All Categories

History

This section provides an overview for heat sinks as well as their applications and principles. Also, please take a look at the list of 36 heat sink manufacturers and their company rankings. Here are the top-ranked heat sink companies as of July, 2025: 1.Applied Power Systems, Inc., 2.Ohmite, 3.CeramTec North America LLC.

Table of Contents

Categories Related to Heat Sinks

A heat sink is a component attached to a device for the purpose of cooling. It is mainly used in electronic equipment to prevent excessive temperature rise.

It is very simple in principle, structure, and does not require physical operation. Therefore, it has the advantage that it is not prone to breakdowns.

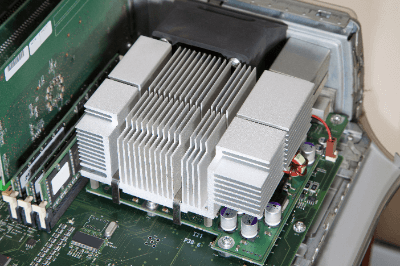

Heat sinks are used in combination with electronic components that generate heat. A typical example is CPU cooling in personal computers.

Electronic components, such as CPUs, will use semiconductors and conductors inside their housings. These parts constantly generate heat during operation, and if left unchecked, the temperature inside electronic products rises, melting the surrounding varnish or burning out semiconductor parts. Heat sinks dissipate the heat from these heat-generating parts and help prevent failures due to overheating.

In a normal CPU, a heat sink is installed and then cooled using a fan. These are called CPU coolers, as a set.

A heat sink is made up of metal parts arranged in the shape of a comb. The comb is called a fin, and the comb shape increases the surface area for enhanced heat dissipation performance. The principle of heat sink is the second law of thermodynamics. This is an extremely simple principle that heat always flows from high-temperature materials to low-temperature materials.

Therefore, if a heat sink is operated alone, it cannot lower the temperature below the atmospheric temperature. Hence, it is used for small electronic components and equipment with a high-heat resistance requirement. Cooling efficiency can be improved by using a fan or pump in conjunction with the heat sink to provide forced circulation.

If the heat generation is high, using a device with even higher cooling efficiency, such as a Peltier element or heat pump is advised.

Heat sink performance is mainly measured by "thermal resistance." Thermal resistance is a value that indicates the resistance to heat transfer, meaning "how many degrees the temperature rises when one watt of heat is applied to an object. The unit of thermal resistance is "K/W" or "°C/W".

Thermal resistance depends on the surface area of the Heat Sink and the material used. The lower the value, the better the performance will be. Heat sinks are designed in a comb or bellows shape because a larger surface area reduces thermal resistance most efficiently.

Another value that indicates the performance of a heat sink is the pressure drop. Pressure drop is a measure of the resistance of air or cooling water passing through a heat sink; the lower the value, The better the performance will be.

Heat sinks are made of metals with high thermal conductivity. Aluminum alloys, copper materials such as brass and bronze, and metals such as silver and iron are used. Copper is the best thermal conductor, but it is heavy and expensive. Therefore, it is rarely used as a material for heat sinks.

Aluminum, on the other hand, is lightweight and Low-cost. Aluminum also has high self-dissipation properties, making it more suitable than copper in some environments where airflow is low.

Aluminum is the primary material used for heat sinks. However, other materials are considered when aluminum does not meet the required specifications.

*Including some distributors, etc.

Sort by Features

Sort by Area

Applied Power Systems, Inc. (APS) was founded in 196 and headquartered in Hicksville, New York. Applied Power Systems is a power electronics company specializing in power conversion systems and thermal management of high power semiconductors. APS offers a large selection of high power thermal management products. These products include standard and custom aluminum extrusion heat sinks for natural convection and forced air-cooling. Cast and machined copper chill plates for liquid cooling. State of the art clamps for flat pack or hockey puck semiconductors. APS also offers driver circuit boards to drive SCR, IGBT and MOSFET devices.

Ohmite, established in 1925 and headquartered in Warrenville, Illinois, is a manufacturer of resistive products. Their product offerings incldue wirewound resistors, thick film resistors for high temperature and humidity resistance, and chip resistors for space-constrained applications. Additionally, they provide power resistors designed to handle high currents and voltages, suitable for power supplies and motors. Ohmite's diverse product range also includes custom-designed resistors tailored to meet specific customer requirements. These products find extensive application across various industries, including electronics, automotive, and industrial.

Adam Tech USA is an American manufacturer of electronic interconnects, cable assemblies, and custom components established in 1987 and headquartered in Union, New Jersey. The company produces electromechanical components including various switches, and custom components such as magnetic pogo pin cable assemblies and fiber optic adapters. It also offers standard as well as custom cable assemblies for unique client projects. The company operates internationally, with subsidiaries and branch offices in Germany, Taiwan, and Brazil.

CeramTec North America is the American subsidiary of CeramTec of Plochingen, Germany. CeramTech North America is headquartered in Laurens, South Carolina. As a fully integrated advanced ceramics manufacturer capable of handling every phase of the development and manufacturing of hermetic products, especially for those in the automotive, chemical, electronics, and medical equipment markets. Technical ceramics products are divided into four major groups of materials: silicate ceramics often made from raw materials and alumina, oxide ceramics including zirconium oxide, non-oxide ceramics based on materials such as carbon, and piezoceramics used to convert signals to and from mechanical and electrical.

KULR Technology Group, Inc., established in San Diego, California in 2013 is a manufacturer of thermal management technologies lightweight heat exchangers, and protection against lithium-ion battery thermal runaway propagation. The company's product range includes Fiber thermal interfaces, internal short circuits, fiber thermal interfaces, thermal capacitors and cell checks. The company serves markets including Automotive and Electric Vehicles, Renewable Energy and Energy Storage and Electronics and IT Infrastructure. The company also offers services including Cell Screening, Fractional Thermal Runaway Calorimetry Testing and Bomb Calorimetry Testing.

C&H Technology was founded in 1979 and is headquartered in Minnetonka, Minnesota. The company is a privately held sales and marketing company specializing in power semiconductors and electronic components commonly used in heavy industrial applications such as welding, aluminum, waste treatment, industrial motor control, and solar inverters. The company partners with manufacturers such as Hitachi, ABB, Mitsubishi Electric, and Powerex. Some of the products the company offers include assemblies, bridge rectifiers, heat sinks, and MOSFET modules.

AmeriStar Manufacturing, Inc. was established in 1908 and headquartered in Mankato, Minnesota. The company is an ISO 9001:2015 certified full-service metal manufacturing company capable of on-site tool making. The company’s services include metal stamping, CNC machining, sheet metal fabrication, electro-mechanical assembly, and engineering & tool building. The company provides support for SMI, VMI, and Kanban programs to support customers’ inventory management as well as other contract manufacturing services including warehousing and shipping.

PSI Industries, Inc., established in Irving, Texas, in 1987 is a manufacturer of turn-key custom aluminum extrusions used in industries such as Automotive and Transportation, Aerospace and Aviation. The company's products include Custom Aluminum Extrusions and services such as machining, cutting, finishing, and fabrication. The company serves markets including Electrical and Electronics, Renewable Energy, Industrial and Machinery and Consumer Goods. The company also offers services including assembly, CNC machining, and a variety of finishing options on anodizing and powder coat lines.

Sinopac Group, established in Rancho Cucamonga, California, in 2002, is a manufacturer of CNC machines and drill tapping machines. The company's product portfolio includes High-precision machines for milling, turning, and drilling operations, as well as sub machines and power metal injection machines, used in industries such as Electronics and Telecommunications, Automotive, Transportation and aerospace and Defense. The company provides Quality Assurance, Technical Support, national distribution, customized services and customer support.

Dynatron was established in Taiwan in 1991 as a manufacturer and supplier of PC thermal solutions. The company's product profile lists case fans, of various sizes, different models of air and liquid coolers, blowers, and other accessories, such as assembly kits, necessary for PC cooling and heat dissipation solutions. These products have uses in The OEM and ODM departments and by helping the application manufacturers in the entertainment, electric vehicle, AI technology, military and medical industry.

CUI Devices, established in 1989 and headquartered in Lake Oswego, Oregon, is an electronic components manufacturer that is ISO 9001 certified. It stocks motion, sensor, and relay solutions and works with several distribution partners, including Mouser Electronics, Digi-Key Electronics, and Electro Sonic. The company gives back to the community by supporting organizations like Tualatin School House Pantry, Girls Who Code, and Friends of Trees, which aim to uplift society by providing basic needs, STEM education, and environmental stewardship. It has contract manufacturing facilities in other countries, including China, Vietnam, and Japan.

CoolJag, established in 1986 and rebranded CoolJag in 2001 with headquarters in the USA, is a manufacturer of high-capacity micro-cooling devices. The company's product line includes air cooling fans and components and liquid cooling devices specialized in "skiving" technology. CoolJag's products are used by a wide range of industries and are found in personal computers, home appliances, heat sink technology, and power supplies, among many others. The company also offers thermal engineering services and high-volume custom product manufacturing to meet client-specific requirements.

Advanced Thermal Solutions, established in 1989, is a global manufacturer and supplier specializing in thermal management of electronics, headquartered in Norwood, Massachusetts, USA. Their range of products includes heat sinks, thermal interface materials, heat pipes & vapor chambers, and liquid cooling systems, which are used to manage and control the temperature of electronic devices. These products are applied in industries such as electronics, automotive, Internet of Things, thermal management, military, and aerospace. Advanced Thermal Solutions, Inc.'s quality management system is certified according to ISO 9001:2015.

PCR Technologies, established in 1991 in the United States, is a manufacturer and supplier of good-quality electronic components and solutions. The company’s product range includes a diverse array of offerings such as custom potentiometers, rotary switches, encoders, and sensors. These components find applications in various industries, including aerospace, defense, medical, and industrial equipment. PCR Technologies is devoted to delivering convenient and cutting-edge electronic solutions that meet the evolving needs of its customers. With a strong emphasis on quality, precision, and customer satisfaction, they continue to enhance the advancements in electronic technology and industries.

Wavelength Electronics is a manufacturing company that specializes in laser control technology, founded in 1993, the company is based in Bozeman, Montana. The company offers a range of products, including laser diode drivers, quantum cascade laser drivers, temperature controllers, instruments, and accessories. Their products are used in many applications, including biomedical, life sciences, remote sensing, military, aerospace and more. Their knowledgeable applications engineers are always available to provide guidance and assistance to customers.

Khatod Optoelectronic, established in 1985 and based in Milan, Italy, is a manufacturer and supplier of optical solutions made of LEDs. Their product portfolio includes optics, optical systems, and reflectors made of PMMA, Silicone Ultra-clear, PC, and PMMI materials, catering to all LED applications. The company manufactures customized LED optical solutions that go through various tests such as IP, Climatic, and IK tests to guarantee quality. All its products are designed with OMP technology and are ideal to be used in indoor environments such as warehouses, offices and supermarkets.

COMPELMA was founded in 1989 and is a developer and manufacturer specializing in electromagnetic compatibility (EMC) and thermal management located in Les Ulis, France. Its product list covers radio frequency shielded glass (CEM), spacer/nut for PCB, high frequency and microwave absorber, as well as heat sinks, thermal interface, and thermoelectric modules. Likewise, 90% of the company's products are custom-designed to meet the client's specific needs. The company is a member of the ICE Group, a federation of 19 industrial companies. It also holds ISO 9001 certification, serving the needs of diverse sectors, including automotive, medical, defense, and telecommunications.

Nippon Electric Glass Co., Ltd. (NEG) is a glass technology products manufacturer originally founded in 1949 and headquartered in Otsu, Shiga. The company specializes in glass for tech and computing applications, particularly for flat-panel displays (FPDs). Their product portfolio includes substrates for FPDs and liquid crystal displays (LCDs), organic light-emitting diodes (OLEDs) and touch panels for smart devices. Other products include high modulus glass fiber, heat-resistant glass and chemically strengthened glass. NEG primarily serves clients in the digital display, automotive, and information technology markets.

DAU, founded in Germany, in 1927 is a manufacturer of high-performance heat sinks for power semiconductors that control motors and electric drives. The company's product portfolio includes liquid-cooling and air-cooling systems to heat pipes, power electronics components and semiconductors. The company serves industries such as Oil and Gas, Aerospace and Defense, Automotive and Transportation, Construction, and Power Generation. The company also provides services including national distribution, product selection, installation, preventative maintenance, troubleshooting, repair and customer service.

Fischer Elektronik, established in 1969 in Lüdenscheid, Germany, operates as both a manufacturer and supplier of electronic components and systems. The company's offerings cater to diverse industries and applications. Among their products are heatsinks for effective electronic cooling, connectors facilitating wire and PCB connections, protective cases, optoelectronics for signal conversion, and assorted accessories like screws and spacers. These solutions underpin quality electronic system design, applied across fields such as industrial automation, medical technology, telecommunications, automotive, and aerospace. Its notable certifications include ISO 9001:2015 for quality management and ISO 14001:2015 for environmental management.

TE Connectivity Ltd., started in 2007 and headquartered in Schaffhausen, Switzerland, is a designer and manufacturer of sensor and connectivity solutions for harsh conditions. It operates three primary segments, namely transport, industrial, and communication solutions, and its product portfolio includes automotive connectors, fiber optic connectors, analog power meters, RTD sensors, and circuit breakers. It serves customers in approximately 140 countries and several industries, including aerospace, automotive, rail, IoT connectivity, and E-mobility. The company manufactures 192 billion products annually and has invested over 610 million USD in research development and engineering.

ADVANCED COOLING TECHNOLOGIES, INC. was founded in 2003 and is a manufacturer of thermal management products based in Lancaster, Pennsylvania, United States. The company manufactures products such as PCM heat sinks, constant conductance heat pipes, and vapor compression coolers. The products are used in various applications such as commercial satellites, military vehicles, and medical devices. The company is certified with ISO 9001:2015 and AS9100 for the quality management system, and is registered on ITAR.

Align Sourcing LLC is a thermoelectric and electronic product manufacturer and supplier based in Hamilton, New Jersey. The company offers a wide array of products through manufacturing affiliates located in the USA, China, and Russia, with a structured supply chain. Their extensive product line includes thermoelectric modules, generators, assemblies, as well as thermal interface materials, heat sinks, and thermoelectric elements, utilized for temperature control, power generation, heat recovery, cryogenics, and medical devices.

Alutronic, established in 1977, and headquartered in Halver, Germany, is a manufacturer and supplier of heatsinks and cooling solutions. Their product line encompasses of heatsink systems, insulation and heat conduction products, and mountings which caters to various industries such as power electronics, automotive, telecommunications, and renewable energy. Alutronic's heatsinks efficiently dissipate heat generated by electronic components, ensuring optimal operating temperatures, which play a vital role in preventing thermal damage and maximizing the lifespan and performance of electronic devices.

MBK Tape Solutions was founded in 1971 and currently operates out of Chatsworth, California under the Boyd Corporation umbrella. MBK is an ISO 9001-2015 certified manufacturer and fabricator of adhesive tape and flexible material that offers bonding, surface protection, sealing, and thermal management solutions. The company specializes in the healthcare, electronics, and industrial industries. The company offers several customer services including die cutting, printing, sheeting, and packaging. In addition, the company offers product development, cleanroom manufacturing, and contract manufacturing to customers.

Based in Ibaraki Prefecture north of Tokyo, Takagi Manufacturing Company is a specialized metal manufacturer specializing in copper components, especially for computing and technology industries. Takagi Manufacturing Company is a pioneer in thermal products, focusing on original product designs of various types including plating, Seebeck units, and heater coolers with a recent emphasis in water-cooled heatsinks for the electronics industry.

Dongguan PowerWinx Metal Industries Co., Ltd., established in 2009 and located in Guangdong, China, is a manufacturer and supplier specializing in precision metal, plastic, and assemblies. The company's product portfolio includes CNC milling, CNC turning, aluminum die castings, magnesium die castings, and plastic injections. These products are utilized in various sectors, including medical, semiconductor manufacturing, automation, telecommunications, and renewable energy. The company also provides services including delivery and technical support. The company is ISO9001, IATF 16949, and ISO14001 certified, and it exports its products to North America, South America, Europe, the Middle East, and Australia.

Greegoo Electric Co. Ltd., established in 1995, is a Chinese manufacturer and supplier based in Wenzhou, Zhejiang, producing motor control units and switch gears. Certified with ISO 9001:2015, the company offers over 1,000 standard models, including bridge rectifiers, diode and thyristor modules, and rectifier diodes. Other product offerings include phase control thyristors (PCT), solid-state relays, and vacuum contractors. The company serves customers in over 50 countries worldwide, including original design manufacturers (ODMs).

Noren Thermal Solutions, an American company established in 1968 and based in Taylor, Texas, is a manufacturer and supplier of thermal solutions technology. The company's product portfolio includes ambient cooling units, Eco-Cool heat exchangers, and heat pipes. These products find applications in various industries, including power generation, automation, and the food and beverage industry. The company offers services including technical support, product customization, and maintenance, while being ISO 9001:2015 certified for its quality management system.

Super Micro Computer, Inc. was established in 1993 and is a manufacturer and supplier of IT infrastructure based in San Jose, California, United States. The company produces rackmount servers, data center solution engineering, and riser card matrix. The products are used in markets such as cloud computing, data center, and edge computing. The company also offers myriad of solutions including AI infrastructure, data analytics applications, and IoT edge solutions. The management system of the company is certified to ISO 9001:2015 and ISO 13485:2016 standards.

MALICO INC., a company founded in 1983 and headquartered in Taoyuan, Taiwan, is a manufacturer and supplier of advanced thermal solutions. The company’s product portfolio includes passive heat sinks, IC package heat spreaders, and revolutionary heat spreaders. These products are used in various applications, including electronics manufacturing, medical devices, and transportation as solutions for electric vehicles (EVs). The company is ISO 9001, ISO 14001, and IATF 16949 certified, with American offices in Boston, Massachusetts; Tampa, Florida; and Dallas, Texas.

Activa Inc, located in Kaoshiung, Taiwan, is a leader of research and development of cooling fans and motors. Examples include cooling fans used in personal computers, cross flow fans, duct fans, DC and stepper motors, Sirocco blowers, ceiling fans, and fan accessories. Additional products include water pumps, air compressors, and AC heating fans.

T-Global Technology Co., Ltd. is a supplier of thermal management products established in 2003 and based in Taoyuan, Taiwan. Its product portfolio includes thermal pads, tape, putty, and grease. It also supplies vapor chambers, heat sinks, thermoelectric cooling chips, and heat pipes. The company is in compliance with RoHS and REACH regulations and has obtained ISO 9001:2015, ISO 14001, and IATF16949 certifications. Its products are utilized for electronics, automotive, manufacturing, energy, and power industries in China, the USA, and the UK. It has partnered with several companies, including Tesla, Siemens, Panasonic, Bosch, and Asus.

Ranking as of July 2025

Derivation Method| Rank | Company | Click Share |

|---|---|---|

| 1 | Applied Power Systems, Inc. |

8.7%

|

| 2 | Ohmite |

6.4%

|

| 3 | CeramTec North America LLC |

5.5%

|

| 4 | Adam Tech USA |

4.5%

|

| 5 | C&H Technology, Inc. |

4.4%

|

| 6 | KULR Technology Group, Inc. |

4.4%

|

| 7 | Sinopac Group |

3.9%

|

| 8 | PSI Industries, Inc. |

3.7%

|

| 9 | CoolJag |

3.7%

|

| 10 | DAU GmbH & Co KG |

3.3%

|

Derivation Method

The ranking is calculated based on the click share within the heat sink page as of July 2025. Click share is defined as the total number of clicks for all companies during the period divided by the number of clicks for each company.Number of Employees

Newly Established Company

Company with a History

*Including some distributors, etc.

*Including some distributors, etc.

| Country | Number of Companies | Share (%) |

|---|---|---|

United States of America

United States of America

|

16 | 61.5% |

Japan

Japan

|

3 | 11.5% |

Taiwan

Taiwan

|

2 | 7.7% |

Italy

Italy

|

1 | 3.8% |

France

France

|

1 | 3.8% |

Austria

Austria

|

1 | 3.8% |

Germany

Germany

|

1 | 3.8% |

China

China

|

1 | 3.8% |

435 products found

435 products

Marix Co., Ltd.

340+ people viewing

Last viewed: 2 hours ago

We offer a high degree of freedom in designing and processing everything from consumer equipment to industrial equipment. A standard heat sink that...

Marix Co., Ltd.

310+ people viewing

Last viewed: 9 hours ago

This is a high-performance heat sink made by joining aluminum extrusion material and thin, narrow-pitch corrugated fins using a unique one-press me...

LSI Cooler Co., Ltd.

220+ people viewing

Last viewed: 4 hours ago

We strive to improve the performance of heat sinks and heat sinks. Semiconductor elements (transistors, CPUs, IGBTs, etc.) used in current electri...

Alpha Co., Ltd.

240+ people viewing

Last viewed: 18 minutes ago

Adopts wing-shaped fins with a thickness of t0.75~0.95, ultra-low pressure drop type heat sink

TAKAGI MFG.CO.,LTD.

440+ people viewing

Last viewed: 17 hours ago

Copper water-cooled heat sink with outstanding cooling effect. It can also be used to heat hot water. We have standard products ranging from 20mm s...

Thermal Component Co., Ltd.

220+ people viewing

Last viewed: 3 hours ago

Forged aluminum. Our basic heat sinks are fixed with easy-to-install miracle clips, support clips, and power clips.

Theward Co., Ltd.

220+ people viewing

Last viewed: 14 hours ago

The material is made by extruding a heated aluminum billet through a mold and then processed. ■Advantages ・Low cost for mass production. ・Narrow...

Mizutani Electric Industry Co., Ltd.

300+ people viewing

Last viewed: 2 hours ago

■Small semiconductor heatsink As a heatsink for molded transistors, it is made of processed colored aluminum and is lightweight and inexpensive. Fu...

Marix Co., Ltd.

420+ people viewing

Last viewed: 11 hours ago

It is possible to fix the semiconductor to the printed circuit board together with the heat sink. For fixing, we offer round pin soldering, termina...

5 models listed

Theward Co., Ltd.

260+ people viewing

Last viewed: 13 hours ago

A method of carving out fins from aluminum or copper plates with a blade. ■Advantages ・Fins can be made thinner. - Can be manufactured with narro...

Mizutani Electric Industry Co., Ltd.

230+ people viewing

Last viewed: 9 hours ago

■Small semiconductor heatsink As a heatsink for molded transistors, it is made of processed colored aluminum and is lightweight and inexpensive. Fu...

LSI Cooler Co., Ltd.

230+ people viewing

Last viewed: 3 hours ago

We strive to improve the performance of heat sinks and heat sinks. Semiconductor elements (transistors, CPUs, IGBTs, etc.) used in current electri...

Alpha Co., Ltd.

190+ people viewing

Last viewed: 19 hours ago

Adopts wing-shaped fins with thickness t 0.75~0.95, low pressure drop type heat sink

TAKAGI MFG.CO.,LTD.

390+ people viewing

Last viewed: 1 hour ago

Made of copper with excellent performance and durability, it is lightweight with a thickness of 3 to 20 mm. You can choose from various types such ...

Thermal Component Co., Ltd.

180+ people viewing

Last viewed: 1 day ago

Forged aluminum. Our basic heat sinks are fixed with easy-to-install miracle clips, support clips, and power clips.

Marix Co., Ltd.

370+ people viewing

Last viewed: 12 hours ago

A large heat sink for forced air cooling for large power supplies such as industrial equipment and equipment. There is a four-sided element mountin...

2 models listed

Asuka electronic service Co., Ltd.

1180+ people viewing

Last viewed: 1 day ago

■ Characteristics ・ A6063 heat sink using material. ・ Stock goods ・ We also accept processed products. * There are other models.

10 models listed

Theward Co., Ltd.

210+ people viewing

Last viewed: 1 hour ago

This is a heat sink that uses heat pipes to increase cooling capacity. ■Advantages ・Since heat can be efficiently transferred to the fins, perfor...

Mizutani Electric Industry Co., Ltd.

220+ people viewing

Last viewed: 2 hours ago

■Small semiconductor heatsink As a heatsink for molded transistors, it is made of processed colored aluminum and is lightweight and inexpensive. Fu...

LSI Cooler Co., Ltd.

220+ people viewing

Last viewed: 1 day ago

We strive to improve the performance of heat sinks and heat sinks. Semiconductor elements (transistors, CPUs, IGBTs, etc.) used in current electri...

Alpha Co., Ltd.

200+ people viewing

Last viewed: 12 hours ago

A well-balanced heat sink that uses wing-shaped fins with a thickness of 0.45 to 0.55, achieving low pressure loss and low thermal resistance.

Asuka electronic service Co., Ltd.

860+ people viewing

Last viewed: 4 hours ago

■ Characteristics ・ A6063 heat sink using material. ・ Stock goods ・ We also accept processed products.

6 models listed

TAKAGI MFG.CO.,LTD.

390+ people viewing

Last viewed: 1 day ago

A conventional water-cooled heat sink with copper or SUS pipe sandwiched between aluminum plates. Although its performance is inferior to laminated...

Thermal Component Co., Ltd.

180+ people viewing

Last viewed: 15 hours ago

Forged aluminum. Our basic heat sinks are fixed with easy-to-install miracle clips, support clips, and power clips.

Marix Co., Ltd.

290+ people viewing

Last viewed: 1 day ago

Large heat sink for forced liquid cooling. This is a heat sink that allows for high-density mounting because the device can be made smaller. We can...

Widework Co., Ltd.

840+ people viewing

Last viewed: 6 hours ago

■ Overview ・ It is a CPU cooler compatible with Intel Socket LGA1700. ・ The aluminum heat sink is attached to the CPU contact surface of the alum...

Theward Co., Ltd.

210+ people viewing

Last viewed: 1 day ago

This is a heat sink that uses a vapor chamber to increase cooling capacity. ■Advantages Because heat can be efficiently transferred to the fins, p...

Mizutani Electric Industry Co., Ltd.

210+ people viewing

Last viewed: 8 hours ago

■Small semiconductor heatsink As a heatsink for molded transistors, it is made of processed colored aluminum and is lightweight and inexpensive. Fu...

LSI Cooler Co., Ltd.

260+ people viewing

Last viewed: 17 hours ago

We strive to improve the performance of heat sinks and heat sinks. Semiconductor elements (transistors, CPUs, IGBTs, etc.) used in current electri...

Alpha Co., Ltd.

180+ people viewing

Last viewed: 4 hours ago

High-efficiency heat sink with wing-shaped fins that has wide directivity in relation to wind direction.