All Categories

History

This section provides an overview for surface roughness measuring gages as well as their applications and principles. Also, please take a look at the list of 9 surface roughness measuring gage manufacturers and their company rankings. Here are the top-ranked surface roughness measuring gage companies as of February, 2026: 1.Reid Supply, 2.Mitutoyo America Corporation, 3.Thread Check Inc..

Table of Contents

Categories Related to Surface Roughness Measuring Gages

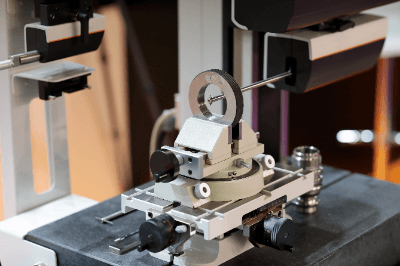

Surface roughness measuring gauges are measuring instruments used to evaluate the state of microscopic irregularities on the surface of a workpiece as a numerical value.

In the past, surface roughness was evaluated subjectively by inspectors visually or by touching the surface with their fingers or fingernails. A surface roughness measuring gauge makes it possible to control the desired condition of a workpiece surface using quantitative values.

Surface roughness measuring gauges are mainly used to analyze minute surface irregularities, for example, to check the finish of metal products. Surface roughness is especially important for metal products that come in contact with other parts, and is a very important factor in the field of tribology, which specializes in friction and wear.

Surface roughness is often used to evaluate the sliding surfaces of mechanical parts and the rolling surfaces of rotating shafts and bearings. It is also used in a wide range of other fields, such as medical care, research and development, and production sites.

Surface roughness measuring gauges are classified into the following two types. Since there are significant differences in the shapes and materials that each method is good at measuring, appropriate operation is required according to the purpose.

The contact type is measured by directly touching the object to be measured with a stylus. Although this method provides measurement results of the surface profile itself, it is not possible to measure a shape smaller than the diameter of the stylus or a part that cannot be physically touched, such as a narrow part where the stylus cannot enter.

In addition, since direct contact is involved, the stylus needs to be replaced periodically, which may damage the object to be measured. In particular, when measuring hard objects such as metals, the stylus may be damaged if it is accidentally pressed with more force than necessary. Handle with care.

The non-contact method uses light instead of a stylus to perform measurement. Typical examples are the confocal method, which measures by reading the reflected light of irradiated light, and the white interference method, which measures by interference fringes created by synthesizing the reflected light of the object to be measured and the mirror when white light is irradiated.

The non-contact method is characterized by its short measurement time, but it cannot measure well in areas where light cannot reach or in shapes where reflection cannot be obtained properly. It is necessary to measure from multiple directions by changing the placement of the object to be measured, or by cutting a portion of the part to allow light to reach it.

There are a great many definitions and parameters for evaluating surface roughness, but the best known is arithmetic mean roughness, which is written with the symbol Ra. It is often used because it is an image of calculating the average value of an uneven surface. In some cases, parameters other than arithmetic mean roughness may be desirable, such as in bearings, where the depth and size of the grooves that collect oil may affect the function of the part.

Other known parameters include maximum height roughness (Rz) and ten-point average roughness (Ry). Roughness parameters are defined in ISO and JIS, but they have been revised several times, so care should be taken when looking at old drawings.

In general, the stylus of contact-type surface roughness measuring gauge is subject to wear and requires periodic replacement. If the tip of the stylus is chipped, it cannot measure correctly, so it is important to check it periodically with a magnifying glass.

The material used for the stylus is diamond or sapphire, which are very hard materials that may damage the surface of the object to be measured. Particular care should be taken when repeatedly measuring the same spot or moving the stylus at a high speed.

*Including some distributors, etc.

Sort by Features

Sort by Area

Mitutoyo America Corporation was founded in Aurora, Illinois in 1963 by Mitutoyo Corporation of Japan as its American sales, marketing, and service subsidiary. The company provides parts service, manufacturing, and turnkey solutions for metrology equipment for aerospace, alternative energy, automotive, semiconductor, and other industries. The company’s product offerings include coordinate measuring machines, sensor systems, test equipment, and vision measuring equipment customized for customer needs. The company’s services include calibration and repair, installation, contract part programming, and training and education for operation as well as calibration.

Thread Check Inc. is an American manufacturer and supplier based in Ronkonkoma, New York, specializing in precision gage solutions. The company product lineup includes thread gages, digital thread depth gages, feeler gauge sets, as well as power-driven thread gages, and spline gauges. Other offerings include plain cylindrical and thread plugs with ring gages, thread and gear measuring wires, three-wire thread measuring systems, thread inspection equipment, and tri-roll thread comparator systems, alongside corresponding software. The company also offers calibration and hardness testing equipment, measuring instruments, precision hand tools, and surveillance masters, along with services like calibration and computer numerical control (CNC) machining.

Filmetrics is an American ISO 9001 certified manufacturer of thin-film thickness measurement systems and optical profilers that was founded in 1995 in San Diego, California. The company's products include thin-film reflectometers for measuring film thickness or refractive index levels, optical profilers for measuring surface topography, and sheet resistance meters for measuring the electrical resistance. The company chiefly serves client manufacturers in the optical, semiconductor, and biomedical sectors. It also offers product customization, training, and calibration services for unique projects.

Kosaka Laboratory Ltd., a company founded in 1950 and headquartered in Tokyo, Japan, is a manufacturer and supplier specializing in the production of precision measuring instruments. The company's product portfolio includes precision measuring instruments, hydraulic equipment, automatic machinery, and food equipment. These products are utilized by various industries, including the packaging industry, electronics, wind-power generation, manufacturing and engineering, and food and beverage. The company holds the ISO 9001 certificate for its Quality Management System (QMS).

Tokyo Seimitsu Co. Ltd., established in 1949 and headquartered in Tokyo, Japan, is a manufacturer of semiconductor production equipment and precision measuring instruments. Its product portfolio includes optical measuring instruments, probing machines, polish grinders, X-ray CT systems, and coordinate measuring machines. In 1952, the company developed Japan’s first high-pressure flow-type air micrometer, and in 1958, it created the world’s first germanium pellet automatic thickness sorting machine. It also developed Japan’s first coordinate measuring machine in 1969, followed by Japan’s first wafer-dicing machine in 1970. The company is the industry’s only semiconductor equipment manufacturer with measurement technology.

Chris-Marine AB, founded in 1962 with headquarters in Denmark, is a manufacturer of maintenance equipment for four-stroke and two-stroke engines. The company's products include electronic cylinder pressure indicators, spray washing machines, injector test fuel valve test rigs, honing machines, grinding machines, and lathes for valves, seats, and seat recess surfaces. Chris-Marine machines are used by trade professionals in power plants, marine servicing businesses, and workshops. The company also provides accessories and after-sales service for all of its products.

Accusize Industrial Tools was born in Toronto, Canada in 2008. Accusize is a distributor of measuring tools, cutting tools, and machine tools for metalworking companies. A portion of offerings that Accusize offers includes collet blocks, expanding arbors, air tools, power tools, die maker tools, annular cutters, bore gages, boring bars, boring heads, BT40 tooling, CAT40 tooling, calibration, layout, & machine setting tools, calipers & attachments, carbide inserts, end mills, force gauges, and metrology and material testing equipment.

MSI-Viking Gage, LLC was founded over 50 years ago and is headquartered in Duncan, South Carolina. MSI-Viking provides manufacturing support to the automotive, aerospace, metals, plastics, medical, energy, food & beverage, and machining industries. MSI-Viking product offerings include 3D scanning systems, 3D additive manufacturing, air gages, bore & hole gages, calipers, CMMs, computed tomography, data collection, depth gages, fixture systems, indicators, laboratory equipment, vision systems, and thread gages among others. Services include calibration, metrology, repair, embedded services, training, and metrology pre-op services.

Ranking as of February 2026

Derivation Method| Rank | Company | Click Share |

|---|---|---|

| 1 | Mitutoyo America Corporation |

22.2%

|

| 2 | Thread Check Inc. |

22.2%

|

| 3 | Reid Supply |

16.7%

|

| 4 | Filmetrics |

11.1%

|

| 5 | Accusize Industrial Tools |

11.1%

|

| 6 | TOKYO SEIMITSU CO., LTD. |

11.1%

|

| 7 | Chris-Marine AB |

5.6%

|

Derivation Method

The ranking is calculated based on the click share within the surface roughness measuring gage page as of February 2026. Click share is defined as the total number of clicks for all companies during the period divided by the number of clicks for each company.Number of Employees

Newly Established Company

Company with a History

*Including some distributors, etc.

*Including some distributors, etc.

| Country | Number of Companies | Share (%) |

|---|---|---|

United States of America

United States of America

|

4 | 50.0% |

Japan

Japan

|

2 | 25.0% |

Sweden

Sweden

|

1 | 12.5% |

Canada

Canada

|

1 | 12.5% |

50 products found

50 products

Kosaka Laboratory Ltd.

540+ people viewing

Last viewed: 9 hours ago

■Features This is a digital surface shape/roughness measuring machine that enables high resolution and wide dynamic range measurement. - A digital ...

Mahr Inc.

470+ people viewing

Last viewed: 11 hours ago

■Measuring station that combines contour measurement and surface measurement This is a measuring machine that performs contour measurement and roug...

Kosaka Laboratory Ltd.

610+ people viewing

Last viewed: 6 hours ago

■Features This is a combination of a surface roughness measuring machine and a contour measuring machine, allowing roughness waviness evaluation an...

Okaya Seiryu Kogyo Co., Ltd.

360+ people viewing

Last viewed: 1 day ago

SORM 3plus is an in-line measurement device for non-contact measurement of surface roughness characteristics of steel sheets being produced.

Kosaka Laboratory Ltd.

610+ people viewing

Last viewed: 1 day ago

■Features Two types of measurements are possible: "Surface roughness" and "Contour shape". The use of a touch panel provides excellent operability,...

Ryokosha Co., Ltd.

350+ people viewing

Last viewed: 5 hours ago

■Summary This is a fully automatic micro-shape measuring machine with outstanding accuracy, stability, and functionality that is ideal for measurin...

Ryokosha Co., Ltd.

450+ people viewing

Last viewed: 19 hours ago

■Summary This is a fully automatic micro-shape measuring machine with outstanding accuracy, stability, and functionality that is ideal for measurin...

Ryokosha Co., Ltd.

400+ people viewing

Last viewed: 1 hour ago

■Summary This is a fully automatic micro-shape measuring machine with outstanding accuracy, stability, and functionality that is ideal for measurin...

Meishin Koki Co., Ltd.

810+ people viewing

■Summary ・3D white interference microscope for measuring nano-level surface properties ・Measure the surface roughness and shape of machined parts...

Kosaka Laboratory Ltd.

520+ people viewing

Last viewed: 1 day ago

■Features Non-contact measurement allows measurements without damaging the sample. The compact optical arrangement makes it possible to measure the...

Ryokosha Co., Ltd.

370+ people viewing

Last viewed: 1 day ago

■Summary This is a digital surface shape/roughness measuring machine that enables high resolution and wide dynamic range measurement. ■Features - ...

Mahr Inc.

310+ people viewing

Last viewed: 1 day ago

■Measuring instruments for mobile use Mobile measuring instruments Mobile measuring instruments allow you to measure exactly where you need results.

3 models listed

Kosaka Laboratory Ltd.

380+ people viewing

Last viewed: 1 day ago

■Features This is a moving table measuring machine with high straightness measurement accuracy, allowing you to measure small precision parts easil...

Mahr Inc.

290+ people viewing

Last viewed: 1 hour ago

■Tactile measuring device Mahr perfected the stylus method, which is widely used around the world. However, it can also meet modern demands for non...

10 models listed

Meishin Koki Co., Ltd.

640+ people viewing

■Summary Both surface roughness and contour shape can be completed with one machine. Features ■If you need to evaluate both surface roughness and ...

Kosaka Laboratory Ltd.

500+ people viewing

Last viewed: 19 hours ago

■Features It is possible to add a three-dimensional surface roughness measurement function to a high-level surface roughness measuring machine. You...

Kosaka Laboratory Ltd.

570+ people viewing

Last viewed: 1 day ago

■Features Measurements can be made in accordance with international standards such as ISO, JIS, DIN, ASME, and BS, as well as new and old standards...

2 models listed

Shinmei General Co., Ltd.

600+ people viewing

Last viewed: 22 hours ago

The Roughness Checker Surtronic Duo is Taylor Hobson's latest portable stylus surface roughness measuring device. One unit can measure ISO 4287 rou...

Kosaka Laboratory Ltd.

710+ people viewing

Last viewed: 14 hours ago

■Features Powerfully performs surface roughness, waviness, and step measurement. It supports a variety of parameters and can analyze multiple stand...

2 models listed

Kosaka Laboratory Ltd.

630+ people viewing

Last viewed: 1 day ago

■Features A portable surface roughness meter with extremely intuitive operation. This measuring machine is suitable for measuring narrow and deep h...

Tsukumo Engineering Co., Ltd.

810+ people viewing

Last viewed: 1 day ago

NanoSeven uses a non-contact method using laser light to measure the surface roughness and step height of an object with sub-nano level accuracy in...

SANKO ELECTRONIC LABORATORY CO.,LTD

580+ people viewing

Last viewed: 1 day ago

■ Features ・ Measure the unevenness of the ship painting surface and memory the data. ・ The memory data is output after 600mm measurement.

Ryokosha Co., Ltd.

420+ people viewing

Last viewed: 19 hours ago

■Summary Contour shape and surface roughness can be measured simultaneously.

Ryokosha Co., Ltd.

340+ people viewing

Last viewed: 1 day ago

■Summary Contour shape and surface roughness can be measured simultaneously.

Ryokosha Co., Ltd.

300+ people viewing

Last viewed: 1 day ago

■Summary Largest measurement range in the series ■Features ・High precision and low cost: It has the same precision as the NH standard series, but...

Ryokosha Co., Ltd.

300+ people viewing

Last viewed: 1 day ago

■Summary Achieves the same measurement range as the NH standard model ■Features ・High precision and low cost: It has the same precision as the NH...

Ryokosha Co., Ltd.

320+ people viewing

Last viewed: 7 hours ago

■Summary Tabletop size low cost model ■Features ・High precision and low cost: It has the same precision as the NH standard series, but has simple...

SANKO ELECTRONIC LABORATORY CO.,LTD

540+ people viewing

Last viewed: 3 hours ago

■ Features ・ Equipped with a large color LCD of a good touch panel. ・ Handy type that can manage surface roughness on site. ・ Built -in printer ...