All Categories

History

This section provides an overview for atomic force microscopes as well as their applications and principles. Also, please take a look at the list of 13 atomic force microscope manufacturers and their company rankings. Here are the top-ranked atomic force microscope companies as of July, 2025: 1.NanoMagnetics Instruments, 2.Krueger Sentry Gauge Co., 3.Keysight Technologies.

Table of Contents

Categories Related to Atomic Force Microscopes

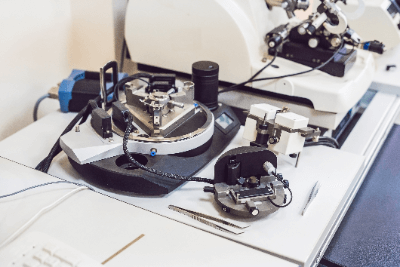

AFMs (Atomic Force Microscopes) are microscopes that visualize the fine surface structure of samples by detecting and scanning the force between a probe called a cantilever and atoms on the sample surface. Unlike scanning tunneling microscopes, which are limited to conductive samples, AFMs can measure a broad range of materials, including insulators and biological samples.

AFMs (Atomic Force Microscopes) are microscopes that visualize the fine surface structure of samples by detecting and scanning the force between a probe called a cantilever and atoms on the sample surface. Unlike scanning tunneling microscopes, which are limited to conductive samples, AFMs can measure a broad range of materials, including insulators and biological samples.

AFMs are primarily used in the industrial field for nanoscale to angstrom-level surface inspection. They are utilized for measuring the uniformity and roughness of semiconductor substrates, inspecting corrosion and degradation of plating on metal electrodes, and observing reactions and structural changes in biomolecules minimally invasively.

Key modes of AFM include:

AFMs measure cantilever displacement caused by atomic forces between the cantilever and the sample surface. Common methods include using a photodiode for displacement detection (optical leverage method) and vibrating the cantilever with a piezoelectric element to monitor amplitude, phase, and frequency. Some AFMs measure the force directly by measuring cantilever flexure, useful for studying membrane proteins and cell mechanics.

AFMs can detect various forces like attraction, repulsion, adhesion, and binding. They are used in catalysis research and can observe minute particles on surfaces without special treatment. By modifying the tip, AFMs can function as chemical sensors, selectively measuring forces other than atomic forces.

Force curves, measured by moving the tip in a reciprocating motion, reflect interaction forces between the tip and the material. These measurements can reveal van der Waals forces, surface tension-based adhesion, and meniscus forces. Force curve measurements have been applied to study the acid-base behavior of solid surfaces.

An STM offers high atomic resolution in ultra-high vacuum environments but struggles with non-conductive materials and surface contamination. AFMs, on the other hand, can measure non-conductive materials and perform measurements in air, as they detect forces between the material and the tip.

*Including some distributors, etc.

Sort by Features

Sort by Area

Krueger Sentry Gauge Co. has its main office located in Green Bay, Wisconsin, is known as a manufacturer of Liquid-Level Gauge since 1942. The company serves petroleum, wastewater, aviation, chemical, agricultural industries, among others with products including level-gauges, overfill alert gauges, leak detection gauges as well as related accessories. The company´s leak detection gauge is a vertical type monitor and is designed for maximum durability, minimal upkeep, and quick installation while their overfill gauge visually alerts you on a tank´s fullness and is also designed such that installation is easily executed.

Bruker, founded in 1960 and based in Billerica, Massachusetts, is a manufacturer and distributor of scientific instruments and analytical and diagnostic solutions. The company's product range includes analyzers, microscopes, and imaging solutions, which have applications in fields such as life science research, cell biology, and microbiology. In 1969, the company developed the world's first FT-NMR spectrometer system, enabling broadband proton decoupling. In 1997, it further expanded its capabilities by acquiring the analytical X-ray division of Siemens AG. The company holds ISO 9001 and ISO 13485 certifications, and its products are available for sale worldwide.

Mad City Labs, Inc. was established in 1998 and is headquartered in Madison, WI, and is a manufacturer of flexure-based piezo nanopositioning systems capable of sub-nanometer positioning resolution. The portfolio of the company includes nanopositioning systems, micropositioning systems, single-molecule microscopy, general microscopy, atomic force microscopy, near-field scanning optical microscopy, and many more. The nanopositioning systems of the company move and maintain the position of objects with sub-nanometer precision and high stability. Applications for nanopositioners include super-resolution microscopy, high-speed confocal imaging, AFM, NSOM, SPM, etc.

Keysight Technologies, Inc. was founded in 1939 and headquartered in Santa Rosa, California. Keysight is a global developer and manufacturer of electronic design and test solutions to communications, networking, aerospace, defense, and government, automotive, energy, semiconductor, electronic, and education industries. Keysight’s communications solutions group solutions include electronic design automation software; radio frequency and microwave test solutions, hardware and virtual network test platforms and software applications, as well as optical laser source solutions. Keysight’s electronic industrial solutions group offers various design tools and verification tools. Keysight offers product support, technical support, and training and consulting services. It sells its products through direct sales force, distributors, resellers, and manufacturer's representatives.

Etaluma, Inc., an American company founded in 2009 and based in Carlsbad, California, is a manufacturer and supplier of LS Microscopes (Lumascopes). The company’s product portfolio includes LS820 Microscopes, objective lenses, and phase contrast accessories. These products are primarily used within the life sciences and biomedical research fields, including biomedical research, educational institutions, and clinical and diagnostic laboratories. The company sells its products to various countries including the United Kingdom, China, and Australia. Some of its customers include Pitt Medicine, Stanford Medicine, and Johns Hopkins University.

NanoMagnetics Instruments or NMI, founded in 1998 and headquartered in Banbury Road Oxford is a manufacturer of Scanning Probe Microscopes, or SPMs, and measurement systems for different scientific and technological fields. The portfolio of the company includes ambient scanning probe microscopes, measurement and characterization systems, low-temperature scanning probe microscopes, controller and standalone electronics, and more. The Ambient SPMs are a specific group of microscopes that are assembled to measure various surface properties of materials and are used in scientific and technological applications.

Hitachi, Ltd was established in 2002 and headquartered in Chiyoda-ku, Tokyo is a manufacturer of industrial electrical equipment and system solutions. The company offers an extensive and diversified product portfolio including industrial drive systems, power electronics, energy-related equipment, power distribution systems, and various other industrial solutions. These products serve as integral components that drive advancements in industrial capabilities across diverse sectors by playing a pivotal role in promoting energy conservation and storage, automating robot systems in large factories, enabling smarter manufacturing through digital solutions, and facilitating efficient transportation within industrial facilities.

Nanosurf AG, established in 1997, is a manufacturer and supplier of STM nano-microscopes for both commercial and academic uses, headquartered in Liestal, Switzerland. The company employs game-changing technology to assist in scanning probes and brought advancement in atomic force microscopes. They manufacture AFM-based single-cell and nanomanipulation tools, compact AFM systems, custom AFM systems for research, and STMs for educational purposes. These nano microscopes are used in multiple industries such as healthcare, chemical, nanoscience, and electronics sectors. The products are precise in performance and can handle samples of any size, shape, or weight through custom integrations.

Park Systems Corporation, established in 1997 in Suwon, South Korea, is a manufacturer of atomic force microscopy (AFM) systems. The company manufactures a comprehensive line of AFM products, including research-grade, industrial, and educational systems. AFM is a critical tool for optimal-resolution imaging, nanoscale measurements, material characterization, and surface analysis. The benefits of the AFM systems include nanoscale precision, topographical and material property mapping, non-destructive imaging, and advanced data analysis. These are essential for academic research, materials science, semiconductor industry, life sciences, and nanotechnology, enabling researchers and engineers to explore and understand the nanoworld, advance technology, and bring uniqueness to various fields.

Oxford Instruments Asylum Research, established in 1999 in Santa Barbara, California, USA, is a manufacturer of atomic force microscopy (AFM) solutions for research and industrial uses. The company offers various optimal-performance AFM systems for nanoscale imaging and characterization, including Cypher, MFP-3D, and Jupiter systems, which are essential tools for material science, nanotechnology, life sciences, and other research areas. These systems provide topographical, mechanical, and electrical characterization at the nanoscale. The benefits include sub-nanometer resolution, advanced imaging modes, quantitative analysis, and compatibility. These systems empower researchers to explore nanomaterials and understand surface properties in fields such as material science, semiconductors, and biology.

attocube systems AG was established in 2001 in Haar, Germany, as a manufacturer and distributor of spatial nano-positioning systems and complete probing tools. The company's product list consists of the atto3DR, neaSCOPE, attoTMS, and attoDRY series, among others. The products find applications in various fields, including motion analysis, nanoscale research, precision motion control, and quality assurance and control, contributing to accuracy and precision in scientific analysis and industrial processes. The company serves various industries, including surface science, laboratory testing, infrastructure, mesoscopic physics, materials science, and nanoprecise positioning.

Ranking as of July 2025

Derivation Method| Rank | Company | Click Share |

|---|---|---|

| 1 | NanoMagnetics Instruments |

16.0%

|

| 2 | Krueger Sentry Gauge Co. |

13.1%

|

| 3 | Keysight Technologies |

11.5%

|

| 4 | Mad City Labs Inc. |

10.0%

|

| 5 | Etaluma, Inc. |

8.8%

|

| 6 | Nanosurf AG |

7.6%

|

| 7 | attocube systems AG |

7.4%

|

| 8 | Park Systems Corporation |

6.1%

|

| 9 | Oxford Instruments Asylum Research |

5.9%

|

| 10 | Bruker Corporation |

5.7%

|

Derivation Method

The ranking is calculated based on the click share within the atomic force microscope page as of July 2025. Click share is defined as the total number of clicks for all companies during the period divided by the number of clicks for each company.Number of Employees

Newly Established Company

Company with a History

*Including some distributors, etc.

*Including some distributors, etc.

| Country | Number of Companies | Share (%) |

|---|---|---|

United States of America

United States of America

|

5 | 41.7% |

Japan

Japan

|

3 | 25.0% |

United Kingdom

United Kingdom

|

1 | 8.3% |

Switzerland

Switzerland

|

1 | 8.3% |

Republic of Korea

Republic of Korea

|

1 | 8.3% |

Germany

Germany

|

1 | 8.3% |

62 products found

62 products

Bruker Corporation

760+ people viewing

Last viewed: 3 hours ago

■Dimension series Bruker's Dimension Icon® atomic force microscopy (AFM) system provides the highest performance, functionality, and productivity f...

8 models listed

Park Systems Japan Co., Ltd.

380+ people viewing

Last viewed: 5 hours ago

■Next-generation technology to accelerate research and development ・Adopts the first dual camera system in research AFM history ・Automatic optimi...

Bruker Corporation

600+ people viewing

Last viewed: 2 minutes ago

Atomic force microscope (material AFM) small platform.

3 models listed

Park Systems Japan Co., Ltd.

550+ people viewing

Last viewed: 5 hours ago

Park NX10 provides reliable data at the highest nanoscale resolution. It can be easily operated at every stage, from sample setting to imaging, mea...

Park Systems Japan Co., Ltd.

390+ people viewing

Park NX7 is the most economical AFM, featuring Park Systems' cutting-edge technology and designed with the same attention to detail as its superior...

Bruker Corporation

640+ people viewing

Last viewed: 15 minutes ago

Atomic force microscope for life sciences JPK Bio AFM ■Scanner It has a scan range of up to 15um in the Z direction, which is sufficient for cell ...

7 models listed

Park Systems Japan Co., Ltd.

330+ people viewing

Last viewed: 19 minutes ago

Park NX12 is a device that integrates the sample stage of an inverted optical microscope with Park Systems' highly versatile and highly accurate AF...

Bruker Corporation

500+ people viewing

Last viewed: 5 hours ago

■Cell mechanics research tool Optical tweezers Quantification of molecular, cellular, and microrheological processes: Dual beam force detection opt...

2 models listed

Park Systems Japan Co., Ltd.

370+ people viewing

Last viewed: 5 hours ago

The Park NX20 300mm is the industry's first atomic force microscope (AFM) for large samples that fully automates measurements of 300mm x 300mm. D...

Bruker Corporation

630+ people viewing

Last viewed: 7 hours ago

■AFM infrared spectroscopy system The long-awaited new generation nanoscale infrared spectroscopy system Dimension IconIR Dimension Icon is AFM's b...

4 models listed

Oxford Instruments Ltd.

460+ people viewing

Last viewed: 3 hours ago

■Nanoscale surface observation WITec's alpha300A atomic force microscope is a reliable, high-quality nanoscale imaging system integrated into a res...

Park Systems Japan Co., Ltd.

340+ people viewing

Last viewed: 19 minutes ago

As an FA engineer, you are expected to find results, but of course errors and mistakes caused by machines cannot be tolerated. The Park NX20 has ea...

Park Systems Japan Co., Ltd.

400+ people viewing

Last viewed: 7 hours ago

The Park NX20 Lite has many unique features that make it ideal for collaborative laboratories, multivariate analysis, and wafer failure analysis. I...

Bruker Corporation

510+ people viewing

Last viewed: 8 minutes ago

AutoAFM (large automatic atomic force microscope). ■Large AutoAFM (automatic atomic force microscope) compatible with 300mm wafers InSight AFP AAF...

Bruker Corporation

390+ people viewing

Last viewed: 1 hour ago

■AutoAFM (Fully automatic atomic force profiler) Insight CAP is a fully automatic AFM for CMP and Etch process evaluation. In addition to the profi...

Bruker Corporation

470+ people viewing

Last viewed: 6 hours ago

■AutoAFM (fully automatic atomic force microscope) for photomasks Insight AFP PM is a fully automated atomic force microscope for photomasks. The b...

Oxford Instruments Ltd.

460+ people viewing

Last viewed: 18 hours ago

■A device that breaks the optical diffraction limit The alpha300 S is a user-friendly instrument that combines confocal microscopy (CM), atomic for...

Oxford Instruments Ltd.

630+ people viewing

Last viewed: 10 hours ago

■Features Cypher S - the base model of the Cypher AFM family with ultra-high resolution, fast scanning, and a complete set of operating modes ・Cyp...

4 models listed

Oxford Instruments Ltd.

440+ people viewing

Last viewed: 1 day ago

■Summary Jupiter XR is an atomic force microscope (AFM/SPM) that can handle large samples, and is an AFM with excellent basic performance that comb...

Oxford Instruments Ltd.

650+ people viewing

Last viewed: 16 hours ago

■Summary The MFP-3D AFM/SPM atomic force microscope family is suitable for a wide range of budgets, capable of measuring large sample sizes, and ha...

3 models listed

Park Systems Japan Co., Ltd.

440+ people viewing

Last viewed: 22 hours ago

Park NX-Wafer is an industry-leading automated AFM measurement system for semiconductor and related fabrication. Enabling wafer fab inspection and...

Oxford Instruments Ltd.

340+ people viewing

Last viewed: 16 hours ago

■Summary - ORCA™ conductive AFM probe holder allows conductive AFM imaging and I-V measurements on all MFP-3D AFM/SPMs. -Standard module can measur...

Park Systems Japan Co., Ltd.

400+ people viewing

Last viewed: 22 hours ago

Park Systems introduces the innovative Park 3DM Series, a fully automated AFM system designed for overhang profiles, high-resolution sidewall imagi...

Oxford Instruments Ltd.

340+ people viewing

Last viewed: 1 hour ago

■Summary ・The ORCA™ (Optimized Resistance Conductance Amplifier) cantilever holder enables conductive AFM imaging and I-V measurements. -Standar...

Park Systems Japan Co., Ltd.

390+ people viewing

Last viewed: 1 hour ago

Identifying nanoscale defects is a very time-consuming process for engineers working with media and flat substrates. Park NX-HDM is an atomic force...

Park Systems Japan Co., Ltd.

380+ people viewing

Last viewed: 1 hour ago

Park NX-Mask is a new generation photomask repair system that supports the miniaturization of devices and the increasing complexity of photomasks. ...

Park Systems Japan Co., Ltd.

360+ people viewing

Last viewed: 8 hours ago

Park NX-Hybrid WLI is the world's first AFM system with a built-in white light interferometer for measurement, quality assurance, front-end process...

Park Systems Japan Co., Ltd.

350+ people viewing

Last viewed: 6 hours ago

The Park NX-IR is a combination of a nanoscale infrared (IR) spectrometer and an atomic force microscope (AFM) for chemical and materials character...