All Categories

History

This section provides an overview for plasma etching systems as well as their applications and principles. Also, please take a look at the list of 18 plasma etching system manufacturers and their company rankings. Here are the top-ranked plasma etching system companies as of February, 2026: 1.Anatech USA, 2.Trion Technology, Inc., 3.AGS Plasma Systems, Inc..

Table of Contents

Categories Related to Plasma Etching Systems

Plasma etching systems utilize plasma, a state of ionized gas, for microfabrication processes in semiconductor LSI (large-scale integrated circuit) manufacturing, including the creation of photomasks and smartphone displays. These systems enable the removal of materials like silicon, silicon oxide, and metal films beneath developed resist patterns, facilitating the formation of extremely fine patterns crucial for the high integration and resolution of LSIs and displays.

Plasma etching systems are integral in producing semiconductor devices, such as memory chips and CPUs, and flat panel displays for devices like smartphones. They play a key role in the manufacturing cycle, which includes exposure, development, etching, and resist stripping processes, allowing for the precise formation of patterns on substrates.

Compared to wet etching, which uses chemical solutions and can cause undercuts due to solution penetration beneath the resist, dry etching with plasma offers clean, vertical cuts along the resist pattern, making plasma etching the preferred method for achieving precise patterning.

In a plasma etching system, the wafer or substrate is placed in a vacuum chamber with electrode plates positioned above and below it. Etching gases, such as fluorocarbon gases for silicon and silicon oxide films or halogenated gases for metal films, are introduced into the chamber. The application of a high-frequency electric or magnetic field ionizes the gas into plasma, and the generated electric field causes ions to bombard the wafer, selectively removing material from exposed areas.

Plasma etching systems can be classified by their plasma generation method into capacitively coupled plasma (CCP), inductively coupled plasma (ICP), and microwave ECR (electron cyclotron resonance) plasma. CCP systems generate plasma between two electrode plates, using the electric field to accelerate ions towards the workpiece for etching, while ICP and ECR systems offer alternative methods for plasma generation, maintaining the principle of ion-accelerated etching.

*Including some distributors, etc.

Sort by Features

Sort by Area

Anatech USA is an American ITAR registered manufacturer of plasma systems and equipment, as well as physical vapor deposition (PVD) systems that was established in 1989. Based in Sparks, Nevada, the company primarily produces various plasma etchers, sputter coaters, PVD systems used in microscopy, and plasma treatment systems for plasma coating, surface activation, and molecular cleaning procedures. Anatech USA also provides additional R&D and spare parts services for its clients in the semiconductor, education, research, and biomedical sectors.

For over 30 years, Trion Technology, Inc. has been a USA-based, small-business original equipment manufacturer of a wide variety of custom plasma etch, photoresist strip, and plasma deposition equipment for the Compound Semiconductor, MEMS, Optoelectronic, and related markets. Our products have the smallest footprint and lowest cost systems with proven production reliability. If you wish for anything from full-blown production cluster tools to a simple laboratory system, Trion makes it.

Plasma-Therm is a manufacturer of plasma processing equipment that was established in 1974. Based in St. Petersburg, Florida, the company primarily manufactures products for etching, dicing, thermal processing, and film deposition, such as ICP and IBE etchers or IBD ion beam deposition systems. It also offers additional technical support, installation, training, and maintenance services. Plasma-Therm products have applications in scientific R&D, microelectronics, nanotechnology, and specialty markets such as MEMS, sensors, photonics, and wireless technology.

AGS Plasma Systems, Inc. (AGS) is an American manufacturer of plasma systems and related products that was established in Santa Clara, California in 1991. The company’s product lineup includes dual chamber research testbeds, versatile parallel plate plasma tools, modular process systems, and plasma systems designed for compound semiconductor manufacturing. It also offers parts and installation services compatible with its portfolio products. AGS products are used mainly by clients in the optoelectronics, semiconductor, data storage, and nanotechnology sectors.

Plasma Etch, Inc., established in 1982 and headquartered in Reno, Nevada, is a manufacturer and supplier of plasma cleaning and etching systems. Their range of products includes plasma cleaners, utilized for removing contaminants like organic residues, metal oxides, and particulates from surfaces in semiconductor, medical device, and printed circuit board manufacturing. Plasma etchers are employed for material etching, while plasma bonders are used to bond materials like metals, plastics, and ceramics. Additionally, they offer plasma adhesion promoters to enhance material adhesion and surface modification services to modify properties like wettability and corrosion resistance.

Hitachi High Tech was established in April 1947 and operates in 26 countries with products and services ranging from semiconductor manufacturing equipment and Medical and Biosystems to Analytical Systems and Manufacturing related equipment and solutions. A unique state-of-the-art technology company with two functions as a manufacturer and a trading company with the motto of "Tackling social issues," the Hitachi High-Tech Group aspires to be a company that pursues not only economic value, such as revenue and profit, but also provides social and environmental value by contributing to resolving social issues through its business activities, including products and services. They also provide one-stop services, such as evaluations and analysis at a global level.

SHINKO SEIKI CO., LTD., established in 1949, and located in Kobe, Japan, is a manufacturer of vacuum devices, electric furnaces and semiconductor manufacturing equipment. Its product line includes a vast array of vacuum pumps such as mechanical booster pumps, vacuum exhaust unit, oil sealed rotary vacuum pumps and water ring vacuum pumps. Its product range also inlcudes soldering equipments, optical inspection equipments, thin film forming equipments, and plasma processing equipments. The company holds several certification for its operation such as the ISO 14004, and the ISO 9001.

Samco Inc, founded in 1979 and headquartered in Kyoto, Japan, is a manufacturer and supplier specializing in semiconductor and electronic component manufacturing systems. The company's product portfolio includes low-stress chemical vapor deposition systems, atomic layer deposition systems, reactive ion etching systems, plasma cleaners, and Aqua Plasma Cleaners. These products are applied in various industries, including semiconductor manufacturing, the electronics industry, optoelectronics, photonics, and biotechnology. The company has office locations overseas, including China, the USA, Singapore, Malaysia, and Liechtenstein.

Sumitomo Precision Products Co. Ltd., established in 1961 and headquartered in Amagasaki, Japan, is a manufacturer of several products, including hydraulic controls, semiconductor manufacturing equipment, aerospace equipment, and environmental systems. It began manufacturing large heat exchangers in 1963, large propellers in 1967, and LNG vaporizers in 1969. In 1974, it began making ozone generators, and in 1988, it started manufacturing equipment for space applications. The company is ISO 14001 certified, and its product portfolio includes landing gear systems for commercial flights, high-temperature heat exchangers, coolant components for machine tools, LNG vaporizers, and silicon oxide sacrificial layer etching systems.

Ulvac Inc., established in 1952 and headquartered in Kanagawa, Japan, is a manufacturer of vacuum equipment, components, peripheral devices, and materials for the solar cell and semiconductor industries, among others. The company operates businesses in six areas, including materials, components, electronic devices, semiconductors, and flat panel display production equipment. Some of its products include roll coaters, semiconductor production equipment, LED production equipment, leak detectors, and vacuum brazing furnaces. It is ISO9001 certified, and its net sales in the 2022 fiscal year were 227.5 billion Japanese Yen, with 34% of this amount coming from semiconductor and electronic device production equipment.

Tokyo Electron Ltd. (TEL) is a Japanese ISO 9001 certified manufacturer of semiconductor production equipment that was originally established as Tokyo Electron Laboratories, Inc. in 1963 before rebranding in 1978. Headquartered in Minato-ku, Tokyo, the company offers a wide range of equipment and software involved in semiconductor production, including coaters and developers, wafer bonders/debonders and trimmers, cleaning systems, flat panel displays (FPDs), and probers. TEL products primarily supply clients in the semiconductor, FPD, and photovoltaic industries.

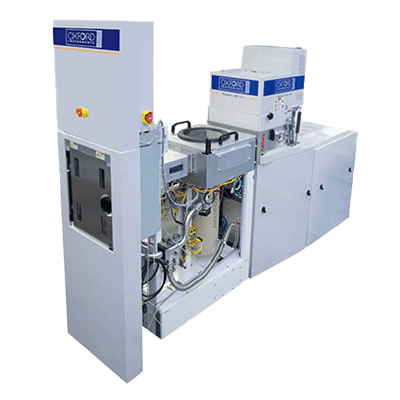

Oxford Instruments Plasma Technology, founded in 1959 with headquarters in the UK, is a manufacturer of technology tools, accessories, and systems for industry and research. The company's products include Ion beam equipment, ICP etching equipment, DRIE (Deep Reactive Ion Etching) machines, and Ionfab processing equipment used in the microelectromechanical systems (MEMS), advanced packaging, and nanotechnology markets. Oxford Instruments are found in biomedical devices, 2D materials, infrared sensors, and RF devices. Oxford Instruments provides global customer support, which includes consultation, installation, maintenance, and repair services.

Henniker Plasma, founded in Runcorn, England, in 2009 is a manufacturer of plasma systems for cleaning, activation & coating. The company's product portfolio includes Low-Cost Plasma Cleaner, Plasma Cleaners, Plasma Surface Activation Systems, Plasma Treatment Coating Systems and Plasma Etch Systems. Their products are used in biomedical research, life sciences, energy storage, and filtration. The company serves markets including Medical and Healthcare, Aerospace and Defense, Consumer Goods, Industrial Manufacturing and Construction and Building.

SAMCO INC. is a Japanese semiconductor ISO 9001:2015 and OHSAS 18001:2007 certified equipment manufacturer that was established in Kyoto in 1979. The company’s specialized product portfolio includes cathode and anode plasma-enhanced chemical vapor deposition (PECVD) systems, reactive ion etching (RIE) systems, and atomic layer deposition (ALD) systems, as well as various ICP etch systems. These are critical process systems for both semiconductor production and R&D applications. SAMCO INC. operates internationally, with a network of sales offices and distribution centers in nine countries including Singapore, India, and the United States.

SENTECH Instruments GmbH was founded in 1990 and is based in Berlin, Germany, and is a manufacturer of measuring instruments for various industrial applications. The company has membership in the German Ministry of Economics, the International Photovoltaic Equipment Association, and, the European Industry Association and provides systems and instruments for plasma etching, atomic layer deposition, cluster configuration, and, thin film measurement, as well as offers spectroscopic ellipsometry, laser ellipsometer, metrology for photovoltaics, and, silicon & thin film solar cells that have applications in the semiconductor, microsystems, photovoltaics, nanotechnology, and materials research industries.

SPTS Technologies Ltd, a subsidiary of KLA Corporation, is a British manufacturer established in 2009 and based in Ringland Way, Newport, specializing in technology and solutions for semiconductor and microelectronic device manufacturers and research institutions. SPTS Technologies offers process technologies tailored for advanced packaging schemes, including high density fan-out wafer level packaging (FOWLP) and three-dimensional integrated circuit (3DIC) packaging. The company also provides support for wafer processing systems used in the manufacturing of Micro Electro Mechanical Systems (MEMS) devices. Additionally, SPTS Technologies offers plasma processing technology to assist the compound semiconductor applications in manufacturing radio frequency (RF) and photonic devices.

Advanced Micro-Fabrication Equipment Inc., founded in 2004 and headquartered in Shanghai, China, is an ISO 9001 and ISO 45001-certified manufacturer of micro-fabrication equipment. The company supplies dielectric and TSV etch tools that help chipmakers with chip processing. Its MOCVD tools are used in volume production by LED manufacturers, and it also produces industrial volatile organic compound purifiers and eco-friendly local scrubbers that are used to treat exhaust gases generated from the manufacturing of semiconductors. It has over 80 honorary awards, and as of 2019, the company had been granted over 900 patents in China and overseas.

ULVAC Europe, established in 1993 in the United Kingdom, is a manufacturer and supplier of vacuum technology solutions for a wide range of industries. The company’s product portfolio includes vacuum pumps, components, leak detectors, and related equipment, which find applications in industries such as semiconductor manufacturing, electronics, research, and industrial processes. ULVAC Europe offers continuous research and development efforts to provide cutting-edge solutions that meet the evolving needs of its customers. With a target on quality, reliability, and technological advancement, ULVAC Europe plays a vital role in shaping the field of vacuum technology and its applications across various sectors.

Ranking as of February 2026

Derivation Method| Rank | Company | Click Share |

|---|---|---|

| 1 | Anatech USA |

13.6%

|

| 2 | Trion Technology, Inc. |

9.7%

|

| 3 | AGS Plasma Systems, Inc. |

8.3%

|

| 4 | Advanced Micro-Fabrication Equipment Inc. |

6.3%

|

| 5 | Hitachi High-Tech America, Inc. |

6.3%

|

| 6 | Plasma-Therm |

6.2%

|

| 7 | Henniker Plasma |

5.7%

|

| 8 | Plasma Etch, Inc. |

5.7%

|

| 9 | Tokyo Electron Ltd. |

5.2%

|

| 10 | SPTS Technologies Ltd. |

4.6%

|

Derivation Method

The ranking is calculated based on the click share within the plasma etching system page as of February 2026. Click share is defined as the total number of clicks for all companies during the period divided by the number of clicks for each company.Number of Employees

Newly Established Company

Company with a History

*Including some distributors, etc.

*Including some distributors, etc.

| Country | Number of Companies | Share (%) |

|---|---|---|

United States of America

United States of America

|

6 | 37.5% |

Japan

Japan

|

6 | 37.5% |

United Kingdom

United Kingdom

|

2 | 12.5% |

Germany

Germany

|

2 | 12.5% |

29 products found

29 products

SAKIGAKE-Semiconductor

620+ people viewing

Last viewed: 9 hours ago

High -speed and high efficiency by heating SIO2 and SI etching and organic products. ■ Product overview ・ Newly heated stage heated in the plasma ...

SHINKO SEIKI CO., LTD.

940+ people viewing

Last viewed: 9 hours ago

It is a new multi -chamber type etching device that can equip multiple etching rooms. Equipped with 2 newly developed ICP etching chamber ・ This d...

SAKIGAKE-Semiconductor

610+ people viewing

Last viewed: 7 hours ago

Ptfe (Teflon) nytherization. Water -repellent treatment of various materials. Glass film formation. Such ■ Product overview ・ A new semi -auto ser...

SHINKO SEIKI CO., LTD.

900+ people viewing

Last viewed: 9 hours ago

EXAM is a multipurpose plasma etching device that can handle multiple purposes that make use of the know -how of semiconductor product devices. Mul...

SHINKO SEIKI CO., LTD.

800+ people viewing

Last viewed: 9 hours ago

The surface wave plasma (SWP), which can generate a large area of high -density plasma, is used for many purposes such as assing and surface trea...

SAKIGAKE-Semiconductor

610+ people viewing

Last viewed: 7 hours ago

SIO2 and SI etching, etc. Made fine circuits such as semiconductor integration circuits. ■ Product overview ·compact ・ Easy operability ・ Touch pa...

SHINKO SEIKI CO., LTD.

690+ people viewing

Last viewed: 8 hours ago

SERIO is a high -density plasma etched device equipped with high density ICP plasma sauce. The proprietary development process has achieved high ve...

Oxford Instruments Ltd.

560+ people viewing

Last viewed: 5 hours ago

■Summary The PlasmaPro 100 ALE atomic layer etch system enables precise control of etching of next generation semiconductor devices. Specifically d...

Oxford Instruments Ltd.

910+ people viewing

Last viewed: 8 hours ago

■Summary The PlasmaPro 100 Cobra ICP RIE system uses high-density inductively coupled plasma to achieve fast etch rates. This process module suppor...

Oxford Instruments Ltd.

640+ people viewing

Last viewed: 8 hours ago

The PlasmaPro 100 Estrelas platform is designed for total flexibility for deep reactive ion etching (DRIE) applications. We can meet the diverse pr...

Oxford Instruments Ltd.

570+ people viewing

Last viewed: 8 hours ago

PlasmaPro 100 Polaris is a single-wafer etch system that provides a smart solution with the etch performance you need to stay competitive. Designed...

Oxford Instruments Ltd.

530+ people viewing

Last viewed: 8 hours ago

The PlasmaPro 100 RIE module provides isotropic and anisotropic dry etching for a wide range of processes. Suitable for research and manufacturing ...

SAKIGAKE-Semiconductor

330+ people viewing

Last viewed: 4 hours ago

Hyperataking on the surface of Teflon and water repellency of non -woven fabric. ■ Use ・ PTFE (Teflon) Hydrylore (NH3 required) ・ Water -repellen...

2 models listed

ULVAC Sales Co., Ltd.

530+ people viewing

Last viewed: 9 hours ago

■Summary The NLD-5700 dry etching system for opto-devices and MEMS is a dry etching system for mass production equipped with a magnetic neutral lin...

ULVAC Sales Co., Ltd.

540+ people viewing

Last viewed: 8 hours ago

■Summary NLD dry etching for research and development NLD-570 is a dry etching system equipped with low pressure, low electron temperature, and hig...

ULVAC Sales Co., Ltd.

440+ people viewing

Last viewed: 8 hours ago

■Summary The batch type natural oxide film removal device RISETM-300 is a batch type pre-clean device that can remove difficult natural oxide films...

ULVAC Sales Co., Ltd.

700+ people viewing

Last viewed: 3 hours ago

■Summary The high-density plasma etching system NE-550EX for research and development is a magnetic field ICP (ISM=Inductively Super Magnetron) typ...

ULVAC Sales Co., Ltd.

450+ people viewing

Last viewed: 4 hours ago

■Summary The high-density plasma dry etching system ULHITETM NE-7800H is a multi-chamber type low-pressure, high-density plasma that is compatible ...

ULVAC Sales Co., Ltd.

620+ people viewing

Last viewed: 9 hours ago

■Summary The NE-5700/NE-7800 dry etching equipment for mass production is a scalable etching equipment that supports from one chamber to multiple c...

Panasonic Industry Co., Ltd.

290+ people viewing

Last viewed: 7 hours ago

The APX300 is a fully automatic batch processing dry etching system that can process multiple wafers of 6 inches or less at the same time, and can ...