All Categories

History

This section provides an overview for robot motors as well as their applications and principles. Also, please take a look at the list of 2 robot motor manufacturers and their company rankings.

Table of Contents

Categories Related to Robot Motors

A robot motor is an electric motor used in robots and automated systems to facilitate motion.

As a component element employed to achieve mechanical movements, robot motors find applications in various parts of robots, such as joints and actuators. Their ability to control position and speed with high precision enables accurate operations and task execution. Stepping motors and servo motors, in particular, excel in this regard. Consequently, once programmed, these motors execute motions repeatedly, ensuring consistent results.

Moreover, they can achieve various types of movements, including rotational and linear, making robots adaptable to diverse tasks. An indispensable element in automated processes, robot motors enhance operational efficiency while reducing human effort.

However, precise control and programming of motors are crucial for realizing accurate movements. Proper motor drivers and controllers, along with suitable algorithms, need to be employed.

Robot motors are widely used across various industries and applications. Here are some common examples of applications:

Industrial robots are utilized in automated production lines, contributing to activities such as assembling automobiles and manufacturing electronic devices. Due to the demand for high precision, servo motors and stepping motors are frequently employed in these robots.

In the medical field, surgical support robots enhance the precision of surgeries. These robots amplify the subtle movements of a surgeon's hands, requiring high control accuracy. Additionally, rehabilitation robots assist in patients' movement retraining and rehabilitation.

Service robots support various tasks in homes and commercial facilities. Cleaning robots perform tasks like floor sweeping and mopping, while drones assist in activities such as product delivery and photography. These robots possess advanced environmental awareness and motion control functions, ensuring efficient and safe operations.

The entertainment industry often employs theme park attractions and entertainment robots. These robots, equipped with flashy movements and lighting effects, provide people with enjoyment and surprises.

Various types of motors are used as robot motors, with DC motors, stepping motors and servo motors being the most commonly used.

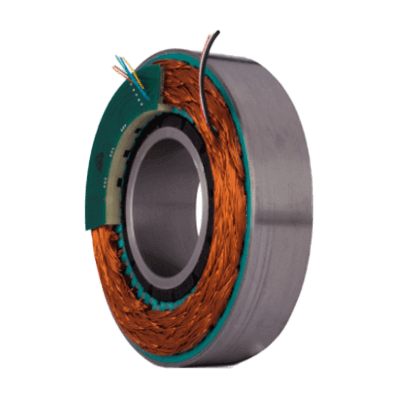

DC motors utilize the principle of electromagnetic induction. They can be categorized into brushed and brushless types. Brushed DC motors maintain rotation by using brushes and a commutator to change the direction of the current. Brushless DC motors, on the other hand, have an external control circuit that regulates the flow of current, offering high efficiency.

Stepping motors rotate in precise steps at specific angles. By supplying current to coils, a magnetic field is generated, causing the rotor to rotate and advance to the next step. Due to their ability to precisely control position, they are used in applications requiring accurate positioning and movements.

Servo motors move at controlled speeds to specified positions. Using a feedback control system, the difference between the target and actual positions is detected, and the motor is adjusted accordingly. They excel in position control and are used for precise positioning in robot arms and machinery.

When selecting a robot motor, various factors need to be considered. Here are some factors to consider when choosing a robot motor:

The type and performance of the motor to be chosen depend on its application. For instance, servo motors may be suitable when position accuracy is crucial, while brushless DC motors may be suitable for applications requiring high torque. Choosing a motor with characteristics and performance that match the application is essential.

Robot motors can be powered by direct current (DC) or alternating current (AC). Choosing the appropriate power source type that aligns with the motor's power requirements is crucial. DC motors are suitable for battery-driven applications, while AC motors are widely used when powered from outlets.

The capacity of the motor is an indicator related to the torque and output the motor produces. Choosing a motor with the appropriate torque and output for the moving mass or load is essential. Using a motor with excessive or insufficient capacity may affect performance and lifespan.

The size of the motor is an important factor to consider based on constraints such as available space for installation. In cases of limited space, a compact motor may be chosen, while applications requiring significant torque may involve selecting a larger motor.

*Including some distributors, etc.

Sort by Features

Founded in New York in 1916, Kollmorgen designs and manufactures motion system, drives, motors, actuators, gear heads, automated guided vehicle (AVG) systems, and accessories across a number of implementations and industries. These include aerospace, AGV, food&beverage, machine tools, metal forming, medical automation and imaging, energy, packaging, pharmaceutical, postal sorting, printing, robotics, smart warehouses, and tire and rubber production. Kollmorgen assists customers both in custom designs and in allowing customers to design their own devices based on individual needs.

Number of Employees

Newly Established Company

Company with a History