54 Emergency Stop Switch Manufacturers in 2024

This section provides an overview for emergency stop switches as well as their applications and principles. Also, please take a look at the list of 54 emergency stop switch manufacturers and their company rankings. Here are the top-ranked emergency stop switch companies as of April, 2024: 1.Rees, Inc., 2.Red Fox Safety Products, 3.ICKey Internet Technology Co., LTD.

Table of Contents

What Is an Emergency Stop Switch?

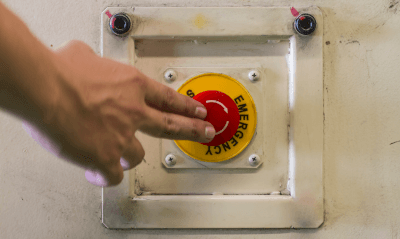

An emergency stop switch is a critical safety device designed to halt equipment operations in emergencies, protecting against serious accidents and injuries. These switches are essential in environments where industrial machinery operates under high torque or pressure, posing risks to human safety.

Uses of Emergency Stop Switches

These switches are commonly found in machinery such as conveyors, presses, and welding robots, where there's a risk of entrapment or pinching. Regulations often mandate their installation on equipment like conveyor belts to prevent entrapment accidents. Pull-rope switches are preferred in some cases for their accessibility along the length of a conveyor.

Principle of Emergency Stop Switches

- Push-Button Type: Typically red for visibility, these switches lock when pressed to ensure machinery remains halted until manually reset. They're designed to interrupt electrical circuits to stop equipment immediately.

- Pull-Rope Type: Used around conveyors, pulling a wire attached to the switch stops the machine. Like push-button types, these switches lock upon activation and require manual resetting.

Other Information on Emergency Stop Switches

- Installation Considerations: The placement of emergency stop switches is crucial for easy access by workers. In large facilities, multiple switches are installed to ensure availability in any emergency.

- Lockout Mechanism: To prevent accidental restarts that could lead to injury or death, some emergency stop switches feature a lockout mechanism. This allows the switch to be padlocked, ensuring that equipment cannot be restarted until it's safe to do so.

List of 54 Emergency Stop Switch Manufacturers

*Including some distributors, etc.

Sort by Features

- Default

- Company Size: largest first

- Year Founded: oldest first

- Year Founded: earliest first

Sort by Area

- United States of America

- China

- France

- Germany

- Hong Kong

- Switzerland

- Taiwan

- United Kingdom

-

-

-

Banner Engineering Corporation

EMERGENCY STOP SWITCHES

Manufacturer Overview

Banner Engineering Corporation, established in 1966 and headquartered in Minneapolis, Minnesota, is a manufacturer and supplier of industrial automation products. They offer an extensive range of sensors, including proximity sensors, photoelectric sensors, and limit switches, for detecting object presence, position, and speed. Additionally, Banner provides a different types of switches, such as pushbuttons, toggle switches, and rotary switches, to control electricity flow and offer system feedback. Their wide array of controls includes PLCs, HMIs, and motion controllers, enabling automation of industrial processes.

-

-

-

-

-

Pinnacle Systems Inc.

Emergency Stop Buttons

Manufacturer Overview

Pinnacle Systems Inc., located in Batavia, IL has been a manufacturer of safety products for industrial machine guarding applications for many decades. The company’s products include safety light curtains, safety mats, ergonomic palm buttons, safety relays, and safety controls, among others. The company also provides risk assessment services for industries. Another flagship product of the company is safety relay hubs which provide a complete safety solution for machines and are programmable as per the requirement of the customer.

-

-

-

-

-

ifm efector, inc.

Safety rope emergency stop switch

Manufacturer Overview

ifm efector (ifm) is a subsidiary of ifm electronic, founded in Germany in 1969. ifm has developed, manufactured and marketed sensors and controls technology to industries that include assembly and robotics, automotive, material handling, metal forming, mobile equipment, plastics, and food and beverage. Ifm produces sensors, condition monitoring equipment, image processing, safety technology, industrial communication, IO-link, systems for mobile machines, displays, software, connection technology, voltage supplies, as well as other accessories.

-

-

-

-

-

Honeywell International Inc

Cable-Pull Switches

Manufacturer Overview

Honeywell International Inc. was founded in 1885 and headquartered in Charlotte, North Carolina. Honeywell is a diversified technology and manufacturing company to global customers in many industries such as aerospace, building technologies, performance materials, manufacturing, and safety. Honeywell produces hardware and software solutions for each industry it serves. In building technologies, Honeywell designs access controls, electrical and wiring, fire life safety, and employee training services. In aerospace, Honeywell designs cockpit systems and displays, engines, cabin management and cleaning, and health and usage monitoring.

-

-

-

-

-

Rees, Inc.

Emergency Stop Switches

Manufacturer Overview

Rees, Inc. began in 1929 and is based in Fremont, Indiana. The company is a designer and manufacturer of electromechanical and industrial control switches that serve the automotive, conveyor, material handling, food processing, and other manufacturing industries. The company manufactures its parts in the United States in ISO 9001:2015 certified facilities. The company’s product categories include various types of switches, control units, contact blocks, and push buttons. The company offers modification options on most parts available upon request.

-

-

-

-

-

Safety Technology International, Inc. (STI)

STOPPER

Manufacturer Overview

Safety Technology International (STI), established in 1980, and headquartered in Waterford, Michigan, is a manufacturer and supplier of safety and security products. Their product range includes protective covers and enclosures for fire alarms, emergency lights, and security devices. These products are designed to safeguard critical equipment from accidental damage, vandalism, and environmental elements. STI's solutions cater to industries such as healthcare, education, hospitality, and commercial buildings, delivering products that ensure the safety and security of valuable assets.

-

-

-

-

-

Red Fox Safety Products

Emergency Stop Switches

Manufacturer Overview

Red Fox Safety Products, started in 2013, is the manufacturer and supplier of wireless remote kill switches which cut off the power supply to the engine/motor at the push of a button to ensure safety and prevent engine-related accidents. The company, located in Drechsel Rd Worley, Idaho, produces switches that are used in rock crushers, construction applications, fuel delivery truck shut down, military training, and farm tractors. The unit has receivers between the operated equipment and the transmitter which has a button to switch the gear down and can be clipped on the shirt or belt.

-

-

-

-

-

Pepperl+Fuchs Inc.

Human-Machine safe interface

Manufacturer Overview

Pepperl+Fuchs, Inc. was founded in Mannheim, Germany in 1945 developing the forerunner of the proximity switch. Pepperl+Fuchs continues to develop proximity sensors as well as other industrial sensors including ultrasonic sensors, rotary encoders, positioning systems, display and signal processing, vibration monitoring, industrial communication, and signal processing as well as related accessories and software. Explosive protection products include safety barriers, surge protection, wireless solutions, HMI systems, power supplies, electrical explosion protection equipment, level measurement, and related software.

-

-

-

-

-

OMEGA Engineering inc.

Emergency stop

Manufacturer Overview

OMEGA Engineering was originally begun in 1962 as a manufacturer of thermocouples and has grown to over 100,000 products for measurement and control of temperature, humidity, pressure, strain force, flow, level pH, and conductivity as well as customer service including data acquisition, electric heating, and custom-engineered products. Additionally, OMEGA offers tools to serve as reference for engineers around the world. OMEGA Engineering serves the aerospace, automotive, wireless, sanitary, test & measurement, process control, power monitoring, environmental, and laboratory markets.

-

-

-

-

-

Euchner-USA, Inc.

EMERGENCY STOP DEVICES

Company Overview

Euchner-USA, Inc. is based in East Syracuse, New York, USA, and is a manufacturer of industrial safety equipment that was established in 1989 as a subsidiary of Germany’s Euchner GmbH + Co. KG. The company produces magnetically coded and transponder-coded safety switches, emergency stop devices, and safety relays for control systems. It also offers light curtains, handheld pendant stations for controlling machinery or processes, and read heads with external evaluation functionality. The company’s products are commonly used in industrial manufacturing operations, including within the automotive, robotics, and machine tool industries.

-

-

-

-

-

Allied Electronics, Inc.

Emergency Stop Switches

Company Overview

Allied Electronics Inc., founded in 1991 with headquarters in the USA, is a distributor and supplier of fuel and vehicle servicing station equipment and accessories. The company's extensive product line of over 57,000 products includes forecourt controller parts, fuel dispenser parts, air compressors, and power conditioners. The company also provides rebuilt parts by brands that include Bennett, Daktronics, FE-Petro, and Gasboy. The company's services include equipment financing, primarily serving the retail petroleum industry, including car wash and price sign manufacturers.

-

-

-

-

-

Baco Controls, Inc.

Emergency Stop Switches

Distributor Overview

Baco Controls is the marketing arm of BACO, originally founded in 1919. Baco Controls was founded in 1980 and is currently located in Central New York. The company is a middle distributor of industrial control and signaling devices, generally selling to consumers and industries through other distributors. The company’s featured product categories include 22 mm and 30 mm Control and Signaling devices, Disconnect Switches, and Cam Switches. The company offers assistance in custom control stations tailored to customers’ specific needs.

-

-

-

-

-

steute Technologies GmbH & Co. KG

Emergency pull-wire switches

Manufacturer Overview

steute Technologies GmbH & Co. KG founded in Löhne, North Rhine-Westphalia, Germany, in 1961, is a manufacturer of electrical sensors and control units. The company manufactures foot switches, optical sensors, magnetic sensors, command devices, and wireless receivers. It has subsidiaries in 11 countries around the world, and sales and service partners in a further 30. At the end of 2012, the company opened a production plant in Shanghai, China and it also employs 450 people worldwide.

-

-

-

-

-

Johnson Electric

Emergency Stop Switches

Manufacturer Overview

Johnson Electric, since 1959, is a manufacturer of motors, micro-switches, solenoids, microelectronics, and flexible printed circuits based in Shatin, Hong Kong. Their products include AC motors, automotive switches & subsystems, cargo bikes, EMI-shielded flexible circuits, snap action switches, used in automotive, building automation, digital security, food & beverage, and laboratory equipment. Johnson Electric has been in the Hang Seng Corporate Sustainability Benchmark index since 2018. The Hong Council of Social Service awarded it the 5+ caring company award in 2022-2023 and additionally, it is an Institute of Business Ethics supporter.

-

-

-

-

-

elobau GmbH & Co. KG

Emergency stop buttons

Manufacturer Overview

elobau Elektrobauelemente GmbH & Co., founded in 1972 with headquarters in Germany, is a manufacturer of contactless sensor technology, operator controls, machine safety, and level measurement. The company's products include multi-axis joysticks, multi-function handles, push buttons, sensor components, and continuous level measurement. elobau’s products are used in both mobile (off-highway) and industrial applications. The company’s products can be found in aircraft, off-road vehicles, agricultural machinery, and industrial machinery. elobau Elektrobauelemente GmbH & Co. has been carbon neutral since 2010.

-

-

-

-

-

K. A. Schmersal GmbH & Co. KG

Pull-wire emergency stop switches

Manufacturer Overview

K.A. Schmersal GmbH & Co.KG was founded in 1945 and is a manufacturer of switchgear and control devices based in Wuppertal, Germany. The company's products include security sensors, solenoid interlocks, safety switches and safety mats. The products are used in escalators, elevators, wood processing, packaging and industrial automation to provide safety at work. The company is ISO 9001 certified and supports local institutions like the University of Wuppertal, charity events and sports clubs. In Brazil, Schmersal has won the international "Great Place To Work" competition five times.

-

-

-

-

-

Zhejiang Benyi New Energy Co., Ltd.

Rapid Shutdown Device

Manufacturer Overview

Zhejiang Benyi New Energy Co., Ltd., founded in 2011 and based in Wenzhou, China, is a manufacturer of protective components for the renewable energy industry. The company offers protective components for photovoltaic systems across the globe. It provides PV protection solutions as well as EV chargers and microinverters. The company also offers solar DC protections, designed to fully protect components that comply with the latest DC standards. It complies with many industrial standards including ISO, RoHS, and CE guidelines.

-

-

-

-

-

IMO Precision Controls

Emergency Stop Station - Complete Unit

Manufacturer Overview

IMO Precision Controls, a company founded in 1972 and headquartered in Hertfordshire, United Kingdom, is a manufacturer and supplier of industrial automation and control products. The company offers a wide range of products and solutions, including automation products, circuit protection, control and switch gears, and solar products. Their products find application in diverse industries such as manufacturing, energy, and transportation. The company also offers customer services that include technical support, value-added assembly, training courses, and tailored solutions to meet clients’ requirements.

-

-

-

-

-

AUSPICIOUS

Emergency Stop Switches

Manufacturer Overview

Auspicious is a Taiwanese manufacturer of automation components founded in 1979 and based in New Taipei City. The company primarily produces various switches, visual and auditory indicators, control stations, and relays. These are used to activate or deactivate circuits, issue warnings when set parameters have been breached, and facilitate communication between different components in an automated production line. Auspicious products have applications in various industries including industrial automation, telecommunications, transportation, and renewable energy.

-

-

-

-

-

EAO AG

Emergency stop switch

Manufacturer Overview

EAO AG is based in Olten, Switzerland, and is a manufacturer of HMI systems and industrial switches that was established in 1978 following the merger of Elektro-Apparatebau Olten AG and Elektro-Apparatebau Zürich AG. The company’s product lineup includes HMI panels for use in medical devices, railway systems and industrial machinery, industrial switches such as emergency stops and keylocks, and modular as well as custom automotive switch systems. It also offers contract manufacturing services including design, development, production, and logistics. The company chiefly serves client manufacturers of industrial machinery, heavy duty vehicles, railway systems, and mass transit vehicles.

-

-

-

-

-

norelem Normelemente GmbH & Co. KG

Emergency stop button

Manufacturer Overview

Normelemente KG, established in 1958 and based in Markgroningen, Baden-Wuerttemberg, is a German manufacturer and supplier that specializes in standard parts and machine components. Norelem offers an extensive catalog of more than 70,000 products, catering to the needs of engineers and designers in various projects. Their product range includes clamping technology, measuring and testing components, electromechanics, systems and components for machine and plant construction, and material handling and transport solutions. These products find applications in diverse engineering fields, such as automotive, aerospace, machinery, and robotics sectors.

-

-

-

-

-

Panasonic Industry Europe GmbH

Emergency stop switch (Pushubutton type)

Manufacturer Overview

Panasonic Industry Europe is the European branch of Panasonic, a global manufacturer of electronics and houseware, originally founded in 1918. Panasonic Industry Europe manufactures in 4 categories: components, devices, energy & building, and automation devices & solutions. Components include relays, capacitors, resistors, sensors, switches, connectors, couplers. Devices include wireless connectivity, e-bike systems, motors, compressors, thermal solutions, GPS antennas, as well as electronic materials. Energy & building includes batteries, fuel cells, solar sells, power tools, and home IoT. Automation devices & solutions include sensors for factory automation, industrial motors, laser welding, and more.

-

-

-

-

-

Schaltbau GmbH

Emergency disconnect switch

Manufacturer Overview

Schaltbau is headquartered in Munich, Germany, since 1929 as a manufacturer of electromechanical components The company produces AC and DC contactors for low and high-voltage applications such as car batteries and charging stations along with snap-action switches for microswitches in safety applications such as wind turbines and printers. The connectors manufactured by Schaltbau transmit energy and signals even in rough environmental conditions which makes them suitable for food processing, offshore operations, mining lighting, and transportation, especially for railway technology.

-

-

-

-

-

Wieland ELECTRIC GMBH

Emergency stop

Manufacturer Overview

Wieland, established in 1910 and based in Bamberg, Germany, is a manufacturer and supplier of electrical connection technology. Their product range includes pluggable connections for seamless plug-and-play electrical device connections, insulated connectors that provide electrical insulation in device connections, cable glands for safeguarding cables and ensuring a watertight seal, terminal blocks used for connecting electrical wires, and contact systems facilitating connections between electrical components. Wieland's products find applications in diverse industries, such as building construction, electrical engineering, and automation.

-

-

-

-

-

EUCHNER GmbH + Co. KG

Emergency stop device / Rope pull switch

Manufacturer Overview

Euchner was established in 1953 as a manufacturer of industrial safety products and is based in Germany. The products designed and manufactured by the company are used by industries that want to minimize risks and hazards. One example of their equipment is a Transponder with Coded Key Systems EKS and CKS which is used for controlling machine functions, storing process parameters, maintaining different access rights, and much more and it helps with procedures like automatic logging on and off for safe and controlled access. There are also safety switches, relays, identification systems, emergency stop devices, and similar items.

-

-

-

-

-

Schneider Electric SE

Emergency stops rope pull switch for explosive atmospheres dust

Manufacturer Overview

Schneider Electric S.E. is headquartered in Rueil-Malmaison, France, and has been operating since 1836. Schneider Electric provides a number of products and services including electrical car charging, energy management software, surge protection devices, load banks, servers and HMIs, valve and valve actuators, feeder automation, grid automation, and SCADA software products, data center cooling and software, home automation and security, light switches, motion control and robotics, signaling units, solar and energy storage, RFID systems, as well as other hardware, services, and software.

-

-

-

-

-

Pilz GmbH & Co. KG

E-STOP pushbutton

Manufacturer Overview

Pilz is headquartered in Ostfildern, Germany. Pilz designs components, systems, and services to assist industrial plant and machinery customers globally. Customers include many industries such as metals, pharmaceutical, food, presses, and robotics. Pilz serves customers through 4 venues: products and industries, services, support, and training. Products and services include everything from sensor technology and small controllers to robotics to software and operation monitoring. Services include machinery and workplace safety and international compliance. Support is offered 24/7. Training is available through courses and qualification programs.

-

-

-

-

-

Schmersal GmbH & Co. KG

SAFE SWITCHING AND MONITORING

Manufacturer Overview

Schmersal GmbH & Co. KG, founded in 1945, by Heinz and Philip Schmersal, is a name in safety technology, is a manufacturer of safety technology solutions, specializing in switchgear and control devices for various industries. With a diverse range of mechanical and electro-sensitive switching devices, they offer an extensive collection of safety switching systems and devices for safeguarding both humans and machinery. The company looks after three key domains: lift technology, automation technology, and safety technology. Their substantial approach position them as a global supplier of safety switching devices, catering to the safety and automation needs of various industries.

-

-

-

-

-

Langir Electric

Emergency Stop Switch

Manufacturer Overview

Langir Electric, founded in 2009 and based in Wenzhou, China, is a manufacturer of switch solutions, including piezo, anti-vandal, and capacitive switches. The company also sells electronic design solutions, control panels, and accessories like flexible light pipes, stainless steel cable ties, and anti-vandal pilot indicators. It also provides custom services and solutions and has over 10,000 customers. The company sells 80% of its products to over 50 countries in regions such as Canada, Europe, and South America. It is ISO 9001certified, and all its products have a one-year major parts warranty.

-

-

-

-

-

Schmersal, Inc.

EMERGENCY-STOP BUTTON

Manufacturer Overview

K.A. Schmersal GmbH & Co. KG, founded in 1945 and headquartered in Wuppertal, Germany, is a manufacturer of systems and solutions for machine safety and occupational health and safety. The company’s over 18,000 devices include safety sensors, safety switches with separate actuators, and solenoid interlocks. It also stocks optoelectronic safety devices, safety relay modules, and safety controllers. The company has a presence in over 60 countries, with seven production sites in three countries, including Brazil, India, and China. All its production subsidiaries are ISO 9001 certified, and its laboratory at the Wuppertal site is recognized by DAkkS and ISO/IEC 17025 accredited.

-

-

-

-

-

EAO Corporation

Emergency stop switch

Manufacturer Overview

EAO was founded in 1947 and is headquartered in Olten, Switzerland, with manufacturing, sales, and distribution companies around the globe. The company serves core markets of transportation, automotive, heavy-duty & special vehicles, and machinery as a manufacturer of switches, keyboards, control elements, and human-machine interface systems. The company has three product divisions: HMI Components, HMI Systems, and EAO Automotive. Together, they include emergency stop switches, passenger convenience devices in transportation, and other switches for human-machine interfaces across industries.

-

-

-

-

-

Autonics Corporation

Emergency Stop Button Switches

Manufacturer Overview

Autonics Corporation, established in 1977 and based in Busan, South Korea, is a developer and manufacturer of automation products, which are marketed worldwide. Some of its products include sensors, peripheral connection equipment, motion devices, control devices, and process automation instruments. The automation products are used in various industries, including automotive, packaging, machine tools, metal, and marine. The company has 12 international offices spanning over 100 countries, a fully automated warehouse system, and various international quality certifications, including RoHS, CE, UL, and EAC. Its safety products meet the functional safety standards IEC 61508 and mechanical safety standards ISO 13849.

-

-

-

-

Manufacturer Overview

iNORéA, founded in 2011 and headquartered in Bègles, France, is a distributor and supplier of electrical components and industrial automation devices. The company's products include a full range of solid-state relays, electric motor starter boxes, and boxed assortments of electrical supplies, which include cable glands, crimp terminals, and terminals. iNORéA caters to both individual and commercial customers, providing discounts for bulk purchases and incentives for manufacturers and distributors to participate in its partnership program.

-

-

-

-

Omron

Emergency Stop Switches

Manufacturer Overview

Omron Corporation, started in 1933 and headquartered in Kyoto, Japan, is a manufacturer of automation components, equipment, and systems, and it developed the first contactless proximity switch in 1960. It has four domains, including industrial automation, electronic components, healthcare, and social systems, and it provides products and services in around 120 countries and regions. Some of its products include microsensing devices, access control systems, industrial robots, surveillance cameras, and blood pressure monitors. In 1971, it developed the first online cash machine, and in 1972, it established Japan’s first welfare factory.

-

-

-

-

-

Motion X Corporation

MX-EPO Series (EPO) Emergency Power Off Systems

Manufacturer Overview

Motion X Corporation was established in 2002 by a group of industry professionals with extensive applied experience in designing, manufacturing, and supporting turnkey motion control systems and subsystems. The company is headquartered in Goleta, California near the University of California, Santa Barbara. The company is a designer and manufacturer of motional control systems and provider of motion control services for customers worldwide, serving industries including semiconductor, data storage, aerospace, microscopy, and photonics. The company also performs contract manufacturing services, fulfilling outsourcing manufacturing requests.

-

-

-

-

-

Murrelektronik GmbH

Emergency off push button

Manufacturer Overview

Murrelektronik, a manufacturer of industrial automation solutions, founded in 1974, and located in Murrhardt, Germany. The company specializes in manufacturing power supplies, interfaces, cables and connectors, and IO systems, utilized across diverse industries, including machine building, automation, packaging, and food processing. Their interfaces enable seamless device and system connections in industrial automation, featuring fieldbus, Ethernet, and serial interfaces. Providing secure and dependable connections, their cables and connectors encompass shielded, fiber optic, and various connector options. Murrelektronik is ISO 9001:2015 certified for its quality management system.

-

-

-

-

-

Apem

Emergency stop

Manufacturer Overview

Apem, originally founded as APR in 1952 in France and incorporated as Apem Inc. in 2008, is a global manufacturer of electronic components. The companyThe company offers a wide range of products, including panel switches, PCB switches, LED indicators, joysticks, and industrial controls, catering to clients in various markets such as agricultural machinery, construction machinery, public environment, defense, and healthcare. Apem also provides a fully customized design and production solution to clients from its offices and facilities located in France, Germany, the UK, the USA, and China.

-

-

-

-

-

Idem Safety Switches Limited

Emergency Stops

Company Overview

Idem Safety Switches Limited, established in 2003 and headquartered in Wigan, England, is a manufacturer of machine safety devices. The company designs and manufactures safety interlock switches for machines. Its product portfolio ranges from simple limit switches to stainless steel 316 and explosion proof safety switches covering all aspects of the human-machine interface. These products are used in several industries including food & beverage, automotive and pharmaceutical. . The company has a network of distributors globally, and provides those details on its website.

-

-

-

-

-

RAFI GmbH & Co. KG

Emergency stop

Company Overview

Rafi GmbH & Co. KG, established in 1900 and located in Berg, Kr Ravensburg, Germany, is a manufacturer and supplier of electromechanical components. Its product range includes Glasscape for capacitive input, Flexscape that merges touchscreen and haptic input, Joyscape for flexible joysticks, ECU processor units for intelligent applications, and control/signaling components for industrial automation. The company has achieved certifications like ISO 9001:2008 for quality management, ISO-TS 16949:2009 for the automotive industry, and ISO 14001 for its environmental management system.

-

-

-

-

-

Georg Schlegel GmbH & Co. KG

Emergency-stop switch

Company Overview

Schlegel is the manufacturer and distributor of switches, push buttons, terminal blocks, and pilot lights with their headquarters in Germany since 1974. Besides switches and simple push buttons, the company also produces membrane and short-stroke pushbuttons, functional modules, control panels, enclosures, and limit switches which can be customized according to the consumer's demands. The products are widely used in departmental stores and administrative buildings. They are also used within the instrument panels of ships, lifts, and other vehicles including machine tools or as components of production equipment.

-

-

-

-

-

Dailywell Electronics CO., LTD.

Emergency push-pull switch

Company Overview

Dailywell Electronics Co. Ltd., founded in 1997 and based in Taipei, Taiwan, is a switch manufacturer and supplier with an annual capacity of 800 million pieces. Its products include toggle, slide, rocker, pushbutton, and anti-vandal switches used in several devices, including audiovisual equipment, aircraft model drones, industrial control equipment, computer peripherals, and medical equipment. The company has its own mold research and development center to design and develop the precise molds used to fulfill the various specifications of the production process. It is ISO 9001, ISO 9002, ISO 14001, and 3C certified.

-

-

-

-

-

VAST China Co., Ltd

Emergency stop buttons

Company Overview

Vast China Co. Ltd is based in Shanghai, China, and is a supplier of motor access control and security products established in 2004. The company’s inventory includes remote keyless entry and passive entry electronic access systems, door controls such as tailgate latches and trunk handles, and camera-focused vision systems such as rearview cameras and blind spot detectors. It also offers exterior trim and lighting products, and smart keys for home security systems. The company commonly supplies client manufacturers of automobiles, recreational vehicles, and motorcycles.

-

-

-

-

-

ELEKTRA TAILFINGEN Schaltgeräte GmbH & Co. KG

MAIN SWITCHES

Company Overview

Elektra Tailfingen Schaltgeräte GmbH & Co. KG is a manufacturer and supplier of industrial switches, testing equipment, and measuring equipment that was established in 1923 in Baden-Württemberg, Germany. The company’s products include current distributors for managing energy throughput to multiple outlets or devices, switches for controlling the flow of current in circuits, and camping distributors for providing or managing power supplies in outdoor environments. It also offers industrial sockets and plugs for providing safe connection or disconnection of power in industrial settings. The company’s products are used mainly by clients in the renewable energy, transportation, and construction industries.

-

-

-

-

-

Comepi srl

Emergency Stop Devices

Company Overview

Comepi Srl, established in 1963 and based in Robbiate, Lecco, Italy is a manufacturer and distributor of control auxiliaries, limit switches, and foot switches, as well as a vast range of safety switches. The company holds ISO 9001:2008 certification. The company's goods are distributed worldwide. It is specialised in safety devices, proximity sensors, control units, and signalling devices. An effective quality system with UNI EN ISO 9001:2008 certification oversees all procedures of the company.

-

-

-

-

-

ESCO Company Ltd.

Emergency Stop Push Button Switch

Company Overview

Esco Company Ltd., established in 1972 and headquartered in Osaka, Japan, is a supplier of maintenance, repair, and operations tools, parts, and equipment. Some of its products include test instruments, magnets, office furniture, protective equipment, and generators, and it serves customers in various fields, including construction sites and office buildings. The company was started to market tools to the air conditioning and refrigeration industry in Japan, and every year since then, it has published a catalog of its tools. In 2015, the catalog reached 110,000 products, and the company has approximately 149,000 items in stock for delivery.

-

-

-

-

-

Jamieson Equipment Co., Inc.

Emergency Stop Switches

Company Overview

Jamieson Equipment Company (JEC) was founded in 1982 and located in the state of Georgia. JEC serves infrastructure-related industries including pavement with concrete, aggregate, and asphalt, chemicals, sewage and waste management, and agriculture and food. JEC sells, installs, retrofits, repairs, and offers training and troubleshooting for a range of components and tools from simple fittings to motion sensors to electronics to valves to actuators, cranes, mixers, silos, hoppers, and plants.

-

-

-

-

-

Rockwell Automation

Cable pull switch

Company Overview

Rockwell Automation, Inc. was founded in 1903 and is headquartered in Milwakee, WI. Rockwell Automation provides industrial automation and digital transformation solutions around the world. Rockwell Automation operates through their intelligent devices, software & control, and lifecycle services segments with both hardware and software products and services. The Intelligent Devices segment offers drives, motion, safety, sensing, industrial components, and configured-to-order products. The Software & Control segment provides control and visualization software and hardware, information software, and network and security infrastructure solutions. The Lifecycle Services segment provides consulting, professional services and solutions, and connected and maintenance services through independent distributors.

-

-

-

-

-

BERNSTEIN

Rope pull switch

Company Overview

BERNSTEIN AG is a manufacturer and distributor of electromechanical components that was established in 1947 in Germany. The company manufactures switches and sensors that range from insulated and metal enclosed to foot switches and safety switchgear. They also provide enclosure technology that deals with the implementation of support systems for various applications such as using housing to accommodate electrical, electronic, or pneumatic components and load-bearing systems made of aluminum and stainless steel. They also offer safety solutions related to the operation of lifts and escalators that are placed in malls and airports

-

-

-

-

-

Altech Corporation

Rope Pull Switches

Company Overview

Altech Corporation, founded in 1984 and headquartered in Flemington, New Jersey, is a supplier and distributor of electronic and control components and is ISO 9001 certified. The company provides a broad line of products, including programmable controllers, monitoring relays, and terminal blocks, used in instrumentation, industrial control, and automation applications. The company’s enclosed disconnect switches are available in different materials like stainless steel, plastic, and aluminum and have a use rating of 16A to 150A/600V AC. The products are all RoHS and REACH compliant and meet diverse national and international standards like IEC, CSA, and UL.

-

-

-

-

-

REPAR2

EMERGENCY MUSHROOM BUTTON

-

-

-

-

-

EMC PARTNER AG

EMERGENCY-STOP

-

-

-

-

-

OMRON Industrial Automation

Emergency stop switch

Company Overview

OMRON Industrial Automation is the UK branch of OMRON, originally founded in Japan in 1933. OMRON Industrial Automation serves food and beverage industry, panel board design, automotive manufacturing industries among others. OMRON Industrial Automation products categories include automation systems such as industrial PCs and human machine interfaces (HMI), safety such as safety switches and safety logic control systems, switching components such as solid state relays, motion & drives such as motion controllers, sensing such as photoelectric sensors, software, robotics, quality control & inspection systems, as well as control components including power supplies and digital panel indicators.

-

-

-

-

-

Salton

Emergency Stops

-

-

-

-

-

ICKey Internet Technology Co., LTD

Emergency Stop Switches

Distributor Overview

Hello BOM is an online electronic component storefront designed to bridge customers and suppliers. Customers supply Hello BOM with their bill of materials (BOM) and Hello BOM uses smart analysis via AI data matching to quickly find precise matches that customers need. This is accomplished via Hello BOM’s growing component stock and product information database to grow increasingly accurate and fast, while also simplifying the process of R&D and purchasing for customers. Products include semiconductors, resistors, capacitors, diodes, inductors, connectors, transistors, and sensors.

-

-

Emergency Stop Switch Manufacturer Ranking

*Including some distributors, etc.Ranking as of April 2024

Derivation Method| Rank | Company | Click Share |

|---|---|---|

| 1 | Rees, Inc. |

11.4%

|

| 2 | Red Fox Safety Products |

4.5%

|

| 3 | ICKey Internet Technology Co., LTD |

4.5%

|

| 4 | Baco Controls, Inc. |

4.5%

|

| 5 | Pepperl+Fuchs Inc. |

4.5%

|

| 6 | EMC PARTNER AG |

2.3%

|

| 7 | EAO AG |

2.3%

|

| 8 | Langir Electric |

2.3%

|

| 9 | Comepi srl |

2.3%

|

| 10 | Zhejiang Benyi New Energy Co., Ltd. |

2.3%

|

Derivation Method

The ranking is calculated based on the click share within the emergency stop switch page as of April 2024. Click share is defined as the total number of clicks for all companies during the period divided by the number of clicks for each company.Number of Employees

- Pepperl+Fuchs Inc.: 7,100

- RAFI GmbH & Co. KG: 1,200

- elobau GmbH & Co. KG: 120

Newly Established Company

- Motion X Corporation: 2002 (22 years ago)

- VAST China Co., Ltd: 1999 (25 years ago)

- AUSPICIOUS: 1979 (45 years ago)

Company with a History

- Schaltbau GmbH: 1929 (95 years ago)

- Euchner-USA, Inc.: 1940 (84 years ago)

- Pepperl+Fuchs Inc.: 1945 (79 years ago)

Emergency Stop Switch Manufacturers in United States

*Including some distributors, etc.

- Banner Engineering Corporation

- Pinnacle Systems Inc.

- ifm efector, inc.

- Honeywell International Inc

- Rees, Inc.

- Safety Technology International, Inc. (STI)

- Red Fox Safety Products

- Pepperl+Fuchs Inc.

- OMEGA Engineering inc.

- Euchner-USA, Inc.

- Allied Electronics, Inc.

- Baco Controls, Inc.

Global Distribution of Emergency Stop Switch Manufacturers by Country

*Including some distributors, etc.

| Country | Number of Companies | Share (%) |

|---|---|---|

United States of America

United States of America

|

12 | 38.7% |

Germany

Germany

|

11 | 35.5% |

United Kingdom

United Kingdom

|

2 | 6.5% |

Taiwan

Taiwan

|

2 | 6.5% |

Hong Kong

Hong Kong

|

1 | 3.2% |

China

China

|

1 | 3.2% |

Switzerland

Switzerland

|

1 | 3.2% |

France

France

|

1 | 3.2% |

List of Emergency Stop Switch Products

5 products are listed.

ifm efector, inc.

Switch lighting type for AS-I connection type emergency stop

10+ people viewing

It is a switch for lighting type stop with a built-in AS-I connection. Characteristics of the product ・ Safe AS-iPCB ・ Built-in AS-I slave with su...

ifm efector, inc.

AS-I connection type Emergency stop switch key reset type

10+ people viewing

It is a switch for lighting type stop with a built-in AS-I connection. Characteristics of the product ・ Safe AS-iPCB ・ Built-in AS-I slave with su...

ifm efector, inc.

Lighting type emergency stop switch

10+ people viewing

It is a switch for lighting type stop with a built-in AS-I connection. Characteristics of the product ・ Safe AS-iPCB ・ Built-in AS-I slave with su...

Matsushima Measure Tech Co., Ltd.

Emergency stop switch pull stop

20+ people viewing

Pull -stop is an emergency stop switch around conveyors and transport machines. In addition to the basic functions of sister products, the followin...

ifm efector, inc.

Safety with AS-I connection AS-I emergency stop operation unit

10+ people viewing

It is a switch for lighting type stop with a built-in AS-I connection. Characteristics of the product ・ Safe AS-iPCB ・ Built-in AS-I slave with su...