All Categories

History

This section provides an overview for abrasion testers as well as their applications and principles. Also, please take a look at the list of 18 abrasion tester manufacturers and their company rankings. Here are the top-ranked abrasion tester companies as of July, 2025: 1.TESTER SANGYO CO,. LTD, 2.Textechno, 3.Ceramic Instruments s.r.l..

Table of Contents

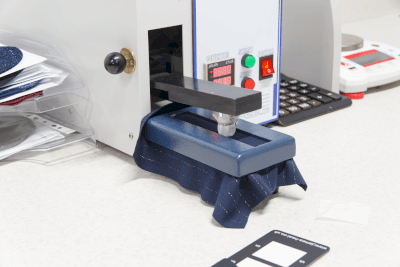

Abrasion testers are specialized machines used to evaluate the wear resistance of materials under various stresses such as tensile, compressive, and torsional. They're crucial for testing materials like metals, plastics, and fabrics, simulating real-world conditions to measure properties like strength and hardness.

These testers are instrumental in the development and quality assurance of products across industries, including industrial and construction equipment, medical devices, and automotive components. They help identify wear-related product failures and facilitate material selection, coating, and lubrication choices.

Abrasion testers operate by applying a load to two contact surfaces under controlled conditions, including lubrication and temperature, to replicate wear processes. They measure wear amount and friction coefficients, providing insights into the wear mechanisms and material durability.

Designed to mimic the frictional wear surfaces experience, abrasion testers vary significantly to cater to the specific conditions under which materials are used. Despite the diversity in wear testing requirements, standardized methods are relatively few, reflecting the complexity of accurately reproducing wear phenomena.

Abrasion testers conduct various tests like Pin-On-Disk, Ball-On-Disk, Ring-On-Disk, Pin-On-Plate, and Ball-On-Plate, each assessing different wear characteristics such as friction coefficients and wear resistance under changing material conditions.

*Including some distributors, etc.

Sort by Features

Sort by Area

Encon Evaporators, founded in 1993, is an American manufacturer based in Hooksett, New Hampshire, specializing in wastewater minimization and recycling solutions. The company provides a range of wastewater evaporation technologies, including drum, vacuum, and thermal evaporators. Encon Evaporators also manufactures circulating flash evaporators (CFE), mechanical vapor compression (MVC) evaporators, slurry dryers, which double as evaporators for drying wastewater and sludge containing variable solids. These products are employed across various industries, including metal finishing and pharmaceutical manufacturing.

Taber® Industries consist of the Material Test and Measurement Division, originally founded in 1941 as Taber Instrument Corporation as a manufacturer of precision instruments. The company's other two divisions are Taber Transducer which is into the manufacture of pressure measurement instruments for critical pressure measurement applications in sectors such as space, military, and satellite aerospace, and Kenco Press which offers low tonnage mechanical stamping presses for applications requiring 3 to 5 tons of force in industries such as manufacturing.

Itoh Denki USA Inc. is based in Wilkes-Barre, Pennsylvania, USA, and is a manufacturer of motor-driven roller (MDR) material handling products established in 1996 as a division of Japan’s Itoh Denki Co. Ltd. The company offers MDR motorized conveyor rollers for low-noise and energy efficient applications, and its Power Moller 24 brand 24v brushless DC motor for high speed and high torque applications. It also offers rollers tailored by customer use cases, including for pallet handling or low-temperature environments. The company mainly serves clients in the logistics, material handling, and industrial manufacturing sectors.

Paul N. Gardner Company, Inc. was established in 1936 and is headquartered in Columbia, Maryland, US, as a manufacturer and distributor of physical testing instruments. The product range comprises laboratory supplies, color testers, abrasion testers, gel timers, density measurement apparatus, holiday detectors, thermometers, hygrometers, and optical testers, among others, with various features and specifications. These products serve a multitude of applications, including quality control, material analysis, surface testing, density measurement, moisture monitoring, and optical property assessment across industries such as manufacturing, aerospace, petroleum, food, construction, automotive, and research.

Rhopoint Americas is an American distributor of test and quality control equipment that was established in 2018 as a North American subsidiary of the UK company Rhopoint Instruments Ltd. Based in Troy, Michigan, the company stocks a wide range of instruments for measuring surface appearance, determining liquid coating properties (e.g. viscosity), and testing packaging. These are primarily used by client manufacturers of paints and coatings, packaging products, and automotive components. Rhopoint Americas also offers onsite training and equipment calibration services for clients requiring technical assistance.

Qualitest International Inc., founded in 1999, is a supplier of testing equipment such as hardness testers, material testing equipment, universal testing machines, and instruments for testing rubber, metals, paper, plastic, paint, and packaging materials used in the gold and jewelry, mining, oil and gas, surveying, and ultrasonic industries. The Lauderdale, Florida-based business offers technical support, calibration, and repair either directly or through the global QualiService authorized network. The company has an online store with international shipping.

Matest is an Italy-based company founded in 1986 and a manufacturer of testing equipment for the construction sector. The ISO 9001 company provides various products such as asphalt analyzers, aggregate rocks, bitumen, steel, and general equipment. It also provides testing equipment and machines for concrete. Also, it deals with electromechanical and hydraulic devices for testing steel as well. The products ensure safety in the construction process. The company also provides training and technical support services.

Ceramic Instruments, established in 1977 and headquartered in Fiorano Modenese, Italy, is a manufacturer and supplier of laboratory instruments. The company's products include laboratory planetary rapid mills, laboratory knives, and hard porcelain jars. These products are used in laboratory environments for the crushing, grinding, and mixing of powders. It also provides equipment for screening and refining, devices for weighing powders, and portable equipment. Its services include standardized testing for ceramic tiles and bricks. It serves industries that include pharmaceuticals, chemical processing, and food processing.

Textechno Group, founded in 1949 and headquartered in Mönchengladbach, Germany, is a textile testing instruments manufacturer. The company's products include filament yarn automatic capacitance evenness testers, Fibrestress, which measures the resistance of synthetic or natural fibers, hairs, yarns, or monofilaments, and Fibrelength, for measurement of the fiber length distribution on fiber bundles. It also supplies modular fiber classification systems, which are created with custom combinations of its instruments. The company took over Lenzing Instruments and was rebranded as Textechno Group in 2004.

YASUDA SEIKI SEISAKUSHO, LTD., founded in 1955 with headquarters in Japan, is a manufacturer of material testing machines. The company's wide range of products includes rubber testing machines, electrical and magnetic wire testing machines, leather testing machines, and dye testing machines. YASUDA SEIKI SEISAKUSHO, LTD.'s testing machines are used to evaluate and quantify the physical properties of materials and can be found in research, industrial, commercial, and governmental organizations. The company offers customer support, including repairs and troubleshooting services.

Tester Sangyo Co., Ltd, established in 1967 and headquartered in Saitama, Japan, is a manufacturer of material testing equipment. Their product portfolio comprises of testing equipment for various materials such as fiber, rubber, pulp and paper, and batteries. These equipments are used to analyze and measure material characteristics such as tensile strength, hardness, friction, and more. Their range of equipment includes high-speed peeling testers, moisture pervious cups, auto notching machines, and pneumatic presses. Tester Sangyo Co., Ltd ensures accurate testing to maintain product quality, performance, and safety standards in diverse sectors including automotive, aerospace, and electronics industries.

Ektron Tek Co., Ltd., since 1968, has been a manufacturer of rubber testing instruments and a rubber testing company in Ohio, USA. The instruments include rheometers, Mooney viscosity, tire aging oven, vibration simulators, and flexometers. Testers for low-temperature retraction, fatigue failure, temperature simulation, gas permeability, and blow point. The company provides management services, laboratory and calibration requests, and software downloads and is certified by ISO 9001:2015, CE, and IEC 17025:2017.

Gibitre Instruments, a company founded in 1979 and headquartered in Bergamo, Italy, is a manufacturer and supplier specializing in measuring instruments. The company's range of measuring instruments includes rheometers, mini force testers, and block ovens for accelerated aging. These products find applications in various industries, including rubber manufacturing, construction, and the electronics industry. The company provides maintenance and calibration services for all installed instruments, as well as training. The company is ISO 17025:2018 certified, with agencies in various countries including Argentina, the Czech Republic, and China.

SDL Atlas is a company established in 2003 and based in Rock Hill, United States, as a textile machinery manufacturer. It specializes in manufacturing abrasion testers, rubbing testers, washing cylinders, single fiber strength testers, and precision fiber microtome. It also manufactures steaming cylinders, sewing and knitting machines, yarn strength testers, yarn bulk meters, and wascators. The company is UKAS accredited and in compliance with the AATCC standards. Its manufactured products are catered to several industries, including textile, nonwovens, and garments industries across several regions, such as the USA, Hong Kong, and China.

Toyo Seiki Seisaku-Sho, Ltd., established in 1934 with headquarters in Tokyo, Japan, is a manufacturer of product and material measuring apparatus. The company's product portfolio comprises testing machines for a range of materials and test applications. Its products include abrasion testers, flammability testers, density testers, and permeability testers. These testing products have numerous applications, including by manufacturers to test the durability and safety of new products, by painters to test coating thickness, and in the production of fire-safe products.

Tokyo Instruments, Inc., established in 1981, and headquartered in Tokyo, Japan, is a manufacturer of opto-electronics products and systems. The company offers a wide range of products, including laser processing machines, aligning systems, photodetectors, analyzers for photoelectron spectroscopy, and spectroscopy array detectors. Also offered are high-speed, high-sensitivity cameras in UV to IR, and photon detectors or counters. The company's product families consist of the Nanofinder series of 3D Laser Raman Microspectroscopy systems and the iDus Workhorse laboratory and OEM CCD platform for low-light spectroscopy.

Ueshima Seisakusho Co., Ltd., established in 1977 and headquartered in Osaka, Japan, is a manufacturer that provides rubber testing equipment. The company offers a wide range of products, including blow point Analyzers, Rubber Process Analyzers, and Rubber Rheometers. It also provides services related to rubber testing equipment. Its product measures the viscoelastic properties of rubber and other elastomers. The company has been certified for ISO 9001 quality management and ISO/IEC 17025:2005. It provides testing equipment to industrial sectors such as rubber, plastics, and paints.

Ranking as of July 2025

Derivation Method| Rank | Company | Click Share |

|---|---|---|

| 1 | TESTER SANGYO CO,. LTD |

11.1%

|

| 2 | Taber Industries |

8.9%

|

| 3 | Paul N. Gardner Company, Inc. |

8.9%

|

| 4 | Textechno |

6.7%

|

| 5 | Ceramic Instruments s.r.l. |

6.7%

|

| 6 | Ektron Tek Co., Ltd. |

6.7%

|

| 7 | YASUDA SEIKI SEISAKUSHO, LTD. |

6.7%

|

| 8 | Toyo Seiki Seisaku-sho, Ltd. |

6.7%

|

| 9 | Gibitre Instruments |

4.4%

|

| 10 | Matest |

4.4%

|

Derivation Method

The ranking is calculated based on the click share within the abrasion tester page as of July 2025. Click share is defined as the total number of clicks for all companies during the period divided by the number of clicks for each company.Number of Employees

Newly Established Company

Company with a History

*Including some distributors, etc.

*Including some distributors, etc.

| Country | Number of Companies | Share (%) |

|---|---|---|

United States of America

United States of America

|

6 | 40.0% |

Japan

Japan

|

4 | 26.7% |

Italy

Italy

|

2 | 13.3% |

Germany

Germany

|

1 | 6.7% |

Taiwan

Taiwan

|

1 | 6.7% |

Austria

Austria

|

1 | 6.7% |

52 products found

52 products

Techno Hashimoto Co., Ltd.

190+ people viewing

Last viewed: 13 hours ago

■Summary Automatic thrust control Equipped with a 3-axis force sensor, it is possible to control the pushing load in one direction while measuring ...

Bruker Corporation

500+ people viewing

Last viewed: 15 hours ago

■Multi-functional friction friction testing machine Bruker's Universal Mechanical Tester (UMT) platform has been the most widely used and versatile...

Hiraizumi Yoko Co., Ltd.

280+ people viewing

Last viewed: 9 hours ago

This is a test machine that reproduces dry, wet, and ice road environments on special discs, and uses a unique powder to collect data from rubber s...

Toyo Seiki Seisaku-sho, Ltd.

530+ people viewing

Last viewed: 5 hours ago

The Rotary Abrage Testa is a test machine (tever -wear test machine) that evaluates the wear resistance of flat materials. The degree of wear of th...

Toyo Seiki Seisaku-sho, Ltd.

390+ people viewing

It is an wear test machine that can contact the drums wrapped in polished paper with a rubber test piece.

Toyo Seiki Seisaku-sho, Ltd.

450+ people viewing

Last viewed: 19 hours ago

The acron wear test machine is a test machine for evaluating the wear resistance of vulcanized rubber. The angle is applied in order to slip betwee...

Toyo Seiki Seisaku-sho, Ltd.

550+ people viewing

Last viewed: 16 hours ago

It is a test machine (Scott fir test machine) that evaluates folding wear strength due to rubber fabric, rubber pulling, vinyl leather, etc.

Toyo Seiki Seisaku-sho, Ltd.

420+ people viewing

Last viewed: 8 hours ago

It is an wear test machine that allows a plastic test piece set on the rotation axis to contact other materials under a certain load.

Toyo Seiki Seisaku-sho, Ltd.

480+ people viewing

Last viewed: 22 hours ago

A vehicle wire wear test machine complies with ISO 6722-1, puts a vertical load (7N or 4Nn) on the insulator in the test piece, and frame the insul...

Grotz Beckelt Japan

690+ people viewing

Last viewed: 16 hours ago

It adapts to a wide range of applications such as textile products, socks, leather, coated chairs, carpets, wood, and shirts. The latest Martindal...

3 models listed

A and Day Co., Ltd.

390+ people viewing

Last viewed: 16 hours ago

The reciprocating friction and wear tester evaluates the surface condition of materials, including sliding properties, by measuring frictional forc...

A and Day Co., Ltd.

360+ people viewing

The high-pressure atmosphere friction and wear tester evaluates the sliding characteristics in a pressure vessel. It is possible to evaluate the fr...

A and Day Co., Ltd.

390+ people viewing

Last viewed: 12 hours ago

The rolling friction and wear tester rotates two cylindrical samples while making contact with each other using independent drive systems. It measu...

A and Day Co., Ltd.

380+ people viewing

Last viewed: 2 hours ago

The small tabletop friction and wear tester (ball-on-disc test) is suitable for evaluating the friction and wear characteristics of materials, such...

Cosmo Trading Co., Ltd.

320+ people viewing

Last viewed: 6 hours ago

Tribometer ■Wide range friction/wear evaluation device Based on decades of experience in tribology, Anton Paar offers a wide range of tribometers. ...

Cosmo Trading Co., Ltd.

230+ people viewing

Last viewed: 6 hours ago

Tribometer ■Wide range friction/wear evaluation device Based on decades of experience in tribology, Anton Paar offers a wide range of tribometers. ...

Cosmo Trading Co., Ltd.

260+ people viewing

Last viewed: 1 day ago

■Wide range friction/wear evaluation device Based on decades of experience in tribology, Anton Paar offers a wide range of tribometers. Tribology i...

Cosmo Trading Co., Ltd.

330+ people viewing

Last viewed: 19 hours ago

Vacuum tribometers are used to measure the sliding life of self-lubricating coatings and the friction and wear properties of solid materials or har...

2 models listed

A and Day Co., Ltd.

1160+ people viewing

Last viewed: 1 hour ago

■Features The EFM-3 series friction and wear test equipment is designed for the scientific elucidation and technical investigation of the relative ...

4 models listed

A and Day Co., Ltd.

480+ people viewing

Last viewed: 2 hours ago

■Supports continuous testing with automatic test piece supply mechanism A&D's Lambourn abrasion tester not only tests the wear resistance of vulcan...

A and Day Co., Ltd.

360+ people viewing

The bearing friction and wear tester evaluates the friction characteristics of radial bearings, etc. The lubricating oil uses a circulation system ...

TP Giken Co., Ltd.

230+ people viewing

Last viewed: 10 hours ago

This machine is a testing machine for measuring the degree of wear of materials such as surface treatment materials such as paint and plating, plas...

TP Giken Co., Ltd.

220+ people viewing

This machine is a tester that tests the hardness of baked coatings on metals and marker pens on stationery by rubbing them against gauze, felt, san...

TP Giken Co., Ltd.

290+ people viewing

Last viewed: 1 day ago

The RCA abrasion tester manufactured by Norman Tool. Inc. in the United States has been manufactured and sold since 1964 and is used by customers a...

Marui Co., Ltd.

170+ people viewing

Last viewed: 1 day ago

■Concrete testing equipment Concrete: aggregate We handle testing equipment to examine the hardness and durability of aggregates. ■Features ・Siev...

Marui Co., Ltd.

130+ people viewing

Last viewed: 19 hours ago

Building material durability testing equipment ■Building material durability: [fatigue] We provide customers with equipment for investigating the m...

Marui Co., Ltd.

150+ people viewing

Last viewed: 2 hours ago

Building material durability testing equipment ■Building material durability: [fatigue] We provide customers with equipment for investigating the m...

Parker Heat Treatment Industry Co., Ltd.

230+ people viewing

Last viewed: 3 hours ago

■Cleaning equipment that meets customer needs Petroleum solvent vacuum cleaning equipment

GS E

280+ people viewing

Last viewed: 1 day ago

It is a wear -resistant performance evaluation device for a water wheel axis (ceramic bearing). Use of test machines ・ Develop a new sticker mate...

GS E

320+ people viewing

Last viewed: 1 day ago

This is an wear test machine that demands the number of repetitions of the cable of the cable with the set displacement, load, and frequency of the...