All Categories

History

This section provides an overview for high voltage transformers as well as their applications and principles. Also, please take a look at the list of 9 high voltage transformer manufacturers and their company rankings. Here are the top-ranked high voltage transformer companies as of February, 2026: 1.Purolite, 2.DAIHEN Corporation, 3.Sunresin.

Table of Contents

Categories Related to High Voltage Transformers

A high voltage transformer is a transformer that inputs high voltage as a primary voltage and outputs a stepped-down or stepped-up secondary voltage.

A high voltage transformer is a transformer that inputs high voltage as a primary voltage and outputs a stepped-down or stepped-up secondary voltage.

A transformer is a device that converts the voltage of an input current to another voltage for output. Converting to a lower voltage than the input voltage is called step-down, and conversely, converting to a higher voltage is called step-up. There are three types of power supply voltage standards: low voltage, high voltage, and special high voltage.

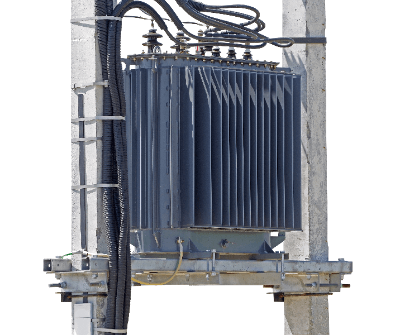

High voltage transformers are generally used to supply power to large facilities with high power consumption, such as factories, hospitals, and commercial facilities.

Electricity generated at power plants is very high voltage, tens of thousands of volts. This power cannot be used if it is transmitted directly to users. However, from the standpoint of transmission efficiency, the power is transmitted at high voltage and low current in the vicinity of the supplier, and then stepped down to a voltage that can be used by a high-voltage transformer.

High voltage transformers are generally built into high voltage receiving facilities called cubicles and placed on rooftops.

A transformer consists of two coils. The two coils are electrically separated but magnetically connected by an iron core.

The coil on the input side is the primary coil and the output side is the secondary coil. When a current flows through the primary coil, a magnetic flux is generated based on Ampere's law. This magnetic flux is transmitted through the iron core to the secondary coil, and based on Faraday's law of electromagnetic induction, a voltage corresponding to the number of turns of the coil is generated. Thus, by using the coil and iron core, it is possible to convert the voltage between the input and output power sources.

Since heat is generated inside the transformer due to power loss, a cooling system is introduced. There are two types of cooling methods: the "oil-filled method" in which the windings are cooled with insulating oil, and the "molded method" in which no oil is used.

Since high voltage transformers are used in facilities where strict disaster prevention measures are required, the "molded type" is often adopted because of its low fire risk. In the case of oil-filled transformers, Class 3 petroleum is used for the insulating oil. Note that as the capacity of the high voltage transformer increases and the amount of oil exceeds 400 L, the oil by itself is considered a hazardous material.

Also, as the capacity increases, it becomes more difficult to use self-cooling transformers, so the forced circulation type is used.

High voltage transformers are relatively inexpensive among industrial equipment because of their simple mechanism. For a transformer with a typical temporary voltage of 6,600V/3,300V and a secondary voltage of 400V/200V/105V, catalog products are available from various heavy electric appliance companies.

Catalog products are considered having an upper limit of around 2,000 kVA, and anything above that is made-to-order. The average price of an oil-filled, self-cooling transformer is several hundred thousand yen for a transformer of several tens of kVA, and several million to 20 million yen for a transformer of 2,000 kVA (as of 2021). Molded systems are more expensive.

The above prices are for general step-down transformers, but those with special specifications are made-to-order, so consultation with heavy electric machinery companies is required for pricing.

The capacity of a high voltage transformer is determined by the allowable current value of the windings and the capacity of the magnetic iron core. If a current exceeding the allowable value flows through the windings, the transformer is protected by an overcurrent relay to prevent burnout.

The capacity of a three-phase motor, for example, is measured in kilowatts (kW), whereas the capacity of a high voltage Transformer is measured in kilovolts (kVA). Catalog products of single-phase, three-wire High Voltage Transformers have an upper limit around 300 kVA, while three-phase 400 V/200 V transformers have an upper limit of 2,000 kVA.

In the case of a cubicle type, the upper limit for commercial products is around 750 kVA due to the size of the enclosure and cooling capacity.

It is important to note that the amount of work applied to a high voltage transformer varies depending on the power factor of the load. The further the power factor is from 1, the less work can be applied. By keeping the power factor of the secondary side of the high voltage Transformer at 1, the high voltage transformer can be used to its capacity without waste.

Since industrial machinery has many motors, the power factor often swings in the lagging direction. As a general measure, a power capacitor is connected in parallel with the load to compensate.

High voltage transformers are designed for maximum efficiency at around 60% load. Therefore, it is important to select a capacitor with a generous margin so that the normally used capacity will be around 60%.

*Including some distributors, etc.

Sort by Features

Sort by Area

Purolite, established in 1981 with its headquarters in Pennsylvania, USA, is now the world's largest manufacturer of premium API radius beads for blood purification and enzyme carriers as well as chromatographic resins for life sciences. Purolite's resins and absorbents find application in drug formulations like APIs and excipients, as well as in demineralization, purification, and extraction processes. The company serves various industries including nuclear power, potable water, food and beverage, and pharmaceuticals. All these resins meet the requirements of the USA, Europe, the UK, and Japan markets.

ZEZ SILKO Ltd., founded in 1994, is a power capacitor manufacturer based in Zamberk, Czech Republic. The company offers several services, such as electrical device power factor correction (PFC) for low and medium voltage. It also conducts power system evaluation, including measurement of network parameters. The company further provides power electronic capacitors, switchboards, and inducting heating capacitors. These products and services find applications in various industries, including electromobility, railway and public transportation, and power industry.

DAIHEN Corporation, established in 1919 and headquartered in Osaka, Japan, is a manufacturer of Power Products, Industrial Robots, and RF/MW Generators & Automatic Matching Units for plasma applications. The company provides an extensive array of products, including Oil-immersed Transformer, Cast Resin Transformer suitable for high buildings, public facilities, and hospitals, Power Distribution Equipment such as closed type power distribution boards and remote monitoring systems, as well as Sensors for Robot Welding and Positioners & Sliders. The company also offers various welding & cutting machines, including TIG Welding Machines, Plasma Cutting Machines, as well as Peripheral Devices for Welding.

Sunresin, a modern manufacturer and supplier, holds the largest market share of Ion exchange resin. Founded in 2001 in Xi'an, China, the company specializes in research and development, production, and sales of polymeric resins, equipment, and services for adsorption and separation resin materials and solutions. With more than 30 worldwide patents and over 10 completed national projects in resin development, its products find applications in various industries, including industrial water treatment, pharmaceuticals, and hydrometallurgy. All applicable production processes are strictly controlled according to environmental regulations.

Hebei UMEK Environment Machine Co., Ltd., established in 2003 in Hebei, China, is a manufacturer and supplier specializing in the production of resins. The company's product portfolio includes ion exchange resins, mixed bed resins, strong acid cation exchange resins, and weak acid cation exchange resins. The products find applications in various industries including water treatment, sewage treatment, food and beverage, power generation, and more. The company serves clients across industries worldwide with offices in Nigeria and South Africa. Its products are sold in America, Argentina, Venezuela, and other South American countries.

China Huayue New Materials Technology Group Co., Ltd., established in 1999 in Tianjin, China, is a manufacturer and supplier of ion exchange resins for water treatment and specialty applications. The company specializes in Ion Exchange Resins (IER) and polymer resins used for adsorption and separation. The company also offers customized solutions and support services for separation and purification projects across various industries, including water treatment, food processing, biotechnology, and pharmaceuticals among others. With a production capacity of 30,000 cubic meters, encompassing over 20 categories and 200 resin types, China Huayue New Materials Technology Group provides a diverse range of solutions to their customers.

Thermax Group, established in 1966 in Pune, India, is a manufacturer and supplier of energy and environment solutions. The company offers a wide range of products and services, including boilers, heaters, chillers, and waste heat recovery systems. These solutions are used in industries such as power, chemicals, pharmaceuticals, and more. Thermax's products ensure sustainable energy and resource management, helping industries optimize their processes while minimizing environmental impact. Additionally, the company aims to provide cutting-edge solutions that address the complex challenges of energy efficiency and environmental conservation.

Tamura Corporation was founded in 1924 in Tokyo, Japan as Tamura Radio Store, making it one of Japan’s oldest electronics companies. Today the company serves the semiconductor, audio consumer appliance, power distribution, and other industries as a developer and manufacturer. The company’s Electronic Component segment has eight categories, among them, transformers, reactors, vacuum tube type power supply transformers, current sensors, and AC adaptors. The company’s Information Equipment segment has 3 subcategories including broadcast studio systems, communication systems, and network systems.

LANXESS AG, established in 2004 and headquartered in Cologne, Germany, is a specialty chemical manufacturer. The company emerged from a restructuring process within Bayer AG, a German pharmaceutical and biotechnology company. As part of this transformation, certain chemical and polymer business units were spun off to create LANXESS as an independent entity. Under various brand names like Bayferrox and Colortherm for synthetic inorganic pigments, Lewatit for ion exchange resins, Bayoxide for iron oxide adsorbers, and Rely+On for disinfectant solutions, LANXESS offers a diverse range of products. These serve various industries, including agriculture, automotive, biosecurity, construction, microbial control, and mining.

Ranking as of February 2026

Derivation Method| Rank | Company | Click Share |

|---|---|---|

| 1 | Purolite |

39.1%

|

| 2 | DAIHEN Corporation |

11.2%

|

| 3 | Sunresin |

10.3%

|

| 4 | ZEZ SILKO Ltd |

9.4%

|

| 5 | LANXESS |

8.2%

|

| 6 | TAMURA Corporation |

6.2%

|

| 7 | Thermax |

6.0%

|

| 8 | Hebei UMEK Environment Machine Co., Ltd. |

4.9%

|

| 9 | China Huayue New Materials Technology Group Co., Ltd. |

4.7%

|

Derivation Method

The ranking is calculated based on the click share within the high voltage transformer page as of February 2026. Click share is defined as the total number of clicks for all companies during the period divided by the number of clicks for each company.Number of Employees

Newly Established Company

Company with a History

*Including some distributors, etc.

*Including some distributors, etc.

| Country | Number of Companies | Share (%) |

|---|---|---|

China

China

|

3 | 37.5% |

Japan

Japan

|

2 | 25.0% |

United States of America

United States of America

|

1 | 12.5% |

Czech Republic

Czech Republic

|

1 | 12.5% |

India

India

|

1 | 12.5% |

65 products found

65 products

Power Supply Technology Co., Ltd.

500+ people viewing

Last viewed: 1 day ago

■Features ・High voltage insulation technology ・Epoxy/silicone vacuum casting ・High voltage wiring to printed circuit board

Power Supply Technology Co., Ltd.

310+ people viewing

Last viewed: 3 hours ago

9 models listed

Power Supply Technology Co., Ltd.

260+ people viewing

Last viewed: 1 day ago

3 models listed

Power Supply Technology Co., Ltd.

370+ people viewing

Last viewed: 8 hours ago

4 models listed

Musashino Tsuko Co., Ltd.

440+ people viewing

Last viewed: 5 hours ago

This transformer has the advantage of being compact, lightweight, and thin due to its unique method of winding grain-oriented silicon steel strips ...

Power Supply Technology Co., Ltd.

250+ people viewing

Last viewed: 9 hours ago

4 models listed

Power Supply Technology Co., Ltd.

340+ people viewing

Last viewed: 3 hours ago

9 models listed

Castech Shoji Co., Ltd.

370+ people viewing

Last viewed: 1 day ago

■Features ・Low iron loss ・Use of core when saturation is high ・Compatible with UL insulation standards ・Using temperature -25℃~105℃ ・Customiz...

Castech Shoji Co., Ltd.

410+ people viewing

Last viewed: 1 day ago

■Features ・High efficiency density 20-30w/inch^2 ・High efficiency>95% ・Low EMI generation ・Low leakage inductance ・Usage range-50kHz to 5MHz ...