (%) |

|---|---|---|

United States of America

United States of America

|

11 | 34.4% |

Japan

Japan

|

9 | 28.1% |

Germany

Germany

|

5 | 15.6% |

China

China

|

3 | 9.4% |

Canada

Canada

|

1 | 3.1% |

Israel

Israel

|

1 | 3.1% |

Belgium

Belgium

|

1 | 3.1% |

Spain

Spain

|

1 | 3.1% |

226 products found

226 products

Easy Test Solution

1170+ people viewing

Last viewed: 33 minutes ago

A digital X -ray inspection device equipped with a 22 -inch detector and enabling a wide range of inspections. A high -precision test with a 20 -in...

Kinki Roentgen Kogyo Co., Ltd.

1370+ people viewing

Last viewed: 33 minutes ago

■It's safe It has a safe structure that uses rust-proof stainless steel to prevent salt damage, as well as lead and lead-containing sheets. Built-i...

2 models listed

Easy Test Solution

1190+ people viewing

Last viewed: 21 hours ago

Equipped with a 15 -inch detector, a digital X -ray inspection device with excellent portable. A high -precision test with a 20 -inch 4K tablet (wo...

Kinki Roentgen Kogyo Co., Ltd.

860+ people viewing

Last viewed: 33 minutes ago

General-purpose X-ray generator that can be used for various purposes ■Delivery record of over 7,000 units We have already delivered more than 7,0...

YXLON International

1940+ people viewing

Last viewed: 3 hours ago

■ Powerful X -ray / CT inspection device ・ Automatic calculation of voice by VOIDINSPECT ・ High -sensitivity type 16 -bit (65,000 gradations) Out...

2 models listed

BeamSense Co., Ltd.

250+ people viewing

Last viewed: 1 day ago

■Features ・Full support for M size board. Built-in motorized XY stage, motorized zoom function, and motorized board tilt function. ・Achieved a de...

Medical Ings Co., Ltd.

260+ people viewing

Last viewed: 19 hours ago

■Simultaneous 2-directional imaging of the whole body in a standing position Simultaneous photography in two directions (front and side) is possibl...

Spectory

1200+ people viewing

Last viewed: 6 hours ago

■ Desktop type / X -ray diffraction device (XRD) AERIS (XRD), a desktop type X -ray diffraction device (XRD), has achieved data quality and data ac...

Toshiba IT & Control Systems Corporation

1790+ people viewing

Last viewed: 1 hour ago

■Applications Large aluminum die castings, iron, castings, cylinders, tires, engine blocks, etc. The 20,000 series is equipped with a line sensor ...

iBit Co., Ltd.

900+ people viewing

Last viewed: 3 hours ago

This is an in-line type inspection device that automatically inspects the soldered parts of mounted boards using X-rays. On high-density type board...

Image Tech Co., Ltd.

990+ people viewing

Last viewed: 3 hours ago

■X-ray inspection device exclusively for shoes that has achieved significant cost reductions This is an X-ray inspection device (X-ray needle inspe...

ANSeeN Co., Ltd.

280+ people viewing

Last viewed: 20 hours ago

Features ■High sensitivity The 1mm thick cadmium telluride (CdTe) semiconductor detector images X-rays much more efficiently than traditional X-ray...

Toshiba IT & Control Systems Corporation

530+ people viewing

Last viewed: 1 hour ago

■Applications This is a highly versatile X-ray CT scanner that can obtain fluoroscopic and CT images with high contrast and a wide dynamic range in...

iBit Co., Ltd.

850+ people viewing

Last viewed: 33 minutes ago

Despite its compact size, it achieves a geometric magnification of 900x. A derivative model with a reel observation function is also available. ■F...

Image Tech Co., Ltd.

850+ people viewing

Last viewed: 2 hours ago

■This is an X-ray inspection device that is ideal for bags and bags. This is an X-ray inspection device (X-ray needle inspection machine) with a be...

Toshiba IT & Control Systems Corporation

390+ people viewing

Last viewed: 9 hours ago

■Applications Small electronic parts, molded products, resin, GFRP, CFRP, textiles, etc. This compact, high-performance micro-CT uses a highly sen...

iBit Co., Ltd.

240+ people viewing

Last viewed: 14 hours ago

A compact yet highly cost-effective X-ray inspection device that achieves a geometric magnification of 900x. ■Features ・Geometric magnification: ...

Image Tech Co., Ltd.

880+ people viewing

Last viewed: 33 minutes ago

We can handle a wide range of items, including general apparel. X-ray inspection equipment ideal for inspection companies. This is an X-ray inspect...

Mediplan Co., Ltd.

290+ people viewing

Last viewed: 18 hours ago

Back in January 1949, Fujifilm Healthcare (formerly Osaka Roentgen Manufacturing Co., Ltd.) announced the "Sirius" capacitor discharge type X-ray d...

Toshiba IT & Control Systems Corporation

260+ people viewing

Last viewed: 12 hours ago

■Applications Mounted substrates, electronic devices, small connectors, small electronic components for vehicles, etc. This is a microfocus X-ray ...

iBit Co., Ltd.

950+ people viewing

Last viewed: 2 hours ago

Compact sealed tube X-ray device achieves 1,000x geometric magnification. The third inspection method, X-ray stereo, which is neither CT nor lamino...

Image Tech Co., Ltd.

350+ people viewing

Last viewed: 1 day ago

■No.1 in the industry. Large apparel can be inspected by adopting a camera with a sensor width of 768 mm. This is an X-ray inspection device (X-ray...

YXLON International

2000+ people viewing

Last viewed: 1 hour ago

Designed intuitively, users with all specialized knowledge can easily perform high -efficient X -rays and CT tests at manual, subsidies and automat...

3 models listed

Toshiba IT & Control Systems Corporation

250+ people viewing

Last viewed: 1 day ago

■Applications Mounted substrates, BGA, electronic components, devices, sensors, resins, etc. This is a model for inspecting mounted boards that pu...

iBit Co., Ltd.

310+ people viewing

Last viewed: 14 hours ago

Although it is a closed type X-ray device, it achieves a high resolution of 2μm. ■Summary ・High resolution of 2μm and geometric magnification of ...

Image Tech Co., Ltd.

190+ people viewing

Last viewed: 21 hours ago

■This is a portable X-ray inspection device that uses a notebook PC, and is small and lightweight so it can be carried by hand. Fixed X-ray inspect...

YXLON International

1670+ people viewing

Last viewed: 1 hour ago

Large inspection areas, multiple extensions, and powerful 450KVX linear pipes to the following levels are raised to the following levels. ■ Charac...

2 models listed

Toshiba IT & Control Systems Corporation

250+ people viewing

Last viewed: 6 hours ago

■Applications Aluminum die-cast parts, mechanical parts, electrical parts, resin molded products, etc. This is an all-in-one type (integrated stru...

iBit Co., Ltd.

230+ people viewing

Last viewed: 9 hours ago

The high output 130kV X-ray source makes it ideal for inspecting multilayer boards with 20 or more layers and power devices. ■Summary The FX-500tR...

Image Tech Co., Ltd.

280+ people viewing

Last viewed: 11 hours ago

This is an X-ray line sensor camera with an inspection range that is ideal for the width of the object to be inspected. ■Provided with specificati...