All Categories

History

This section provides an overview for hardness testing instruments as well as their applications and principles. Also, please take a look at the list of 23 hardness testing instrument manufacturers and their company rankings. Here are the top-ranked hardness testing instrument companies as of February, 2026: 1.KING Tester Corporation, 2.Anton Paar GmbH, 3.ACRN.

Table of Contents

Categories Related to Hardness Testing Instruments

Hardness testing instruments evaluate the hardness of various materials and products.

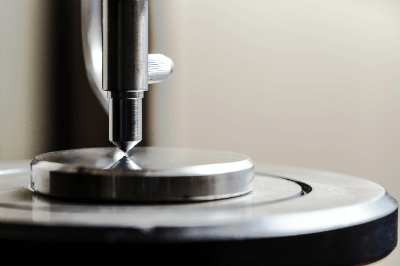

Depending on their basic principles, hardness testing methods can be broadly classified into indentation testing and dynamic testing. The indentation test is performed by pressing a hard indenter into the surface of a test specimen and measuring the size of the surface area or depth of the indentation. The smaller the indentation area and the shallower the indentation depth, the harder the material is evaluated.

In the dynamic test method, a hammer is dropped from a certain height, and its rebound height is measured. This test method is called the Shore hardness test and utilizes the property that the harder the specimen is, the higher it will bounce back.

Various hardness testing instruments are used to perform the above test methods, depending on the indenter, the load applied to the indenter, and how the indentation is measured. When evaluating hardness, it is essential to select the appropriate testing method and instrument based on the test specimen's size, shape, and purpose, as well as on the agreement between the recipient and the testing party.

Vickers hardness test and Brinell hardness test are used to measure the surface area of indentation.

Vickers Testing Instrument

Vickers hardness testing instruments are used to test various materials, including metallic materials. It is characterized by a small test load and evaluates hardness in a narrow range. It is also used to assess the hardened layer depth of various surface treatments, such as carburizing, induction hardening, and nitriding layers, as well as the hardness distribution of welds.

Brinell Hardness Testing Instrument

The Brinell hardness testing instrument tests castings, forgings, and other metallic materials with rough surfaces and heterogeneous grain structures. It is characterized by a large test load and large indentation, allowing for average hardness evaluation over a relatively wide range.

The Rockwell hardness test is a test method to measure indentation depth. The Rockwell hardness testing instrument is mainly used for hardened metal materials. When evaluating the hardness of the hardened layer in hardened metal materials, the appropriate test conditions (set as a scale) must be selected according to the hardness and depth of the hardened layer.

Shore hardness testing, a dynamic test method, is used to test the hardness of large parts and rolling rolls and is a common test method used in the field within machine shops. The advantages of the Shore hardness testing instrument are that it can be used for product inspection because the indentation is less noticeable, and the instrument is small and portable.

The principles of hardness testing instruments differ depending on the type.

In the Vickers hardness testing instrument, a diamond indenter with a 136° square face angle is pressed into a test specimen under a test load. The diagonal length of the square indentation created by this load is measured with a metallographic microscope attached to the tester.

JIS specifies test loads from 10gf to 100kgf. The test performed at one kgf or less is called the micro-Vickers hardness test. The testing instrument is the same for both Vickers and Micro-Vickers testing instruments. Both tests can be performed by changing the test load. Changing the test load does not change the hardness value as long as there is no irregularity in the material.

For the Vickers hardness test, the specimen should be no larger than the palm size. The surface to be tested also needs to be mirror polished, so it is almost always necessary to cut out the part of the specimen whose hardness is to be determined.

The Brinell Hardness testing instrument uses a ball indenter, steel, or cemented carbide ball 10 mm in diameter. A test load of 3,000 kgf is often used. The load is calculated by dividing the load applied to a spherical indentation in the test surface by the surface area of the permanent indentation.

The Rockwell hardness testing instrument applies load in three stages. First, a reference load is used, then a higher test load is applied, and then the load is returned to the reference load. The hardness evaluation is based on the difference in indentation depths between the two reference loads applied before and after the test.

In the Rockwell hardness test, the scale is determined by the combination of several test loads and indenter types. For example, if a diamond cone with a tip radius of 0.2 mm and a tip angle of 120° is used and the primary load is ten kgf, the A scale is used if the test load is 60 kgf, the D scale if 100 kgf, and the C scale if 150 kgf.

A test using a 1/16" (1.5875mm) steel ball with a basic load of 10kgf and a test load of 100kgf falls under the B scale. Tests conducted with a basic load of 3 kgf and test loads of 15, 30, and 45 kgf are called Rockwell superficial hardness tests. It is used especially for hardness testing of thin steel plates.

In today's Rockwell hardness testing instruments, the indenter is interchangeable and can be set to different base and test loads. The advantage is that loadings and depth measurements are performed automatically.

In the Shore hardness test, a diamond hammer of a specific shape and mass is dropped on a test specimen from a certain height, and the bounce height is measured. Unlike other testing instruments, the Shore hardness testing instrument is very small and uses no electricity.

Hardness testing instruments need to be calibrated periodically to ensure that they are performing correctly. The testing machine manufacturer usually services this.

Also, in daily operations, checking the accuracy using test specimens is essential. A standard test specimen with guaranteed hardness is prepared, and before the actual test is conducted, it is checked to ensure the correct results can be obtained with the standard test specimen. This preliminary check can also help you notice mistakes in test load or indenter selection.

*Including some distributors, etc.

Sort by Features

Sort by Area

Phase II, founded in 1982 and headquartered in Upper Saddle River, New Jersey, is a manufacturer of material testing tools. The goods include durometers, force gauges, vibration meters, hardness & surface roughness testers, and ultrasonic thickness gauges. The machine tool accessories include change tool holders, rotary table tailstocks, lathe tool post sets, collet indexers, and dex spacers. The firm provides Gage calibration and certification services and is AMTMA, ASNT, and ASTM International member.

KING Tester Corporation has been a manufacturer of Hardness Testing Equipment since 1936 in Pennsylvania. The company designs Brinell Hardness Testers which are available as Portable Brinell Tester, Chain Adapter, Tester Bases, and Test Heads, along with Rockwell testers, handheld and automatic reading Scopes, and some specialty products like In Line, and TWIN X Automatic Hardness Tester, and CaseRock Series that helps determine the hardness of a metal throughout the case in a reduced time frame. These products help Construction, Heat Treating, Manufacturing, Aerospace, Foundries, and many other industries.

Affri, founded in Induna Olena, Lombardi in 1954 is a manufacturer of Hardness Testing systems. The company's product portfolio includes Microhardness Testers used to provide accurate measurements for small samples, Macro hardness Testers, universal Hardness Testers and Portable Hardness Testers. The company serves industries such as Oil and Gas, Aerospace and Defense, Automotive and Transportation, Construction, and Power Generation. They also offer services such as equipment repair, instrumentation system upgrades and retrofits, preventive maintenance, warranty service.

Pharma Test Apparatebau AG is a manufacturer of testing equipment for the pharmaceutical, food, and cosmetics industries established in 1979 and based in Hainburg, Germany. The company primarily produces galenic instruments for ampoule testing, tablet hardness testing, and tablet disintegration testing. It also offers online and offline automated dissolution testing systems, media preparation tools, and ultraviolet visible (UV-VIS) spectrometers. The company mainly serves clients in the European Union’s pharmaceutical, food, and dietary supplements industries.

Marposs S.p.A. is headquartered in Bentivoglio, Italy. The company serves industries such asa aerospace, semiconductors, machine tooling, and biomedical as a manufacturer and as a service provider. The company’s products vary by industry but include tools for gauging, profiling, and monitoring, as well as data management systems and machines for testing and automation. The company’s services include after sales service, customer training, original spare parts, retrofit and upgrade of existing machinery, and project management consulting services.

IMADA, founded in Japan, in 1947 is a manufacturer of force gauges and Force Measurement related equipment. The company's product portfolio includes Load Cells (Force Sensors), Force Test Stands, Torque Testers, Torque Test Stands Attachments, and Grips & Fixtures. The company serves industries such as Oil and Gas, Aerospace and Defense, Automotive and Transportation, Construction, and Power Generation. They also provide services such as technical and commercial consultation of force measurement products, repair, calibration and global distribution.

Future-Tech Corp., established in 1995 and headquartered in Kanagawa, Japan, is a manufacturer of hardness testers and accessories. Its products are supplied in the domestic market of Japan, and also to more than 35 countries around the world. The company offers a range of products including the Microhardness Tester FM-X Series, which is a new standard of Microvickers hardness tester. Its series adopts the loading by Load-cell and the multistep load switching, which have made it possible to achieve heavy accuracy. The company also produces and sells sample preparation machines such as cutting machine and grinding press.

Anton Paar, founded in 1933 and headquartered in Graz, Austria, is a manufacturer and supplier of analytical instruments Their product range includes density meters for measuring liquid and solid density, concentration meters for analyzing solution concentration, viscosity meters for assessing liquid viscosity, particle size analyzers for measuring particle size in liquids or solids, and chromatography systems for substance separation and identification in mixtures. Anton Paar's products cater to a wide range of industries, including food and beverage, pharmaceutical, and chemical, providing analytical solutions for diverse applications.

MARKTEC Corporation, founded in 1955 as Tokushu Toryo Co. Ltd., and based in Tokyo, Japan, is a manufacturer and seller of fluorescent paint and metal testing materials. The company offers a wide range of products for Penetrant Testing such as Dye Penetrant Flaw Detection Material, Magnetic Particle Testing, Eddy Current Testing, Ultraviolet Light Testers, and many more. The company’s products serve various industries such as automobile, construction, steel, and heavy industries among others. It holds the ISO 9001:2015 and ISO 14001: 2015 certifications.

JFE Advantech Co.,Ltd. was established in 1973 and is a manufacturer of water instruments and measuring devices based in Nishinomiya, Hyogo, Japan. The company produces various products such as submerged level detectors, ultrasonic pulse coherent flowmeters, optical dissolved oxygen meters, electromagnetic flow velocity meters, and comprehensive water quality meters. The products have been used in various applications including sewage treatment plants, agricultural water systems, factory drainage, hydroelectric power plant, and deep wells management. The company have been certified with ISO 9001 for the water instruments and measuring products in 1995.

Chongqing Leeb Instrument Co., Ltd is a researcher, manufacturer, and marketer of NDT instruments established in 2001 and located in Chongqing, China. The products are metallurgical microscopes, ultrasonic flow detectors, thickness gauges, and hardness testers for micro lakers, Rockwell, and Brinell. The company offers services such as delivery in 7 work days, one to three annual warranties, online assistance, technical & training support, and export to over $& countries. The company has ISO 9001:2015 quality management system certification, and all the products are CE and FCC certified.

TMTECK, founded in Beijing, China, in 2006 is a manufacturer of Ultrasonic Transducers and Coating Thickness Gauges. The company's product portfolio includes ultrasonic transducers that utilize the advanced technology to detect flaws and measure material thickness, ultrasonic testing equipment for flaw detection, material characterization, and thickness measurement and Accessories. The company serves markets including Medical and Healthcare, Aerospace and Defense, Consumer Goods, Industrial Manufacturing and Construction and Building. The company provides services such as Product Selection Guidance, Engineering Support, and Custom Manufacturing.

Struers is a manufacturer of materialographic equipment and consumables based in France since 1875. The company designs equipment used for cutting, mounting, grinding, polishing, and verifying materials for enhancing and streamlining the processes of sample preparation, from manufacturing and quality assurance to failure investigation and research. There are cut-off machines such as Magnutom-5000, Mounting accessories, machines, and consumables along with automated solutions for grinding and polishing. These products cater to automobile and airplane manufacturers including mobile phone producers and aerospace sectors.

ACRN, founded in 1997, is a manufacturer and designer of physical testing and measurement solutions with over 2000 equipped plants & laboratories and headquarters in France. The product categories are equipment used for torque testing, force measurement, leak testing, sensors, and measurement. The products include torque wrenches & screwdrivers, vacuum chambers, dynamometers, tube seattle testers, and compression test stands used in cosmetics, pharmaceuticals, food, packaging, and industrial markets. The company provides services such as calibration & metrology, custom-made equipment, specific testing, and after-sale services.

TOP Cloud-agri, founded in 2008 and based in Hangzhou, Zhejiang Province of China, is a manufacturer and designer of agriculture testing instruments. The company produces products such as weather monitor instruments, food safety instruments, flour and oil testing instruments, and general lab equipment. All the testing instruments made by the company are used in seed breeding, cleaning, storage, and water quality detection. The company holds 14 national invention patents, 20 appearance patents, 57 utility model patents, and 70 software copyrights with ISO 9 0 0 1, ISO 1 4 0 0 1, and ISO 4 5 0 0 1 certificates.

Industrial Physics, a portfolio company of KKR a private-equity firm, is a manufacturer of test, measurement, and inspection equipment, based in the United States. The company specializes in the food and beverage, paper and plastics, paint and coatings, materials testing, and consumer electronics markets. They operate across a family of brands, including TQC Sheen, Technidyne, and C&W Equipment. They have been supporting manufacturers, laboratories, and production lines across a multitude of industries.

Chengyu Testing Equipment Co. Ltd, established in 2010, is a manufacturer and supplier of testing machines based in Jinan, China, and with branches in Qingdao, and Hong Kong China. The company’s product portfolio consists of compression testers, tensile testing equipment, hardness testers, fatigue testing machines, and bending testing machines used in geotechnical laboratories, civil engineering, construction, mining, educational and research establishments. The company also offers test fixturing, software accessories, and calibration services that meet the ASTM, JIS, BSI, DIN, and ISO standards and specifications.

BIOBASE, established in 1999, is a high-tech manufacturing enterprise whose business covers biomedical, e-commerce, intelligent manufacturing, scientific equipment In Vitro Diagnosis (IVD) instrument and reagent based in China. Specialized in research, development, and manufacturing of laboratory and medical equipment, catering to life sciences, healthcare, and environmental protection industries. Their product range includes biological safety cabinets, incubators, centrifuges, and more. The company has branch offices in 24 provinces in China, with overseas establishment in USA, Dubai, India, Algeria, Singapore, and business partners in 130 countries.

Ranking as of February 2026

Derivation Method| Rank | Company | Click Share |

|---|---|---|

| 1 | KING Tester Corporation |

8.6%

|

| 2 | ACRN |

7.8%

|

| 3 | Anton Paar GmbH |

7.8%

|

| 4 | Struers |

6.3%

|

| 5 | Industrial Physics |

5.9%

|

| 6 | Marposs |

5.9%

|

| 7 | Pharma Test |

5.5%

|

| 8 | MARKTEC Corporation |

5.1%

|

| 9 | Phase II |

4.7%

|

| 10 | Biobase Biodusty, Co., Ltd. |

4.7%

|

Derivation Method

The ranking is calculated based on the click share within the hardness testing instrument page as of February 2026. Click share is defined as the total number of clicks for all companies during the period divided by the number of clicks for each company.Number of Employees

Newly Established Company

Company with a History

*Including some distributors, etc.

*Including some distributors, etc.

| Country | Number of Companies | Share (%) |

|---|---|---|

Japan

Japan

|

7 | 38.9% |

United States of America

United States of America

|

3 | 16.7% |

China

China

|

3 | 16.7% |

Germany

Germany

|

1 | 5.6% |

Italy

Italy

|

1 | 5.6% |

Austria

Austria

|

1 | 5.6% |

Denmark

Denmark

|

1 | 5.6% |

France

France

|

1 | 5.6% |

149 products found

149 products

Matsuzawa Co., Ltd.

580+ people viewing

Last viewed: 7 hours ago

Combined use with Rockwell hardness test and superficial hardness test Rockwell RMT-X series: Pioneer of Rockwell hardness testers. Matsuzawa's Ro...

Pulstech Industry

970+ people viewing

Last viewed: 10 hours ago

feature It is a scanner that detects "unevenness of hardness" on the surface of the steel material due to the world's first contact and non -destru...

Itani Koki Seisakusho Co., Ltd.

1020+ people viewing

Last viewed: 1 hour ago

KING (King Brinell Hardness Tester) is manufactured by King Corporation, headquartered in the United States, and has been used by automobile manufa...

F.I. Tech Co., Ltd.

500+ people viewing

Last viewed: 9 hours ago

The HM2000 series is a revolutionary hardness testing machine that has a wide range of applications and can obtain valuable physical property data ...

FTS Co., Ltd.

180+ people viewing

Last viewed: 14 hours ago

By using a special alumina ball indenter with a diameter of 3 mm, it is now possible to measure lighter samples, smaller samples, and thinner sampl...

Matsuzawa Co., Ltd.

560+ people viewing

Last viewed: 10 hours ago

■Uses electric load method (no weight) ・Achieves high precision testing force by adopting feedback control ・Easy switching of test force using to...

Meishin Koki Co., Ltd.

520+ people viewing

Last viewed: 10 hours ago

■Summary A lightweight and compact size force measuring device that can be used on a desk as an alternative to force gauges and push-pull gauges. ...

Itani Koki Seisakusho Co., Ltd.

450+ people viewing

Last viewed: 10 hours ago

BRINtronic-MD is a device that automatically measures indentation diameter readings in Brinell hardness tests. By using a high-precision CCD camera...

Matsuzawa Co., Ltd.

540+ people viewing

Last viewed: 10 hours ago

Rockwell hardness test machine Rockwell RMT-X series: Pioneer of Rockwell hardness testers. Matsuzawa's Rockwell hardness tester continues to purs...

ZwickRoell Corporation

700+ people viewing

Last viewed: 10 hours ago

■Summary DuraVision solves a variety of testing tasks and is known for its efficiency in macro hardness testing applications. - Even in harsh indus...

Matsuzawa Co., Ltd.

520+ people viewing

Last viewed: 10 hours ago

Economy model for manual investigation, analog type, made-to-order product ■Color LCD touch panel ・Improved visibility and operability. -Equipped...

F.I. Tech Co., Ltd.

590+ people viewing

Last viewed: 1 hour ago

The HM2000 series is a revolutionary hardness testing machine that has a wide range of applications and can obtain valuable physical property data ...

Matsuzawa Co., Ltd.

540+ people viewing

Last viewed: 5 hours ago

■Easy hardness measurement with one touch By touching the start button on the touch panel, you can easily perform the test cycle (initial test forc...

Matsuzawa Co., Ltd.

520+ people viewing

Last viewed: 10 hours ago

This is an analog type testing machine using a dial gauge and a digital type testing machine that can be equipped with an auto brake (optional). ■...

Matsuzawa Co., Ltd.

470+ people viewing

Last viewed: 1 day ago

A new image processing algorithm enables stable reading without being affected by scratches, etching, changes in brightness, etc. In order to detec...

Matsuzawa Co., Ltd.

470+ people viewing

Last viewed: 10 hours ago

Compatible with all kinds of samples. We will propose and provide one that suits your various needs. Manually operated economy model (analog type)...

ZwickRoell Corporation

800+ people viewing

Last viewed: 10 hours ago

■Summary DuraVision solves a variety of testing tasks and is known for its efficiency in macro hardness testing applications. - Even in harsh indus...

Matsuzawa Co., Ltd.

530+ people viewing

Last viewed: 10 hours ago

■Color LCD touch panel ・Improved visibility and operability. -Equipped with 4 measurement modes (fracture toughness (KC), light test force Brinell...

Matsuzawa Co., Ltd.

490+ people viewing

Last viewed: 10 hours ago

■Easy hardness measurement with one touch By touching the start button on the touch panel, you can easily perform the test cycle (initial test forc...

Matsuzawa Co., Ltd.

630+ people viewing

Last viewed: 10 hours ago

Compatible with all kinds of samples. We will propose and provide one that suits your various needs. ■Micro Vickers sample (sample) example ・Very...

Matsuzawa Co., Ltd.

520+ people viewing

Last viewed: 10 hours ago

This is an analog type testing machine using a dial gauge and a digital type testing machine that can be equipped with an auto brake (optional). ■...

Matsuzawa Co., Ltd.

760+ people viewing

Last viewed: 10 hours ago

Compatible with all kinds of samples. We will propose and provide one that suits your various needs. ■Micro Vickers sample (sample) example ・Very...

Matsuzawa Co., Ltd.

390+ people viewing

A new image processing algorithm enables stable reading without being affected by scratches, etching, changes in brightness, etc. In order to detec...

ZwickRoell Corporation

820+ people viewing

Last viewed: 3 hours ago

■Summary DuraVision solves a variety of testing tasks and is known for its efficiency in macro hardness testing applications. - Even in harsh indus...

Matsuzawa Co., Ltd.

490+ people viewing

Last viewed: 9 hours ago

The Vickers test has a very wide range of possible hardness, and is characterized by a constant value regardless of the test force. However, it req...

Matsuzawa Co., Ltd.

560+ people viewing

Last viewed: 10 hours ago

■Color LCD touch panel ・Improved visibility and operability. -Equipped with 4 measurement modes (fracture toughness (KC), light test force Brinell...

ZwickRoell Corporation

740+ people viewing

Last viewed: 10 hours ago

■Summary DuraVision solves a variety of testing tasks and is known for its efficiency in macro hardness testing applications. - Even in harsh indus...

Matsuzawa Co., Ltd.

600+ people viewing

Last viewed: 10 hours ago

■Wide measurement range Test force loads A wide range of test forces are electrically controlled. The test force control function using a load cell...

ZwickRoell Corporation

850+ people viewing

Last viewed: 10 hours ago

■Summary DuraVision solves a variety of testing tasks and is known for its efficiency in macro hardness testing applications. - Even in harsh indus...

FTS Co., Ltd.

310+ people viewing

The Portable hardness tester e-handy is an innovative, patented hardness tester developed by Ernst (DIN50158 standard). A portable hardness tester ...