All Categories

History

This section provides an overview for pressure calibrators as well as their applications and principles. Also, please take a look at the list of 28 pressure calibrator manufacturers and their company rankings. Here are the top-ranked pressure calibrator companies as of July, 2025: 1.Keller America, Inc., 2.Palmer Wahl Instrumentation Group, 3.HUBER INSTRUMENTE AG.

Table of Contents

Engaged in research on nitride semiconductor growth using the MBE method at Waseda University Graduate School. After graduating from graduate school in 2016, he joined a non-ferrous metal manufacturer.

Engaged in equipment maintenance and engineering work at metal smelting plants. Moved to a chemical manufacturer in 2022. Engaging in similar tasks.

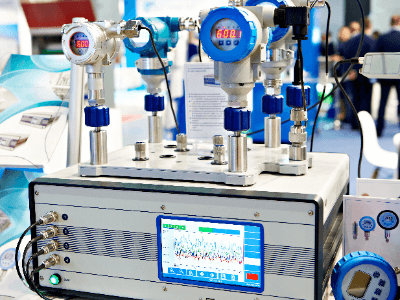

A pressure calibrator is an instrument used in the maintenance of pressure gauges.

A pressure calibrator is an instrument used in the maintenance of pressure gauges.

Also called a pressure standard, it is used to calibrate pressure gauges. The reason why pressure gauges need to be calibrated is to ensure conformity to standards and laws, and to ensure traceability. If calibration is not performed at a certain cycle, reliability is lost and the measurement data cannot be trusted.

Also, if the calibration range is significantly out of range, large measurement errors will occur. In addition, there is a possibility of accidents such as damage to the pressure vessel. Therefore, it is necessary to consider whether calibration should be performed within the general calibration range and to determine the calibration cycle of the pressure gauge.

Calibration documents for calibrating a pressure calibrator include an inspection certificate, inspection report, traceability system chart, and a copy of the calibration certificate of the standard instrument, etc.

Pressure calibrators are mainly used in industrial applications. The following are examples of applications of pressure calibrators.

As shown above, they are mainly used for maintenance of pressure gauges and other instruments. In addition, when pressure gauges are manufactured, their functions are checked using pressure calibrators.

Deadweight pressure gauges, often used as pressure calibrators, are based on the most basic pressure principles and have long been highly reliable pressure calibrators. Pressure is defined as the vertical downward force multiplied by the cross-sectional area.

Deadweight pressure gauges are measured by a cylinder, a piston, and a weight of known weight on the piston. The cylinder is fitted with a piston that moves without friction. There is pressurized fluid in the cylinder, which is held back by the gravity of the deadweight through the piston.

Since a balance of forces is generated there, the pressure is calculated and measured using the gravity of the deadweight and the cross-sectional area. In order to improve the accuracy of deadweight pressure gauges for gases, the fit of the piston and cylinder and the surrounding environment may also be taken into consideration.

For this reason, the piston and cylinder are carefully cleaned, but the effect may be small if the inside diameter is large. However, more stable performance can be expected from deadweight pressure gauges for liquids than from deadweight pressure gauges for gases.

The most commonly used pressure calibrators are deadweight testers. Deadweight testers are available for hydraulic and pneumatic pressure, and the model is selected according to the pressure gauge to be calibrated and the application. Another selection criterion is whether the pressure gauge is portable or stationary.

Deadweight testers can measure mechanical and electrical pressure, but cannot calibrate equipment that measures high vacuum conditions, such as ionization vacuum gauges. Other electronic pressure calibrators are also available.

Electronic pressure calibrators have the ability to record various types of data in memory, and are sometimes used to calibrate pressure transmitters, pressure switches, and electro-pneumatic/air-electric transducers. There are two types of pressure gauges mainly used in pressure calibrators: digital pressure gauges and mechanical pressure gauges.

The calibration method uses a gas or liquid as the pressure medium, repeatedly raises and lowers the pressure, and calculates the calibration value from the average value. Calibrators generally used for calibration are dead-weight pressure balances and digital pressure gauges.

*Including some distributors, etc.

Sort by Features

Sort by Area

KELLER America, Inc. was founded in 1975 and based in Newport News, Virginia. The company’s founder developed the first integrated silicon pressure measuring cell and since its founding, the company has been a developer in pressure measurement solutions for numerous industries including automotive, aerospace, and power generation. In addition to optional accessories, the company has 9 main product lines. Among these are OEM Sensors Transducers & Transmitters, Pressure Calibrators, Digital Pressure Gauges, Pressure Pumps, and Custom Pressure Solutions.

Palmer Wahl Instruments Inc., started in 1836 and based in North Carolina, United States, is a manufacturer of industrial temperature and pressure equipment. The company offers various temperature products, such as utility thermometers, thermowells, temperature sensors, and bimetal thermometers, as well as pressure products, such as pressure gauges, pressure chart recorders, and calibrators. The company holds ISO 9001:2015 certification and adheres to ANSI/NCSL Z-540 and MIL-STD-45662A standards. Its products find application in the electronic, HVAC, manufacturing, medical, and transportation sectors in the USA, Australia, Denmark, Sweden, and Iceland.

Fluke Corporation, established in 1948 and based in Everett, Washington, is a manufacturer of precision calibration solutions. The company provides instrumentation and software tailored for electrical, temperature, pressure, flow, and RF measurements. These instruments are commonly utilized in calibration laboratories and process measurement instrument shops globally, including National Metrology Institutes. The companu also offers services and software solutions for assisting organizations in effectively managing assets and operations, with support ranging from individual to enterprise-level integration.

Ashcroft was founded in 1852 in Bridgeport, Connecticut to create instruments to protect steam-powered industry workers and today is a manufacturer in pressure and temperature measurement instrumentation.Ashcroft serves the chemical, food & beverage, metals & minerals, oil & gas, pharmaceutical & research, power, and water & wastewater markets. Ashcroft products include pressure instruments including pressure gauges, switches, sensors, and isolators; test instruments including calibrators, controllers, testers, and test gauges; and temperature instruments including thermometers, thermowells, RTDs, thermocouples, multipoint temperature sensors, and OEM temperature sensors.

Setra Systems is a manufacturer and supplier of sensing solutions, founded in 1967 and headquartered in Massachusetts, USA. The company's product portfolio includes various sensors and instruments, such as differential pressure sensors, absolute pressure sensors, relative pressure sensors, and more. These sensors find applications in HVAC, medical, industrial automation, and aerospace industries. The company also provides custom sensor solutions tailored to the specific requirements of its customers. The company offers technical support to help customers select suitable sensors for particular applications.

OMEGA Engineering Inc., founded in Norwalk, CT, in 1962 is a manufacturer of products used to measure temperature and humidity, flow and level, and pressure. The company's product portfolio includes thermocouple probes and assemblies, pressure gauges and switches, and air velocity measurement systems, wireless systems and portable optic sensors. The company serves markets including Automotive and Electric Vehicles, Renewable Energy and Energy Storage and Electronics and IT Infrastructure. The company also offers customer services that include support, custom research projects and customized services.

Additel Corporation is a test tool and portable calibrator manufacturer founded in 2011 in Brea, California. The company produces a diverse range of products that are exported to more than 100 countries around the world. These include but are not limited to automated and digital pressure calibrators, digital pressure test gauges, pressure test and calibration pumps, and multifunction process calibrators. Additionally, the enterprise offers calibration, repair, and rental unit services. The company counts with multiple NVLAP accreditations, an ISO 17025 Accredited Calibration laboratory, and is also ISO 9001.2015 certified.

Headquartered in Everett, Washington, Fluke is an American-born company operating since 1948. Fluke offers a variety of testing equipment including digital multimeters, thermal cameras, solar PV testing equipment, thermometers, oscilloscopes, leak detection devices, as well as testing-equipment related accessories. Fluke offers direct online sales.

Based in San Marcos, Texas, Mensor LP is an American supplier founded in 1969. Specializing in electronic pressure measurement, the company provides customized solutions for pressure measurement and control across a range of industries, including automotive, aerospace, heating, ventilation, and air conditioning (HVAC), and power engineering. In 2006, Mensor joined WIKA Group, an American manufacturer specializing in measurement and calibration technology since 1946. Along with the British manufacturers DH-Budenberg and ASL (Automatic Systems Laboratories), which were acquired by WIKA Group in 2011 and 2013, Mensor develops calibration technology for pressure, temperature, and electrical measurements.

DRUCK & TEMPERATUR Leitenberger GmbH, based in Germany, is a manufacturer of pressure measurement, temperature measurement, level measurement, torque & force measurement, and data logger equipment. Established in 1986, the company offers a wide range of measurement products that are used in various industries, including automation, process engineering, quality assurance, and research. One sample product is their pressure measurement equipment. These device measures the pressure of fluids and gases, and are used in various applications. Additionally, they offer technical support services, including training and consulting.

AREMECA, founded in 1989 and headquartered in Vendome, France, is a manufacturer specializing in pressure calibration equipment. The company offers a range of products, including hydraulics comparison test pumps, hydraulics dead weight testers, and pneumatic comparison test pumps among others. Additionally, it provides services such as equipment calibration, commissioning and installation, as well as maintenance and repair. These products are applied in control laboratories, renewable energy plants, and oil and gas refineries.

Huber Instrumente AG is a manufacturer of pressure measurement devices and meteorology stations that was established in 1978 in Nunningen, Switzerland. The company designs and produces various pressure measurement instruments including Bourdon tube pressure gauges, digital handheld pressure gauges, and pressure calibrators. It also offers mobile meteorology stations, HMCS software for calibration works certification, and panel manometers for measuring pressure parameters. The company provides additional services such as laboratory outfitting, consultation, and training for quality management or calibration operations.

GIUSSANI S.R.L., founded in 1947 and headquartered in Bergamo, Italy, is a manufacturer of glass thermometers with electronic contacts, relays, and amplifiers. The company offers a range of products, including thermostatic calibrators, manual pressure generators, sanitary tap test benches, endurance test benches, and laboratory tables, and trolleys with universal supports. It also provides calibration and repair services, hydraulic laboratory tests, rental services for portable instruments, and second-hand thermostatic calibrators. These instruments are used in various applications, including the drying of Italian pasta and, more generally, in process control.

Ellab (Elektrolaboratoriet A/S) was founded in 1949, in Denmark as a manufacturer of validation and monitoring products. The company provides Validation Solutions with Wireless Data Loggers, Wired Thermocouple Systems, and Validation and Qualification Software along with Monitoring and Calibrating solutions. They also provide Field Services and Consulting and their equipment and systems help in biological and pharmaceutical processes. In the Healthcare sector, they help deal with Steam Sterilization, Laboratories, and Environmental Test Chambers and they also have various applications in the Food industry.

WIKA Instrumentation Taiwan Ltd., founded in 1946 and headquartered in Taoyuan, Taiwan, is a manufacturer of equipment for measuring pressure and temperature. The company offers an extensive product catalog, including pressure gauges with output signals, thermometers with switch contacts, accessories for bypass level indicators, digital pressure gauge calibration equipment, and hoses and gas refill sets. These instruments find applications in the semiconductor industries, basic materials, power generation, power transmission and distribution, and machine building.

Beijing Spake Technology Co., Ltd. was founded in 1998 and is a manufacturer of pressure temperature calibration equipment based in Beijing, China. The company produces various products such as automatic pressure calibrator, pressure reducer calibrator with electronic pressure source, industrial digital thermometer, SDP pressure module, and digital pressure gauge. The company has participated in various exhibitions suh as Hannover Messe, WIN Eurasia, and International Metrology Measurement Technology and Equipment Exhibition. The products have obtained CE certificate and Explosion-Proof Certificate, and the company has passed the ISO 9001:2000 quality inspection.

Time Electronics Ltd., established in 1967 and located in Tonbridge, England, is a manufacturer that designs and manufactures calibration and metrology instruments. The company offers a range of precision test instruments for calibration, including decade boxes, portable voltage, and current calibrators. It also provides electrical multifunction calibrators, ATE/bench calibrators and multimeters, and electrical test equipment calibrators. It offers a compact working environment to cover multiple applications in test and measurement with its CalBench system. Moreover, the company is accredited to ISO 9001:2008. It serves various industries, including electronics, aerospace and aviation, industrial sectors, and music.

Baker Hughes Co. (BHC) is an American service provider and manufacturer of industrial oilfield equipment that was established in 1987 following the merger of Baker International and Hughes Tool Company. Based in Houston, Texas, the company produces several categories of oilfield products including drilling equipment, pipe and subsea production systems, generators, and storage systems. It also offers process control components and actuators such as pumps, valves and regulators. BHC provides various services for oilfield and liquefied natural gas (LNG) operations, including regasification, well construction, transportation, and storage.

NAGMAN INSTRUMENTS AND ELECTRONICS PRIVATE LIMITED founded in Sembarambakkam, Chennai, India, in 1972, is a manufacturer of TC sensors and portable calibration instruments. The company’s product catalog includes pressure calibrators, dead-weight testers, pyrometers, electric vacuum pumps, and calibration management software. The company’s products are certified by ISO-9001 and ITC India. It also has received the EEPC award and Bharathy Award. It has supplied 50,000 portable calibrators and 1,500 Test Benches to major industries in India and 85 countries worldwide.

AMETEK Sensors, Test & Calibration, founded in 1961 and based in Massachusetts, USA, is a manufacturer, distributor, and supplier of instruments and process control solutions for advanced manufacturing processes. The company provides a range of standard and customized solutions for various industries such as calibration, temperature measurement, and weighing solutions. Its products are constantly used throughout the oil and gas, power, and wastewater industries, helping to save and produce energy, ensure safety in hazardous areas, and control temperatures.

Ralston Instruments, founded in 1969, is an American manufacturer based in Novelty, Ohio, specializing in pressure calibration solutions. The company's product lineup of pressure calibration products encompasses the Ralston Quick-test System, comprising adapter and hose kits, valves, straight adapters, and test point fittings. Alongside these, it offers other calibration products such as compressed gas control, digital pressure calibrations, accompanying software, as well as calibration test pumps. These products find application in various sectors, including maritime, manufacturing, and the oil and natural gas industries. Notably, the company holds accreditation from the American Association for Laboratory Accreditation (A2LA) for performing calibrations on metrological instruments.

AMETEK, Inc. is based in Berwyn, Pennsylvania, USA, and is a manufacturer of testing instruments and electrical utility products established in 1968 following the merger of American Machine and Metals and Pennsalt Chemicals. The company’s products include process analyzers for measuring properties of media in industrial processes, calibration instruments for its process analysis sensors or gauges, and power quality analyzers for diagnosing the reliability of electrical output. The company also provides asset management, calibration and repair, and custom engineering services for client-specific projects.

Stiko, established in 1963 and headquartered in Roden, Drenthe, the Netherlands, is a mechanical pressure and temperature instrument designer, manufacturer, and supplier. The company's products include thermometers, pressure gauges, and calibration instruments. It also offers a range of related products: instruments with built-in transmitters and Peli Case chart recorders. Specializing in small-batch production runs, customized private label production of safety-critical solutions makes up over 90% of the company's output. Stiko was acquired by Ashcroft Inc., a subsidiary of Nagano Keiki Co. Ltd., in 2019.

ATEQ Leak Testing, established in 1975 in France, is a manufacturer and supplier of leak testing equipment and solutions. The company’s product range includes various leak testers, such as differential pressure decay testers, mass flow testers, and vacuum decay testers. These cutting-edge technologies are comprehensively utilized in industries such as automotive, medical devices, aerospace, and electronics manufacturing. Putting emphasis on quality and creativity, ATEQ Leak Testing provides advanced leak-testing solutions that ensure product integrity and reliability. With a global network of offices and distributors, ATEQ continues to deliver accurate and efficient leak-testing solutions to industries worldwide, enhancing quality control and safety.

TCR Tecora, based in Cogliate, Italy, was founded in 1974 and specializes in stack emissions measuring systems, continuous dioxin emission samplers, industrial hygiene equipment, and oxygen and combustion control analyzers. The company also provides water-cooled portable chiller, a sequential sampler for gaseous compounds, an Andersen cascade impactor, and single and multi-jet nebulizers. It offers products from other brands like Skypost, ECHO PM, Bravo Basic, and Flowcal Air. Its main clientele includes environmental agencies, environmental laboratories, indoor air quality consultants, and industries such as cement, power, oil refining, and metal.

Tradinco Instruments is a Dutch distributor of calibration sensors and equipment that was established in 1963 in Zoetermeer, the Netherlands. The company’s product lineup includes pressure sensors, equipment test benches, and booster pumps for generating high pressure. It also offers various calibration services, as well as leak testing and inspection for customers requiring additional support. The company’s products are used mainly by clients in the oil and gas, food processing, and energy industries.

Ranking as of July 2025

Derivation Method| Rank | Company | Click Share |

|---|---|---|

| 1 | Keller America, Inc. |

8.2%

|

| 2 | Palmer Wahl Instrumentation Group |

7.1%

|

| 3 | Omega Engineering, Inc. |

6.1%

|

| 4 | HUBER INSTRUMENTE AG |

5.9%

|

| 5 | Ellab |

5.1%

|

| 6 | Ashcroft, Inc. |

4.8%

|

| 7 | GIUSSANI S.R.L. |

4.6%

|

| 8 | Setra Systems, Inc. |

4.6%

|

| 9 | Additel Corporation |

4.6%

|

| 10 | Mensor LP |

4.6%

|

Derivation Method

The ranking is calculated based on the click share within the pressure calibrator page as of July 2025. Click share is defined as the total number of clicks for all companies during the period divided by the number of clicks for each company.Number of Employees

Newly Established Company

Company with a History

*Including some distributors, etc.

*Including some distributors, etc.

| Country | Number of Companies | Share (%) |

|---|---|---|

United States of America

United States of America

|

9 | 40.9% |

Italy

Italy

|

2 | 9.1% |

China

China

|

2 | 9.1% |

United Kingdom

United Kingdom

|

2 | 9.1% |

Japan

Japan

|

1 | 4.5% |

Germany

Germany

|

1 | 4.5% |

France

France

|

1 | 4.5% |

Switzerland

Switzerland

|

1 | 4.5% |

Denmark

Denmark

|

1 | 4.5% |

Taiwan

Taiwan

|

1 | 4.5% |

Netherlands

Netherlands

|

1 | 4.5% |

105 products found

105 products

Maximator Fluid Technologies Co., Ltd.

230+ people viewing

Last viewed: 17 hours ago

This modular pressure controller combines state-of-the-art control/measurement technology, modular design, and user-friendly features. Additel783 c...

Maximator Fluid Technologies Co., Ltd.

250+ people viewing

The Additel793 pressure controller combines the latest control/measurement technology, modular design, and ease of use/maintenance features into a ...

Maximator Fluid Technologies Co., Ltd.

270+ people viewing

Last viewed: 21 hours ago

The new Additel 273Ex handheld multi-function pressure calibrator has a color touch screen, a Japanese user interface for smartphone-like operabili...

Maximator Fluid Technologies Co., Ltd.

260+ people viewing

Last viewed: 17 hours ago

A portable automatic pressure calibrator in a handheld size—this is our most exciting product yet. Additel 760 series automatic pressure calibrator...

Maximator Fluid Technologies Co., Ltd.

270+ people viewing

Last viewed: 2 minutes ago

Additel673 pressure calibrators provide accurate pressure calibration solutions for gauges, pressure transmitters, and switches. The product range ...

Maximator Fluid Technologies Co., Ltd.

270+ people viewing

Last viewed: 1 day ago

A portable automatic pressure calibrator in a handheld size—this is our most exciting product yet. Additel 760 series automatic pressure calibrator...

Maximator Fluid Technologies Co., Ltd.

210+ people viewing

Last viewed: 16 hours ago

Maximator Fluid Technologies Co., Ltd.

240+ people viewing

Last viewed: 22 hours ago

A portable automatic pressure calibrator in a handheld size—this is our most exciting product yet. Additel 760 series automatic pressure calibrator...

Takitech Co., Ltd.

590+ people viewing

Last viewed: 6 hours ago

■Features Since it contains temperature correction data, it starts up quickly even in cold seasons, and you can start measuring immediately by simp...

6 models listed

Maximator Fluid Technologies Co., Ltd.

290+ people viewing

Last viewed: 21 hours ago

At Additel, innovation and continuous improvement are part of our culture, and this is reflected in the new products we introduce. When we set out ...

Maximator Fluid Technologies Co., Ltd.

250+ people viewing

Last viewed: 4 hours ago

At Additel, innovation and continuous improvement are part of our culture, and this is reflected in the new products we introduce. When we set out ...

Maximator Fluid Technologies Co., Ltd.

240+ people viewing

Last viewed: 14 hours ago

At Additel, innovation and continuous improvement are part of our culture, and this is reflected in the new products we introduce. When we set out ...

Maximator Fluid Technologies Co., Ltd.

260+ people viewing

Last viewed: 1 day ago

At Additel, innovation and continuous improvement are part of our culture, and this is reflected in the new products we introduce. When we set out ...

Maximator Fluid Technologies Co., Ltd.

220+ people viewing

Last viewed: 18 hours ago

At Additel, innovation and continuous improvement are part of our culture, and this is reflected in the new products we introduce. When we set out ...

Maximator Fluid Technologies Co., Ltd.

270+ people viewing

Last viewed: 1 hour ago

■ Additel's new 762 Automatic Hydraulic Calibrator automatically controls and generates pressures up to 70PMa in an easy-to-use, portable size Adit...

Maximator Fluid Technologies Co., Ltd.

190+ people viewing

Aditel Corporation introduces the new ADT762 automatic hydraulic calibrator. As Aditel continues to strive to meet customer needs through innovatio...

Maximator Fluid Technologies Co., Ltd.

220+ people viewing

Last viewed: 2 hours ago

Additel151 pressure modules are designed with flexibility and efficiency in mind and can be easily replaced as needed to meet changing needs and wo...

Maximator Fluid Technologies Co., Ltd.

190+ people viewing

Last viewed: 14 hours ago

This modular pressure controller combines speed, state-of-the-art control/measurement technology, modular design, and user-friendly features. The A...

Maximator Fluid Technologies Co., Ltd.

210+ people viewing

Last viewed: 15 hours ago

For many years Additel has provided robust, highly accurate and high quality calibration equipment for the field. The Additel 780 series pressure c...

Toyo Signal Communication Co., Ltd.

170+ people viewing

Last viewed: 1 day ago

Easy pressure increase Achieves smooth and quick pressure increase. A pressure pump with a wide range of fine adjustments after boosting pressure, ...

Fluke Calibration

220+ people viewing

Last viewed: 13 hours ago

■Main functions ・Electric pump allows pressure to be calibrated with one hand ・Pressure measurement uncertainty is 0.025%, the highest among comp...

Fluke Calibration

210+ people viewing

■Main functions - Unique built-in electric pump allows pressure to be calibrated with one hand ・Easy-to-use switch test function that allows you t...

Fluke Calibration

210+ people viewing

■All functions necessary for calibrating and testing pressure transmitters and pressure gauges ranging from low pressure to 20MPa (3000psi) are int...

Fluke Calibration

250+ people viewing

Last viewed: 6 minutes ago

■Main functions 7 of 100, 300, 500, 1,000, 1,500, 3,000, 5,000 psi (6.9, 20, 24.5, 69, 103.4, 200, 345 bar) to 16 PSI (1.1 bar) or 36 psi (2.48 bar...

Fluke Calibration

200+ people viewing

Last viewed: 9 hours ago

■A highly reliable and easy-to-maintain calibrator that can calibrate pressure gauges/sensors in a wide range of pressures, from low pressure to 20...

Fluke Calibration

280+ people viewing

Last viewed: 19 hours ago

■Features ・Pressure range: 0-5psi and 0-3,000psi (0-35 kPa, 0-21MPa) -Models 7250xi and 7250i have excellent accuracy of 0.005% of reading. - Mode...

Fluke Calibration

180+ people viewing

Last viewed: 3 hours ago

The new Series 7252 offers a unique and flexible approach to automated calibration over a wide pressure range. The 7252 includes two pressure range...

Fluke Calibration

270+ people viewing

■Main functions ・Automatic pressure generation and adjustment up to 2 MPa ・Easy recording using onboard tests ・Automatic internal pressure fine ...

Fluke Calibration

280+ people viewing

Last viewed: 1 day ago

■PPC4 - Redefining the superior performance of digital pressure calibrators ・With pressure range up to 14 MPa ・Achieves control accuracy of 4 ppm...

SATACO Co., Ltd.

190+ people viewing

Last viewed: 2 hours ago

■Features ・Built-in booster type can boost pressure up to 70MPa ・High pressure gas production equipment test product - Comes with a safety cover ...