12 Industrial Microscope Manufacturers in 2024

This section provides an overview for industrial microscopes as well as their applications and principles. Also, please take a look at the list of 12 industrial microscope manufacturers and their company rankings. Here are the top-ranked industrial microscope companies as of July, 2024: 1.Motic, 2.AmScope, 3.Bruker Corporation.

Table of Contents

1987~1991: Engaged in research on wire covering materials at Polymer Materials Laboratory.

1991~1997: Worked as a patent Engineer at Koike International Patent Office.

1997~2005 Worked as an intellectual property member at GE Yokogawa Medical System, currently working as a writer.

Linkedinhttps://www.linkedin.com/in/%E8%A3%95%E5%AD%90-%E9%88%B4%E6%9C%A8-92b21a234/

researchmap

https://researchmap.jp/0315rs2017

What Is an Industrial Microscope?

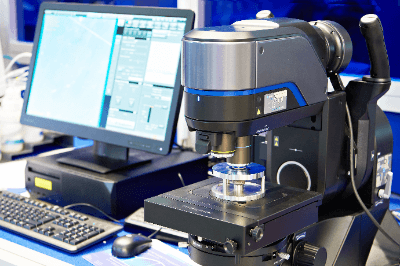

Industrial microscopes are used for process inspection and analysis in the manufacture of semiconductors, electronic components, and liquid crystal displays.

Industrial microscopes are used for process inspection and analysis in the manufacture of semiconductors, electronic components, and liquid crystal displays.

To facilitate data analysis, most industrial microscopes are equipped with a digital camera or CCD to capture images on a PC.

Uses of Industrial Microscopes

Industrial microscopes are used for manufacturing process inspection and analysis of industrial products, such as semiconductors and electronic components. The most common industrial microscope is the metallurgical microscope, which is used to observe surfaces by irradiating light and using reflected light.

Metallurgical microscopes are used for surface observation of opaque industrial products, such as ceramic structures, metals and alloys, polished surfaces of components, and electronic parts. They are also used for development, analysis, and inspection during the manufacture of products such as magnetic heads, liquid crystals, and films.

It can also be used for detailed observation of solder joint surfaces on circuit boards and the depth of penetration of welds. They are also used for evaluation and analysis after casting, heat treatment, and metallurgy in metal processing.

Principle of Industrial Microscope

The two most common types of industrial microscopes are the upright microscope, which is used to view the sample from above, and the inverted microscope, which is used to view the sample from below. The upright microscope is the most common and common type of microscope. The sample is placed under the objective lens and observed from above the objective lens. In an inverted microscope, the tip of the objective lens is on the upper side and the specimen is observed from below.

In both upright and inverted microscopes, the light source is located inside the objective lens. The light source illuminates the surface of the sample, and the reflected light from the sample surface is used to observe the shape of the sample surface. A prism or lens is placed between the objective lens and the eyepiece lens, and the light irradiated from the objective lens side to the sample and reflected back is magnified for observation. Magnification ranges from 50x to 1,000x.

There are many types of metallurgical microscopes used for Industrial Microscopes that have multiple functions, and there are a wide variety of models that can perform bright-field, dark-field, and differential interferometry with reflected illumination. In the dark-field method of reflected illumination, fine scratches, cracks, and pores appear shining and are suitable for observation of the specimen surface. In the differential interference method with reflected illumination, fine irregularities that are difficult to detect with the bright-field method can be detected, and it is widely used in inspection processes.

Types of Industrial Microscopes

As mentioned above, there are two types of industrial microscopes: upright microscopes and inverted microscopes.

1. Upright Microscope

In general, upright microscopes have the advantage that both transmission and reflection can be selected according to the illumination method, and the optical system can be easily designed.

2. Inverted microscope

Inverted microscopes are often used in the field of metals, etc., because the surface to be observed is placed in a downward position, allowing the observation surface to be easily leveled with respect to the optical axis.

Other Information on Industrial Microscope

1. Industrial Microscope With Multiple Functions

Industrial microscopes have not only the function of a metallurgical microscope but also other functions for efficient observation. For example, some models have multiple observation methods, including ordinary optical microscopes, polarizing microscopes, and scanning probe microscopes.

In addition, since industrial microscopes are used for manufacturing process inspection and analysis of industrial goods, they are generally capable of importing CCD or digital camera images into a PC. This facilitates data analysis, thereby improving the efficiency of inspection and analysis.

Furthermore, there are Industrial Microscopes that combine several functions, such as a camera and 3D measurement, in addition to the microscope function.

2. Difference Between Industrial Microscope and Measuring Microscope

An industrial microscope is, in a broad sense, a generic term for microscopes used in manufacturing and other industrial fields. Therefore, not only optical microscopes but also electron microscopes and digital microscopes fall under the category of industrial microscope. However, the industrial microscope generally refers only to optical metallurgical microscopes.

Metallurgical microscopes often use reflective illumination to shine light on the surface of the object to be measured, and their primary use is for surface observation. Measuring microscopes, on the other hand, use transillumination in addition to reflective illumination. In addition, the stage on which the object to be measured is placed is equipped with a digital scale and counter as standard equipment, and has mechanisms and functions for measurement.

In other words, industrial microscopes are mainly used for observation, and do not require the same amount of stage movement or magnification guarantee for the magnified observation image as measuring microscopes.

List of 12 Industrial Microscope Manufacturers

*Including some distributors, etc.

Sort by Features

- Default

- Company Size: largest first

- Year Founded: oldest first

- Year Founded: earliest first

Sort by Area

- United States of America

- Deutschland

- Germany

- Italy

- Japan

-

-

-

Bruker Corporation

Microscopes

Manufacturer Overview

Bruker, founded in 1960 and based in Billerica, Massachusetts, is a manufacturer and distributor of scientific instruments and analytical and diagnostic solutions. The company's product range includes analyzers, microscopes, and imaging solutions, which have applications in fields such as life science research, cell biology, and microbiology. In 1969, the company developed the world's first FT-NMR spectrometer system, enabling broadband proton decoupling. In 1997, it further expanded its capabilities by acquiring the analytical X-ray division of Siemens AG. The company holds ISO 9001 and ISO 13485 certifications, and its products are available for sale worldwide.

-

-

-

-

-

Nikon Metrology

Industrial Microscopes

Manufacturer Overview

Nikon Metrology Inc., a manufacturer based in Brighton, Michigan, United States, specializing in providing solutions for industrial measurement, inspection, and quality assurance needs, was founded in 2010 with the merger of Nikon Instruments Inc.’s industrial instrument business unit and the former Metris NV, a company acquired by Nikon Corporation. The company develops systems for manufacturing operations, including 3D laser scanners, industrial microscopy tools, and laser radar measuring systems. It also provides X-ray and computed tomography (CT) systems, optical manual measuring instruments, and video measuring systems. Furthermore, the company extends its offerings to encompass flat-panel display (FPD) lithography systems and imaging solutions.

-

-

-

-

-

OPTIKA S.r.l.

Industrial Microscopes

Manufacturer Overview

Optika Italy, established in 1971 and headquartered in Ponteranica, Italy, is a manufacturer and supplier of microscopes and microscopy accessories. The company offers a range of products, including biological microscopes, stereo microscopes, polarizing microscopes, inverted microscopes, and digital cameras with software. These tools find application across diverse sectors such as education, research, industry, and medicine. All of its processes adhere to the Quality Management System, following the UNI EN ISO 9001 standard.

-

-

-

-

-

Leica Microsystems Vertrieb GmbH

Macroscopes

Manufacturer Overview

Leica Microsystems is a developer and manufacturer of microscopes and scientific instruments for the analysis of microstructures and nanostructures. The company is a provider in compound and stereo microscopy, digital microscopy, confocal user scanning, and super-resolution microscopy with related imaging systems, electron microscopy, sample preparation, and surgical microscopy used in medical, life science, and industrial applications. The company’s services include service plans, preventative maintenance, remote care, and qualification services for ensuring compliance of Leica equipment to governmental regulations.

-

-

-

-

-

ZEISS Microscopy

Industrial Microscopy

Manufacturer Overview

ZEISS Microscopy, established in Jena, Germany, in 1846 is a manufacturer of optics and optoelectronics used in Precision Mechanics, Binoculars, Microscopy, and Eyeglass Lenses. Their product portfolio includes precision optics, such as lenses, mirrors, and prisms, laser mirrors used in laser cutting, and medical devices, optoelectronic devices and Coatings and Thin Films. The company also provides solutions including industrial quality, microscopy research, project simulation, sample testing and product development. The company also offers customer services that include support, custom research projects and customized services.

-

-

-

-

-

Nikon Metrology Inc.

Industrial Microscopes

Manufacturer Overview

Nikon Metrology Inc. is a manufacturer of advanced optical and precision technology. It is headquartered in Brighton, Michigan, and was established in 1917. The company manufactures a range of measuring instruments, including X-ray/CT inspection equipment, laser radar, 3D laser scanners, Image measurement systems and Optical measuring machines. Some of its popular products are the CrystaView 5 CMM software, the Nexo T2 laser tracker, and the MM-600 optical comparator. Nikon Metrology Inc. also provides after sale service, technical support and training services. Its products are used in various industries, including automotive, aerospace, and medical.

-

-

-

-

-

Motic

Industrial Microscope

Manufacturer Overview

Motic is a global manufacturer of various microscopes for educational, medical, and scientific applications. The company was originally founded in 1988 by Hong Kong-based Chinese company Speed Fair Co., Ltd, but now operates primarily out of its US office in Waltham, Massachusetts. The company's product line includes stereo microscopes for 3D visualization and dissection, industrial microscopes for quality control and inspection, and compound microscopes for life science and research. Motic also produces common microscopy parts and accessories, such as replacement bulbs, mount camera adaptors, and stage plates.

-

-

-

-

-

Meiji Techno

INDUSTRIAL MICROSCOPES

Company Overview

Meiji Techno Co., Ltd. (MTC) is a Japanese manufacturer and distributor of optical microscopes originally established in 1964 as Azuma Optics Company before rebranding in 1975. Based in Saitama, the company produces various microscopes for applications in education and life sciences, including inverted, compound, stereo, and polarizing models. These are utilized by clients in laboratory operations and quality control, analysis, and testing within the industrial sector. MTC has manufacturing facilities in Japan and China, with distribution operations in Shanghai, California, and New Jersey. Its North American subsidiary Meiji Techno America was incorporated in 1986, and is located in San Jose.

-

-

-

-

-

Parco Scientific Company

Industrial Microscopes

Company Overview

Parco Scientific Company is a manufacturer and distributor of scientific products for the institutional and industrial sectors that was established in 1968 in Westland, Michigan, USA. The company offers biology products such as dissection tools and anatomy models, microscopy products such as microscopes and related accessories, and chemistry products such as glassware and balances. It also offers maintenance and repair services for its portfolio products. The company chiefly serves North America’s research and educational institutions, with clients in the industrial processing sector.

-

-

-

-

-

AmScope

Microscopes

Company Overview

AmScope, founded in 1996 and headquartered in Irvine, California, is a manufacturer and distributor that specializes in delivering microscopy and imaging solutions. Its comprehensive product range includes various microscopes, camera systems, accessories, slide scanners, and optics components. These offerings are utilized for research, diagnostics, and quality control in the scientific, educational, and industrial sectors. AmScope's microscopes find extensive application in laboratories and educational institutions for the magnification and analysis of microscopic samples. The company's camera systems enable image and video documentation, enhancing microscopy-related research.

-

-

-

-

-

Evident

Industrial Microscope Solutions

Company Overview

Evident Corporation is a scientific research and development company in Shinjuku, Tokyo that was established in 2008. Formerly known as Olympus Scientific Solutions, the company specializes in developing cutting-edge technology and products for various industries, including aerospace, automotive, electronics, energy, and medical research. Evident Corporation has proliferated and expanded its product offerings and services to meet the needs of its customers. Their product offerings include non-destructive testing (NDT) solutions such as thickness gauges and automated inspection systems, XRF analyzers like handheld XRF analyzers, industrial microscopes, and video scopes and borescopes.

-

-

-

Industrial Microscope Manufacturer Ranking

*Including some distributors, etc.Ranking as of July 2024

Derivation Method| Rank | Company | Click Share |

|---|---|---|

| 1 | Motic |

17.8%

|

| 2 | AmScope |

13.2%

|

| 3 | Bruker Corporation |

11.4%

|

| 4 | Nikon Metrology |

9.6%

|

| 5 | Leica Microsystems Vertrieb GmbH |

8.7%

|

| 6 | Parco Scientific Company |

8.2%

|

| 7 | Meiji Techno |

7.3%

|

| 8 | Evident |

6.8%

|

| 9 | ZEISS Microscopy |

6.8%

|

| 10 | OPTIKA S.r.l. |

5.9%

|

Derivation Method

The ranking is calculated based on the click share within the industrial microscope page as of July 2024. Click share is defined as the total number of clicks for all companies during the period divided by the number of clicks for each company.Number of Employees

- ZEISS Microscopy: 35,000

Newly Established Company

- Motic: 1988 (36 years ago)

- OPTIKA S.r.l.: 1971 (53 years ago)

- Meiji Techno: 1964 (60 years ago)

Company with a History

- ZEISS Microscopy: 1846 (178 years ago)

- Meiji Techno: 1964 (60 years ago)

- OPTIKA S.r.l.: 1971 (53 years ago)

Industrial Microscope Manufacturers in United States

*Including some distributors, etc.

Global Distribution of Industrial Microscope Manufacturers by Country

*Including some distributors, etc.

| Country | Number of Companies | Share (%) |

|---|---|---|

United States of America

United States of America

|

2 | 28.6% |

Japan

Japan

|

2 | 28.6% |

Italy

Italy

|

1 | 14.3% |

Germany

Germany

|

1 | 14.3% |

| Deutschland | 1 | 14.3% |

List of Industrial Microscope Products

2 products are listed.

Leica Microsystems Vertrieb GmbH

Routine Industrial microscope DM2700 m

30+ people viewing

Ideal optical microscope for inspection and confirmation in routines ■ Stable white light with LED lighting at any time LED lighting provides a ce...

GOKO Imaging Devices Co., Ltd.

Digital Microscope with stage GOKO EV-1D

30+ people viewing

Last viewed: 3 hours ago

Digital Microscope with stage GOKO EV-1D ・Best suited for visual inspection and documentary evidence ・GOKO's unique zoom system: No need to re-f...