All Categories

History

This section provides an overview for carbon brushes as well as their applications and principles. Also, please take a look at the list of 13 carbon brush manufacturers and their company rankings. Here are the top-ranked carbon brush companies as of March, 2026: 1.Ohio Carbon Industries, 2.St Marys Carbon, 3.Sinotech.

Table of Contents

Categories Related to Carbon Brushes

Engaged in research on nitride semiconductor growth using the MBE method at Waseda University Graduate School. After graduating from graduate school in 2016, he joined a non-ferrous metal manufacturer.

Engaged in equipment maintenance and engineering work at metal smelting plants. Moved to a chemical manufacturer in 2022. Engaging in similar tasks.

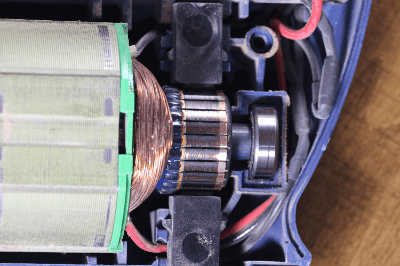

Carbon Brushes are conductive sliding parts used in motors and generators.

Carbon Brushes are conductive sliding parts used in motors and generators.

They are used in DC motors and large generators. Since they are sliding parts that wear out, they need to be replaced periodically. If used beyond the marked wear limit line, there is a risk of motor failure.

Carbon Brushes are used in some motors. They are used in three main applications: rectification, current collection, and grounding.

Rectification is an application used for the purpose of reversing the polarity of the winding of a DC motor. The following is an example of the use of a carbon brush for commutation:

Carbon Brushes are used inside DC motors attached to battery-powered power tools and in-vehicle equipment.

Current collection is an application in which carbon brushes are used for the purpose of passing electricity through a rotating body.

The following is an example of a carbon brush used for current collection:

A carbon brush is used inside a device called a slip ring that transmits electric power and electrical signals to rotating parts. Applications vary, such as internal temperature transmission in mixers.

Most AC motors are cage-type induction motors that do not have carbon brushes, but if a wound induction motor is selected, carbon brushes are used for the secondary winding connection.

Grounding brushes are sometimes used to prevent electrical corrosion. Electrical corrosion is a phenomenon in which electricity flows through the rotating shaft of rotating equipment, causing the bearings to corrode due to electrolysis.

This phenomenon is most likely to occur in inverter-driven motors and generators, and is prevented by grounding the rotating shaft with a carbon brush. Carbon brushes that ground the shaft for the purpose of electrolytic corrosion are also called ground brushes or grounding brushes.

Carbon Brush consists of a brush part, a lead wire, and a spring.

The brush part is the part that contacts and slides against the rotating body. In most cases, graphite is used as the material. Graphite is used because it is lightweight, rust-resistant, conductive, and slides well.

The size of the brush is selected according to the dimensions of the holder for carbon brush.

Catalog products exist, but in many cases, if you contact the carbon brush manufacturer for the shape and dimensions, they can manufacture a similar product for you.

Lead wire is the wiring part connected to the brush. Most of them are bare copper wires with twisted wire structure. The shape and size of the terminals are selected according to the shape of the terminal block to be connected.

The larger the current value used, the thicker the lead wire and the larger the terminal in many cases.

The spring is the part that applies pressure to push the brush portion against the commutator. It may be omitted if the brush holder is equipped with a spring. Springs are generally mounted around the lead wires.

Brush motors were the predominant type of motor for DC power supplies. Brush motors use carbon brushes and commutators inside. Therefore, DC motors had the disadvantage of requiring periodic replacement of carbon brushes, which wear out over time.

In recent years, many products have adopted brushless motors for DC power supply motors. Brushless motors are motors that use a dedicated power supply unit to modulate the power supply side. Although they require a dedicated power supply unit, brushless motors are easy to maintain and compact because they do not have brushes.

Brush motors are used when speed control is not required because of their simple structure and low cost. Brushless motors are used when speed control or constant torque operation is desired.

*Including some distributors, etc.

Sort by Features

Sort by Area

Ohio Carbon Industries, founded in 1988 and located in Great Lakes Region, USA is a manufacturer of carbon brushes. The ISO-9001-certified company specializes in the production of superior and affordable carbon brushes, grounding brushes, copper and machined graphite, and 3D paintings. The custom products manufactured by this company are variedly used in defence, aviation, medical and wind power sectors. The company is headquartered in Ashland, Ohio and is ITAR-certified. Moreover, the company also specialises in custom design and production of transit system parts such as trolley car parts, people mover parts and third rail system parts.

St Marys Carbon, established in 1939 and based in St. Marys, Pennsylvania, USA is a manufacturer of carbon graphite. The American manufacturing company specializes in the production of brushes, bearings, mechanical seal rings, rotors, wear plates and graphite plugs. The company caters to diverse domains like aviation, automotive, construction, industrial manufacturing, oil and gas and defence. Founded by Jerome E. Lanzel, Sr. company is certified by ISO-9001, US Government Military authorities and International Traffic in Arms.

Helwig Carbon Products, Inc., founded in 1928 and based in Milwaukee, Wisconsin, USA is a manufacturer of new-generation carbon products. The ISO-certified company specializes in making carbon brushes, brush holders, spring assemblies, shaft grounding systems and mechanical carbons. The products of this American manufacturing company are available in Australia, Canada, and Mexico and cater to aerospace, medical, mining, power, steel and fractional HP motor industries. Founded by Walter O. Helwig, the company provides on-site support, motor testing, grade information, motor maintenance training and trade shows.

Sinotech is based in Portland, Oregon with offices in China. Sinotech is a distributor for custom-engineered electrical motors, motor components, and mechanical components manufactured in China. Sinotech’s motors include AC motors, DC motors, brushless DC motors, slotless high speed BLDC motors, stepper motors, cordless motors, gear motors, servo motors, and miniature motors. Motor components include laminations, wound coils, armature and field coils, brushes, and communicators. Mechanical components include assemblies, die castings, investment castings, sand castings, shafts, steamed metal parts, tubular metal parts, machined extrusions, plastic parts, rubber parts, and secondary processing.

Anglo Carbon & Contacts Ltd, founded in 1959 and based in Waterloo Road, Pudsey, United Kingdom, is a manufacturer of carbon and graphite-based products. The private company specializes in custom design and production of electrical and mechanical carbon and graphite products. The electrical products include fractional horsepower motors, earthing straps and carbon brushes and the mechanical products include carbon seals, packing rings and rotary vane pumps. The products manufactured by this company are largely used in oil and gas, aviation, defence, transport and domestic sectors.

Aupac Co. Ltd, founded in 1958 at Yamato City, Japan is a manufacturer of carbon brushes molds, assembly and peripheral components. The company was originally called Nitto Carbon Works but renamed in 1973 and employs automatic molding technology for making carbon brushes used to conduct electric supply to motors. They make carbon brush for micro motor, brush for automotive motor, brush for power tools and comma-shaped carbon brushes. They find applications in automotive, vacuum cleaners, power supply cranes, power tools and other mechanical applications. Brushes permit smooth flow of electricity to the motor and bars resistance, which prevent motor damage.

Resonac Corporation is a Japanese chemical manufacturer and supplier, catering to various industries was established in June 1939. Resonac Corporation has developed expertise in electronics, mobility, high-performance materials, olefins and derivatives, basic chemicals, graphite, device solutions, and life sciences. Serving a diverse range of industries, their product portfolio includes inorganics, aluminum, electronics, chemicals, and inorganic materials. With its headquarters in Tokyo, Japan, the company provides innovative solutions and products tailored to diverse customer needs. Resonac Corporation is recognized for its advanced technologies in the industry.

CFC CARBON CO., LTD, established in 2006 and based in Yizhuang Economic Development Zone, Beijing, China is a manufacturer of new-generation carbon products. The Carbon Group company specialises in the production of graphite, graphite felt, carbon composite and pyrolytic graphite. The company is equipped with the strongest technical strength, the team of experts, the largest equipment number, the largest productivity, and the competent detection facilities. Headquartered in Beijing, China, the factories of this company are located all over the country.

Toyo Tanso Co., Ltd., headquartered in Osaka, Japan, since 1941, is a manufacturer specializing in advanced carbon materials and related processing. The company offers a diverse range of products: isotropic graphite renowned for its electrical and thermal conductivity; carbon fibers; and graphene with applications spanning electronics, composites, and energy storage. Their portfolio also encompasses other materials like activated carbon and carbon nanotubes, crucial across various fields from water filtration to medical devices. Furthermore, Toyo Tanso provides essential processing services, including cutting and 3D printing.

Mersen, situated in Michigan, United States, is a manufacturer of a large collection of electrical equipment along with advanced materials. The company produces high and medium-voltage fuses, power transfer for rail vehicles, cooling solutions, and bus bars. It also manufactures DC fuses, air-cooled heat sinks, aluminum electrolytic capacitors, corrosion-resistant materials, and carbon insulation for high-temperature processes. Its high-voltage voltage fuses have been used for protection in high-voltage switchgear and control gear and high-voltage systems for decades. It serves various industries, including energy, electronics, transportation, and corrosive chemicals.

Morgan Advanced Materials-Technical Ceramics, established in 1964 in the United Kingdom, is a manufacturer of advanced technical ceramic components from ceramic glass, precious metals and dielectric materials. The company is a subsidiary of Morgan Advanced Materials and specializes in manufacturing upscale, performance oriented functional as well as structural ceramic materials for usage in multiple industries such as aerospace, automotive, power generation, healthcare, semiconductors and glass processing applications. Some of their products include Alumina ceramic components, ceramic cores, wax injection and assembly, ceramic foundry products and Haldenwanger products. They come with high-temperature resistance, electrical insulation, and wear resistance along with enhanced performance.

Ranking as of March 2026

Derivation Method| Rank | Company | Click Share |

|---|---|---|

| 1 | Ohio Carbon Industries |

15.4%

|

| 2 | St Marys Carbon |

12.2%

|

| 3 | Sinotech |

8.2%

|

| 4 | Toyo Tanso Co.,Ltd. |

7.9%

|

| 5 | Anglo Carbon & Contacts Ltd |

7.8%

|

| 6 | Schleifring GmbH |

7.7%

|

| 7 | CFC CARBON CO., LTD |

7.1%

|

| 8 | Resonac Holdings Corporation. |

7.1%

|

| 9 | Mersen |

6.8%

|

| 10 | Aupac Co., Ltd. |

6.4%

|

Derivation Method

The ranking is calculated based on the click share within the carbon brush page as of March 2026. Click share is defined as the total number of clicks for all companies during the period divided by the number of clicks for each company.Number of Employees

Newly Established Company

Company with a History

*Including some distributors, etc.

*Including some distributors, etc.

| Country | Number of Companies | Share (%) |

|---|---|---|

United States of America

United States of America

|

4 | 40.0% |

Japan

Japan

|

3 | 30.0% |

United Kingdom

United Kingdom

|

1 | 10.0% |

China

China

|

1 | 10.0% |

Germany

Germany

|

1 | 10.0% |

141 products found

141 products

Toyo Tanso Co., Ltd.

910+ people viewing

Last viewed: 1 day ago

■Product overview Electrical brushes play an important role in passing electric current between stationary and rotating parts through sliding conta...

111 models listed

Hios Co., Ltd.

320+ people viewing

Last viewed: 1 day ago

As a guideline for replacing the carbon brush, replace it when it wears down to the grooves on the side of the brush. When replacing, please replac...

Nisshin Sangyo Co., Ltd.

250+ people viewing

A wire brush made of iron wire. Ideal for polishing work such as removing rust from metal and removing paint. It is also used to remove stubborn di...

S Isaacs Shokai Co., Ltd.

370+ people viewing

A brush with a handle that is convenient for removing dust and stubborn dirt. By using it in conjunction with Carbon Cleaning Foam, you can effecti...

Daigen Shokai Co., Ltd.

390+ people viewing

Last viewed: 1 day ago

■Summary ・This is a processed carbon brush that we use when repairing Aichi Denki joint removers at our company. ・Please note that the carbon bru...

Narutoya Co., Ltd.

400+ people viewing

Last viewed: 1 day ago

■Applications ・For cleaning and maintenance work on metal surfaces ・Before and after welding work ・For removing paint ・Cup brush is effective f...

Cains Co., Ltd.

260+ people viewing

Replacement carbon for EA818EA-1A